I've been working on a waveguide project where I would develop high performance waveguides for some popular tweeters, and than share the files for anyone to print or CNC as they are able. The discussion started here: 3D printed waveguides - Techtalk Speaker Building, Audio, Video Discussion Forum for more details. The short summary is starting with the SB26ADC and a 5" waveguide, I varied flare radius, phase shields, depths, etc. I've started to find some best practices (at least with this dome/horn combo) and all future guides will have elliptical mouths, and with and without phase shields. I then skipped to 8" designs to verify those best practices scale, so anything in between should be trivial to design and still have the expected performance. Tweeters that I'm currently designing for are: SBA SB26ADC, SBA SB19ST, Satori TW29RN, and Transducer Labs N26C-A.

To get some frame of reference, here measurements of the Kef Reference 5 prototype, and Revel Concerta2 (which I suspect also uses the SB26ADC):

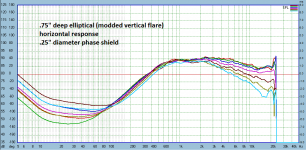

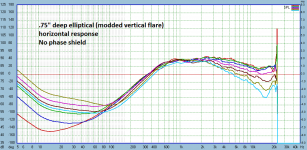

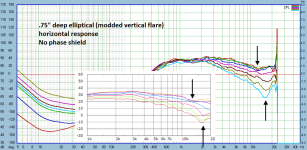

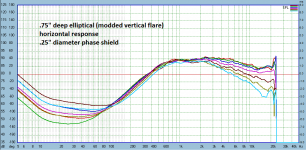

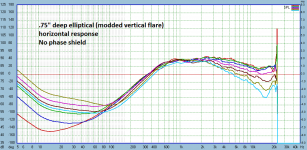

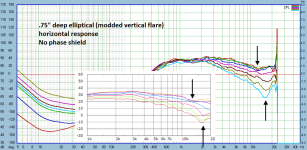

Here is my "C" waveguide with SB26ADC, with and without phase shield:

Quite good results I think, better than Revel achieved with the same tweeter! Anyway, the reason I am posting now though this project is still in its infancy, is I've connected with a couple gentleman with the ability to model waveguides. This could speed things up considerably, as waveguide design is extremely iterative otherwise because 90% of the performance happens at the dome/throat interface and this is not easily modeled.

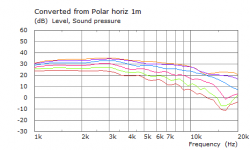

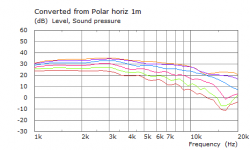

We've started with verifying that the sim can accurately predict reality. With as close a representation as possible of the dome here are the results:

Extremely encouraging! I'd like to do some additional verification - particularly of the 8" guides I've started working on - and then I hope to push the sims to the max, and start producing some really excellent guides for popular tweeters.

To get some frame of reference, here measurements of the Kef Reference 5 prototype, and Revel Concerta2 (which I suspect also uses the SB26ADC):

Here is my "C" waveguide with SB26ADC, with and without phase shield:

Quite good results I think, better than Revel achieved with the same tweeter! Anyway, the reason I am posting now though this project is still in its infancy, is I've connected with a couple gentleman with the ability to model waveguides. This could speed things up considerably, as waveguide design is extremely iterative otherwise because 90% of the performance happens at the dome/throat interface and this is not easily modeled.

We've started with verifying that the sim can accurately predict reality. With as close a representation as possible of the dome here are the results:

Extremely encouraging! I'd like to do some additional verification - particularly of the 8" guides I've started working on - and then I hope to push the sims to the max, and start producing some really excellent guides for popular tweeters.

BTW I should add some background on measurement conditions. I use MLS signal with a 6ms gate to remove the first reflections. Measurements were at 1.5m or so, with a calibrated mic. The baffle was not the big baffle I used for measurements at my drivervault site, but 2'-ish by 3'-ish rectangle with the driver offset. Sim showed quite smooth response to about 1khz, but I suspect diffraction is starting to creep into the measurements <4khz and are significant closer to 1khz. Angles are 0-60 in 10 degree increments.

Last edited:

Some examples (the mouths are round to facilitate easy mounting on my baffle with just a circle cutout, actual print files are elliptical flanges):

Attachments

Last edited:

Fantastic work! Those guides look great too, are they 3D printed? This is a great concept, subscribed even though I doubt I have anything to contribute. I do have access to a 3D printer so maybe I could do some testing if required. Best of luck!

Very interesting. Keep us opdated 🙂

Would really like to try a waveguide with one of the SB tweeters.

Would really like to try a waveguide with one of the SB tweeters.

Subscribed. I have a pair of 26ADC and Satori TW29RN and some friends with 3D printers 🙂.

Not sure if possible but I would be very interested in (and even pondered trying to sim it myself) a Seas DXT type waveguide.

Not sure if possible but I would be very interested in (and even pondered trying to sim it myself) a Seas DXT type waveguide.

Thanks everyone for the encouragement! I'll start posting some .stl or .obj files after I measure a few guides I just received from the printer. No definitive designs, but at least people can play round with them and see what they think so far.

Very cool work. So these just mount on top of the existing tweeter faceplate? No disassembly of the tweeter?

I have access to a CNC machine, if you want to prototype a pair in aluminum let me know, I can probably make that happen. Not sure I can make the waveguide with integrated phase plugs though. Might have to be 2 pieces, or it might just be really difficult to do in any case. If you have 3d files in .stp format it's pretty trivial for me to see how bad the CAM work would be.

I have access to a CNC machine, if you want to prototype a pair in aluminum let me know, I can probably make that happen. Not sure I can make the waveguide with integrated phase plugs though. Might have to be 2 pieces, or it might just be really difficult to do in any case. If you have 3d files in .stp format it's pretty trivial for me to see how bad the CAM work would be.

Mounting depends on the tweeter. For all the SBA/Satori drivers, their faceplate comes off easily and is not integral to locating the diaphragm like many tweeters are. So pretty easy to mate, and they have keyholes, so matching that in my design makes centering the dome pretty much plug-and-play. The Transducer Lab tweeters require the faceplate to stay attached or you'll rip the diaphragm off with it. Luckily there flat faceplate again makes mounting very easy.

Early on in the thread at PE, we discussed this, and it would be fairly easy to design the phase plug as a standalone item with cylindrical keys at the end, with a matching depression in the waveguide wall which would be easily made with the end mill of the CNC. I "hope" with some optimization the phase plug won't be necessary.

Early on in the thread at PE, we discussed this, and it would be fairly easy to design the phase plug as a standalone item with cylindrical keys at the end, with a matching depression in the waveguide wall which would be easily made with the end mill of the CNC. I "hope" with some optimization the phase plug won't be necessary.

I "hope" with some optimization the phase plug won't be necessary.

That's the next topic on the agenda, I guess 😉

Last edited:

Have you thought making/simulating a waveguide for the SB29RDC-C000-4 tweeter?

No I haven't. Are the diaphragm dimensions the same as the TW29RN?

Hi,

First of all I wanted say that I'm very impressed about the work Brandon is presenting here.

Actually I'm in contact with Brandon and Ro808 and try to support this work here with respective simulations (see post #1 by Brandon).

Just some disclaimers:

- I'm probably not the most experienced person with respect to simulations around here. I started a 'how to use ABEC'-thread in a German DIY forum some time ago (see here if interested). There are some DIYs with much more experience on simulations and waveguide construction around in this German forum, who considerably contributed to the ABEC-thread. I'm still learning...

- However, I'll support Brendons great work as good as possible anyway.

- My replies my be late and some results may be communicated via Brendon and Ro808 as I have only very little time for the hobby actually...

@Zonnenschimmel

The linked thread is on how to construct a constant directivity waveguide. Funny enough, I ended up with elliptical waveguides as well, comparable to Brandons approach.

Regards,

Christoph

First of all I wanted say that I'm very impressed about the work Brandon is presenting here.

Actually I'm in contact with Brandon and Ro808 and try to support this work here with respective simulations (see post #1 by Brandon).

Just some disclaimers:

- I'm probably not the most experienced person with respect to simulations around here. I started a 'how to use ABEC'-thread in a German DIY forum some time ago (see here if interested). There are some DIYs with much more experience on simulations and waveguide construction around in this German forum, who considerably contributed to the ABEC-thread. I'm still learning...

- However, I'll support Brendons great work as good as possible anyway.

- My replies my be late and some results may be communicated via Brendon and Ro808 as I have only very little time for the hobby actually...

@Zonnenschimmel

I did quite some simulations on how the Seas DXT waveguide works here. Especially #199 to #206. May be this helps.Not sure if possible but I would be very interested in (and even pondered trying to sim it myself) a Seas DXT type waveguide.

The linked thread is on how to construct a constant directivity waveguide. Funny enough, I ended up with elliptical waveguides as well, comparable to Brandons approach.

Regards,

Christoph

Thanks for the help so far Christoph! I just applied for the student license of ABEC and see how far I can get. When you get a chance PM me with your basic workflow for going from the CAD file to ABEC sim. Nothing detailed is necessary, just a high level overview.

Thanks

Brandon

Thanks

Brandon

Thanks for the link, I can read some German but it'll take some google-translate help to get all the details 🙂

Hi Brandon, I'll PM you or will give the workflow here. May need some time though...

A critical step for ABEC simulations is getting a proper mesh from the *.stp file. I do this with Gmsh and described basic steps here.

Basic information on 'how to ABEC' can be found here (watch out, German) or in the extremely helpful 🙂D) helpful and examples provided with ABEC.

Hi Zonneschimmel, Just let me know, if something get's lost in translation 😀, I'll b happy to translate and clarify...

A critical step for ABEC simulations is getting a proper mesh from the *.stp file. I do this with Gmsh and described basic steps here.

Basic information on 'how to ABEC' can be found here (watch out, German) or in the extremely helpful 🙂D) helpful and examples provided with ABEC.

Hi Zonneschimmel, Just let me know, if something get's lost in translation 😀, I'll b happy to translate and clarify...

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!