LocTite324 with SF3287 Activator

I used LocTite324 and activator SF3287 with good results on my Kirksaeter Monitor 80 double magnet tweeters which after about 30 years the second magnet fell off both speakers. Ron

I used LocTite324 and activator SF3287 with good results on my Kirksaeter Monitor 80 double magnet tweeters which after about 30 years the second magnet fell off both speakers. Ron

Attachments

Yes, the glue gap will alter the overall path reluctance. However, you have to consider the entire path reluctance of the magnetic circuit. Reluctance is like magnetic resistance, they add in series. If you have a gap that is say 10 mils thick and one square inch, it is equivalent to a gap of 20 mils and 2 square inches. So the magnet glue thickness is not so critical because the overall area of the path is so large.I'll have to take your word for how to quantify gaps although my intuition is more about power-laws, not series addition. Yes, very helpful analysis.

But isn't the gap (the one filled with the VC wire... sometimes even edge-wound in the fine old days of Stephens drivers) very tiny, like closer to 2 mm than to 8 mm?

Most glues would result in insignificant added space in the gap. But some, like Gorilla family, not as small.

Ben

Also, as was pointed out, the magnet permeability may be quite low. Neo magnets are close to free air, so they will basically dominate the path reluctance.

Jb weld is pretty well thought of in my neck of the woods, but I've not used it on speaker magnets.

With two part epoxies, make sure it can handle the expected temp, look for a glass transition temp over 100 C. Sometimes called heat distortion temp, or alpha transition, or softening temp.

Jn

Loctite 326 with 7649 accelerator

I've ordered some 326 to re-glue the magnets on a pair of ns-10s', it's cheaper than 324 in my part of the world.

From the datasheet: https://www.farnell.com/datasheets/40157.pdf

"LOCTITE® 326 typical applications include bonding ferrites to

plated materials in electric motors, loudspeaker hardware..."

"Suited to magnet bonding", "Temperature resistant up to +120°C"...

The brochure looks good!

I've ordered some 326 to re-glue the magnets on a pair of ns-10s', it's cheaper than 324 in my part of the world.

From the datasheet: https://www.farnell.com/datasheets/40157.pdf

"LOCTITE® 326 typical applications include bonding ferrites to

plated materials in electric motors, loudspeaker hardware..."

"Suited to magnet bonding", "Temperature resistant up to +120°C"...

The brochure looks good!

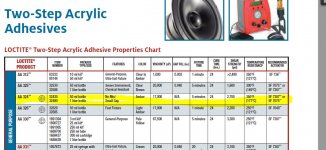

I found this too http://henkeladhesivesna.com/knowle...ds/2018/01/REVISED-speaker-bonding-tech-1.pdf

Loctite being a subsidiary of Henkel...

Loctite being a subsidiary of Henkel...

FWIW I commercially make speakers and always use 2 part Industrial Epoxy.

The 8 to 16 hour curing type, slightly thicker than honey.

In my neck of the woods, Ciba Geigy "Araldit" epoxy is king, search for something locally equivalent .

Needs very clean degreased surfaces.

This Epoxy does not cure *glass* hard, has a little resiliency and takes impact very well.

I preheat magnet and steel to lukewarm temperature, Epoxy flows and "wets" surfaces better, then I oven cure them so "8/16 hours" (at 25C room temperature) becomes way less than 1 hour.

I magnetize only after full speaker assembly.

The 8 to 16 hour curing type, slightly thicker than honey.

In my neck of the woods, Ciba Geigy "Araldit" epoxy is king, search for something locally equivalent .

Needs very clean degreased surfaces.

This Epoxy does not cure *glass* hard, has a little resiliency and takes impact very well.

I preheat magnet and steel to lukewarm temperature, Epoxy flows and "wets" surfaces better, then I oven cure them so "8/16 hours" (at 25C room temperature) becomes way less than 1 hour.

I magnetize only after full speaker assembly.

A question for rlj, does the donut magnet that you indicate have to go on in a particular orientation in respect of the magnet it is being reattached to. I ask because I have some old tweeters with a similar setup and in both the bottom magnet has come free. Glenn

glueing second magnet onto first magnet

The second magnet would only stay on the first magnet if the poles are aligned north onto south, otherwise the second magnet would slide off of the first magnet.

The second magnet would only stay on the first magnet if the poles are aligned north onto south, otherwise the second magnet would slide off of the first magnet.

For re-attaching shifted magnets, without removal of magnets from the frame --

will super glue work for tweeter?

will super glue work for tweeter?

The most important part with ALL gluing is cleanliness!

1. Clean

2. Clean

3. CLEAN

4. Prime

5. Glue (right tempertaure, and for epoxy 60-70 deg C)

6. Apply pressure to keep small distance between parts and as fixation during cure.

1. Clean

2. Clean

3. CLEAN

4. Prime

5. Glue (right tempertaure, and for epoxy 60-70 deg C)

6. Apply pressure to keep small distance between parts and as fixation during cure.

What is the recommended solution to clean metal parts prior to gluing?

Or is it a combination and a certain sequence?

Or is it a combination and a certain sequence?

Another question -- adjusting the shifted magnet:

What would be a good tool to help set the voice coil gap evenly in something like a compression driver?

What would be a good tool to help set the voice coil gap evenly in something like a compression driver?

I used JB weld 2 part steel type epoxy on one of my EPI woofer magnets,it worked perfect.First time I did it the pole piece was a little off center after curing.I was able to put the speaker on my electric stove and heat up the epoxy again to soften it and re position the pole piece.After complete curing i ran a bead of hot glue at all the magnet/plate joints just for insurance.

Would Super Glue Work as Speaker Magnet Glue?

I don't believe so. If I were you and I'd use the epoxy that have proven results. My donut magnet had the + pole marked with a sticker. It would only stay on the base magnet when the + pole was carefully aligned over the - pole of the speaker magnet.

I don't believe so. If I were you and I'd use the epoxy that have proven results. My donut magnet had the + pole marked with a sticker. It would only stay on the base magnet when the + pole was carefully aligned over the - pole of the speaker magnet.

Attachments

By what means do you set the voice coil gap evenly?

The epoxy was barely plastic and I just nudged the pole piece with a screwdriver eyeballing it.It came out ok as i was able to properly shim and glue in a new spider.I guess I have good vision.I've seen some videos where they built a pvc pipe jig.

Prime?The most important part with ALL gluing is cleanliness!

1. Clean

2. Clean

3. CLEAN

4. Prime

5. Glue (right tempertaure, and for epoxy 60-70 deg C)

6. Apply pressure to keep small distance between parts and as fixation during cure.

- Home

- Loudspeakers

- Subwoofers

- Speaker magnet glue