Those CL60's will get very hot. so no heatshrink. Get them a little bit up from any metal. And don't let any wires get glose to them. everytime i use those euroblocks, i cut out a peice of bitumen to have under the Block for extra safety.

Last edited:

Also I didn't put shrink wrap on my CL-60 legs because the black insulation on them went far enough down the legs to cover the exposed wire. Hope that's cool.

Hi Jesse,

missing shrinkwrap on the legs of your CL-60's is not the thing that concerns me here. The CL-60's get very hot in use (including their legs) - they're designed that way, to lower their resistance when in steady-state, after the initial switch-on.

Having them so close to the Euro terminal blocks, there's the real risk that you melt away the insulation on the terminals, resulting in a short.

CL-60's short always be mounted vertically resp. well away from every nearby surface, and with their full, unshortened leg length to not put too much heat into the terminal blocks. Have a look at 6L6's build guides ...

All the best, Claas

Edit: ZenMod and AudioSan beat me to it ... 😛😀

Last edited:

Use this type of terminal block.

1546670-4 TE Connectivity AMP Connectors | Connectors, Interconnects | DigiKey

Bend legs so Thermistor is mounted vertically.

1546670-4 TE Connectivity AMP Connectors | Connectors, Interconnects | DigiKey

Bend legs so Thermistor is mounted vertically.

Roger that. I will order the black terminal strips. I'd like to not have ruined my CL60s by cutting the legs off. This pic is from 6L6 guide and shows short legs. Can I do that? Or is there concern that the heat could melt the solder?

TB200-04 Eaton - Bussmann Electrical Division | Connectors, Interconnects | DigiKey

Thank you Chede and audiosan. It's good to have it explained in other words too.

There are an awful lot of pics and guides with the CL60s in euroblocks and very close to other wires.

TB200-04 Eaton - Bussmann Electrical Division | Connectors, Interconnects | DigiKey

Thank you Chede and audiosan. It's good to have it explained in other words too.

There are an awful lot of pics and guides with the CL60s in euroblocks and very close to other wires.

Attachments

You could use the ones with the short legs still always for the connection between signal ground and chassis ground - normally no current flowing there, no heat. And in case of a fault, they need only to pass so much current that the circuit breaker trips ... so, unlikely to get very hot because of their thermal inertia ...

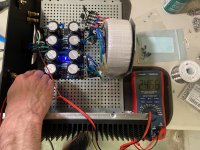

Okay. Got the right parts. Does this look safe? All the crimps are also soldered.

Thank you!

Thank you!

Attachments

Last edited:

Heatshrink added... Do the secondaries have polarity? And even if they do, does it matter where on the monolithic bridge I plug them in? (understanding that they should be on opposite corners.) My transformer is an antek with two blue and two green secondaries. As long as I plug a matching blue and green (i tested for continuity) into each monolithic bridge, on opposite corners of the square bridge, I should be good right?

Thanks!

Thanks!

They have polarity after a fashion, the lead of the winding being the blue wires on the secondaries. (noted by the dot on the schematic printed on the label.)

Make them match on each bridge and you'll be fine.

Make them match on each bridge and you'll be fine.

As long as they can not potentially ground out, you should be good.

Good luck with your build, I am really enjoying mine, it was well worth the effort.

Good luck with your build, I am really enjoying mine, it was well worth the effort.

Consider what happens when the bolt holding the MOSFET heats up. It's going to get longer.

Three things could happen at that point:

(a) the transistor case could swell even more, keeping everything nice and tight

(b) the Keratherm could un-compress a bit, but still be compressed enough to maintain excellent thermal conduction

(c) the transistor could be come loose, causing thermal conduction to plummet

For those of us using mica or a ceramic pad you're down to one of (a) or (c).

Since (c) is not good, I like to have some sort of spring washer in there: preferably a Belleville washer or failing that a wavy washer. I'll even use a split washer if I really have nothing else.

Three things could happen at that point:

(a) the transistor case could swell even more, keeping everything nice and tight

(b) the Keratherm could un-compress a bit, but still be compressed enough to maintain excellent thermal conduction

(c) the transistor could be come loose, causing thermal conduction to plummet

For those of us using mica or a ceramic pad you're down to one of (a) or (c).

Since (c) is not good, I like to have some sort of spring washer in there: preferably a Belleville washer or failing that a wavy washer. I'll even use a split washer if I really have nothing else.

I love popping into the threads to see what new tips I can pick up.

I had been using "large" washers and split washers for all my builds. I've started to make incremental attempts to ensure that should I choose to leave a build in my system for longer than a few months 😀 that it will stand the test of time through a number of thermal cycles and whatever else comes along.

I'm not a fastener expert by any means, but I just looked up "Belleville Washers" - I've never used them before, but based on skimming a few notes on the interwebs, they seem ideally suited to the task.

Picking up a pile for the bench. Thanks for sharing, Jeff!

I had been using "large" washers and split washers for all my builds. I've started to make incremental attempts to ensure that should I choose to leave a build in my system for longer than a few months 😀 that it will stand the test of time through a number of thermal cycles and whatever else comes along.

I'm not a fastener expert by any means, but I just looked up "Belleville Washers" - I've never used them before, but based on skimming a few notes on the interwebs, they seem ideally suited to the task.

Picking up a pile for the bench. Thanks for sharing, Jeff!

- Home

- Amplifiers

- Pass Labs

- F5 V3