I recorded the temperature right at the LM3886. Even a few cm away from the LM3886, it was considerably cooler. Using a heat spreader would be a good idea. I would probably make it at least 5-6 mm thick, preferably more.

~Tom

Thanks !

Word. And +1.Whoa. This is much needed real-world information, thanks for posting!

The speed of these chip amps create nearly instantaneous heat (high heat pressure) so thinner bases will have insufficient mass to spread the heat away from the source in time to avoid thermal overload. When the heatsink base is thicker, the molecules can propagate the heat further out to the edges making better use of the material available and that's why the "small" heatsink in the example above performs more poorly than the Pentium Pro heatsink even though there is about the same amount of metal. Other factors like surface mating play a much larger role than most people imagine and can skew the guidelines put forward above.

Someone mentioned insulators here. Datasheets I have viewed put their thermal resistance between 0.5 to around 1 degree C/Watt. But it's academic anyway, because Digikey and Mouser do not stock any decent TO-220-11 insulators that I can find. And they seem to be phasing out mica.

I have salvage mica insulators, but none appropriate for TO-220-11. I'm going to see if Radio Shack has any TO-3 mica insulator kits and cut them down, I guess.

So I was wondering if anyone knew of any credible vendors that sell mica or sil-pads for the TO-220-11 package? If I can't find anything decent, I'll be better off with the TF package, I guess.

I do have a nice stash of large salvage heatsinks from old school receivers and amplifiers, so I'll use one for each chip. I might even do dual monoblock - I have plenty of large transformers.

The only think I haven't sorted out is what insulators to use. I'd rather go with the T package. So thank you for any advice on this matter.

I have salvage mica insulators, but none appropriate for TO-220-11. I'm going to see if Radio Shack has any TO-3 mica insulator kits and cut them down, I guess.

So I was wondering if anyone knew of any credible vendors that sell mica or sil-pads for the TO-220-11 package? If I can't find anything decent, I'll be better off with the TF package, I guess.

I do have a nice stash of large salvage heatsinks from old school receivers and amplifiers, so I'll use one for each chip. I might even do dual monoblock - I have plenty of large transformers.

The only think I haven't sorted out is what insulators to use. I'd rather go with the T package. So thank you for any advice on this matter.

I had a look around at interesting options for heatsinking that could allow for novel packaging. I gave up because my fabrication skills would never allow them to be realised. I have always been a fan of heatpipes for getting heat away even if they have other issues and the drive for fanless PCs for home theatre means there are some interesting and affordable options out there IF you can arrange things around it.

One example is the nofan range :: NOFAN Corporation :: Noiseless Computer, Noiseless Cooler, Noiseless Computer Case, Noiseless Power Supply, and other various noiseless computer components. Specialized Noiseless Computer hardware manufacturer. . Specs are hard to come by, but IIRO .75C/W and designed for 80W CPUs. But the heasink is orthogonal to what we need so you would need an intermediate block or some fancy mounting of the pcbs. But at least to my warped aesthete it could look quite nice. If only I could fabricate a nice chimney in chrome around it.

The other shame is that 3M don't make TC-2810 available in small quantities that don't need a £70 mixing gun to dispense.

Tom has shown that there are some really interesting options for this. Everyone has a stash of PC heasinks somewhere or some dead graphics cards...

One example is the nofan range :: NOFAN Corporation :: Noiseless Computer, Noiseless Cooler, Noiseless Computer Case, Noiseless Power Supply, and other various noiseless computer components. Specialized Noiseless Computer hardware manufacturer. . Specs are hard to come by, but IIRO .75C/W and designed for 80W CPUs. But the heasink is orthogonal to what we need so you would need an intermediate block or some fancy mounting of the pcbs. But at least to my warped aesthete it could look quite nice. If only I could fabricate a nice chimney in chrome around it.

The other shame is that 3M don't make TC-2810 available in small quantities that don't need a £70 mixing gun to dispense.

Tom has shown that there are some really interesting options for this. Everyone has a stash of PC heasinks somewhere or some dead graphics cards...

Someone mentioned insulators here. Datasheets I have viewed put their thermal resistance between 0.5 to around 1 degree C/Watt.

Then one might as well use the TF package.

But it's academic anyway, because Digikey and Mouser do not stock any decent TO-220-11 insulators that I can find. And they seem to be phasing out mica.

Some of the oversized TO-247 pads will fit the LM3886T. You have to read the data sheet carefully, though, to ensure that the pad will in fact fit. Not only does it have to be the right X and Y dimensions, the hole for the mounting screw also has to be located in the right spot.

The SilPad 1500ST I used, I actually cut from an 8x10 (inch) sheet of the stuff. The sheet was $30-ish at Mouser. It's not like the stuff goes bad, so if you buy one sheet, you'll have a lifetime supply...

Everyone has a stash of PC heasinks somewhere or some dead graphics cards...

Even if you don't, there's always eBay.

~Tom

Someone mentioned insulators here. Datasheets I have viewed put their thermal resistance between 0.5 to around 1 degree C/Watt.

Aluminium oxide comes for free on heatsinks and it is a good insulator... provided you don't use screws.

Be careful about the °C/W ratings of silpads. These depend on surface area. Since, for example, a TO220 has a much smaller metal area on its back than a LM3886, the same material and thickness will give you a much lower thermal resistance with the LM3886 than with a TO220. Even TO247 is a bit smaller.

THANKS A LOT for experimenting and posting 🙂

Since using mica+grease is so much better and takes, what? 1 minute extra? ... 2 ???? I can't see why anybody would use the plastic one.

C'mon ... you lose half power capability 😱

And it still needs to be greased 😉

Or a much larger heatsink which negates other gains 🙁

I see it akin to wrapping wires together "just because soldering is complicated" 🙄 .

Since using mica+grease is so much better and takes, what? 1 minute extra? ... 2 ???? I can't see why anybody would use the plastic one.

C'mon ... you lose half power capability 😱

And it still needs to be greased 😉

Or a much larger heatsink which negates other gains 🙁

I see it akin to wrapping wires together "just because soldering is complicated" 🙄 .

THANKS A LOT for experimenting and posting 🙂

You're quite welcome.

Since using mica+grease is so much better and takes, what? 1 minute extra? ... 2 ???? I can't see why anybody would use the plastic one.

A minute or two extra on the production line eats directly into the profit margin. In addition, there are many ways to screw up the goop+mica interface as well. Too much goop ruins the thermal interface. The goop itself is actually not all that thermally conductive, but it is a lot more conductive than air.

For the typical DIYer, I think the main issue is sourcing the mica. I am not aware of any electronics distributor who carries it in a size that fits an LM3886. Digikey shows seven (7) mica thermal pads in stock... They fit TO-36 and TO-3. Not useful.

Another idea for heatsinking... measured only +4*C rise for every 10Watts of power dissipated.

Forced air is amazing for removing heat. The fans do tend to be a bit noisy.

~Tom

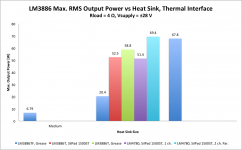

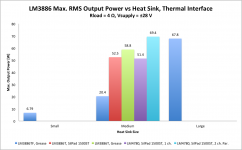

I decided to add another couple of data points: LM4780 (one channel driven, one channel idle); LM4780 (two channels in parallel). See attached graph.

The thermal resistance from the junction to the package is specified to be 1.0 ºK/W for the LM3886 and 0.8 ºK/W for the LM4780. I wanted to see if the lower thermal resistance of the LM4780 would make any difference or if it would get outweighed by the quiescent power of the un-driven channel. There is no way to turn the unused channel completely off. Even if the channel is muted, it still draws the full quiescent current.

The single LM4780 channel delivers slightly lower power than the single LM3886 when mounted on the "medium" (Pentium Pro) heat sink. The LM4780 starts tripping the SPiKe protection around 51-52 W.

When the two channels of the LM4780 are connected in parallel (using 0.1 Ω ballasting resistors on the outputs), good things happen. Now the output devices in the respective channels only deliver half the output current, hence, remain within their safe areas of operation. With the two channels in parallel, the IC can deliver the full 68-69 W.

The heat sink temperature is slightly higher than with the LM3886. No surprises there. The LM4780 does burn an additional 3 W in quiescent power. At the peak dissipated power, the heat sink reaches 106 ºC (yikes!). It turns out that's hot enough to melt the plastic zip-lock bags that Mouser uses for their parts... 🙂

I also decided to address the "what about music?" question. After all, these amplifiers are mostly used for music reproduction. To avoid the discussion about which recordings of which artists constitutes "music", I used a multi-tone signal developed by Audio Precision. This signal consists of 32 tones, equal in amplitude, logarithmically spaced in frequency from 14 Hz to 20 kHz. AP uses this signal for some of their more advanced testing. This test signal has a crest factor (ratio between peak and RMS power) of 13 dB. A comprehensive analysis of 4500 music tracks by Sound-on-Sound Magazine found an average crest factor of 14 dB for their music collection. Hence, I argue that while the 32-tone signal isn't music per se, it does have the same characteristics as music when it comes to the peak vs RMS power, hence, can serve as a test signal representing average music.

When delivering the 32-tone test signal at the maximum amplitude possible without clipping, the "medium" Pentium Pro heat sink reaches 90 ºC.

I stand by my recommendation that if you you're going to skimp on the heat sink size on your chip amp, please add a thermal switch so the amp turns off before somebody gets burn blisters from touching it.

~Tom

The thermal resistance from the junction to the package is specified to be 1.0 ºK/W for the LM3886 and 0.8 ºK/W for the LM4780. I wanted to see if the lower thermal resistance of the LM4780 would make any difference or if it would get outweighed by the quiescent power of the un-driven channel. There is no way to turn the unused channel completely off. Even if the channel is muted, it still draws the full quiescent current.

The single LM4780 channel delivers slightly lower power than the single LM3886 when mounted on the "medium" (Pentium Pro) heat sink. The LM4780 starts tripping the SPiKe protection around 51-52 W.

When the two channels of the LM4780 are connected in parallel (using 0.1 Ω ballasting resistors on the outputs), good things happen. Now the output devices in the respective channels only deliver half the output current, hence, remain within their safe areas of operation. With the two channels in parallel, the IC can deliver the full 68-69 W.

The heat sink temperature is slightly higher than with the LM3886. No surprises there. The LM4780 does burn an additional 3 W in quiescent power. At the peak dissipated power, the heat sink reaches 106 ºC (yikes!). It turns out that's hot enough to melt the plastic zip-lock bags that Mouser uses for their parts... 🙂

I also decided to address the "what about music?" question. After all, these amplifiers are mostly used for music reproduction. To avoid the discussion about which recordings of which artists constitutes "music", I used a multi-tone signal developed by Audio Precision. This signal consists of 32 tones, equal in amplitude, logarithmically spaced in frequency from 14 Hz to 20 kHz. AP uses this signal for some of their more advanced testing. This test signal has a crest factor (ratio between peak and RMS power) of 13 dB. A comprehensive analysis of 4500 music tracks by Sound-on-Sound Magazine found an average crest factor of 14 dB for their music collection. Hence, I argue that while the 32-tone signal isn't music per se, it does have the same characteristics as music when it comes to the peak vs RMS power, hence, can serve as a test signal representing average music.

When delivering the 32-tone test signal at the maximum amplitude possible without clipping, the "medium" Pentium Pro heat sink reaches 90 ºC.

I stand by my recommendation that if you you're going to skimp on the heat sink size on your chip amp, please add a thermal switch so the amp turns off before somebody gets burn blisters from touching it.

~Tom

Attachments

Then one might as well use the TF package.

That's what I was thinking.

Yes, I had explored this a couple of months ago and I was not impressed with the choices. I will take a second look.Some of the oversized TO-247 pads will fit the LM3886T. You have to read the data sheet carefully, though, to ensure that the pad will in fact fit. Not only does it have to be the right X and Y dimensions, the hole for the mounting screw also has to be located in the right spot.

I did see some kits on ebay from China; mica insulator for TO-220-11, screw and insulator, for like $8 for 7 or something like that. But I'm not too sure about stuff like that.

SP1500ST-0.008-02-1012 Bergquist Company | MouserThe SilPad 1500ST I used, I actually cut from an 8x10 (inch) sheet of the stuff. The sheet was $30-ish at Mouser. It's not like the stuff goes bad, so if you buy one sheet, you'll have a lifetime supply...

Well thank you. The datasheet provides me with what I need to know.

I still will explore cutting down old TO3 mica kits and then crunch some numbers.

By the way, I do appreciate not only your comments on my posts, but also this research that you have posted. It is most helpful.

By the way, I do appreciate not only your comments on my posts, but also this research that you have posted. It is most helpful.

Thanks. It's comments like that that keep me alive. Glad I could help.

~Tom

More good information.I decided to add another couple of data points: ........................

~Tom

That's the bit I did not give last time.

Any chance of posting the same test set up for 8r0 dummy load?

and maybe also for +-38Vdc with 8r0 dummy load?

Tomchr, do your measurements confirm the TI power dissipation curves?

After reaching maximum power dissipation are you able to continue increasing the power output and see a lowering of the power dissipation.

After reaching maximum power dissipation are you able to continue increasing the power output and see a lowering of the power dissipation.

I chuckled out loud when I read the "Pentium Pro" heatsink hahahha I have used those same heatsinks for everything over the years!

With a nominal specification applied the TF package of 2 degrees C/ watt, it seems marginal; the best I can hope for is 2.4 degrees C/ watt. I'm hoping to stay under 2 degrees/ watt total.

I'm going to use big salvage transformers that provide +/- 30 volts no load, and the heat sinks that were originally used with the transformers. The transformers came out of old Pioneer receivers that were great units until they emitted the magic smoke. (Both units suffered from badly degrading circuit boards that were for all practical purposes beyond repair; the boards were cracking and crumbling.) I will use computer fans. I can crunch numbers all day, but I will still have limited choices; so I'm going to make the best of what I can get my hands on.

Since I will be using them for music, I will probably be fine. I will be driving vintage speakers "4-8 ohm" which in reality are closer to 6 ohm, with terrible impedance curves.

I'm going to use big salvage transformers that provide +/- 30 volts no load, and the heat sinks that were originally used with the transformers. The transformers came out of old Pioneer receivers that were great units until they emitted the magic smoke. (Both units suffered from badly degrading circuit boards that were for all practical purposes beyond repair; the boards were cracking and crumbling.) I will use computer fans. I can crunch numbers all day, but I will still have limited choices; so I'm going to make the best of what I can get my hands on.

Since I will be using them for music, I will probably be fine. I will be driving vintage speakers "4-8 ohm" which in reality are closer to 6 ohm, with terrible impedance curves.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Chip Amps

- LM3886 Thermal Experiment (with data)