Nice Graham!

Thanks for all the pics!

It's easy to see ( from the polars ) why the STH100 is highly regarded ( I didn't realize you were going to pickup a pair of those ).

🙂

Thanks for all the pics!

It's easy to see ( from the polars ) why the STH100 is highly regarded ( I didn't realize you were going to pickup a pair of those ).

🙂

So the big has about the same directivity control lower frequency (around 2kHz) as the much smaller horn? Odd. Are those measured with the wide dimension set horiontal?

Nice Graham!

Thanks for all the pics!

It's easy to see ( from the polars ) why the STH100 is highly regarded ( I didn't realize you were going to pickup a pair of those ).

🙂

Cool man. Yeah, I'd had them for a few months from when I put the SB Acoustics 19mm dome in them as an experiment!

So the big has about the same directivity control lower frequency (around 2kHz) as the much smaller horn? Odd. Are those measured with the wide dimension set horiontal?

Yes, sorry, I forgot that the proposed H9800 orientation is buried a couple of pages back. It's is, indeed, vertically mounted. The H9800 are only 2cm wider (when vertical) than the STH100 but twice as deep!

I'll do some horizontal when I get time but for the moment both combos look promising.

I am sure the remaining glitch at 16k is caused by the mating of the adapter to the throat of the H9800. It shows on the measurements of the SB19 dome I put on it previously which both use the 1"-1.5" adapter. I wonder I can mitigate this with some carefully smooshed blu-tac and if that will clean the rest of the response up?

Hi Graham,

Make sure you make at least one test box ( for the 8pr200 ).

My experience ( though, not with that model ) is that you may want to run them sealed after you've auditioned them both ways.

Sealed, may benefit from a larger enclosure ( just thinking out loud ).

🙂

Make sure you make at least one test box ( for the 8pr200 ).

My experience ( though, not with that model ) is that you may want to run them sealed after you've auditioned them both ways.

Sealed, may benefit from a larger enclosure ( just thinking out loud ).

🙂

Hi Earl,

Cheers for the (quite sensible) reminder (that I was probably going to lazily bypass) to do that test box!

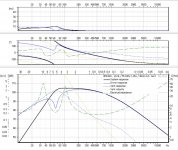

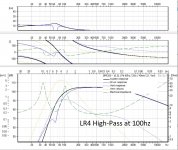

My rationale for the vented alignment was to augment the 100hz region with vent contribution so that when the high-pass is used the sum output would be attenuated and therefore, relive the cone of some movement (similar to eq'ing down the horn boost on the CD). Am I making what could be a much simpler design more complicated?

From what I understand inter-modulation distortion is to be avoided (especially as I have small woofers) and keep total system efficiency balanced. Am I barking up the wrong tree here? Surely, a sealed box would ask more of the woofer in terms of cone travel?

Is it a group delay / low Q transient thing?

A sealed box with a Q of 0.65 would be 5.5L.

I'm not arguing at all, I am super keen to understand all suggestions. Thanks again! 🙂

Cheers for the (quite sensible) reminder (that I was probably going to lazily bypass) to do that test box!

My rationale for the vented alignment was to augment the 100hz region with vent contribution so that when the high-pass is used the sum output would be attenuated and therefore, relive the cone of some movement (similar to eq'ing down the horn boost on the CD). Am I making what could be a much simpler design more complicated?

From what I understand inter-modulation distortion is to be avoided (especially as I have small woofers) and keep total system efficiency balanced. Am I barking up the wrong tree here? Surely, a sealed box would ask more of the woofer in terms of cone travel?

Is it a group delay / low Q transient thing?

A sealed box with a Q of 0.65 would be 5.5L.

I'm not arguing at all, I am super keen to understand all suggestions. Thanks again! 🙂

Last edited:

Hi Earl,

SNIP

My rationale for the vented alignment was to augment the 100hz region with vent contribution so that when the high-pass is used the sum output would be attenuated and therefore, relive the cone of some movement (similar to eq'ing down the horn boost on the CD). Am I making what could be a much simpler design more complicated?

SNIP

Is it a group delay / low Q transient thing?

A sealed box with a Q of 0.65 would be 5.5L.

SNIP

This is simply a matter of trying both types and choosing the one that sounds best for your tastes.

Something to keep in mind with all this ( theoretical ) stuff is;

Imaging has never been quantified into a single ( or set of ) measurement(s).

It is always determined ( to either be present or not ) through listening ( a novel concept ) .

I feel the same holds true with the debate over sealed versus ported ( one needs to decide after listening to both flavours ).

BTW, I'm not an advocate ( really ) for one over the other .

🙂

Ah, I see! I always jump to the *"I want evidence"* stance and you're right, I will have to use my ears at one stage. I don't think I do that enough. Thanks for all your input so far! 🙂

Right, my wife caught wind of the scale of this project and I can feel the disapproving whinge coming my way.

So, I was thinking of ways to keep the system size down without effecting performance and I wondered what people thought about this:

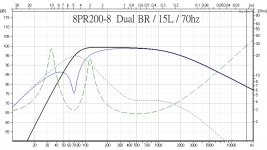

Optimal BR cabinet volume for two drivers is ~21L. With this alignment it cuts volume by just over a quarter at 15L. I feel I can use an appropriate slope in the crossover to tackle the rising hump around 100hz or just PEQ it out.

The only thing that changes really is group delay by a 1ms increase at XO frequency:

A large benefit of this tuning frequency is that the port resonance goes higher and I can afford a larger diameter vent. I can also stuff the vent and ave a reasonable Q sealed cabinet to chop and change to!

Thoughts, anyone? 🙂

So, I was thinking of ways to keep the system size down without effecting performance and I wondered what people thought about this:

Optimal BR cabinet volume for two drivers is ~21L. With this alignment it cuts volume by just over a quarter at 15L. I feel I can use an appropriate slope in the crossover to tackle the rising hump around 100hz or just PEQ it out.

The only thing that changes really is group delay by a 1ms increase at XO frequency:

A large benefit of this tuning frequency is that the port resonance goes higher and I can afford a larger diameter vent. I can also stuff the vent and ave a reasonable Q sealed cabinet to chop and change to!

Thoughts, anyone? 🙂

Attachments

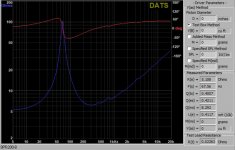

So, I treated myself to a DATS V3! Long overdue TBH.

I broke the 8PR200 in with a sine wave at 58hz for about ten minutes (I read a paper by Scott Hinson that long term driver break in is a myth !?) at decent volume. Enough to see the cone move and annoy my wife.

The result I got back is that the FS is waaaay higher than the spec sheet. I measure 67.5hz vs. published 58hz. Is this usual, should I break in the driver further?

Mine:

Factory:

My precision scales haven't arrived to weigh the blu-tac I will use for the Vas measurement, yet. I'm hoping to cut the baffles this weekend - British weather permitting.

I broke the 8PR200 in with a sine wave at 58hz for about ten minutes (I read a paper by Scott Hinson that long term driver break in is a myth !?) at decent volume. Enough to see the cone move and annoy my wife.

The result I got back is that the FS is waaaay higher than the spec sheet. I measure 67.5hz vs. published 58hz. Is this usual, should I break in the driver further?

Mine:

Factory:

My precision scales haven't arrived to weigh the blu-tac I will use for the Vas measurement, yet. I'm hoping to cut the baffles this weekend - British weather permitting.

Attachments

What is there in the picture, routing jig?🙂

ps. my 8pr155 measured very close to spec but faital 15fh520 driver had high fs as well, they said to measure after warming it up with signal, didn't help. I should try again some day now after months of regular use if it still is out from the spec.

ps. my 8pr155 measured very close to spec but faital 15fh520 driver had high fs as well, they said to measure after warming it up with signal, didn't help. I should try again some day now after months of regular use if it still is out from the spec.

Last edited:

Yes, a template to flush mount the driver! The baffle is 27mm thick so still has 18mm to bite in to. It's not the neatest ever but hey.

In the end I gave the drivers about 2 hours of 30hz with as much cone travel as I dared and slowly the FS dropped. However, it did rise again after not being used. It makes me question the whole breaking in thing of drivers.

For instance, if lots of cone movement causes inter modulation distortion then larger cones must be used to achieve a wide and clean appropriate pass band. So, let's say a 15" woofer comes from the factory way out of spec and needs to be broken in and after which it spends its life in a fancy studio monitor (I'm thinking larger JBL/TAD monitors used in domestic audiophile set ups) not moving very much because it doesn't need to given the moderate SPL requirements. Won't it return to being out of spec by not moving very much? Won't the surround/suspension be stressed so little that it will begin to stiffen?

I've been reading another thread about using larger PA drivers for high end audio which looks at this but the topic has kept my mind active before snoozy time.

In the end I gave the drivers about 2 hours of 30hz with as much cone travel as I dared and slowly the FS dropped. However, it did rise again after not being used. It makes me question the whole breaking in thing of drivers.

For instance, if lots of cone movement causes inter modulation distortion then larger cones must be used to achieve a wide and clean appropriate pass band. So, let's say a 15" woofer comes from the factory way out of spec and needs to be broken in and after which it spends its life in a fancy studio monitor (I'm thinking larger JBL/TAD monitors used in domestic audiophile set ups) not moving very much because it doesn't need to given the moderate SPL requirements. Won't it return to being out of spec by not moving very much? Won't the surround/suspension be stressed so little that it will begin to stiffen?

I've been reading another thread about using larger PA drivers for high end audio which looks at this but the topic has kept my mind active before snoozy time.

Last edited:

Yeah might be so and to be honest I was a bit bummed to find this out since made some effort to find a driver that would do this and that within the budget and all other constraints and then it didn't. There are drivers that measure like in the specsheet and then there are drivers that don't. Might be faulty driver, or faulty specsheet , or this was the intent all along. Such driver in a PA setup would drift towards intended spec during a loud night, and not out of spec. Anyway, not sure all this really matters much, just design around what you have and all will be golden. A minor setback, if fs isn't nice on paper but the speaker sounds fine. Btw, the tymphany driver measures pretty dang smooth frequency response! Have fun!🙂

Last edited:

Yes, a template to flush mount the driver! The baffle is 27mm thick so still has 18mm to bite in to. It's not the neatest ever but hey.

In the end I gave the drivers about 2 hours of 30hz with as much cone travel as I dared and slowly the FS dropped. However, it did rise again after not being used. It makes me question the whole breaking in thing of drivers.

For instance, if lots of cone movement causes inter modulation distortion then larger cones must be used to achieve a wide and clean appropriate pass band. So, let's say a 15" woofer comes from the factory way out of spec and needs to be broken in and after which it spends its life in a fancy studio monitor (I'm thinking larger JBL/TAD monitors used in domestic audiophile set ups) not moving very much because it doesn't need to given the moderate SPL requirements. Won't it return to being out of spec by not moving very much? Won't the surround/suspension be stressed so little that it will begin to stiffen?

I've been reading another thread about using larger PA drivers for high end audio which looks at this but the topic has kept my mind active before snoozy time.

Quick answer: driver "break in" is mostly a myth.

If a particular driver is way out of spec, it just needs to be replaced 🙂

As to PA drivers' suitability for home hi-fi, most aren't suited at all, but that's got nothing to do with break in. Rather, it's because their specs aren't fit for reproducing low-level detail in the first place.

In fact, most PA woofers are built to withstand abuse, not to be subtle.

One spec to keep an eye on is the ratio of the mechanical resistance to diaphragm mass (Rms/Mms), or the related (Fs/Qms). For high quality home hi-fi, the lower, the better.

A typical 15" PA woofer will have (Fs/Qms) > 7 or 8 (sometimes even >10).

The TAD TL-1601a's (Fs/Qms) is 4. That's one of the reasons why it sounds different (i.e., way more detailed even at low volume).

Marco

Not sure what all this means yet, but out of interest calculated both ratios for 15fh520. Specsheet says rms/mms to be around 25, measured around 38. Fs/Qms from specsheet ~3.6, measured ~5.2.

Further Progress...

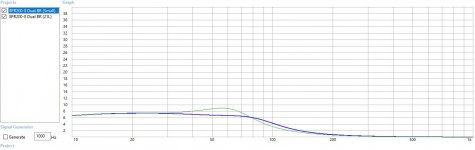

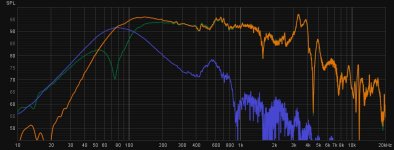

After a lot of titting-about I got the semi-finished cabs tuned to a reasonable frequency (76hz) that will give me enough room for a 100hz crossover with some DSP taming of the hump. I will also be able to try these with a sealed alignment as the cab in 9.5L ish.

Internally it is lined with wool felt with a double layer on the rear. 18mm MDF middle section with 18mm birch ply on the sides. Speakon connectors and 50mm PVC pipe vent.

Here is the LF response:

It's starting to shape up but and my wife didn't go mental when she saw the stack I propped up to see what it will look like in the end. I will have to tilt the horn down to ear level with some sort of rest/support.

After this is done I need to start thinking about a more appropriate sub/bass driver that can be accomated in a 24L ish cabinet for underneath the mid-bass. The 8" subs I have at the moment don't look or feel right in this config. Maybe just double up on the SB acoustics subs?

After a lot of titting-about I got the semi-finished cabs tuned to a reasonable frequency (76hz) that will give me enough room for a 100hz crossover with some DSP taming of the hump. I will also be able to try these with a sealed alignment as the cab in 9.5L ish.

Internally it is lined with wool felt with a double layer on the rear. 18mm MDF middle section with 18mm birch ply on the sides. Speakon connectors and 50mm PVC pipe vent.

Here is the LF response:

It's starting to shape up but and my wife didn't go mental when she saw the stack I propped up to see what it will look like in the end. I will have to tilt the horn down to ear level with some sort of rest/support.

After this is done I need to start thinking about a more appropriate sub/bass driver that can be accomated in a 24L ish cabinet for underneath the mid-bass. The 8" subs I have at the moment don't look or feel right in this config. Maybe just double up on the SB acoustics subs?

Attachments

Marco, i see what you mean.

I'd been thinking that a higher qms driver would absorb less detail than the stiffer one.

For pa, you can change the specs.

For example, i had a pa buddy that used qts .26 drivers fror subs

After about an hour of pounding, he estimated they floated up to near .31

Initially the box was lean, but dropped into place after fully warming up.

But that is a different case where the drivers are pushed hard for 5 hours straight.

I'd been thinking that a higher qms driver would absorb less detail than the stiffer one.

For pa, you can change the specs.

For example, i had a pa buddy that used qts .26 drivers fror subs

After about an hour of pounding, he estimated they floated up to near .31

Initially the box was lean, but dropped into place after fully warming up.

But that is a different case where the drivers are pushed hard for 5 hours straight.

- Home

- Loudspeakers

- Multi-Way

- System Based Around JBL H9800 Horn