Bill Waslo proposed something like that, basically a waveguide that can be 'scaled' to just about any size. Basically the first 15-20cm are 3D printed, and then the rest of the waveguide is a simple conical horn.

This is pretty clever

I agree that it is really clever. Is this a 'normal' syn, though (with a 1" HF driver and ~1,000Hz crossover)?

Cloning the Cask05 version (2" driver, lower crossover) in this manner looks like it would be simpler / require a smaller 3D printed part. You'd only have to print the first few cm.

That was my next question as well.

It seems a throat adapter -> horn wall connector would be small enough to fit relatively inexpensive printers (Monoprice*). The Monoprice printer linked has a ~12cm x 12cm x 12cm capacity.

That reminds me, bwaslo, which printer do you have?

The 'mumps' in the K402, are those nearer the throat? Or are they the shapes the Australian gentleman cut from XPS?

I'm not sure how big the K402 is, but I think it might be a bit too big, even in our large (~650sq/ft) living room. Though, oddly enough I think I could pull it off if it were oriented vertically as in the drawing bwaslo posted.

*Maker Select 3D Printer v2 (Refurbished) - Monoprice.com

It seems a throat adapter -> horn wall connector would be small enough to fit relatively inexpensive printers (Monoprice*). The Monoprice printer linked has a ~12cm x 12cm x 12cm capacity.

That reminds me, bwaslo, which printer do you have?

The 'mumps' in the K402, are those nearer the throat? Or are they the shapes the Australian gentleman cut from XPS?

I'm not sure how big the K402 is, but I think it might be a bit too big, even in our large (~650sq/ft) living room. Though, oddly enough I think I could pull it off if it were oriented vertically as in the drawing bwaslo posted.

*Maker Select 3D Printer v2 (Refurbished) - Monoprice.com

Bill, the obvious solution is that you'll just have to build them into the wall of your living room 🙂

I support this endeavor, fwiw.

If it's an exterior wall you could get away with whatever depth you need and make a nice grill cover and it would 'disappear' .... 😀

I've considered trying to build some big horns into the corner of the ceiling in our living room. We have an absurdly large attic, so this idea seems to pop into my head often.

@Bert--> A couple of months until the horn mold is complete and producing parts--which is the essential part of a kit. Since I haven't produced a molded horn yet, there is some risk in the date, but life challenges getting back into the shop are resolving themselves presently, and the weather is warming here to permit glassing the mold back section and subsequent casting parts.

The box is really simple to build--and there is a bit of latitude in the size/shape that you choose since reactance annulling isn't an issue with a modified tractrix (straight sided + tractrix flare) horn of this size. I'm planning to experiment with BB ply with nicer veneer.

Here is a comparison shot of the K-402 horn relative to a La Scala I. The horn and box is about the size of a La Scala II, but it has performance like that of a Jubilee in about 3x smaller volume package--and it has better performance than a Jubilee in terms of its directivity and clarity:

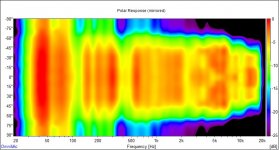

Below you'll find a recently produced plot based on original data gathered from Jan 2016. This is a polar horizontal coverage spectrogram of the developmental prototype. Note the directivity that extends below 100 Hz, and output down to 30-35 Hz when measured outside on an elevated stand:

The dropouts in SPL are due solely to the lack of proper crossover filter overlap used at that time (400-550 Hz), microphone--ground plane 1/4 wave bounce (100-150 Hz), and on-axis EQing anomalies at 2.4 kHz. These dropouts are not representative of the configuration's inherent horn/driver polar performance.

Its outstanding low frequency polar performance is due to the dimensions of the horn mouth in controlling its polars down to ~40 Hz. This directivity is more effective than even the Jubilee bass bin, making this MEH effective in corner or wall/floor boundary gain, or simply suspended off the floor against a wall. This is verification of its original design goal to function as a center, corner, or even free-standing loudspeaker.

Chris

The box is really simple to build--and there is a bit of latitude in the size/shape that you choose since reactance annulling isn't an issue with a modified tractrix (straight sided + tractrix flare) horn of this size. I'm planning to experiment with BB ply with nicer veneer.

Here is a comparison shot of the K-402 horn relative to a La Scala I. The horn and box is about the size of a La Scala II, but it has performance like that of a Jubilee in about 3x smaller volume package--and it has better performance than a Jubilee in terms of its directivity and clarity:

Below you'll find a recently produced plot based on original data gathered from Jan 2016. This is a polar horizontal coverage spectrogram of the developmental prototype. Note the directivity that extends below 100 Hz, and output down to 30-35 Hz when measured outside on an elevated stand:

The dropouts in SPL are due solely to the lack of proper crossover filter overlap used at that time (400-550 Hz), microphone--ground plane 1/4 wave bounce (100-150 Hz), and on-axis EQing anomalies at 2.4 kHz. These dropouts are not representative of the configuration's inherent horn/driver polar performance.

Its outstanding low frequency polar performance is due to the dimensions of the horn mouth in controlling its polars down to ~40 Hz. This directivity is more effective than even the Jubilee bass bin, making this MEH effective in corner or wall/floor boundary gain, or simply suspended off the floor against a wall. This is verification of its original design goal to function as a center, corner, or even free-standing loudspeaker.

Chris

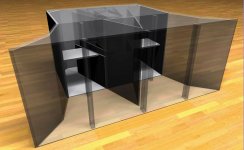

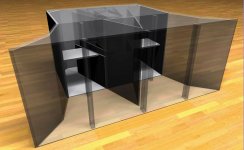

Here's the box that I used for the prototype (with an enclosed hole in the back that was used in a KPT-305 assembly) which worked well enough in terms of back chamber volume and stiffness vis-à-vis woofer performance:

If the user intends to employ compression drivers of large depth (like TAD TD-4001/4002 or EV DH1A), then I recommend a box that's about one inch deeper (23.6" vs. 22.6"...Note that a Klipschorn is 28" deep). The width of the back (when looked at in horizontal orientation) can be even narrower if desired and still accommodate the dual 15" woofers enclosed, or even narrower if using dual 12" woofers.

Also note that this assembly can be used in open baffle format--like a co-axial Klangfilm Bionor--without the need for separate treble horn. An open baffle can also be sized for use in the corner of a room, effectively reducing the required baffle size by 50% in each dimension.

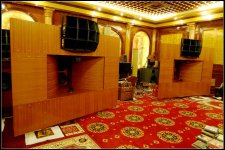

Or perhaps built into false room corners, like William Cowan's DIY Unity horns:

Chris

If the user intends to employ compression drivers of large depth (like TAD TD-4001/4002 or EV DH1A), then I recommend a box that's about one inch deeper (23.6" vs. 22.6"...Note that a Klipschorn is 28" deep). The width of the back (when looked at in horizontal orientation) can be even narrower if desired and still accommodate the dual 15" woofers enclosed, or even narrower if using dual 12" woofers.

Also note that this assembly can be used in open baffle format--like a co-axial Klangfilm Bionor--without the need for separate treble horn. An open baffle can also be sized for use in the corner of a room, effectively reducing the required baffle size by 50% in each dimension.

Or perhaps built into false room corners, like William Cowan's DIY Unity horns:

Chris

Last edited:

Hi Chris,

Can the horn be oriented vertically as shown on post 125?

I've subcribed to this post so I'll be able to follow your

development.

Cheers,

Bert

Can the horn be oriented vertically as shown on post 125?

I've subcribed to this post so I'll be able to follow your

development.

Cheers,

Bert

Yes it can be oriented vertically for 60 degree nominal horizontal coverage. It's effectively a point source radiator, so either orientation works.

Chris

Chris

Chris,

What Klipsch (or other?) bass corner horn model do you think it's best to reach to 35-40hz? I want to do one to see if I like it. The listening room is aprox. 5m / 5m and I can place them right in the corners. The plan is to do a smaller MEH above them (not sure of the crossover point yet, I kind of like more >160hz crossover point, than 100 Hz of a big MEH). Thanks!

What Klipsch (or other?) bass corner horn model do you think it's best to reach to 35-40hz? I want to do one to see if I like it. The listening room is aprox. 5m / 5m and I can place them right in the corners. The plan is to do a smaller MEH above them (not sure of the crossover point yet, I kind of like more >160hz crossover point, than 100 Hz of a big MEH). Thanks!

Last edited:

There are but two Klipsch-produced corner bass horns: the Klipschorn bass bin, and the Jubilee bass bin. Of the two, the Jubilee bass bin has better directivity/mouth geometries than the Khorn bass bin. Both produce about 32 Hz (-3 dB point) when in good corners. Both bass bins produce over a decade of good output, which is just about as much as one can get with a conventional horn, especially one that's folded. Both horns are designed well for folded corner horns. If you are thinking about using a K-402-MEH sized horn on top, then either bass bin will work well, but I'd be careful about crossing over much higher than 200 Hz for either bass bin, if polar coverage is important to you (...it is to me...). There is an option to attaching a custom-made "nose" on the bass bins to solve the dual mouth diffraction issue at higher frequencies, but this results in a larger footprint:

The Khorn bass bin has a fairly sharp high frequency cut off above 400 Hz, while the Jubilee bass bin can actually produce good output to over 1100 Hz, but its dual-mouth diffraction effects above about 210 Hz begin to significantly narrow its acoustic coverage angles above that point.

Other than that, there are few true front-loaded corner horns still in production or still available. You might be able to find some old Peavey or Altec Lansing VOTT bass bins (A2/A4--which are huge and really won't get you down to 35 Hz) but these are sought out by collectors who have pushed their resale values to 10x or more what they should be worth.

Chris

The Khorn bass bin has a fairly sharp high frequency cut off above 400 Hz, while the Jubilee bass bin can actually produce good output to over 1100 Hz, but its dual-mouth diffraction effects above about 210 Hz begin to significantly narrow its acoustic coverage angles above that point.

Other than that, there are few true front-loaded corner horns still in production or still available. You might be able to find some old Peavey or Altec Lansing VOTT bass bins (A2/A4--which are huge and really won't get you down to 35 Hz) but these are sought out by collectors who have pushed their resale values to 10x or more what they should be worth.

Chris

For the sake of completeness, there are two more Klipsch-produced bass horns that I really don't consider to be corner horns: the MWM bass bins and the newest KPT-1515-LF, which has a different footprint. Both have about the same LF performance, IIRC.

The space between the horn mouths in the KPT-1515-LF is even greater than a Khorn or Jubilee bass bin (or the MWM bass bin), which will lower the effective high frequency point to preserve polar coverage--i.e., lower than 210 Hz. It also has trouble reaching 35 Hz at least in its spec sheet (40 Hz -3dB point in full space). But in a room corner, it should go almost an octave lower. But this thing is big.

The MWM bass bins have been used by several people that I know in a home environment (in corners eighth space and along a floor-wall quarter space). It doesn't go as low as the Jubilee bass bin or the Khorn bass bin, and it's even wider and deeper than the KPT-1515-LF (i.e., they're big). But if you've got the room and the size doesn't bother you, they are options to consider.

The space between the horn mouths in the KPT-1515-LF is even greater than a Khorn or Jubilee bass bin (or the MWM bass bin), which will lower the effective high frequency point to preserve polar coverage--i.e., lower than 210 Hz. It also has trouble reaching 35 Hz at least in its spec sheet (40 Hz -3dB point in full space). But in a room corner, it should go almost an octave lower. But this thing is big.

The MWM bass bins have been used by several people that I know in a home environment (in corners eighth space and along a floor-wall quarter space). It doesn't go as low as the Jubilee bass bin or the Khorn bass bin, and it's even wider and deeper than the KPT-1515-LF (i.e., they're big). But if you've got the room and the size doesn't bother you, they are options to consider.

Which compression drivers?

Hi Chris (and others),

I fully understand the reasons for going for a large horn (i.e., the K-402). However, I am a bit concerned about which 2" compression driver to choose.

I know and fully undertand that others may have different takes, but if I go for these MEHs, I will go for a first-rate compression driver right from the beginning (I don't want to spend the next years thinking: "could this be improved, if I had chosen compression driver X, Y, Z instead?").

The problem is, that I do not know which of-the-shelf 2" to go for! A TAD 4001 would probably be great, but they are really expensive even second-hand (an almost impossible to get in Europe). So my question is:

* Is there any specific 2" Be driver that you recommend? (e.g., TAD 4001; JBL 244X with Be diaphragm; Radian 950Be, or??)

* The 1.5" JBL 2435H (Be) should be really great and can be had for a reasonable price second-hand, but this is a 1.5" driver, so would you consider making a no-compromise 1.5" throat adapter to allow for using 1.5" drivers?

Thanks a lot for all the work you put into this!

Best regards

Peter

Hi Chris (and others),

I fully understand the reasons for going for a large horn (i.e., the K-402). However, I am a bit concerned about which 2" compression driver to choose.

I know and fully undertand that others may have different takes, but if I go for these MEHs, I will go for a first-rate compression driver right from the beginning (I don't want to spend the next years thinking: "could this be improved, if I had chosen compression driver X, Y, Z instead?").

The problem is, that I do not know which of-the-shelf 2" to go for! A TAD 4001 would probably be great, but they are really expensive even second-hand (an almost impossible to get in Europe). So my question is:

* Is there any specific 2" Be driver that you recommend? (e.g., TAD 4001; JBL 244X with Be diaphragm; Radian 950Be, or??)

* The 1.5" JBL 2435H (Be) should be really great and can be had for a reasonable price second-hand, but this is a 1.5" driver, so would you consider making a no-compromise 1.5" throat adapter to allow for using 1.5" drivers?

Thanks a lot for all the work you put into this!

Best regards

Peter

I currently use TAD TD-4002s on my two fronts (K-402 over KPT-KHJ/LF bass bins). I'm bonded to those drivers in a way that I've never been bonded to anything audio before (as well as the horns that they're mounted to). No chatter, perfect dynamics--even heavy cymbals sound like the real thing. TAD TD-4001s would sound identical to the 4002s in terms of their performance on 2-way MEHs, but cost even more and more than double the weight of the 4002s.

I haven't heard the Radian Be 2" driver or the equivalent JBL 2" Be driver. I would imagine that they would be exceedingly close to the TADs in overall sound. I once did a close inspection of the differences in material properties of titanium (or aluminum) vs. beryllium. Overall the advantage is about a 7-to-1 ratio in terms of lightness combined with stiffness. It's not close and it never will be. Anyone that tries to convince you that their titanium diaphragm driver sounds as good as a beryllium diaphragm driver--well, I'd recommend that you take your money and ears elsewhere. Any "replacement drop in" Be diaphragm that performs only marginally better than a titanium diaphragm it replaces in the same driver (I'm thinking old JBL drivers especially) means that the driver design is not meant to take advantage of the Be material properties, so avoid those drivers altogether. That would be my advice.

The next in line that I've personally heard would be a properly EQed (and perhaps bi-amped) BMS 4592ND dual diaphragm driver (i.e., the full 2" throat model). I've found that once you find a driver that doesn't chatter from 10-20 kHz, when you carefully EQ them flat, they become almost impossible to tell apart by listening (but they must be EQed FLAT). An added advantage to the dual-diaphragm drivers is even better control of FM distortion, which is already quite low for 2" compression drivers. The 4592s have poly diaphragms but have good performance because they have broken up the job inter two separate frequency bands and have optimized for each band. Dual diaphragm drivers are tailor made for MEH use because they avoid that "I can't get the midrange close enough to the throat" syndrome that you see in virtually every 3-way MEH design. Why have two crossovers in the 100-4000 Hz band when you can have just one without any other disadvantages?

The next 2" compression drivers that I've actually heard, measured and dialed in are the HF200 series Faital Pro drivers. These chatter above 10 kHz but they disguise their chattering quite well. You can hear it, but only if you're paying attention during predominant ride cymbal passages, and it won't actually reach out and grab your attention.

The next in line are the B&C DE75 or DE750 drivers. I could easily live with these drivers if they weren't in the left or right front speaker spot in my 5.1 array. In the center, these drivers do a very credible job and don't announce themselves by having a different HF timbre, but they do color the cymbal transients to a noticeable degree.

There are a range of other 2" drivers with titanium diaphragms that all chatter and sound very much like the B&C DE75/750 drivers. These are easy to live with for some time before you decide to upgrade and sell off your lower cost drivers.

As far as 1.4" or 1.5 inch throat BE drivers--that's exactly what the TAD TD-4002 driver is--with its own 1.5"-2" snout. I would recommend this if the snout is done well, but note that you're going to give up a little on the HF coverage above 7 kHz (i.e., the driver's phase plug position vs. the minimum throat diameter and the expansion to 2" means that the adapter will move the voice coils further away from the apex of the horn throat). You can't avoid losing a little HF coverage, but I'm not sure it's going to be terribly audible above 7-10 kHz. I know at least one guy that tried to shorten the snout and found that there are issues that arise trying to do that successfully.

As far as producing an adapter--this could be easily done by producing a cast resin replica of the 4002 snout (which, as you might know, is no longer in production). The only issue is time and effort in the total scheme of things. I've already got my eyes on other multiple entry horns of differing coverage angles and sizes to address those that cannot accommodate the "K-402 size" that I am initially working on. If the demand is there for a 1.4-2 or 1.5-2 inch adapters of better quality, that could be part of the future planning.

Note that if I hear more drivers on the horn than I've enumerated above, my opinions might change, but for the time being, that's my best shot at answering your questions.

Chris

I haven't heard the Radian Be 2" driver or the equivalent JBL 2" Be driver. I would imagine that they would be exceedingly close to the TADs in overall sound. I once did a close inspection of the differences in material properties of titanium (or aluminum) vs. beryllium. Overall the advantage is about a 7-to-1 ratio in terms of lightness combined with stiffness. It's not close and it never will be. Anyone that tries to convince you that their titanium diaphragm driver sounds as good as a beryllium diaphragm driver--well, I'd recommend that you take your money and ears elsewhere. Any "replacement drop in" Be diaphragm that performs only marginally better than a titanium diaphragm it replaces in the same driver (I'm thinking old JBL drivers especially) means that the driver design is not meant to take advantage of the Be material properties, so avoid those drivers altogether. That would be my advice.

The next in line that I've personally heard would be a properly EQed (and perhaps bi-amped) BMS 4592ND dual diaphragm driver (i.e., the full 2" throat model). I've found that once you find a driver that doesn't chatter from 10-20 kHz, when you carefully EQ them flat, they become almost impossible to tell apart by listening (but they must be EQed FLAT). An added advantage to the dual-diaphragm drivers is even better control of FM distortion, which is already quite low for 2" compression drivers. The 4592s have poly diaphragms but have good performance because they have broken up the job inter two separate frequency bands and have optimized for each band. Dual diaphragm drivers are tailor made for MEH use because they avoid that "I can't get the midrange close enough to the throat" syndrome that you see in virtually every 3-way MEH design. Why have two crossovers in the 100-4000 Hz band when you can have just one without any other disadvantages?

The next 2" compression drivers that I've actually heard, measured and dialed in are the HF200 series Faital Pro drivers. These chatter above 10 kHz but they disguise their chattering quite well. You can hear it, but only if you're paying attention during predominant ride cymbal passages, and it won't actually reach out and grab your attention.

The next in line are the B&C DE75 or DE750 drivers. I could easily live with these drivers if they weren't in the left or right front speaker spot in my 5.1 array. In the center, these drivers do a very credible job and don't announce themselves by having a different HF timbre, but they do color the cymbal transients to a noticeable degree.

There are a range of other 2" drivers with titanium diaphragms that all chatter and sound very much like the B&C DE75/750 drivers. These are easy to live with for some time before you decide to upgrade and sell off your lower cost drivers.

As far as 1.4" or 1.5 inch throat BE drivers--that's exactly what the TAD TD-4002 driver is--with its own 1.5"-2" snout. I would recommend this if the snout is done well, but note that you're going to give up a little on the HF coverage above 7 kHz (i.e., the driver's phase plug position vs. the minimum throat diameter and the expansion to 2" means that the adapter will move the voice coils further away from the apex of the horn throat). You can't avoid losing a little HF coverage, but I'm not sure it's going to be terribly audible above 7-10 kHz. I know at least one guy that tried to shorten the snout and found that there are issues that arise trying to do that successfully.

As far as producing an adapter--this could be easily done by producing a cast resin replica of the 4002 snout (which, as you might know, is no longer in production). The only issue is time and effort in the total scheme of things. I've already got my eyes on other multiple entry horns of differing coverage angles and sizes to address those that cannot accommodate the "K-402 size" that I am initially working on. If the demand is there for a 1.4-2 or 1.5-2 inch adapters of better quality, that could be part of the future planning.

Note that if I hear more drivers on the horn than I've enumerated above, my opinions might change, but for the time being, that's my best shot at answering your questions.

Chris

Last edited:

One reason would be that you get an acoustic lowpass filter on the midrange that you don't get with a 2-way, which reduces any out of band distortion the driver produces. Also you can use a smaller diameter aperture HF driver to better approximate a point source up high (not that I'm likely to hear high enough for that to make a difference, though)Why have two crossovers in the 100-4000 Hz band when you can have just one without any other disadvantages?

Hi Bill!

Note that I strongly believe that the disadvantages of the 3-way MEH in terms of disturbing the most audible bands (i.e., the most sensitive aural frequency bands as measured by the equal loudness curves - SPL to phons) over a smooth and clean 2" compression driver full-range far outweigh any audible effects of added FM distortion of a two-way design (the only downside that I can really imagine)...

...as compared to a 1" compression driver crossed at ~1-2 kHz...then adding additional holes in the MEH aperture extremely close to the horn apex, the headaches of adding another set of filters right in the middle of the most audible band (1-2 kHz) and the problems of integrating everything properly and getting 1 or more midrange drivers dialed in.

The reason why Tom Danley uses 3-ways with separate midranges is clearly SPL, and SPL only. In his smaller Synergy monitors, he's using coaxial drivers. The added holes in the aperture of the horn for the coaxial drivers is a necessary evil for the way that he chose. I'd choose a dual-diaphragm compression driver - like the BMS 4592ND to avoid that. I bet that Tom would, too if he didn't have to drive even his monitors to very high SPL (which is not needed for home hi-fi, IMHO).

There is an apparent urban myth surrounding "out-of-band distortion"--which I can neither hear nor measure at audible levels in any of the 2" compression drivers that I've used (and I've used a few over the past 10 years on the K-402s). I would guess that this notion is really coming from using cheap 1" compression drivers with titanium or aluminum diaphragms on DIY MEH designs. I'm really not sure, however.

The "point source" thing you mention is a phase plug issue, not a hole-in-the-horn issue. Getting more diaphragm area dramatically decreases FM and harmonic distortion (among other types) over 1" compression drivers. See the JBL literature on this subject. It's pretty good.

In any case, this particular thread is focusing on two-way MEHs. Threads on 3-way MEHs are plentiful on diyAudio.

Some here might wonder how I came to the MEHs: it was from a totally different background with regard to MEH design by way of the two-way Jubilee design that uses 2" compression drivers...which has been my main system for over 10 years now. An MEH 2-way using 2" compression drivers on a K-402-sized horn is a very short excursion from that point...

Chris

Note that I strongly believe that the disadvantages of the 3-way MEH in terms of disturbing the most audible bands (i.e., the most sensitive aural frequency bands as measured by the equal loudness curves - SPL to phons) over a smooth and clean 2" compression driver full-range far outweigh any audible effects of added FM distortion of a two-way design (the only downside that I can really imagine)...

...as compared to a 1" compression driver crossed at ~1-2 kHz...then adding additional holes in the MEH aperture extremely close to the horn apex, the headaches of adding another set of filters right in the middle of the most audible band (1-2 kHz) and the problems of integrating everything properly and getting 1 or more midrange drivers dialed in.

The reason why Tom Danley uses 3-ways with separate midranges is clearly SPL, and SPL only. In his smaller Synergy monitors, he's using coaxial drivers. The added holes in the aperture of the horn for the coaxial drivers is a necessary evil for the way that he chose. I'd choose a dual-diaphragm compression driver - like the BMS 4592ND to avoid that. I bet that Tom would, too if he didn't have to drive even his monitors to very high SPL (which is not needed for home hi-fi, IMHO).

There is an apparent urban myth surrounding "out-of-band distortion"--which I can neither hear nor measure at audible levels in any of the 2" compression drivers that I've used (and I've used a few over the past 10 years on the K-402s). I would guess that this notion is really coming from using cheap 1" compression drivers with titanium or aluminum diaphragms on DIY MEH designs. I'm really not sure, however.

The "point source" thing you mention is a phase plug issue, not a hole-in-the-horn issue. Getting more diaphragm area dramatically decreases FM and harmonic distortion (among other types) over 1" compression drivers. See the JBL literature on this subject. It's pretty good.

In any case, this particular thread is focusing on two-way MEHs. Threads on 3-way MEHs are plentiful on diyAudio.

Some here might wonder how I came to the MEHs: it was from a totally different background with regard to MEH design by way of the two-way Jubilee design that uses 2" compression drivers...which has been my main system for over 10 years now. An MEH 2-way using 2" compression drivers on a K-402-sized horn is a very short excursion from that point...

Chris

Granted, but you brought up 3-way Unity/Synergy approaches, I didn't. I've never heard a K402, but then you've never heard my horns. I've not heard anything remotely similar to the problems you describe, though.

Hi!

Interesting project Chris! I've never heard MEH or Klipsch products, but I very much like the dynamics of NS1000 and soundstage of my DIY fullrange builds so I've been looking for suitable DIY horn system passively for many years.

MEHs are the most interesting design to me but there really isn't kits available and jumping in without one is too scary at the moment (small kids, average salary etc. 🙂

A project that I would have confidence to endeavor would have

- readymade horn, or at least the throat and very detailed plans how to manufacture the horn. Maybe some jig parts to help manufacturing.

- readily available drivers

- detailed info on the crossover and EQ so that I'd be sure to get the sound working in my room.

I'm afraid selling a kit cannot provide you a profit, but maybe selling very good blueprint ( includes videos / plans / 3D files ) for such a project could bring you some income?

Also I'm not sure though how one could produce the horn at home from something else than wood cheap enough?

I tried some online 3D printing company price quote calculator for a much smaller horn that I found .stl file for and it was several thousand Euro to 3D print two horns..

So it seems only way to get good horn cheap enough is to mass produce them by molding?

Anyway, I'm following with great interest how your project turns out!

Here is the poll:

1) What common compression driver(s) and woofers would you most want to use (brand and model) in a kit?

Any thats readily available.

2) What is the lowest crossing frequency (i.e., "fc") that you would want out of the loudspeaker?

Dictated by size of the cabinet

3) What maximum size would you be willing to build/buy for your listening environment?

I've got stereo setup for music.

80cm * 80cm front is already too large for the wife. Larger is fine if there is possibility to disquise the speakers as decorative elements 🙂

4) How much would you realistically be willing to spend per loudspeaker to make them from a kit?

A thousand per complete speaker is fine, if success is guaranteed by self confidence building the kit.

No confidence, no kit. Unless very cheap.

5) Would you be willing to use an active crossover instead of passive?

Yes, please.

Thanks already for good read!

Interesting project Chris! I've never heard MEH or Klipsch products, but I very much like the dynamics of NS1000 and soundstage of my DIY fullrange builds so I've been looking for suitable DIY horn system passively for many years.

MEHs are the most interesting design to me but there really isn't kits available and jumping in without one is too scary at the moment (small kids, average salary etc. 🙂

A project that I would have confidence to endeavor would have

- readymade horn, or at least the throat and very detailed plans how to manufacture the horn. Maybe some jig parts to help manufacturing.

- readily available drivers

- detailed info on the crossover and EQ so that I'd be sure to get the sound working in my room.

I'm afraid selling a kit cannot provide you a profit, but maybe selling very good blueprint ( includes videos / plans / 3D files ) for such a project could bring you some income?

Also I'm not sure though how one could produce the horn at home from something else than wood cheap enough?

I tried some online 3D printing company price quote calculator for a much smaller horn that I found .stl file for and it was several thousand Euro to 3D print two horns..

So it seems only way to get good horn cheap enough is to mass produce them by molding?

Anyway, I'm following with great interest how your project turns out!

Here is the poll:

1) What common compression driver(s) and woofers would you most want to use (brand and model) in a kit?

Any thats readily available.

2) What is the lowest crossing frequency (i.e., "fc") that you would want out of the loudspeaker?

Dictated by size of the cabinet

3) What maximum size would you be willing to build/buy for your listening environment?

I've got stereo setup for music.

80cm * 80cm front is already too large for the wife. Larger is fine if there is possibility to disquise the speakers as decorative elements 🙂

4) How much would you realistically be willing to spend per loudspeaker to make them from a kit?

A thousand per complete speaker is fine, if success is guaranteed by self confidence building the kit.

No confidence, no kit. Unless very cheap.

5) Would you be willing to use an active crossover instead of passive?

Yes, please.

Thanks already for good read!

- Home

- Loudspeakers

- Multi-Way

- Full-Range Synergy Kit Questions