Kef Q100... yes i know that one. Do you really know that speaker?

Do you know that feeling when you see something, something that gets under your skin. Gently crawl under the skull and torture brain at night when you lie down, then gently whisper that driver it's the chosen one.

This is exactly how I felt when I saw the construction and engineering that was put into this driver. But the comments and various reviews indicated that it was just an ok speaker, and those things turned me off from buying it.

But wait someone opened the box and the crossover was only with three components.

One coil on midbass on tweeter capacitor and resistor.

Ok, I smell a rat.

This means war, Kef.

I prayed to the gods of DIY, and went to war against poorly executed Crossovers.

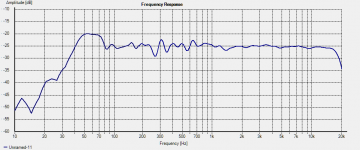

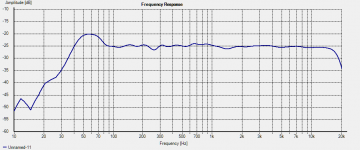

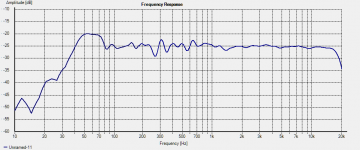

Made new enclosures, new measurements in new enclosures and these are the results.

Mic is Umik-1

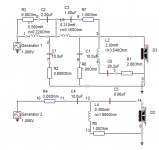

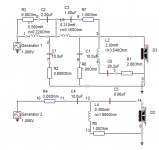

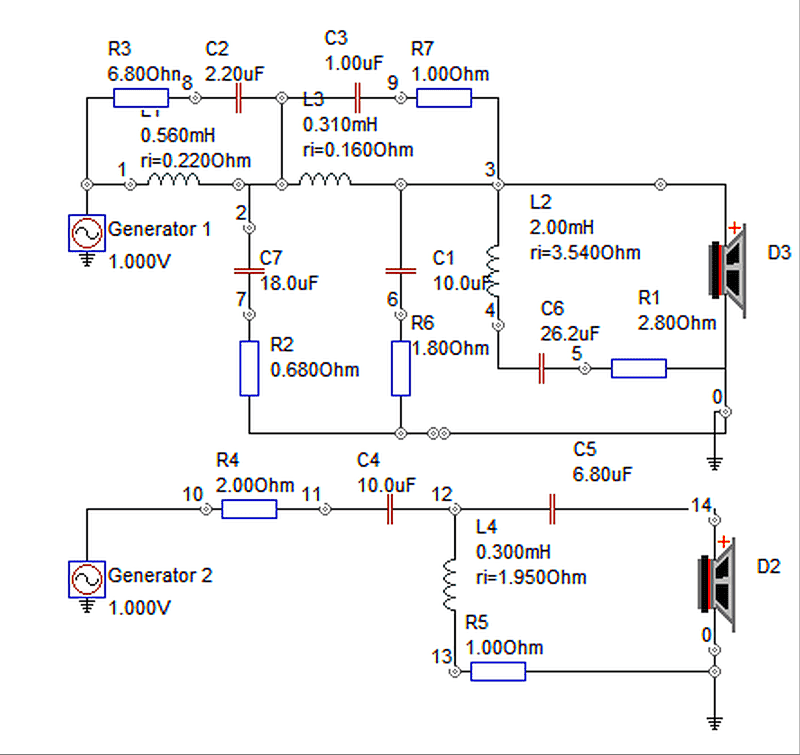

Crossover

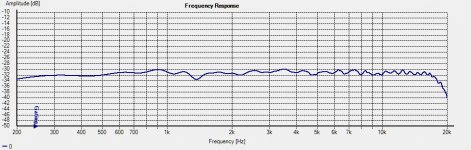

On axis

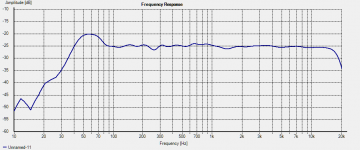

Of axis 0-10-20-30-40-50

3db/oct

I don't know exactly how the speaker behaves below 200hz due to the measurement in the room. This response is combined from two measurements, read approximation…

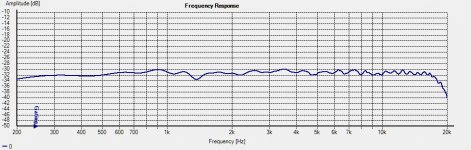

6db/oct

Do you know that feeling when you see something, something that gets under your skin. Gently crawl under the skull and torture brain at night when you lie down, then gently whisper that driver it's the chosen one.

This is exactly how I felt when I saw the construction and engineering that was put into this driver. But the comments and various reviews indicated that it was just an ok speaker, and those things turned me off from buying it.

But wait someone opened the box and the crossover was only with three components.

One coil on midbass on tweeter capacitor and resistor.

Ok, I smell a rat.

This means war, Kef.

I prayed to the gods of DIY, and went to war against poorly executed Crossovers.

Made new enclosures, new measurements in new enclosures and these are the results.

Mic is Umik-1

Crossover

On axis

Of axis 0-10-20-30-40-50

3db/oct

I don't know exactly how the speaker behaves below 200hz due to the measurement in the room. This response is combined from two measurements, read approximation…

6db/oct

Last edited:

Amazing design.

What inspired you, Kef design of the 70s and 80s. What is the overall sensitivity and what does the impedance now look like?

What tools did you use for the modelling?

Do you own a crossover component company by chance?

What inspired you, Kef design of the 70s and 80s. What is the overall sensitivity and what does the impedance now look like?

What tools did you use for the modelling?

Do you own a crossover component company by chance?

That's a nice response. As above - what are the losses through that network?

Personally wouldn't bother, but in the interests of the science, that's still some nice work.

Personally wouldn't bother, but in the interests of the science, that's still some nice work.

I'm looking at the polars and they are not bad. Clearly you have put in the work with these. This kind of a result is not easy to achieve, but is worthwhile.

Amazing design.

What inspired you, Kef design of the 70s and 80s. What is the overall sensitivity and what does the impedance now look like?

What tools did you use for the modelling?

Do you own a crossover component company by chance?

I am inspired by the knowledge we now have, I mean the index of directivity, reduced diffraction ... I always liked the idea of sound starting from one point.

LspCAD is software that I use.

Nop i don have component company🙂. I could do with half the components, but I wanted to squeeze the last drop. It required hard work but I'm happy with the results.

KEF Q100 Speaker Review -> your measurements

Hi,

KEF Q100 Speaker Review | Audio Science Review (ASR) Forum

=> KEF Q100 Speaker Review | Page 22 | Audio Science Review (ASR) Forum

Hi,

KEF Q100 Speaker Review | Audio Science Review (ASR) Forum

=> KEF Q100 Speaker Review | Page 22 | Audio Science Review (ASR) Forum

Last edited:

That's a nice response. As above - what are the losses through that network?

Personally wouldn't bother, but in the interests of the science, that's still some nice work.

The losses are not large, maybe 1 db. The problem is always the baffle step where a lot of efficiency is lost

The response certainly looks good with your crossover, but hard to judge who won the war without seeing the other side- what does the response look like on/off axis with the stock crossover?I prayed to the gods of DIY, and went to war against poorly executed Crossovers.

I really do not know. I didn't go crazy with capacitors, WIMA is very good.Ive got a pair of those drivers.

Can you estimate the cost of a pair of crossovers?

Coils are order from Amplifier valve kits, HIFI pre-amplifiers, speaker kits, AMP Parts, upgrade components | Hifi Collective

I just did a quck calculation using the basics -

Dayton audio 1% Poly Caps $48

Dayton Audio 2% Resistors $14

Jantzen 18 AWG Aircore Inductors $40

So total $92 give or take.

Dayton audio 1% Poly Caps $48

Dayton Audio 2% Resistors $14

Jantzen 18 AWG Aircore Inductors $40

So total $92 give or take.

Enclosure is made from MDF 19mm, front baffle 22mm, internal bracing glued with elastic glue.What did you design for the enclosure?

The response looks great.

Crazy quantity of components.

Front baffle is glued to enclosure with soft polyurethane glue that is used for gluing car windshield. Driver is coupled with back and side walls.

I don't have pictures of the whole making process but i hope this is enough to get the idea.

In my opinion, this speaker sounds better than the LS50.

But...

As with the LS50 as well as the r300 also with this speaker, I have problems with two things. The first is the ferrofluid in the tweeter. The tweeter sound is great but it can be better. I have repeatedly found that removing ferrofluids from the tweeter has a very beneficial effect on sound, which is logical. But because of the bad crossover it was necessary to protect them somehow.

The other is a stupid thing is rubber ring they put in to control resonance membrane. I understand the engineering (since I am an aircraft engineer) approach to having a goal and now looking for a way to reach it, but you have to be aware that it is all a matter of compromise. Now, either they were aware that the sound would be compromised or they relied too heavily on measurements, and they didn't care much for the sound. Again on the other hand if they didn't do it I wouldn't be able to use the 6db / Oct switch with AL drivers.

I still enjoy these speakers, but I know it can do better, and that's what annoys me. The sound of the piano is slightly blurred because of the rubber that exists between the voice coil and the membrane. The voice coil and membrane must be firmly attached in order for even the smallest vibrations to be transferred to the diaphragm and converted into an acoustic signal.

I hope Dr. Jack Oclee-Brovn is aware of this problem.

This phenomenon is also present in the r series of drivers, and is also present in bass drivers.It measures ok or doesn't sound good. goes deep but sounds muffled.

But...

As with the LS50 as well as the r300 also with this speaker, I have problems with two things. The first is the ferrofluid in the tweeter. The tweeter sound is great but it can be better. I have repeatedly found that removing ferrofluids from the tweeter has a very beneficial effect on sound, which is logical. But because of the bad crossover it was necessary to protect them somehow.

The other is a stupid thing is rubber ring they put in to control resonance membrane. I understand the engineering (since I am an aircraft engineer) approach to having a goal and now looking for a way to reach it, but you have to be aware that it is all a matter of compromise. Now, either they were aware that the sound would be compromised or they relied too heavily on measurements, and they didn't care much for the sound. Again on the other hand if they didn't do it I wouldn't be able to use the 6db / Oct switch with AL drivers.

I still enjoy these speakers, but I know it can do better, and that's what annoys me. The sound of the piano is slightly blurred because of the rubber that exists between the voice coil and the membrane. The voice coil and membrane must be firmly attached in order for even the smallest vibrations to be transferred to the diaphragm and converted into an acoustic signal.

I hope Dr. Jack Oclee-Brovn is aware of this problem.

This phenomenon is also present in the r series of drivers, and is also present in bass drivers.It measures ok or doesn't sound good. goes deep but sounds muffled.

Last edited:

I will use this driver or R100 driver in my next project as a midrange driver up to 200-300hz.

But before that I will try to remove the freofluid on a sample, and remove the rubber between voicecoil and the membrane.

if I can do that I'm sure I'll have a great coax driver.

Of course, keeping in mind what happens to the distortions.

I'm waiting for a donation from a buddy, if he can't get them, I'll wait for someone to call to donate🙂

But before that I will try to remove the freofluid on a sample, and remove the rubber between voicecoil and the membrane.

if I can do that I'm sure I'll have a great coax driver.

Of course, keeping in mind what happens to the distortions.

I'm waiting for a donation from a buddy, if he can't get them, I'll wait for someone to call to donate🙂

- Home

- Loudspeakers

- Multi-Way

- Justice for KEF Q100