there are 2 ways to deal with rezonance/refelection.

you can supress it with a shitload of dampening material and stiff walls.

was the standard for quite a long time.

or you can distribute the energy in a wide band, so it is not really audible.

for that you need no thick walls, but clever ratio and geometry.

the 3 root of 2 stuff i posted does just that.

the edges do not have a common divider so they will not resonate at the same freqvency, allso the harmonics will differ. so they can not reinforce eatch other.

an other solution is to place bracers in order to avoid harmonics to amplify eatch other.

you can supress it with a shitload of dampening material and stiff walls.

was the standard for quite a long time.

or you can distribute the energy in a wide band, so it is not really audible.

for that you need no thick walls, but clever ratio and geometry.

the 3 root of 2 stuff i posted does just that.

the edges do not have a common divider so they will not resonate at the same freqvency, allso the harmonics will differ. so they can not reinforce eatch other.

an other solution is to place bracers in order to avoid harmonics to amplify eatch other.

Really? If I use a 4'' diameter pipe the optimal length of the pipe would be 4''? That's perfect for my build then.

What would you do to get a non flat surface end of the pipe? I've only seen flat surface caps for the pipes.

1/2 foam spheres from such places as "Hobby Lobby"

sch 40 and sch 80 PVC pipe have reducer couplers which could be stacked into a long taper. Probably not cheap. Probably something I would want to hand-fit at a store to confirm usability.

Reducer Coupling

Size (in) Length

¾ x ½ ....2 5/32 .

1 x ¾ ....2 1/4

1¼ x 1 ....2 17/32

1½ x ¾ ....2 7/8

1½ x 1 .... 2 21/32

1½ x 1¼ ....2 13/16

2 x 1½ ....3 1/16

3 x 2 ....3 5/8

4 x 3 ....4 3/8

6 x 4 ....6 13/16 1

8 x 6 ....10 25/32 2

10 x 2 ....11 9/32 4

10 x 3 ....11 9/32 4

10 x 4 ....11 9/32 4

10 x 6 ....10 25/32 2

==========

Sonotube cardboard tubes used for cement foundations can be cut with a saber saw. Cutting out triangles(point toward speaker) would allow glue + duct tape to combine the remaining triangles(point toward exit) into a single sealed taper.

=========

As discussed earlier(Brett) pyramid and conical shapes can be constructed from triangle wood panels. A conical taper can be bent inside a cabinet to also provide bracing.

Reducer Coupling

Size (in) Length

¾ x ½ ....2 5/32 .

1 x ¾ ....2 1/4

1¼ x 1 ....2 17/32

1½ x ¾ ....2 7/8

1½ x 1 .... 2 21/32

1½ x 1¼ ....2 13/16

2 x 1½ ....3 1/16

3 x 2 ....3 5/8

4 x 3 ....4 3/8

6 x 4 ....6 13/16 1

8 x 6 ....10 25/32 2

10 x 2 ....11 9/32 4

10 x 3 ....11 9/32 4

10 x 4 ....11 9/32 4

10 x 6 ....10 25/32 2

==========

Sonotube cardboard tubes used for cement foundations can be cut with a saber saw. Cutting out triangles(point toward speaker) would allow glue + duct tape to combine the remaining triangles(point toward exit) into a single sealed taper.

=========

As discussed earlier(Brett) pyramid and conical shapes can be constructed from triangle wood panels. A conical taper can be bent inside a cabinet to also provide bracing.

sch 40 and sch 80 PVC pipe have reducer couplers which could be stacked into a long taper. Probably not cheap. Probably something I would want to hand-fit at a store to confirm usability.

Reducer Coupling

Size (in) Length

¾ x ½ ....2 5/32 .

1 x ¾ ....2 1/4

1¼ x 1 ....2 17/32

1½ x ¾ ....2 7/8

1½ x 1 .... 2 21/32

1½ x 1¼ ....2 13/16

2 x 1½ ....3 1/16

3 x 2 ....3 5/8

4 x 3 ....4 3/8

6 x 4 ....6 13/16 1

8 x 6 ....10 25/32 2

10 x 2 ....11 9/32 4

10 x 3 ....11 9/32 4

10 x 4 ....11 9/32 4

10 x 6 ....10 25/32 2

==========

Sonotube cardboard tubes used for cement foundations can be cut with a saber saw. Cutting out triangles(point toward speaker) would allow glue + duct tape to combine the remaining triangles(point toward exit) into a single sealed taper.

=========

As discussed earlier(Brett) pyramid and conical shapes can be constructed from triangle wood panels. A conical taper can be bent inside a cabinet to also provide bracing.

Thank you for that

after reading a post of Arty , I did that simulation with a mw16-4 of sb acoustic to compare heavy stuffing square cabinet and triangle end box. My result with Leonard software regarding the spl is that both box look the same. Is there a better way to see the difference between the two concepts ?

Attachments

Try simming with no stuffing.Is there a better way to see the difference between the two concepts ?

Try simming with no stuffing.

Yes I did that also and even before I did the simulation I knew the result.

I'm pretty sure the concept is better than a square box with full of stuff. I just wanna see it in simulation if it is possible. I try to prove it to myself that concept is better before I start going to home depot

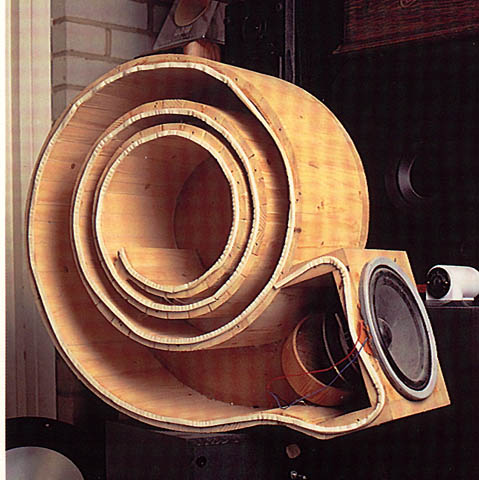

Another rear chamber besides Dagger, is Nautaloss. Easy to make with foam core. Also very transparent - no boxiness at all.

http://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor.html

http://www.diyaudio.com/forums/full-range/247598-nautaloss-ref-monitor.html

Another rear chamber besides Dagger, is Nautaloss

Similar, a prototype of the B&W nautilus:

dave

I found 4" pipe didn't give that much volume. Though talking in metric speak.... 100mm diameter pipe by 120mm long gives just under a litre volume. Whereas 120mm pipe of the same length gives 1.35L.

This is using ventilation ducting. It's quite floppy until braced by end caps or "sockets" routed in panels. when braced it's nicely rigid. I used bitumen/aluminium flashing tape on the outside to deaden it, lined the walls with 12mm wool felt and stuffed with 20g wool.

If wanting to avoid a flat end cap, possibly routing smaller disks of ply/mdf/wood can be formed into a "Mayan pyramid".... And the edges bevelled?!

This is using ventilation ducting. It's quite floppy until braced by end caps or "sockets" routed in panels. when braced it's nicely rigid. I used bitumen/aluminium flashing tape on the outside to deaden it, lined the walls with 12mm wool felt and stuffed with 20g wool.

If wanting to avoid a flat end cap, possibly routing smaller disks of ply/mdf/wood can be formed into a "Mayan pyramid".... And the edges bevelled?!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Help with midrange chamber design