Mine? They are 17-18mm.

In Monotube2's case, they are 20mm thick and no fins! But sheer mass of 25kg of welded plate aluminum (looks like T-6092?) should be fine for a BB even.

Last edited:

I meant: the Accuton mid in combination with 2 Alcone woofers in the crossover region pulls it a little lower.

In Monotube2's case, they are 20mm thick and no fins! But sheer mass of 25kg of welded plate aluminum (looks like T-6061?) should be fine for a BB even.

That is one massive and nice case! Suprisingly light though, since my sinks weight 10kg each.

By the way, I will build similar speakers like danny the difference I will use one Alcone woofer with Hi-Vi F10 woofer. I have all the drivers only need some good tweeters.

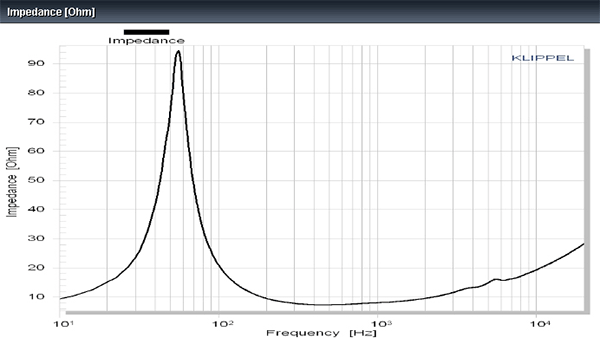

That will be around 4 Ohms speakers.

That is why I need something beefy amplifier. At the moment I think (one option) to drive one of the woofers active with that the speakers will be 8R.

I will see.

Greetings

That will be around 4 Ohms speakers.

That is why I need something beefy amplifier. At the moment I think (one option) to drive one of the woofers active with that the speakers will be 8R.

I will see.

Greetings

That is one massive and nice case! Suprisingly light though, since my sinks weight 10kg each.

If I remember well each box is 27/28 kgs ( please note that the front panel is much more light with the two 10" holes )

A 9lb 400VA 25V toroidal trafo is on its way to my lab. Did you know that you can't order more than 1 at a time? Antek uses USPS Priority mail and there is a weight limit that is broken with two.

I have the BB output MOSFETs.

I am missing some of the small SMT PWM fan control stuff that JPS64 put into the controller board. That is needed or 100W will quickly toast the MOSFETS without proper cooling.

I have the BB output MOSFETs.

I am missing some of the small SMT PWM fan control stuff that JPS64 put into the controller board. That is needed or 100W will quickly toast the MOSFETS without proper cooling.

Since more than half the heat would be radiating inward (assuming everything is mounted inside), isn't there a potential for excessive heat build up affecting, or decreasing the life span of, the speaker materials (cones, surrounds); even with the 20W version?In Monotube2's case, they are 20mm thick and no fins! But sheer mass of 25kg of welded plate aluminum (looks like T-6092?) should be fine for a BB even.

Boards received!

Time to populate them. They will be replacing a pair of F5 boards powered by an 800VA transformer and CRC filter (Juma CM will be tested too)

I am guessing that if the heatsinks are good for the F5, they should be good for the ALPHA

Time to populate them. They will be replacing a pair of F5 boards powered by an 800VA transformer and CRC filter (Juma CM will be tested too)

I am guessing that if the heatsinks are good for the F5, they should be good for the ALPHA

Since more than half the heat would be radiating inward (assuming everything is mounted inside), isn't there a potential for excessive heat build up affecting, or decreasing the life span of, the speaker materials (cones, surrounds); even with the 20W version?

It will be warmer inside the cabinet - this is where adding insulation pads internally would help. Foil covered pink Owens Corning fiberglass anyone? That would force heat to radiate outwards.

It will be warmer inside the cabinet - this is where adding insulation pads internally would help. Foil covered pink Owens Corning fiberglass anyone? That would force heat to radiate outwards.

Mounted outside on the back side, directly wired to the speakers ( no binding posts )

Don't forget the fan! Those heatsinks will not be able to do much passively cooled, and the amp's largest thermal load is at idle.

It's looking good and very close to first sound. Can you please show closeup of how you clamped the MOSFETs to those Dell CPU coolers? Usual L-angle and screws?

Hi, I wont forget fans 🙂 i'll power them first with external aux supply. Usually I check wires like 10 times, don't trust myself enough.

Theres just thick aluminium plate bolted on top of mosfets, needs some reinforcement, it was 5mins quick and dirty experiment. Maybe a little longer and bolts to other ends also. Bolted L-angle would be stiffer and I might chance to that later.

Theres just thick aluminium plate bolted on top of mosfets, needs some reinforcement, it was 5mins quick and dirty experiment. Maybe a little longer and bolts to other ends also. Bolted L-angle would be stiffer and I might chance to that later.

Attachments

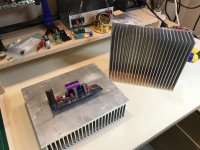

My new heatsinks arrived today, they should be ample for 20w Alpha. I'll attach a few quick pics for scale.

Each heatsink is 8" of this profile:

http://www.heatsinkusa.com/10-080-wide-extruded-aluminum-heatsink/

I'm pretty swamped for awhile, but I'm hoping to sneak in some time to get these prepped. I've matched my mosfet's and just need to mount to heatsinks, then wire up the proto-chassis for first sound.

Each heatsink is 8" of this profile:

http://www.heatsinkusa.com/10-080-wide-extruded-aluminum-heatsink/

I'm pretty swamped for awhile, but I'm hoping to sneak in some time to get these prepped. I've matched my mosfet's and just need to mount to heatsinks, then wire up the proto-chassis for first sound.

Attachments

- Home

- Amplifiers

- Solid State

- Aksa Lender P-MOS Hybrid Aleph (ALPHA) Amplifier