The tapped horn concept is old. Very old. And has been used in the old console sound systems from the 50's. More people have heard them than you think.

Seeing that an easy means of simulating them was not available until fairly recently, those old versions probably sounded pretty awful.

I wonder how much the environment is affecting things. Usually drivers are measured in free air (at least for ts), not in IB. And even with the doors and windows open in a car it's not really IB, the car is going to have a significant effect. All of this will change the impedance curve. Change the impedance curve and the derived parameters will change.

I don't think the precision of the weights is the culprit here, and I don't think he switched from aluminum to copper. To keep the price low I don't think that's a feasible option, and this driver is all about being the value leader. It's possible he used more wire in the coil and a different cone, but still, 843 g is a HUGE value for Mms.

I would pop that thing out of the car to measure, I think that might be the problem. I don't discount the fact that it might be using new parts but I don't think that alone accounts for the high Mms you measured.

I'll address this one more time in this thread.

When I have the option to re-measure I will post the results in the other thread.

If Ron wants it posted here he can chime in.

The magnets used for the shift in Fs weigh 161.1 grams with the scale properly calibrated.

The stated weight before was 229.7 grams.

It's a strain gauge scale, and it should be a little more accurate than that, but now it is once again.

I'm keeping the calibration weights in the same tool kit I keep the other stuff I use for driver measurement.

Now I can redo the math on the Cms and the Vas to get an accurate set of mechanical parameters.

The electrical parameters will not change with an erroneous Vas calculation. The variables that I can think of that change are the BL the Qms and the Vas. Not to leave out the drivers compliance Cms.

Addressing your assertion of drivers are measured in free air.

You have heard of an IEC baffle.

It is the standard on what a driver is measured on.

In fact there are baffle standards for different driver sizes.

The car has the driver almost vertically. Close enough that there is no chance of cone suspension sag.

The trunk and the doors are all open during the test.

AND THE TESTING IS DONE IN THE SMALL SIGNAL DOMAIN! You cannot see the driver moving while you are doing the testing. So how the car influences the measurements is a little beyond me.

It makes no difference at all.

And I have done literally multiple hundreds of small signal tests on drivers baffled or unbaffled. Vertical or horizontal. Even tried them upside down for kicks and giggles!

Yes there are tiny differences. The differences make no change in the modeling parameters or the finished enclosure.

Nice.

Does make me wonder though - what were they using before? 🙂

Fingers?

Old slide rule with a few rubbed off numbers.....

@ just a guy

Don't start this all over again please!

I'm one who does not like the sound of tapped horns. I've heard them and built them. My reasons are simple.

Keep in mind another thing.

The tapped horn concept is old. Very old. And has been used in the old console sound systems from the 50's. More people have heard them than you think.

I didn't start anything, I was replying to a statement that is IMO wrong. I have a tapped horn and a front loaded horn here at home. I much prefer the tapped horn sound. It's not subtle either. I have some stuffing in the first few feet of the tapped horn and that undoubtedly has something to do with it but that's not against the rules and my tapped horn sounds much better than my flh.

I'll address this one more time in this thread.

When I have the option to re-measure I will post the results in the other thread.

If Ron wants it posted here he can chime in.

The magnets used for the shift in Fs weigh 161.1 grams with the scale properly calibrated.

The stated weight before was 229.7 grams.

It's a strain gauge scale, and it should be a little more accurate than that, but now it is once again.

I'm keeping the calibration weights in the same tool kit I keep the other stuff I use for driver measurement.

Now I can redo the math on the Cms and the Vas to get an accurate set of mechanical parameters.

The electrical parameters will not change with an erroneous Vas calculation. The variables that I can think of that change are the BL the Qms and the Vas. Not to leave out the drivers compliance Cms.

Addressing your assertion of drivers are measured in free air.

You have heard of an IEC baffle.

It is the standard on what a driver is measured on.

In fact there are baffle standards for different driver sizes.

The car has the driver almost vertically. Close enough that there is no chance of cone suspension sag.

The trunk and the doors are all open during the test.

AND THE TESTING IS DONE IN THE SMALL SIGNAL DOMAIN! You cannot see the driver moving while you are doing the testing. So how the car influences the measurements is a little beyond me.

It makes no difference at all.

And I have done literally multiple hundreds of small signal tests on drivers baffled or unbaffled. Vertical or horizontal. Even tried them upside down for kicks and giggles!

Yes there are tiny differences. The differences make no change in the modeling parameters or the finished enclosure.

Anything that can alter the impedance curve makes a difference. And it doesn't matter if it's measured at small signal or large. Measure the t/s parameters in a closed box and see if you get anything that makes sense. The reason you won't is because the closed box changes the impedance curve, and that has nothing to do with small signal or large signal. Doesn't matter if the doors and trunk are open, the car itself is going to have a considerable effect on the driver under test and solid reflective boundaries and cavities change the impedance curve. There are a bunch of solid reflective boundaries and cavities in a car at very close distances.

I'm not sure if the problem is the weight error, the boundary effect or something else, but I can pretty much guarantee you the MMS on that driver is not 843 grams. Something is wrong somewhere.

Last edited:

The Mms isn't 843 grams.

The entire calculation is based on known mass added. Known piston diameter and the resulting shift in Fs.

I'm a little tired to crunch the numbers to get the correct mechanical paramters.

But I really don't even need to run the test again.

I need to rework the math appropriately to the known mass.

The shift in Fs is accurate. That won't change.

The piston diameter is accurate that won't change.

Give me a few minutes and I'll update the numbers so you can sleep tonight.

The entire calculation is based on known mass added. Known piston diameter and the resulting shift in Fs.

I'm a little tired to crunch the numbers to get the correct mechanical paramters.

But I really don't even need to run the test again.

I need to rework the math appropriately to the known mass.

The shift in Fs is accurate. That won't change.

The piston diameter is accurate that won't change.

Give me a few minutes and I'll update the numbers so you can sleep tonight.

Hi Mark,

Thanks for the effort.

So we should apply these T/S parameters to further SI18 designs together w/ the JAG Fix (as in the Hornresp Wizard as the "Large Voice Coil" button)?

Regards,

Thanks for the effort.

So we should apply these T/S parameters to further SI18 designs together w/ the JAG Fix (as in the Hornresp Wizard as the "Large Voice Coil" button)?

Regards,

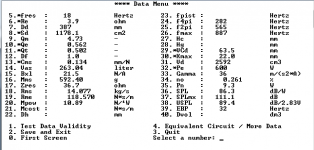

Yep. These ones are a keeper. They have been verified a few times through two different programs I trust.

Sorry I messed this up.

But the obvious stretch in Mms was a bit much for me to swallow.

Until I had a way to confirm or deny the accuracy of the mass used I was stuck with wondering if I was right or wrong.

Since I use the same magnets each time for a mass added measurement it is not difficult to perform a correction.

And I'm happy to have been able to do so.

Sorry I messed this up.

But the obvious stretch in Mms was a bit much for me to swallow.

Until I had a way to confirm or deny the accuracy of the mass used I was stuck with wondering if I was right or wrong.

Since I use the same magnets each time for a mass added measurement it is not difficult to perform a correction.

And I'm happy to have been able to do so.

Last edited:

Hi Mark,

Thanks for the effort.

So we should apply these T/S parameters to further SI18 designs together w/ the JAG Fix (as in the Hornresp Wizard as the "Large Voice Coil" button)?

Regards,

This set is definitely better than the first set but MMS is still really really high and Vas is quite low. These are within the realm of plausibility but I still don't think they are right. There may be a different factory building the driver but I don't think totally new parts are used so MMS should not be 150 g higher than it was previously. There can be some degree of natural variance in suspension parts stiffness but not usually in MMS which you can literally cut right out and measure on a scale.

Personally I would start from scratch, pull the driver out of the car (it's only 8 screws, why not just do it?) measure again. If the impedance curve isn't right none of the specs will be right either and I don't think you can do a proper impedance measurement in a car.

But even if we were to assume these specs were right, that would only indicate that there is a large variation in specs from batch to batch, so best to measure each driver before simulating.

And yes, whatever set of specs you use this driver won't sim right without adjustment for the large coil.

Last edited:

This set is definitely better than the first set but MMS is still really really high and Vas is quite low. These are within the realm of plausibility but I still don't think they are right. There may be a different factory building the driver but I don't think totally new parts are used so MMS should not be 150 g higher than it was previously. There can be some degree of natural variance in suspension parts stiffness but not usually in MMS which you can literally cut right out and measure on a scale.

Personally I would start from scratch, pull the driver out of the car (it's only 8 screws, why not just do it?) measure again. If the impedance curve isn't right none of the specs will be right either and I don't think you can do a proper impedance measurement in a car.

But even if we were to assume these specs were right, that would only indicate that there is a large variation in specs from batch to batch, so best to measure each driver before simulating.

And yes, whatever set of specs you use this driver won't sim right without adjustment for the large coil.

I really don't give a rats *** what you think.

You seem so self impressed by what you think you know that it blocks your ability to see and understand the obvious.

I suggest you go out and get your knowledable fingers on said driver. Drop a cool $1500 on some quality measurement equipment. Learn how to measure drivers and then argue.

Bloody hell you can be an agrivating little son of a motherless dog!

Rant over.

I really don't give a rats *** what you think.

You seem so self impressed by what you think you know that it blocks your ability to see and understand the obvious.

I suggest you go out and get your knowledable fingers on said driver. Drop a cool $1500 on some quality measurement equipment. Learn how to measure drivers and then argue.

Bloody hell you can be an agrivating little son of a motherless dog!

Rant over.

What is so obvious that I am not seeing and understanding?

Let's recap. A couple of weeks ago you measured a driver. You did it wrong and got a really wrong answer. You used wrong specs and did a sim. Then a couple weeks later you said you talked to Nick and he changed factories and that's why the specs are different. You never once mentioned you suspected a problem with these specs until I brought up the fact that MMS was clearly wrong and you could tell just by looking at it. When TB46 mentioned the same thing awhile back you defended these clearly wrong measured parameters (post 232) saying Bl is higher so MMS is higher too. Your new Bl spec is almost identical to the Bl measured by data-bass and I'm pretty sure if you measured the driver properly all the specs would be pretty close to those measured by data-bass, which in turn are not that far off from the published specs.

I use a cheap sound card and a jig with LIMP, it cost about $12 total. You don't need $1500 of measurement equipment. You don't need to have the driver or measure it to know that 843 g MMS is not even remotely reasonable or to know that you shouldn't measure t/s parameters in a car.

I was trying to be nice and polite but I really don't see how pointing out YOUR mistake makes me unable to see and understand the obvious but maybe you can teach me.

Last edited:

Last Try

Here is a design that should take you to 16 Hz and lower. Its acoustic length is 1/2 the wavelength of a 16 Hz. signal (32 ft.). It is made from 16" and 24" diameter RW Sonotube. If the dimensions of the "horn/waveguide" enclosure you plan on using are not comparable to the length of the acoustic waves you want to produce, then at those frequencies the driver will be doing all the work with little or no help from the enclosure. WHG

Again you are producing part of a musical instrument. The criteria here are solely subject ones. You will be tuning it by ear. All that the measurements will tell you, is whether the design is feasible or not. I will try to provide additional information later should there be a further interest. WHG

Most of the horn designs I've seen require some degree of precision woodworking. It would require an attention to detail in the shop. I think I could do it, but it will take discipline.

As those who have accompanied me on this rather long ourney know, one of the issues I've been experiencing is a shortage of real estate in our pipe/speaker chamber. Olver's triangular design helped me take advantage of a corner where typical rectangular (or even circular) woofers wouldn't be a good fit. I hope to find out that the two subwoofers in our setup will be sufficient for 16 Hz.

The speculating I'm doing now is purely what to do if the SPL isn't sufficient?

Being able to suspend a "pipe" over from the ceiling so it is over the organ pipes would keep the path clear for the technicians to gain access to the pipes. That has some real advantages.

But here's the issue I keep seeing. Some of the fine people in this forum like one type of horn, but think another sounds terrible. I'm not familiar with the many derivations. And I don't have any local venues where I can go and do a comparison of the various kinds of horns.

What's a guy to do?

BO

Here is a design that should take you to 16 Hz and lower. Its acoustic length is 1/2 the wavelength of a 16 Hz. signal (32 ft.). It is made from 16" and 24" diameter RW Sonotube. If the dimensions of the "horn/waveguide" enclosure you plan on using are not comparable to the length of the acoustic waves you want to produce, then at those frequencies the driver will be doing all the work with little or no help from the enclosure. WHG

Again you are producing part of a musical instrument. The criteria here are solely subject ones. You will be tuning it by ear. All that the measurements will tell you, is whether the design is feasible or not. I will try to provide additional information later should there be a further interest. WHG

Attachments

Have you considered drafting license terms and agreements for commercial entities?

Hi zettairyouiki,

Not really. I told Bose that they were free to use Hornresp any way that they wanted to. I was most impressed however, that they had the decency to seek permission first 🙂.

In addition to Bose, Hornresp has been used by Avantgarde Acoustic in Germany and P.Audio in Thailand. It seems likely that other commercial entities may also have used it.

At least one British University is using Hornresp as a learning tool in its Acoustical Engineering course.

Kind regards,

David

Here is a design that should take you to 16 Hz and lower. Its acoustic length is 1/2 the wavelength of a 16 Hz. signal (32 ft.). It is made from 16" and 24" diameter RW Sonotube. If the dimensions of the "horn/waveguide" enclosure you plan on using are not comparable to the length of the acoustic waves you want to produce, then at those frequencies the driver will be doing all the work with little or no help from the enclosure. WHG

Again you are producing part of a musical instrument. The criteria here are solely subject ones. You will be tuning it by ear. All that the measurements will tell you, is whether the design is feasible or not. I will try to provide additional information later should there be a further interest. WHG

Interesting Bill.

I'll simulate it this afternoon.

Hi zettairyouiki,

Not really. I told Bose that they were free to use Hornresp any way that they wanted to. I was most impressed however, that they had the decency to seek permission first 🙂.

In addition to Bose, Hornresp has been used by Avantgarde Acoustic in Germany and P.Audio in Thailand. It seems likely that other commercial entities may also have used it.

At least one British University is using Hornresp as a learning tool in its Acoustical Engineering course.

Kind regards,

David

I hope that this makes your work all the more worthwhile David.

How about those Blue Jays?

At the end of the day, it's just a game. We may like how our team comes out in the standings. But their standings are often temporary.

We can notice it and even keep track of it. But it won't make the World a better place.

Only we - by our industry and our attitude - can do that.

BO

You've scratched the itch. Now just move on.

RAWC Notes

Some notes on tube sizes that will permit use of different driver Sd's

Do = ((2)^(1/2))*Di+dD

Try dD an inch or two larger than what I used

WHG

Interesting Bill.

I'll simulate it this afternoon.

Some notes on tube sizes that will permit use of different driver Sd's

Do = ((2)^(1/2))*Di+dD

Try dD an inch or two larger than what I used

WHG

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Tapped Horn Cabinet for 16 Hz. organ speaker