thanks X - it would be interesting sometime in the future to see if the cheap and cheerful Visaton BG20 is suitable for some sort of XKi alignment. BB20 sounds pretty good in my fake Druid style MLTL. Perhaps it and the similar BetsyK are more suited to direct radiator than K (?)

I have one pair of the Pioneer B20FUs: Fs: 43 Hz * SPL: 90 dB1W/1m * Vas: 1.75 cu. ft. * Xmax: 3.0mm * Qms: 3.02 * Qes: .62 * Qts: .51. Would these be workable?

Hey fellas, it sounds like a repeatable, scientific design process for Karlsons is taking shape. That's great ! We have had good Sealed and BR models for years, and MJK cracked the nut for TLs - hopefully we will see DIY Karlsons aplenty on DIYA. Good job.

BTW, what is good software for modelling the 6th order BP enclosures? Would love to try a tiny Karlson for some good small FRs (B3N, Mark Audio, anyone ?) and the BG20 is a great idea for a smallish kick-butt portable PA.

cheers,

blakkasnight

BTW, what is good software for modelling the 6th order BP enclosures? Would love to try a tiny Karlson for some good small FRs (B3N, Mark Audio, anyone ?) and the BG20 is a great idea for a smallish kick-butt portable PA.

cheers,

blakkasnight

fwiw I've had BOFU in a "K10" size K-coupler

and BG20 in K12 1958 style - I would think it could be made smaller.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

and BG20 in K12 1958 style - I would think it could be made smaller.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Hey fellas, it sounds like a repeatable, scientific design process for Karlsons is taking shape. That's great ! We have had good Sealed and BR models for years, and MJK cracked the nut for TLs - hopefully we will see DIY Karlsons aplenty on DIYA. Good job.

BTW, what is good software for modelling the 6th order BP enclosures? Would love to try a tiny Karlson for some good small FRs (B3N, Mark Audio, anyone ?) and the BG20 is a great idea for a smallish kick-butt portable PA.

cheers,

blakkasnight

If you have Akabak (need an old pre 64bit Windows or a virtual machine) I will share the 6th order band pass code for all to use. There is the online calculator that GregB mentioned a few pages back. xrk971. If you are interested in the MA CHR70 for instance I can model that. Probably very similar to an RS100.

I have one pair of the Pioneer B20FUs: Fs: 43 Hz * SPL: 90 dB1W/1m * Vas: 1.75 cu. ft. * Xmax: 3.0mm * Qms: 3.02 * Qes: .62 * Qts: .51. Would these be workable?

is this the 8" coaxial, I have a pair that did not work out with Voight speaker also...

Alpair 6p

Hi X

I have a couple of Alpair 6p that need a second chance in life😀

Do you think they would be suitable candidates?

Driver 4.0 Ohm

Revc 3.80 Ohm

Fo 74 Hz

Sd 36.3 Cm²

Vas 3.6 Ltr

Cms 1.97 m M/N

Mmd 2.20 g

Mms 2.32 g

BL 2.67 T·M

Qms 1.78

Qes 0.57

Qts 0.43

Levc 6.94 u H

No 0.255 %

SPLo 86.0 dB

Xmax 5 mm (1 way)

Power 15 watts nom. 30 Max

Coil 18-mm dia. Alu-CCAW

Flange 114 mm

Cutout 96 mm

Depth 52.5 mm

Hi X

I have a couple of Alpair 6p that need a second chance in life😀

Do you think they would be suitable candidates?

Driver 4.0 Ohm

Revc 3.80 Ohm

Fo 74 Hz

Sd 36.3 Cm²

Vas 3.6 Ltr

Cms 1.97 m M/N

Mmd 2.20 g

Mms 2.32 g

BL 2.67 T·M

Qms 1.78

Qes 0.57

Qts 0.43

Levc 6.94 u H

No 0.255 %

SPLo 86.0 dB

Xmax 5 mm (1 way)

Power 15 watts nom. 30 Max

Coil 18-mm dia. Alu-CCAW

Flange 114 mm

Cutout 96 mm

Depth 52.5 mm

Hi X

I have a couple of Alpair 6p that need a second chance in life😀

Do you think they would be suitable candidates?

Driver 4.0 Ohm

Revc 3.80 Ohm

Fo 74 Hz

Sd 36.3 Cm²

Vas 3.6 Ltr

Cms 1.97 m M/N

Mmd 2.20 g

Mms 2.32 g

BL 2.67 T·M

Qms 1.78

Qes 0.57

Qts 0.43

Levc 6.94 u H

No 0.255 %

SPLo 86.0 dB

Xmax 5 mm (1 way)

Power 15 watts nom. 30 Max

Coil 18-mm dia. Alu-CCAW

Flange 114 mm

Cutout 96 mm

Depth 52.5 mm

I have never modeled anything with an A6 before but the specs and TS looks promising. You and I must be brothers in a past life given the closeness of our handles 🙂

I will get a sim going and post back.

The BOFU is a whizzer cone full range not a coaxial.

I have this, it is whizzer cone?

Attachments

those were nice mellow whizzer cone speakers - the surrounds on mine rotted quickly - generally coaxial speakers either have a tweeter mounted in front of the low frequency driver, or small dome nestled in the woofer's voice coil, or use a compression driver which attaches to the rear of the woofer magnet.

here's an on axis comparison of a BOFU vs a stamped frame Nirvana Super 8 with both run in my fake Druid pipe

here's an on axis comparison of a BOFU vs a stamped frame Nirvana Super 8 with both run in my fake Druid pipe

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

I have this, it is whizzer cone?

Yes. A whizzer is a secondary small cone attached to the voice coil to act as a tweeter through breakup modes. A coaxial has an actual secondary tweeter driver that is electrically driven.

ot - for the "kompletest" who likes matching motif - NZXT's PH240 case - tapered slot for intake on the tront - tapered slot on top for exhaust

XKi with Beta 8CX build begins

I made some good progress on the Beta 8cx XKi. I was going to make it out of wood because this driver seems like it might put out quite a bit of SPL and the motor is pretty heavy once the CD is mounted on. However, Freddi reminded me that making something out of wood at this point would ruin my reputation as a foam core speaker builder. So I decided to go with laminated foam core and cardboard CLD sandwich construction. Plus, it is very clean, lightweight, and easy to work with.

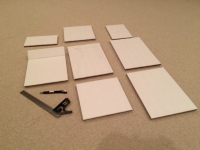

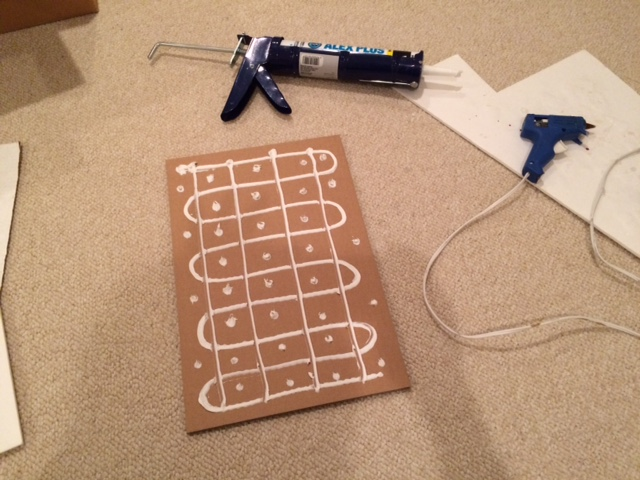

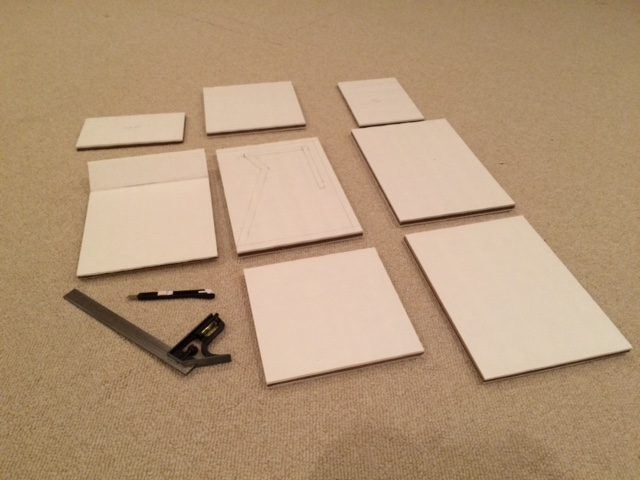

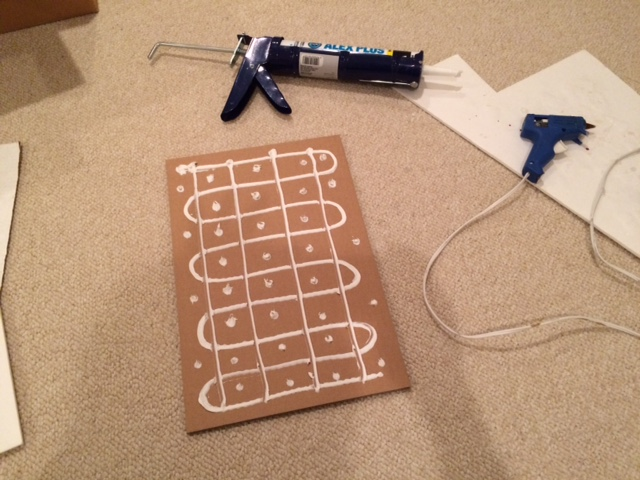

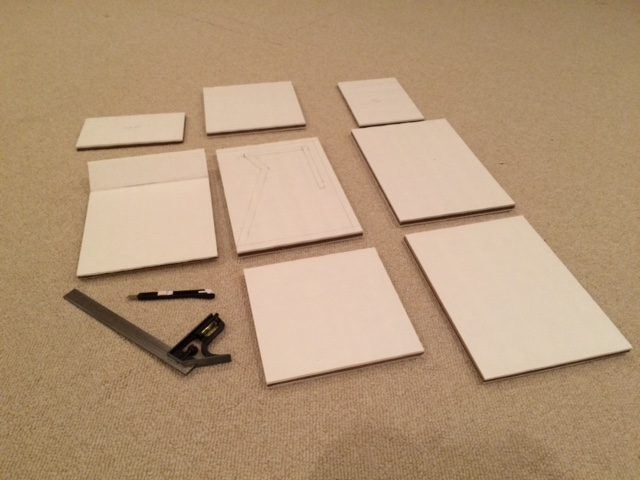

I started by cutting all the panels and pieces in triplicate (2 foam core and 1 cardboard). I am using heavy duty 2 ply cardboard and sandwiching the cardboard between two foam core panels held together by latex caulking and dabs of hot melt glue.

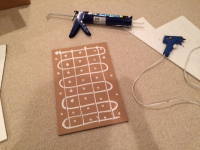

Here is a photo of the CLD composite panel construction:

It took over an hour just to glue the panels after making the 3-ply sandwiches. I am using houselhold bathroom latex caulking for the CLD. Here are all the pieces:

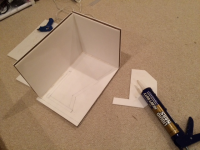

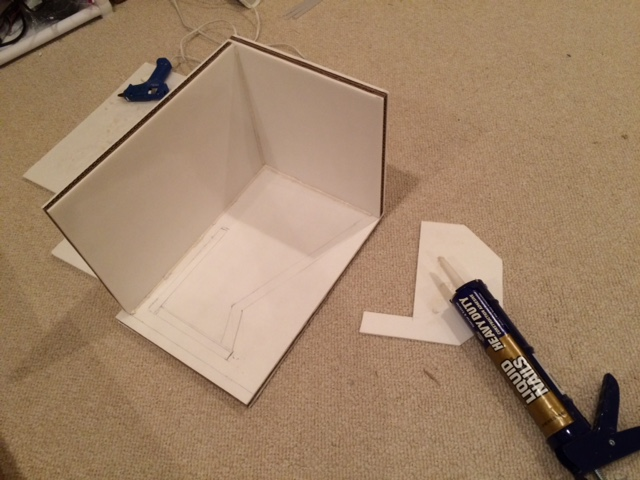

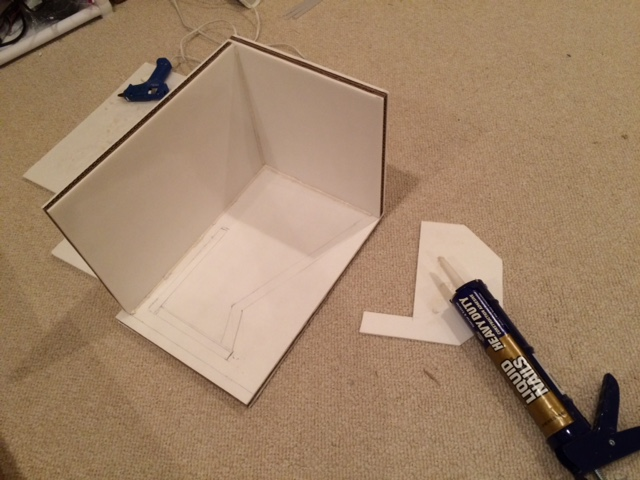

Here is the speaker starting to take shape:

Note the bracing in the vent to keep the vent gap accurate and to reduce vibrations on the vent panels.

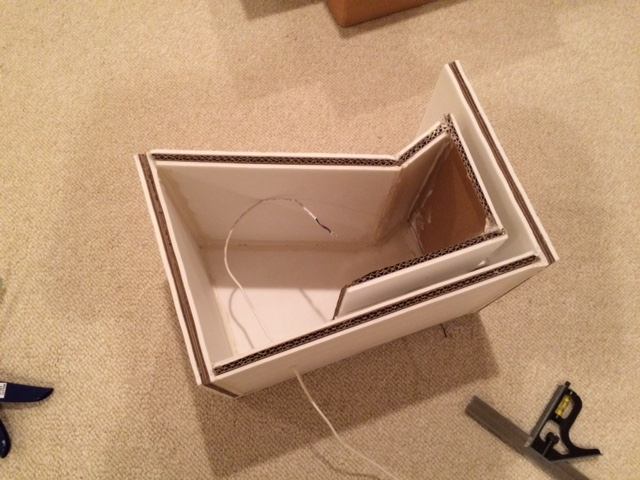

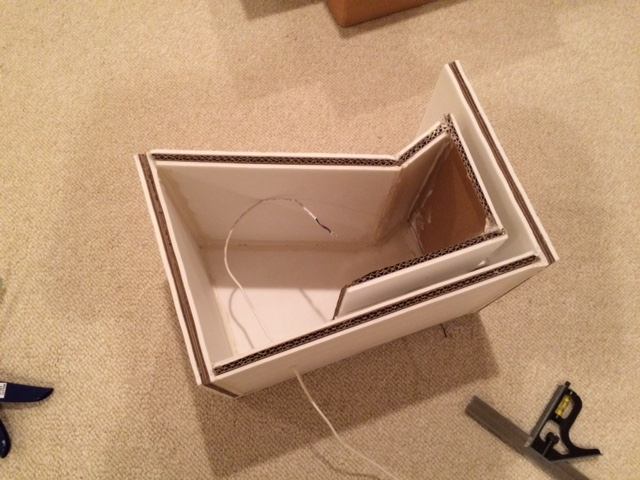

More progress...

Final capping operation with second side piece laid on top:

I used mostly non-VOC Liquid Nails to glue the panels together and used hot melt glue sparingly in dabs to tack the pieces together.

I think I need to wait 24 hours before it is strong enough (and dry enough to take on the weight of a Beta 8cx and PRC D280Ti compression driver.

I made some good progress on the Beta 8cx XKi. I was going to make it out of wood because this driver seems like it might put out quite a bit of SPL and the motor is pretty heavy once the CD is mounted on. However, Freddi reminded me that making something out of wood at this point would ruin my reputation as a foam core speaker builder. So I decided to go with laminated foam core and cardboard CLD sandwich construction. Plus, it is very clean, lightweight, and easy to work with.

I started by cutting all the panels and pieces in triplicate (2 foam core and 1 cardboard). I am using heavy duty 2 ply cardboard and sandwiching the cardboard between two foam core panels held together by latex caulking and dabs of hot melt glue.

Here is a photo of the CLD composite panel construction:

It took over an hour just to glue the panels after making the 3-ply sandwiches. I am using houselhold bathroom latex caulking for the CLD. Here are all the pieces:

Here is the speaker starting to take shape:

Note the bracing in the vent to keep the vent gap accurate and to reduce vibrations on the vent panels.

More progress...

Final capping operation with second side piece laid on top:

I used mostly non-VOC Liquid Nails to glue the panels together and used hot melt glue sparingly in dabs to tack the pieces together.

I think I need to wait 24 hours before it is strong enough (and dry enough to take on the weight of a Beta 8cx and PRC D280Ti compression driver.

Attachments

XKi with A6

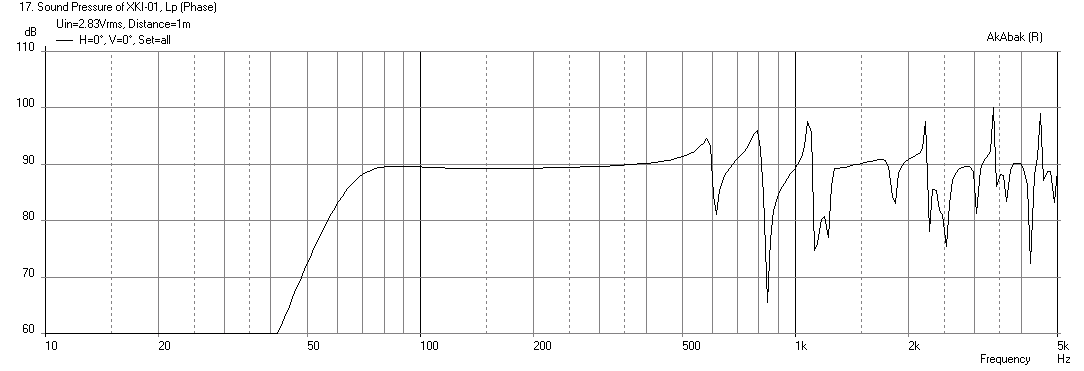

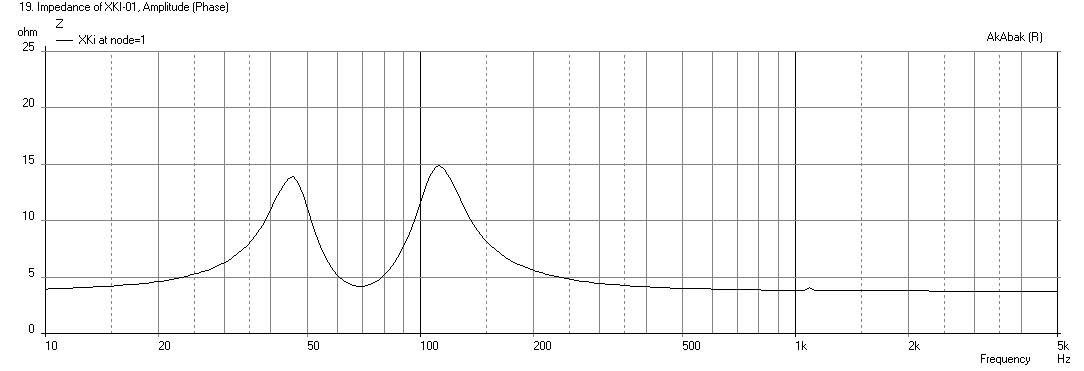

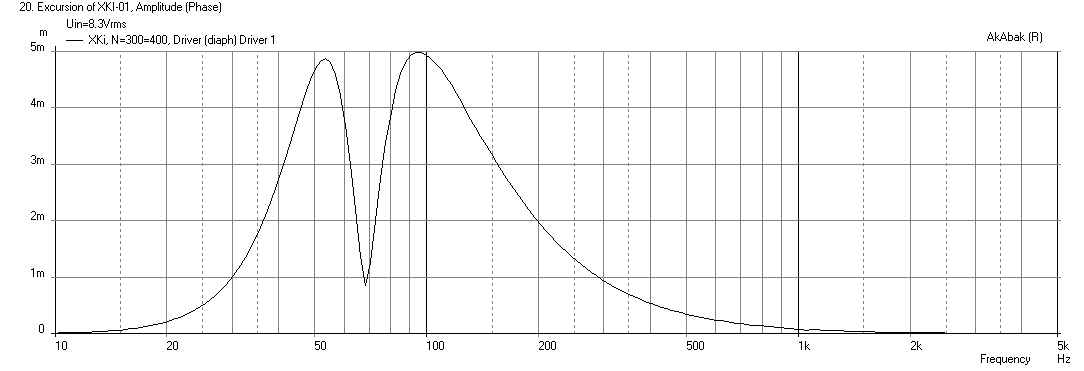

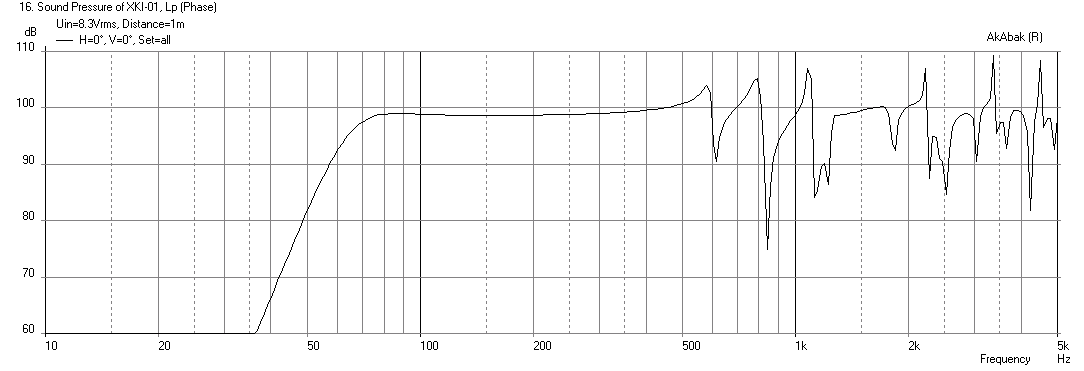

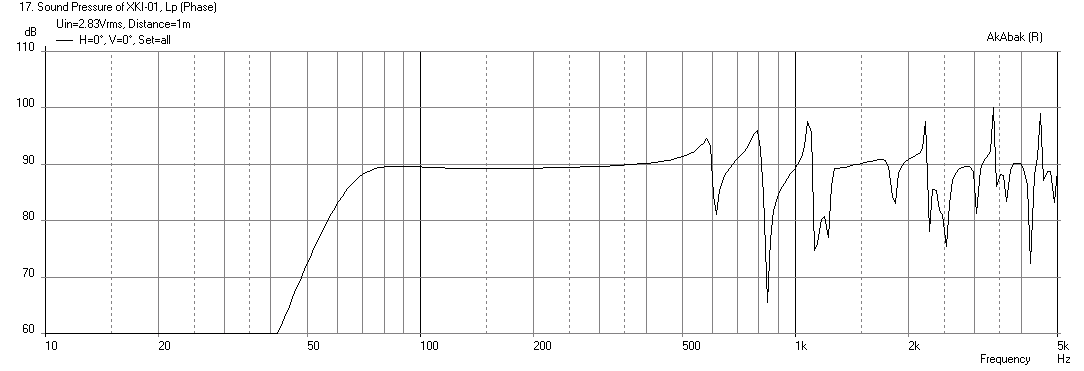

Here is the design for an XKi with the A6p:

6in Wide x 10in tall x 6.3in deep (all internal dims) with a 6in wide x 0.5in tall x 11in long vent. Total active volume (front and back) is 5 liters. Make the triangle front chamber 2.5in deep from front. Use 1/2in plywood.

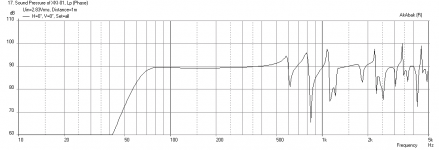

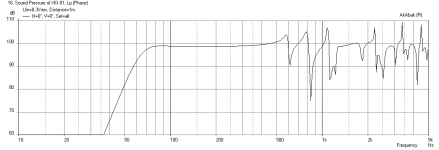

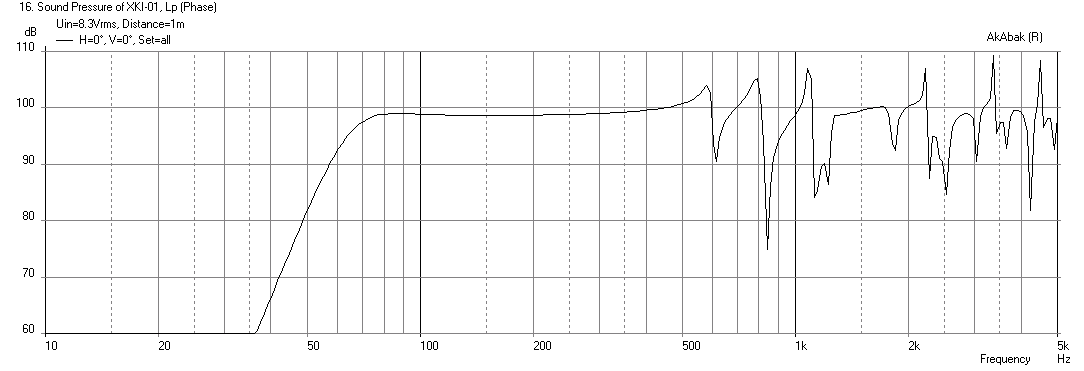

Here is SPL at 2.83v (fb is about 67Hz):

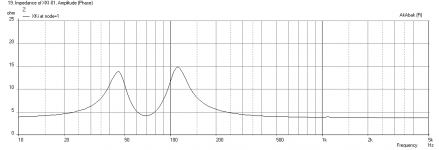

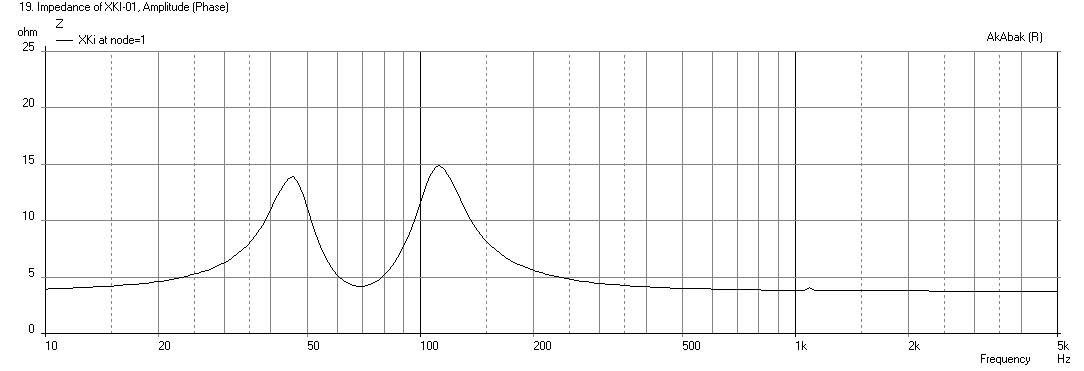

Here is Impedance:

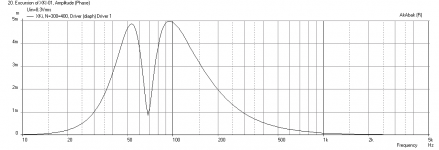

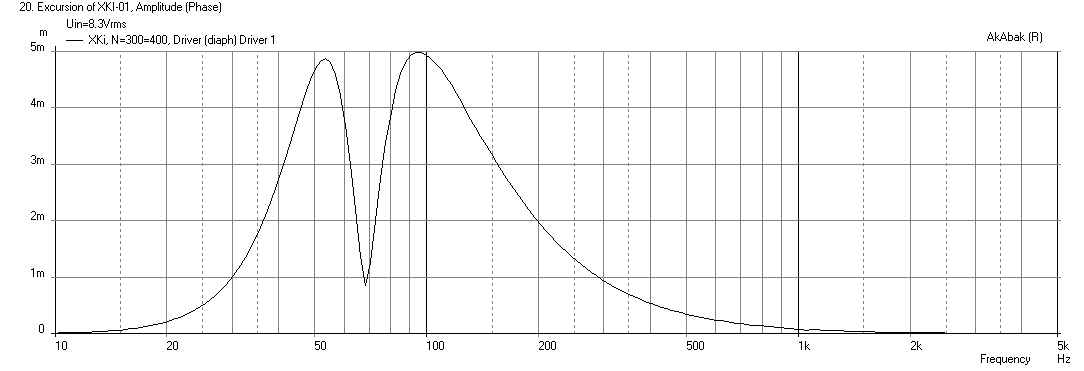

Here is cone displacement at xmax of 5mm and 8,3v drive:

Here is max SPL - about 100dB at 8.3v:

Hi X

I have a couple of Alpair 6p that need a second chance in life😀

Do you think they would be suitable candidates?

Driver 4.0 Ohm

Revc 3.80 Ohm

Fo 74 Hz

Sd 36.3 Cm²

Vas 3.6 Ltr

Cms 1.97 m M/N

Mmd 2.20 g

Mms 2.32 g

BL 2.67 T·M

Qms 1.78

Qes 0.57

Qts 0.43

Levc 6.94 u H

No 0.255 %

SPLo 86.0 dB

Xmax 5 mm (1 way)

Power 15 watts nom. 30 Max

Coil 18-mm dia. Alu-CCAW

Flange 114 mm

Cutout 96 mm

Depth 52.5 mm

Here is the design for an XKi with the A6p:

6in Wide x 10in tall x 6.3in deep (all internal dims) with a 6in wide x 0.5in tall x 11in long vent. Total active volume (front and back) is 5 liters. Make the triangle front chamber 2.5in deep from front. Use 1/2in plywood.

Here is SPL at 2.83v (fb is about 67Hz):

Here is Impedance:

Here is cone displacement at xmax of 5mm and 8,3v drive:

Here is max SPL - about 100dB at 8.3v:

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- XKi - X's ab initio Karlson 6th Order Bandpass