Bach On,I do think the ported bass box with the two 15 inch drivers is putting out pretty good sound. I do notice some "thruming" in the box. A short note seems to have reverb. That bothers me. But the box does seem tight with little that I would describe as rattles or wood flexing. I do suspect I need to add a wood brace between the front and rear walls. I originally had one in there, but removed it to add the port.

I believe I also need to substantially increase the damping fill in the box. I saw where someone sprayed adhesive to the interior walls and applied poly-fill to the still-sticky walls to reduce reflections. I've only got two or three inches of fiberglass damping material at the bottom of the box. I think more might help.

Your measurement of 67 dB for the 21 Hz sine wave compared to 72 dB for 81(?)Hz is encouraging, -5 dB is not too bad at all.

Any damping you put in the box will reduce low frequency output. Damping will reduce interior upper frequency reverberation, but at the expense of LF output. Typically, subs that are high passed use no damping, your case is a bit different, as IIRC you are running the subs full or extended range. A low pass filter on the subs would be a good idea, eliminating the upper "ring", and not requiring more damping.

As far as bracing, you can't have too stiff of a box. As a general rule, at the power levels you are using, there should be braces on any panel exceeding about 18", as any panel flex does reduce output somewhat.

That said, bracing has more effect in the upper frequencies than LF, to avoid more physical work, and reduce the reverberation (which probably is not a problem musically anyway) a low pass filter on the subs would be the most cost effective solution, you can find used analog crossovers for $25-$50 now.

Art

Hi Bach On,

Post #577: "...took a look at the "drawing". Hmmm. The clearance at the back of that driver is really close..."

It looks like it would work, obviously adding an additional layer of 3/4" between driver and box (or a spacer ring) would move the driver out 3/4", and stiffen the box (18" corner box).

Just some more notes:

Your Dual 15" vented box is a nice size box for your application, @ 16Hz its output comes within 5.5dB of a single SI HT18" in that same box. Your dual ST385's will consume 197W, and the 18" 595W @ 16Hz. The single 18" is limited by its rated power, and the dual 15" is Xmax limited. With a dual 18" you would just be overworking the port, so the output from the port (the very lows you are looking for) would not be helped as much as you might think.

As to filling/stuffing/resonances: I have used old pressed fiberglass ceiling tiles glued against three walls (e.g.: back - bottom - side), and then covered this w/ 3-1/2" fiberglass batting, but I doubt that this is necessary for a subwoofer. Don't stuff it so much that you loose output.

Walls and sound is a completely different subject. 🙂 It's almost impossible to keep the lows from penetrating the walls, even if you are ready for a major remodelling. Fiberglass in the walls, and a second sheet of plaster board on one side of the wall is a start to reduce the transmitted sound. Make sure that you caulk even the smalles gaps at the top and bottom plates; any gap will allow the sound to bypass all your other good work.

Try getting some average sound measurements using 1/3 octave warble tones too. I found that helpful in the past.

Regards,

Post #577: "...took a look at the "drawing". Hmmm. The clearance at the back of that driver is really close..."

It looks like it would work, obviously adding an additional layer of 3/4" between driver and box (or a spacer ring) would move the driver out 3/4", and stiffen the box (18" corner box).

Just some more notes:

Your Dual 15" vented box is a nice size box for your application, @ 16Hz its output comes within 5.5dB of a single SI HT18" in that same box. Your dual ST385's will consume 197W, and the 18" 595W @ 16Hz. The single 18" is limited by its rated power, and the dual 15" is Xmax limited. With a dual 18" you would just be overworking the port, so the output from the port (the very lows you are looking for) would not be helped as much as you might think.

As to filling/stuffing/resonances: I have used old pressed fiberglass ceiling tiles glued against three walls (e.g.: back - bottom - side), and then covered this w/ 3-1/2" fiberglass batting, but I doubt that this is necessary for a subwoofer. Don't stuff it so much that you loose output.

Walls and sound is a completely different subject. 🙂 It's almost impossible to keep the lows from penetrating the walls, even if you are ready for a major remodelling. Fiberglass in the walls, and a second sheet of plaster board on one side of the wall is a start to reduce the transmitted sound. Make sure that you caulk even the smalles gaps at the top and bottom plates; any gap will allow the sound to bypass all your other good work.

Try getting some average sound measurements using 1/3 octave warble tones too. I found that helpful in the past.

Regards,

Hi Bach On,

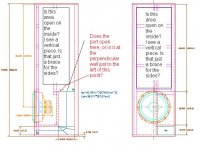

I fleshed out your geometry from Post #556 to get a feel for the available volume; see attached (What looks like a drawing is really just a sketch w/ notes. You'll have to figure out how to build this thing, and how to get it into the loft. You may have to build that in place, and provide for a removable driver baffle. Don't forget some protective grill, or so, for the driver(s).)

I also ran some more simulations. 🙂

Regards,

tb46,

I looked a bit more at your 90 degree box sketch. I am trying to get an idea of how to construct this - such as a materials list. I get the impression you seem to feel a double thickness of MDF on the driver face would pull it forward and would probably produce a stronger box. Would double thickness also be needed for the other sides? I feel enough bracing would suffice for those sides.

I've got some questions. I took part of your sketch and asked them in text within the drawing. I'm trying to get a sense of whether the top portion of the box (roughly 48 inches high) is an open area?

Too, I'm trying to determine the exact path of the port at the rear. I drew a line to the point in question. I'd appreciate it if you'd take a look at the sketch with my notes.

Maybe you can sense where I'm going with this.

I'm going to have to remeasure the floor to ceiling height of that chamber and the height of the doorway. I'm not certain we can get that box in through the door and tilt it into an upright position. And I don't relish trying to build the box in that chamber.

Thanks,

Bach On

Drawing Post #565 and #584

Hi Bach On,

For what it's worth: I have a hard time building something like this the first time if I haven't made the drawing myself. You'll have to adjust any suggested dimensions to fit the available corner. Make a cardboard cutout of the floor, and make sure that it fits all the way up to the top of the corner. Strangely, some people in construction think that 1/8" is close enough. 🙂 At least we have a pretty good idea now about the available volume.

With the suggested bracing I don't think you need the added wall thicknesses. Internal volume is at a premium. If you add any additional layer(s) do it from the outside, also: one way to get around building the whole thing in place (in the loft) is to build it downstairs, and then cut it horizontally above the driver and port area, the bottom is one piece, and the top the other piece (after cutting you could attach a small lip (1/4-1/2") above the cut from the inside to aid in the glue joint, just watch the total height) and join the two pieces inside the loft. You have enough room, to glue the box back together at the cutline, and then operlap the cutline from the outside. There are a lot of ways to do this, and not loose any strength.

Regards,

Hi Bach On,

For what it's worth: I have a hard time building something like this the first time if I haven't made the drawing myself. You'll have to adjust any suggested dimensions to fit the available corner. Make a cardboard cutout of the floor, and make sure that it fits all the way up to the top of the corner. Strangely, some people in construction think that 1/8" is close enough. 🙂 At least we have a pretty good idea now about the available volume.

With the suggested bracing I don't think you need the added wall thicknesses. Internal volume is at a premium. If you add any additional layer(s) do it from the outside, also: one way to get around building the whole thing in place (in the loft) is to build it downstairs, and then cut it horizontally above the driver and port area, the bottom is one piece, and the top the other piece (after cutting you could attach a small lip (1/4-1/2") above the cut from the inside to aid in the glue joint, just watch the total height) and join the two pieces inside the loft. You have enough room, to glue the box back together at the cutline, and then operlap the cutline from the outside. There are a lot of ways to do this, and not loose any strength.

Regards,

Attachments

Maybe there is something I don't understand here, but why is this thread continuing to spin hypothetical castles-in-the-air when there is a functional speaker waiting to be evaluated?

Wouldn't it be rational decision-making to evaluate what you've got? Not build a new box.

Even looked at kind-of engineering-wise, people are making proposals - which involve a whole lot of effort at carpentry and buying real expensive drivers - without having an adequate picture of the setting, preferences, budget, sonic goals, familiarity with organ music, etc.

Granted, some of us enjoy a few days in the carpentry shop more than an hour with a software manual learning how to test speakers...

How come nobody wants a nice trip to North Carolina (a bit east of Raleigh) at blossom time? Visit Bach On and give him a hand.

Ben

Wouldn't it be rational decision-making to evaluate what you've got? Not build a new box.

Even looked at kind-of engineering-wise, people are making proposals - which involve a whole lot of effort at carpentry and buying real expensive drivers - without having an adequate picture of the setting, preferences, budget, sonic goals, familiarity with organ music, etc.

Granted, some of us enjoy a few days in the carpentry shop more than an hour with a software manual learning how to test speakers...

How come nobody wants a nice trip to North Carolina (a bit east of Raleigh) at blossom time? Visit Bach On and give him a hand.

Ben

Last edited:

Maybe there is something I don't understand here, but why is this thread continuing to spin hypothetical castles-in-the-air when there is a functional speaker waiting to be evaluated?

Wouldn't it be rational decision-making to evaluate what you've got? Not build a new box.

Even looked at kind-of engineering-wise, people are making proposals - which involve a whole lot of effort at carpentry and buying real expensive drivers - without having an adequate picture of the setting, preferences, budget, sonic goals, familiarity with organ music, etc.

Granted, some of us enjoy a few days in the carpentry shop more than an hour with a software manual learning how to test speakers...

How come nobody wants a nice trip to North Carolina (a bit east of Raleigh) at blossom time? Visit Bach On and give him a hand.

Ben

Ben,

You are correct that I'm looking ahead as much or more than I'm testing what I have. And you are wise to remind me to keep my eye on the ball. Here's all I can say.

1. I can do the esoteric planning and pipe dreams from home - where I can't measure.

2. I can only do testing and measurement at the church - and I can't spend all my time there..

3. The other driver has already been ordered and paid for (my money). If the corner cabinet gets built - I'll do it and pay for it. (That's my choice. Everyone needs skin in the game.)

4. Nearly everyone who has taken part in this thread has expressed an opinion that more drivers would be needed to get the pedal frequencies up to a volume level sufficient for our Sanctuary.

5. Given a choice - and if the cost isn't too high - I'd rather have a system where turning down the volume a bit is a possibility than having to turn the volume up to levels that are more likely to create distortion.

Besides, I'm not spending any money or sawing any wood yet. Think of this as playing "what if?". 😱

Bach On

I'd be the first (OK, the second) to admit I don't have a good picture of the various factors, technical and human.

But based on an enormous volume of my past (and continuing) errors, I'd say you just can't be compulsive enough in working in an orderly decision-making manner. - which means testing, testing, testing, not theorizing. And to toot the same horn again, a newcomer to DIYaudio would get a distorted impression of the precision of castles-in-the-air modeling as compared to sound in the pews.

Well, back to my 6,000 volt electrostatic bias supply mock-up spread across the living room floor. Too bad if any vermin cross my floor tonight.

Ben

But based on an enormous volume of my past (and continuing) errors, I'd say you just can't be compulsive enough in working in an orderly decision-making manner. - which means testing, testing, testing, not theorizing. And to toot the same horn again, a newcomer to DIYaudio would get a distorted impression of the precision of castles-in-the-air modeling as compared to sound in the pews.

Well, back to my 6,000 volt electrostatic bias supply mock-up spread across the living room floor. Too bad if any vermin cross my floor tonight.

Ben

Last edited:

I'd be the first (OK, the second) to admit I don't have a good picture of the various factors, technical and human.

But based on an enormous volume of my past (and continuing) errors, I'd say you just can't be compulsive enough in working in an orderly decision-making manner. - which means testing, testing, testing, not theorizing. And to toot the same horn again, a newcomer to DIYaudio would get a distorted impression of the precision of castles-in-the-air modeling as compared to sound in the pews.

Well, back to my 6,000 volt electrostatic bias supply mock-up spread across the living room floor. Too bad if any vermin cross my floor tonight.

Ben

I know testing is needed. That's why I bought the equipment. So you're preaching at the choir in that respect.

But I do have other things I need to do, so my pace probably isn't as fast as it should be. I do intend to get there.

But I plan to be ready when the tests show a need. Think of this as foreplay.

Bach On

P.S. Is that mockup the DC or AC version? 🙄

Last edited:

No criticism of anuybody intended. Rather, puzzled at posters who are ceaseless in pitching new new boxes.

B.

B.

I'm currently still waiting on an HT18 18 inch driver from Stereo Integrity. This is the 4 ohm version with 2 voice coils. I'm trying to think ahead. My question is whether to put this speaker on the same circuit as the big box I made with the twin Dayton 15 inch drivers? The low bass frequencies will be powered by a new Crown XLS1500 amp.

The amp is set to lowpass mode. So one input signal is run through the amp's crossover system (the other input channel goes offline on that amp when this happens). Both output channels will play the same signal. I'm tinkering with the crossover frequency - it's currently set around 100 Hz. The other input channel will go through a different amp (a Crown XLS1000) into a different set of speakers - probably one or two Allen HC12s. The signals for both these amps will be for organ pedals only. Lowest tones will go to the homemade cabinets; upper bass, including overtones, partials, etc. to the HC12s via the XLS1000.

I guess the amp for the two subwoofer boxes could be routed to the two homemade speaker cabinets in parallel mode. But here's my thinking - clarifications and corrections will be appreciated.

Left output signal will begin as 8 ohms. Going in parallel through the two 15 inch drivers box, the signal will be at a nominal 4 ohms. That's how I've been running it in testing. The right output channel has NOT been utilized - though it can be.

If I take the right hand 8 ohm output signal from that XLS1500 and send it to both voice coils of the SI18 inch speaker wired in parallel, the amp will think it is powering two speakers on that channel - so the power signal circuit will be at a nominal 2 ohms. Thus, the left hand volume control on the amp would control the 15 inch box and the right hand volume control would control the 18 inch box.

I can see some advantages in being able to control the volume going to the two subwoofers independently.

What are the disadvantages in this plan?

Bach On

The amp is set to lowpass mode. So one input signal is run through the amp's crossover system (the other input channel goes offline on that amp when this happens). Both output channels will play the same signal. I'm tinkering with the crossover frequency - it's currently set around 100 Hz. The other input channel will go through a different amp (a Crown XLS1000) into a different set of speakers - probably one or two Allen HC12s. The signals for both these amps will be for organ pedals only. Lowest tones will go to the homemade cabinets; upper bass, including overtones, partials, etc. to the HC12s via the XLS1000.

I guess the amp for the two subwoofer boxes could be routed to the two homemade speaker cabinets in parallel mode. But here's my thinking - clarifications and corrections will be appreciated.

Left output signal will begin as 8 ohms. Going in parallel through the two 15 inch drivers box, the signal will be at a nominal 4 ohms. That's how I've been running it in testing. The right output channel has NOT been utilized - though it can be.

If I take the right hand 8 ohm output signal from that XLS1500 and send it to both voice coils of the SI18 inch speaker wired in parallel, the amp will think it is powering two speakers on that channel - so the power signal circuit will be at a nominal 2 ohms. Thus, the left hand volume control on the amp would control the 15 inch box and the right hand volume control would control the 18 inch box.

I can see some advantages in being able to control the volume going to the two subwoofers independently.

What are the disadvantages in this plan?

Bach On

Bach On,If I take the right hand 8 ohm output signal from that XLS1500 and send it to both voice coils of the SI18 inch speaker wired in parallel, the amp will think it is powering two speakers on that channel - so the power signal circuit will be at a nominal 2 ohms. Thus, the left hand volume control on the amp would control the 15 inch box and the right hand volume control would control the 18 inch box.

I can see some advantages in being able to control the volume going to the two subwoofers independently.

What are the disadvantages in this plan?

The output of the amp is voltage, the 2 ohm load can potentially see 775 watts, the 4 ohm load 525 watts. Not a lot of power, but for sustained sine wave like tones, still enough to heat coils pretty warm.

Having separate gain controls (and limiter & crossover settings, if possible) for the two subs is desirable.

Art

Watching!

Comment on the independent volume control for the two subwoofers.

I thought you had volume control in the artisan software for each rank?

Would solve that problem I think.

Comment on the independent volume control for the two subwoofers.

I thought you had volume control in the artisan software for each rank?

Would solve that problem I think.

Yes. We would. But if the 18 inch box is louder or softer than the twin 15 inch box, independent controls would allow adjustment so each was putting out an appropriate amount of sound.

Bach On

Bach On

They would not be that much different in loudness to each other.

The biggest difference could be the corner loading. But a standard framed wall with two half inch layers of wall board is pretty much invisible below 30 hertz anyway.

The biggest difference could be the corner loading. But a standard framed wall with two half inch layers of wall board is pretty much invisible below 30 hertz anyway.

One question

The Crown XLS has a high pass filter that is approx 20Hz or higher with a 2nd order slope or -12dB per octave. Since you are going for 16Hz--that amp is filtering out your desired frequency range--are you using massive EQ to counter that filter or?

The Crown XLS has a high pass filter that is approx 20Hz or higher with a 2nd order slope or -12dB per octave. Since you are going for 16Hz--that amp is filtering out your desired frequency range--are you using massive EQ to counter that filter or?

One question

The Crown XLS has a high pass filter that is approx 20Hz or higher with a 2nd order slope or -12dB per octave. Since you are going for 16Hz--that amp is filtering out your desired frequency range--are you using massive EQ to counter that filter or?

Good point. But the loss at 16 Hz may be insignificant.*

B.

*and some people may think adding bass capability desirable even if chasing a 16Hz organ note to be a bit of a will-of-the-wisp

Hi Bach On,

Just another doodle as to a corner box. I tried to get most of the boards dimensions (top view) below 24", and a suggestion for a protective grill as well as for a cutline in the box. Note that the hypotenuse board is connected w/ two triangular braces to the other boards, you'll need a table saw for those pieces (and probably for the square bracing). Everytime the outer dimensions change, the port also changes a bit, but it's basically the same. I left out most of the bracing, you'll do that as you go along anyway.

Just some more food for thought before you start cutting up more wood. 🙂

Regards,

Just another doodle as to a corner box. I tried to get most of the boards dimensions (top view) below 24", and a suggestion for a protective grill as well as for a cutline in the box. Note that the hypotenuse board is connected w/ two triangular braces to the other boards, you'll need a table saw for those pieces (and probably for the square bracing). Everytime the outer dimensions change, the port also changes a bit, but it's basically the same. I left out most of the bracing, you'll do that as you go along anyway.

Just some more food for thought before you start cutting up more wood. 🙂

Regards,

Attachments

OK, guys. I've tinkered around with REW a bit. I've used it to produce tones. I've been able to record some data. But I'm not certain I know what the folks here want me to provide for them.

Frankly, I think TrueRTA does most of the same things. I also think it is somewhat more user friendly. But I understand that for this forum REW is the gold standard.

Please tell me what data you want me to collect and post.

Bach On

Frankly, I think TrueRTA does most of the same things. I also think it is somewhat more user friendly. But I understand that for this forum REW is the gold standard.

Please tell me what data you want me to collect and post.

Bach On

Very glad to see you're making progress. Doing measurements isn't for the forum's amusement. It's essential for you to establish objective information at each stage of your project. A sad old joke among the DIY crowd is that every stupid change sounds better, if you do it yourself. That's why you need objective assessment.OK, guys. I've tinkered around with REW a bit. I've used it to produce tones. I've been able to record some data. But I'm not certain I know what the folks here want me to provide for them.

Frankly, I think TrueRTA does most of the same things. I also think it is somewhat more user friendly. But I understand that for this forum REW is the gold standard.

Please tell me what data you want me to collect and post.

Bach On

I'm sure others are more sophisticated with REW, but here's a start.

The basic measurement is just a frequency plot and you can see distortion along with it by just clicking a tab on REW.

Put your mic in the church pews, on a stand or otherwise not sitting on a surface, and in such a way that you can keep it there indefinitely or replace it in the same place for future runs. Likewise for settings on amps to be reproducible in the future.

Set measurement for 15 to 12,000 Hz, 256k, 1 sweep, and -10dB (and use your amp to adjust to sort of typical loudness). Don't worry about any calibrations for now.

When the sweep is done and the plot appears, choose "Distortion" tab. There will be camera glyph in the upper left corner; a mouse click will take a snapshot of your plot that can be posted.

That's maybe 50% of the knobs you need to play with. Always easy the second time you do it.

Ben

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- 16Hz for church organ