It is probably Micropore, it is a 3M product that too!

I still don't know about the thin film. Could be what you are suggesting, Båndsei.

Neither of them are suitable as membrane for an AMT, I think.

I still don't know about the thin film. Could be what you are suggesting, Båndsei.

Neither of them are suitable as membrane for an AMT, I think.

Hi

WrineX

I have just shipped your alu/pet film

Sending you this one too.

[/url][/IMG]

Happy Newyear.

Bernt Båndsei.

Niceeeee!!!!!!!!! THx allot Bernt!!!, Pm me your bank information and ill transfer the money.

btw that menbrame looks super clean!

And a very happy new year as well! let it be a nice productive /learnsome year 🙂

I see your Quads... why bother with anything else 🙂

Well the quads i did Not make myself ,I did repair all the panels. But I want something that is similar but then of my own making 🙂

And maybe maybe maybe ....I can somewhere in the far far future make living of something I really enjoy doing 🙂

Flua

Is it microporre tape you mean?

Or "stegepose" bag used for meat in oven?

Bernt

Correct. I understand this is known to you. Reading more of the thread I see that the 3M tape is of no use here.

Back to business

Back to the old membrane design (6,5 mm deep and 1,6 mm wide pockets with 4,5 wide aluminium stripes) then but this time with a slightly modified folding tool that resulted a higher quality membrane with more even spaced folds and aluminium strips.

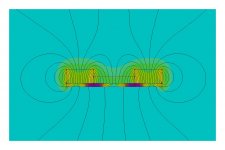

I'm trying to reduce the LF distortion. One idea is then to remove the membrane frame altogether. So I glued a plastic quarter-round base shoe to the magnets directly:

Then I glued the membrane in place, still no frame:

Put some sealing strip on the back, just to disturb any standing wave build up:

Back to the old membrane design (6,5 mm deep and 1,6 mm wide pockets with 4,5 wide aluminium stripes) then but this time with a slightly modified folding tool that resulted a higher quality membrane with more even spaced folds and aluminium strips.

I'm trying to reduce the LF distortion. One idea is then to remove the membrane frame altogether. So I glued a plastic quarter-round base shoe to the magnets directly:

Then I glued the membrane in place, still no frame:

Put some sealing strip on the back, just to disturb any standing wave build up:

Attachments

Apart from the high 2nd HD, this was a nice surprise:

Then I realized, there are no back pole pieces yet! Hmm...

So what about the 2nd HD. Just trying to set a tone where the distortion is high and then use REW's RTA or simply just listen lead this first mitigation:

With this result, look at the distortion components below 300 Hz:

Then I realized, there are no back pole pieces yet! Hmm...

So what about the 2nd HD. Just trying to set a tone where the distortion is high and then use REW's RTA or simply just listen lead this first mitigation:

With this result, look at the distortion components below 300 Hz:

Attachments

the distortion is shifting ? up.

i do the same usually nail the distortion and use the rta and fidl untill you see something happen.

btw you chose 6.5 mm because of the high roll of ?

Are the end of the membranes supported in any way or hanging in freely? you glued the sides into the motor but also the shorts sides ?

Did you stiffen the ends of the membrane with an extra tape ?

i do the same usually nail the distortion and use the rta and fidl untill you see something happen.

btw you chose 6.5 mm because of the high roll of ?

Are the end of the membranes supported in any way or hanging in freely? you glued the sides into the motor but also the shorts sides ?

Did you stiffen the ends of the membrane with an extra tape ?

No, that's a mirage; the scales are different. What is happening is that the 2nd HD went down by 15 dB below 300 Hz.the distortion is shifting ? up.

Yes, it is a good method.i do the same usually nail the distortion and use the rta and fidl untill you see something happen.

Actually it was the other way around; I abandoned the 2 by 10 mm because its roll off.btw you chose 6.5 mm because of the high roll of ?

Now that the folding tool is better, I think I'll stick by the 1,5 mm wide pockets, might go deeper though.

The membranes are suspended by a strand of Loctite Hybrib Glue on each side of the membrane's top and bottom.Are the end of the membranes supported in any way or hanging in freely?

The strand also keeps the pockets intact.

Just by the strand mentioned above.you glued the sides into the motor but also the shorts sides ?

Yes. I don't think it is necessary though.Did you stiffen the ends of the membrane with an extra tape ?

Yes, I was kind of surprised by the low 3rd HD levels.>500Hz = SOTA for 3:rd overtone. Congrats!

//

The big susprise was the even SPL, the "acoustic" bevel is necessary in the gap (that is, the quarter-round base shoe) to avoid standing waves notches.

Within +/- 3 dB from 240 Hz to 18 kHz calls for no EQ!

Even if SOTA is acheived for the 3rd HD, the hunt continues for even lower 2nd HD.

To make the mitigation above more permanent I put glue strands every eight centimeters. Only on the back of the membrane:

Still no back pole pieces, perhaps they aren't needed?

(Then båndsei was right all along

)

)I have been opposed to use retainers, but I don't think that they did any harm to the SPL. It is a little jumpier, but I reckon that there are other explanations for that:

Now the level of the 2nd HD follows the SPL up to 400 Hz.

Attachments

no EQ ? so you dont have the rise in frequency as i had ? mine had a rise above 4khz up to 18khz

hmm must take a look at that .loctide stuff.

distortion looks incredible by the way, but its hard to compare measurements between these and my holm ones. might take one with rew tomorrow see how it compares. of course yours goes lower ... way lower and spl is waaaaaay up 🙂

about the 6.5 mm i ment was, you dont go deeper because of high end will roll off ? 🙂 i asked this since if i would use 10mm magnets it would be nice to use as much gap as possible so go for like 8mm or something. but i wondered if this would screw up the hf response.

did you lose SPL without the back pole pieces?

its kind of weird that works since i imagine an amt as multiple ribbons behind each other , a normal ribbon will wiggle and act weird if you leave out one stack of magnets, left or right.

if you did not lose much , that would eb great. i mean distortion is already extreme low compared to anything else. it would also make it possible to make even deeper pleats since in one of you top shot pictures you can see you have sooooo much space left behind the back of the membrane till the edge of the magnets. the membrane is really using only 1/3 of you magnet sort off. i mean there is still a allot of magnetic field that is not put to use.

also not having to cut of fabricate a rear would save costs allot, wich you could invest in extending.... hmmmm fullrange damn this is al interesting stuff and so many parameters , its mind boggling to be honest

hmm must take a look at that .loctide stuff.

distortion looks incredible by the way, but its hard to compare measurements between these and my holm ones. might take one with rew tomorrow see how it compares. of course yours goes lower ... way lower and spl is waaaaaay up 🙂

about the 6.5 mm i ment was, you dont go deeper because of high end will roll off ? 🙂 i asked this since if i would use 10mm magnets it would be nice to use as much gap as possible so go for like 8mm or something. but i wondered if this would screw up the hf response.

did you lose SPL without the back pole pieces?

its kind of weird that works since i imagine an amt as multiple ribbons behind each other , a normal ribbon will wiggle and act weird if you leave out one stack of magnets, left or right.

if you did not lose much , that would eb great. i mean distortion is already extreme low compared to anything else. it would also make it possible to make even deeper pleats since in one of you top shot pictures you can see you have sooooo much space left behind the back of the membrane till the edge of the magnets. the membrane is really using only 1/3 of you magnet sort off. i mean there is still a allot of magnetic field that is not put to use.

also not having to cut of fabricate a rear would save costs allot, wich you could invest in extending.... hmmmm fullrange damn this is al interesting stuff and so many parameters , its mind boggling to be honest

Last edited:

Take it as an observation; of course will the back pole pieces be mounted.

But right now it is good to have access to the whole backside of the membrane.

But right now it is good to have access to the whole backside of the membrane.

Take it as an observation; of course will the back pole pieces be mounted.

But right now it is good to have access to the whole backside of the membrane.

Haha ok 🙂 clear!! Goor itis still ableyo be measured without 🙂

I don't understand. What is ableyo, goor and itis?Haha ok 🙂 clear!! Goor itis still ableyo be measured without 🙂

Back to the old membrane design (6,5 mm deep and 1,6 mm wide pockets with 4,5 wide aluminium stripes) then but this time with a slightly modified folding tool that resulted a higher quality membrane with more even spaced folds and aluminium strips.

What changes did you made to folding jig?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT