Hi there,

Just saw yesterday that my wood distributor has baltic birch plywood in 24mm, 27mm or 30mm thickness. For my first speakers project, I used 18mm as suggested. The petite Onken were built with 24mm (25mm suggested).

I'm wondering for the 416 bass-reflex cab what should be the better option. I am tempted to go with 30mm as I saw few interesting project made with 30mm thickness and more (60mm!). But honestly, I don't have any knowledge to decide which thickness. Do you guys have any experience with 27mm or 30mm baltic birch speakers cab?

Sébastien

Just saw yesterday that my wood distributor has baltic birch plywood in 24mm, 27mm or 30mm thickness. For my first speakers project, I used 18mm as suggested. The petite Onken were built with 24mm (25mm suggested).

I'm wondering for the 416 bass-reflex cab what should be the better option. I am tempted to go with 30mm as I saw few interesting project made with 30mm thickness and more (60mm!). But honestly, I don't have any knowledge to decide which thickness. Do you guys have any experience with 27mm or 30mm baltic birch speakers cab?

Sébastien

When stiffness is asked for rather go for bracing than more wall thickness. 24mm will absolutely do. I use Petite Onken cabinets made of 22mm birch ply. The side walls are very stable due to the port construction and everything else is taken care of by bracing.

Hi guys,

Thanks for your suggestion. I admit that the Petite Onken bracing in its own port is an excellent idea. Kaputt, did you place other bracing in yours beside the one on the original plan?

With this project, I want to keep the internal felt curtain (see picture,) which is excellent to deal with internal standing waves, and the front to back renforcement in 50mm x 50mm. This curtain in place won't leave much space for bracing. An option could be another 50mm x 50mm piece going across the cab from side to side in front of the curtain, behind or in both places.

To discuss,

Sébastien

Thanks for your suggestion. I admit that the Petite Onken bracing in its own port is an excellent idea. Kaputt, did you place other bracing in yours beside the one on the original plan?

With this project, I want to keep the internal felt curtain (see picture,) which is excellent to deal with internal standing waves, and the front to back renforcement in 50mm x 50mm. This curtain in place won't leave much space for bracing. An option could be another 50mm x 50mm piece going across the cab from side to side in front of the curtain, behind or in both places.

To discuss,

Sébastien

Attachments

Hi GM and everyone,

I've just found an enclosure resonances calculator on mh-audio website. Plus, it gives the ratio. Actually, the cab shows good quality with its projeted dimensions:

mh-audio.nl

Sébastien

I've just found an enclosure resonances calculator on mh-audio website. Plus, it gives the ratio. Actually, the cab shows good quality with its projeted dimensions:

mh-audio.nl

Sébastien

No clue, but would like to know also.

Yes, there's mathematically ideal locations and for a typical golden ratio cab, it's ideal offset is around 0.42 IIRC. As the vented cab's aspect ratio increases there comes a point where it develops 1/4 WL TL pipe action that increases damping on the vent if down near/at the bottom, so in this situation the driver's ideal location becomes a function of its length, cross sectional area and taper ratio, if any based on how smooth a response one wants, i.e. how much internal damping is required to smooth it out...

GM

Hi there,

The work really progressed in the last month. I received in April my Great Plains Audio 416-8B. I also had the time in May to start the assembly. Picture don't show it, but I installed felt in the cabs. The port is actually not glued. I made a system which could allow to move it for adjustement. I started with a lenght that Ajmars help me calculate using a Francis Brooke's extremity correction for rectangular port.

Well, speakers are almost ready to be try! I need to sand the boxes, paint them and place the speakers and cables before a first try! I called them "416 French Connection" for inspiration and help Ajmars gave me in the project.

Here's a few pics:

The work really progressed in the last month. I received in April my Great Plains Audio 416-8B. I also had the time in May to start the assembly. Picture don't show it, but I installed felt in the cabs. The port is actually not glued. I made a system which could allow to move it for adjustement. I started with a lenght that Ajmars help me calculate using a Francis Brooke's extremity correction for rectangular port.

Well, speakers are almost ready to be try! I need to sand the boxes, paint them and place the speakers and cables before a first try! I called them "416 French Connection" for inspiration and help Ajmars gave me in the project.

Here's a few pics:

Attachments

Hi Sebastien,

I would be very interested to hear about your new setup and how it compares to the petite onken. I will be building enclosures soon for my GMA 416-8B.

Best regards,

S

S

I would be very interested to hear about your new setup and how it compares to the petite onken. I will be building enclosures soon for my GMA 416-8B.

Best regards,

S

S

Last edited:

The 416 French Connection are finish since a little bit more than one month. I joined some pictures of them painted. Comparing to the petite Onken, they offer deeper and more extented bass and a bit more dynamic impact, which place them more closer to the kind of impact of a bass-horn cab like a Voice of the Theatre but they are going deeper than the VOTT which the petite Onken already did.

I was wondering if there would be loss in the low-midrange comparing to the excellent GPA 414-8B, but I don't find any. GPA 416-8B has to my ears the same qualities as its little brother and a bit more. I actually cut it around 650 Hz with a second order filter.

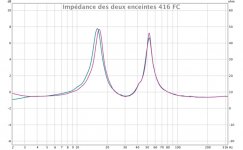

I worked quite a bit to get a good cab tuning and had to play a bit also with internal treatment. I add to the felt 3 polyester pillows and ajust the lenght of the port to 125 mm that was it. You can see on the impedance measure the tuning around 30 Hz.

Sébastien

I was wondering if there would be loss in the low-midrange comparing to the excellent GPA 414-8B, but I don't find any. GPA 416-8B has to my ears the same qualities as its little brother and a bit more. I actually cut it around 650 Hz with a second order filter.

I worked quite a bit to get a good cab tuning and had to play a bit also with internal treatment. I add to the felt 3 polyester pillows and ajust the lenght of the port to 125 mm that was it. You can see on the impedance measure the tuning around 30 Hz.

Sébastien

Attachments

Last edited:

Hi Sebastien,

looks awesome. how does it sound like? what compression drivers are you using for the mid/high frequency? what amplifier are you using to drive this speaker. ahhh. to much questions..

BTW i just want to share some photos of my previous project (June 24, 2016) 360L Onken,

Together with other Big Brother Speakers.

and my newly acquired all Hirata Tango Transformer 300B SET Amp for the 360L Onken

looks awesome. how does it sound like? what compression drivers are you using for the mid/high frequency? what amplifier are you using to drive this speaker. ahhh. to much questions..

BTW i just want to share some photos of my previous project (June 24, 2016) 360L Onken,

Together with other Big Brother Speakers.

and my newly acquired all Hirata Tango Transformer 300B SET Amp for the 360L Onken

Last edited:

Hi Norelco,

You can read some comment above regarding the sound of them comparing to the petite Onken for example. Regarding the amplifier, I am actually using a 5687 WOT tubes preamp and a recent Kaneda design number 228+ power amplifier (29W in 8 Ohms).

Onken OS-500MT tooks care of the mid via an Onken 500Wood horn and an Onken 5000T tweeter tooks 8kHz and above.

Regarding your Onken 360L project. I tought this speaker was design to be use with Altec 416-8A. Isn't it?

Regards,

Sébastien

You can read some comment above regarding the sound of them comparing to the petite Onken for example. Regarding the amplifier, I am actually using a 5687 WOT tubes preamp and a recent Kaneda design number 228+ power amplifier (29W in 8 Ohms).

Onken OS-500MT tooks care of the mid via an Onken 500Wood horn and an Onken 5000T tweeter tooks 8kHz and above.

Regarding your Onken 360L project. I tought this speaker was design to be use with Altec 416-8A. Isn't it?

Regards,

Sébastien

Yes you are right, Onken 360L are designed with 416 8A, but for my ears 416 8B has no problem and I'm happy with the result.

Regards

Sent from my iPhone using Tapatalk

Regards

Sent from my iPhone using Tapatalk

Hi Norelco,

Good to hear that. It reminds me of my petite Onken project. Instead of the original 414-8B from Altec, I used a Great Plains Audio 414-8B and the resultat was excellent.

Have a good day,

Sébastien

Good to hear that. It reminds me of my petite Onken project. Instead of the original 414-8B from Altec, I used a Great Plains Audio 414-8B and the resultat was excellent.

Have a good day,

Sébastien

Digging this one up, but I’ve read through a few times and maybe I missed it...

Where in the heck are you guys finding the felt?

Where in the heck are you guys finding the felt?

Good question, I use to buy up to 1" thick just up the road and now can't find anything over a 1/2". Regardless, OC 703 duct board is all I've used in big pieces since '69.

GM

GM

I’m building the original Hiraga Onken plans, and trying to stay as close to the original plans as possible.

Would OC 703 work as a substitute? Assuming you’d need to cover in lighter felt and still somehow duplicate the felt curtain...

Would OC 703 work as a substitute? Assuming you’d need to cover in lighter felt and still somehow duplicate the felt curtain...

Digging this one up, but I’ve read through a few times and maybe I missed it...

Where in the heck are you guys finding the felt?

The only place I found with the original felt is a company called Laoureux in France. And it is pretty expensive.

Fournisseur de feutre industriel - Laoureux.

On all my speaker's project, I used a 12 mm thick sub-floor felt which we can find easily. I has the same density as the original one.

Sébastien

i bought some of that hospital felt in France. It was wonderful stuff, and very expensive.

Sébastien is correct that under carpet felt is the next best choice - and something you can find.

Sébastien is correct that under carpet felt is the next best choice - and something you can find.

Sebastien, you can find some good wool from bed company or take it from an old bed if yu ask a beds vendor... not an enthusiastic task but... it's the hobby that asks such "sacrifices"

Of course the under carpet felt is not costing much... if for any reason you want it from France, ask a french fellow fro Melaudia to buy some at "Saint Maclou" and send you, not too much expensive cause the low weight and the low price... though CE frontiers are closed (dunno fr goods though). You also may ask to a local company that "greens" the old clothes for insulating house with pannels or rolls made of it...

At the end qualofil from Dupont&Nemours seen in some pilows can be cheap (Ikea) : qualofil is basicly like hollofil fiber but wit 4 open tube in it.... surface in increased and mass-spring-mass behavior as well... theorically.

I really don't know but is it possible to tune the cabinet to make it deeper cause the Waf and putt one driver more like the Onken W but behind like do Logan Martin adding a 8 shape radiating pattern ? (although ML seems to uses one sealed volume per bass driver design for the high end line... it's not vented as an Onken)

hope that helps

Of course the under carpet felt is not costing much... if for any reason you want it from France, ask a french fellow fro Melaudia to buy some at "Saint Maclou" and send you, not too much expensive cause the low weight and the low price... though CE frontiers are closed (dunno fr goods though). You also may ask to a local company that "greens" the old clothes for insulating house with pannels or rolls made of it...

At the end qualofil from Dupont&Nemours seen in some pilows can be cheap (Ikea) : qualofil is basicly like hollofil fiber but wit 4 open tube in it.... surface in increased and mass-spring-mass behavior as well... theorically.

I really don't know but is it possible to tune the cabinet to make it deeper cause the Waf and putt one driver more like the Onken W but behind like do Logan Martin adding a 8 shape radiating pattern ? (although ML seems to uses one sealed volume per bass driver design for the high end line... it's not vented as an Onken)

hope that helps

Last edited:

That's a very good idea!Sebastien, you can find some good wool from bed company ...

The felt used in France was something Mr. Hiraga had found for bed toppers in hospitals to prevent bed sores. It was soft and came in a big roll.

The felt used in France was something Mr. Hiraga had found for bed toppers in hospitals to prevent bed sores. It was soft and came in a big roll.I just looked around the web and there are many wool felt bed toppers for sale, often inside a cover. That could work if getting some from a mattress company isn't an option.

- Home

- Loudspeakers

- Multi-Way

- Beyond the petite Onken