Hi Scott,

I doubt it was intentional. They may have more automated means of keeping a centre these days. It's a "do the best you can" spec I guess.

-Chris

Chris this is an expensive current solution and as sloppy as it could get, how can we expect anything better?

Hi Scott,

Not being an expert in this, I have no idea. But it is worth a question to the prospective plant to see what their normal limits are. I don't know about demanding a specific allowable runout. You would have to be familiar with the equipment to make your own spec for this.

So basically, we are left with only a question for them.

-Chris

Not being an expert in this, I have no idea. But it is worth a question to the prospective plant to see what their normal limits are. I don't know about demanding a specific allowable runout. You would have to be familiar with the equipment to make your own spec for this.

So basically, we are left with only a question for them.

-Chris

Chris this is an expensive current solution and as sloppy as it could get, how can we expect anything better?

Their web page says "Adjust the speed of your turntable more accurately than any stroboscope on the market." So if the center is off and we believe that they really do know what they're saying then perhaps the copy you have is a reject that made it past QC?

Chris this is an expensive current solution and as sloppy as it could get, how can we expect anything better?

Can you figure out the plant it’s from by the deadwax?

——

Edit: Adjust+ comes with its own test record pressed in 180 gramm HQ vinyl in germany.

——

The automated machines simply don’t have great tolerances and obviously we can’t realistically ask them to upgrade their machinery. It’s a crapshoot.

The options I believe are:

1. The bookmold method, I believe possible from RTI and Quality

Cost per disc increases quite a bit because it’s a fully manual process.

2. We could also send out discs Unpunched.

I don’t see how we will EVER get this thing actually pressed without using option 1 or 2 and not get flamed by the GB participants.

It might be sensible to explore ways to mitigate the problem ourselves (center punch printable template) rather than rely upon the plant.

If not I think the next most sensible thing is to talk to Third Man Records. Or, I think it’s worth a shot from some of the reading I’ve done. They have the newest plant by a long shot, probably high quality fairly virgin or at least recently renovated machines. Seems well bankrolled.

The old guard plants that I’ve spoken to seem almost vehemently uninterested in this dilemma and actually offended if you suggest these tolerances aren’t acceptable.

It’s like if I started a conversation with you with “You know, these Bybees really opened up my soundstage.”

The whole convo just goes straight to hell.... regardless of how much pleasantries and friendliness you try to roll into it.

I have a feeling GZ can’t hack it. They’ve pressed most of the other test discs that everyone complains about poor tolerances on. One must assume these labels wanted high quality results and attempted to get them and failed.

Everyone I spoke to said if you want the best and most reliable center hole results, it’s bookmold or bust.

Obviously, the stamper center hole is absolutely critical. With multiple masters we could select the best of the bunch.

Last edited:

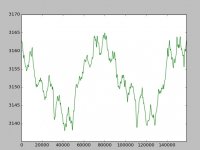

Here's a plot almost perfect 3152Hz mean but +- 0.4% off center.

Run out has only a job number and SST stamped in it (other than Adjust + A or B).

EDIT - Thanks for that link. A quick look shows that the mean is used and the warp and eccentricity are assumed to be there. The good Dr. is quite OCD about the azimuth set up.

Run out has only a job number and SST stamped in it (other than Adjust + A or B).

EDIT - Thanks for that link. A quick look shows that the mean is used and the warp and eccentricity are assumed to be there. The good Dr. is quite OCD about the azimuth set up.

Attachments

Last edited:

Well then, how much is it to do by the bookmold method? We are after a better test LP as part of the original mandate and getting this will cost something. Then it's just up to each person if they can bear the cost.

I don't see any point in anyone flaming the effort. We've been completely transparent about the problems and options. Facts is facts in this case.

-Chris

I don't see any point in anyone flaming the effort. We've been completely transparent about the problems and options. Facts is facts in this case.

-Chris

I don’t recall off the top of my head. Not double, but it was a big step up in price.

I did some preliminary research, contacted just about every notable plant and vinyl mastering facility in the US and EU.

It was absolutely stunning to me the difficulty in getting a straight answer. I think I managed two real quotes which reflected tolerances/specs in writing.

I then passed this off to Scott and Pano. They have been spearheading the project thus far, and I was just trying to make some progress as I’ve had some experience with this before.

After it was all said and done I recommended the guys at Sony Pictures mastering who took over Doug Sax’s stuff. The other big name mastering guys didn’t want to touch it, some referenced fears for their cutter heads.

Then there was a few domestic (US) plants that I thought might give us the best results. I think RTI was the front runner for me.

Pano (and maybe Scott?) still seems preferential to GZ. From my interaction I did not feel confident with them. I’m not sure what the differences where between our interactions or if Pano got more headway than I.

I didn’t want to voice my opinion too strongly as they have a better handle on the technical issues at hand.

I did some preliminary research, contacted just about every notable plant and vinyl mastering facility in the US and EU.

It was absolutely stunning to me the difficulty in getting a straight answer. I think I managed two real quotes which reflected tolerances/specs in writing.

I then passed this off to Scott and Pano. They have been spearheading the project thus far, and I was just trying to make some progress as I’ve had some experience with this before.

After it was all said and done I recommended the guys at Sony Pictures mastering who took over Doug Sax’s stuff. The other big name mastering guys didn’t want to touch it, some referenced fears for their cutter heads.

Then there was a few domestic (US) plants that I thought might give us the best results. I think RTI was the front runner for me.

Pano (and maybe Scott?) still seems preferential to GZ. From my interaction I did not feel confident with them. I’m not sure what the differences where between our interactions or if Pano got more headway than I.

I didn’t want to voice my opinion too strongly as they have a better handle on the technical issues at hand.

I'm trying to understand something here so please forgive me if I am asking Socrates for lessons on the alphabet. How do you know the variation in speed is not the table? or at least what percentage of it could be.

Thanks

Other LP's are fine and I don't see how the TT could produce .555 Hz easily unless it was out of round by 0.4% which is highly unlikely. You could also rotate the LP relative to the platter and figure it out.

Eccentricity is an irrelevance - LP is produced as well as can be.

If any member needs greater precision they make a bigger hole and glue a polo mint at the correct centre - this is a DIY group after all.

Time to get them produced methinks. Original brief was to produce a test LP at cheaper cost (to forum members) than the commercial offerings.

If any member needs greater precision they make a bigger hole and glue a polo mint at the correct centre - this is a DIY group after all.

Time to get them produced methinks. Original brief was to produce a test LP at cheaper cost (to forum members) than the commercial offerings.

Hi Hearinspace,

With how tightly controlled the AC power frequency is controlled here, I can't see your oscillator bettering the mains by very much. Not unless your turntable has it's own internal oscillator, then quality becomes a big question. Or perhaps it needs repair?

What TT are you using if I may ask? Also, you would think that with the weight vs driving force of most good tables, the most you would hear would be a slow change in tones. To make a high rate of change, your bearings would have to be shot, or the platter is light in comparison to the amount of driving force available. Certainly an idler wheel drive might be able to do that.

-Chris

With how tightly controlled the AC power frequency is controlled here, I can't see your oscillator bettering the mains by very much. Not unless your turntable has it's own internal oscillator, then quality becomes a big question. Or perhaps it needs repair?

What TT are you using if I may ask? Also, you would think that with the weight vs driving force of most good tables, the most you would hear would be a slow change in tones. To make a high rate of change, your bearings would have to be shot, or the platter is light in comparison to the amount of driving force available. Certainly an idler wheel drive might be able to do that.

-Chris

Eccentricity is an irrelevance - LP is produced as well as can be.

If any member needs greater precision they make a bigger hole and glue a polo mint at the correct centre - this is a DIY group after all.

Time to get them produced methinks. Original brief was to produce a test LP at cheaper cost (to forum members) than the commercial offerings.

Some feel differently.

The idea presently I believe is to have a novel, improved test record, not just a cheaper one.

Of course, GB will be at cost so cost will be much less than a commercial offering.

Nonetheless I’m also eager to see something get rolling, but don’t see the sense in rushing an inferior result.

Once they’ve finalized the tracks and measurement techniques, a lot depends on the stamper and then evaluating the test pressings. I’ll be quite excited when we get to that stage.

Some feel differently.

The idea presently I believe is to have a novel, improved test record, not just a cheaper one.

I'm starting to lean toward pulling the trigger. I forgot now, do we have vertical and horizontal tone arm resonance covered? Lucky seems to have lost interest and without his knowledge of the literature and maths I don't see how we can get any use out some of the esoteric tracks. I had a hard time separating the ones that really helped a user get more performance or were fundamental research on designing a cartridge from the ground up.

Other than a couple of oddities only LD fully understood I think we are pretty well covered. I need to go through my top down list again and check that what I might want to do it covered but I think other than repeating sweeps across the record we are close.

One thing I did notice is that some of the older test records had track for measuring VTA, but I couldn't work out how that was cut or the measurement, but seems like a jolly useful thing to have?

One thing I did notice is that some of the older test records had track for measuring VTA, but I couldn't work out how that was cut or the measurement, but seems like a jolly useful thing to have?

Other than a couple of oddities only LD fully understood I think we are pretty well covered. I need to go through my top down list again and check that what I might want to do it covered but I think other than repeating sweeps across the record we are close.

One thing I did notice is that some of the older test records had track for measuring VTA, but I couldn't work out how that was cut or the measurement, but seems like a jolly useful thing to have?

I think the tracks had different VTA cut vertical IMD test tone. Yosh pages are really good sources.

VTA

http://www7a.biglobe.ne.jp/~yosh/recspecs.htm

I think the tracks had different VTA cut vertical IMD test tone. Yosh pages are really good sources.

I think we touched on this, nobody is going to cut tracks with different VTA's for us and give us an LP that we can sell for $15.

- Home

- Source & Line

- Analogue Source

- Test LP group buy