Back from the holidays and things.

guys:

Sorry ended up too busy over Christmas and the first 9 days+ of the New Year. Will try to get back on track with the Garrard.

My kids all took off and I ended up dog sitting a 115 lb. Rotty/Pitt mix who thinks he's a lap dog. He's a very good dog, but is still a bit of a puppy (under 3 years old), so a bit of a handful.

Hope the holidays (which ever one you celebrate) and the New Year have ben good for all.

guys:

Sorry ended up too busy over Christmas and the first 9 days+ of the New Year. Will try to get back on track with the Garrard.

My kids all took off and I ended up dog sitting a 115 lb. Rotty/Pitt mix who thinks he's a lap dog. He's a very good dog, but is still a bit of a puppy (under 3 years old), so a bit of a handful.

Hope the holidays (which ever one you celebrate) and the New Year have ben good for all.

TT news?

Hi there N: I like to watch Gold Rush and read Nanook. Wishing you and family well. ...regards, Michael

guys:

Sorry ended up too busy over Christmas and the first 9 days+ of the New Year. Will try to get back on track with the Garrard.

My kids all took off and I ended up dog sitting a 115 lb. Rotty/Pitt mix who thinks he's a lap dog. He's a very good dog, but is still a bit of a puppy (under 3 years old), so a bit of a handful.

Hope the holidays (which ever one you celebrate) and the New Year have ben good for all.

Hi there N: I like to watch Gold Rush and read Nanook. Wishing you and family well. ...regards, Michael

Any diy turntables in Japan?

Take a look at the TechDAS turntables. TechDAS

Take a look at Ginga turntable for $110,000.

GINGA (2012) | AUDIO NOTE

It would be good to see reasonable price turntables coming out of Japan as in the 60s and 70s. For example Technics SP10, Technics SL1200.

Take a look at the TechDAS turntables. TechDAS

Take a look at Ginga turntable for $110,000.

GINGA (2012) | AUDIO NOTE

It would be good to see reasonable price turntables coming out of Japan as in the 60s and 70s. For example Technics SP10, Technics SL1200.

wow!

Ya, those turntables seem like OVERKILL if that is possible in audio. As I've stated before, the costs associated with goods is high compared to the value of the raw materials. Add labour, manufacturing profit, distributor profit, dealer profit, freight, engineering costs....you get the picture.

Can we (the diyAudio.com community) build a state of the art turntable from scratch? Probably. But if we had to sell them to make a living? I wouldn't be surprised if the costs did not climb very quickly (as I stated recently in the 219 thread) to the point that we could end up with the world's most expensive diy turntable.

The question arises as to what price point is the knee in the performance vs. price curve? Can we afford it? Or do we try to make a silk purse from a sow's ear? Sreten has pointed this out numerous times, and generally speaking I tend to agree with him (even though it may not seem that I do). But here's the rub: if we cannot find good donor tables, what are our choices?

As far as I am concerned the choices are as follows:

Obviously, the idea of using old idlers was the idea for me because so many have old changers that (with just a modicum of work) can be made to sound better than they ever did. This approach was also taken additionally because many of the vintage tables that are worth having have all been had, so a changer could substitute for a single play manual tt if all the automation is removed.

Ultimately if we could have all the parts made economically, we could even sell them, but if one is not a machinist, then the best we can do is pay the shop for materials and machining time and labour. and isn't this where we began?

Ya, those turntables seem like OVERKILL if that is possible in audio. As I've stated before, the costs associated with goods is high compared to the value of the raw materials. Add labour, manufacturing profit, distributor profit, dealer profit, freight, engineering costs....you get the picture.

Can we (the diyAudio.com community) build a state of the art turntable from scratch? Probably. But if we had to sell them to make a living? I wouldn't be surprised if the costs did not climb very quickly (as I stated recently in the 219 thread) to the point that we could end up with the world's most expensive diy turntable.

The question arises as to what price point is the knee in the performance vs. price curve? Can we afford it? Or do we try to make a silk purse from a sow's ear? Sreten has pointed this out numerous times, and generally speaking I tend to agree with him (even though it may not seem that I do). But here's the rub: if we cannot find good donor tables, what are our choices?

As far as I am concerned the choices are as follows:

- find the best "non-beater" table of the type and brand one might want and simply get it into the best operating condition possible without serious modifications. Expect to pay top dollar. This includes rebuilt tables such as those offered by numerous folks.

- purchase a new example of an "evergreen" design, something that has been in production for a numer of years in various guises, is a known quantity and which has the possibilities of future upgraded at a later date.

- design and build a turntable from scratch using whatever budget we can have access to, knowing that sometimes a design on paper makes sense, but in reality sounds terrible for a number of reasons. Here we can scavenge for the best used parts that we can find and afford and put together a turntable that was never made by a manufacturer, but that follows a known design principle.

Obviously, the idea of using old idlers was the idea for me because so many have old changers that (with just a modicum of work) can be made to sound better than they ever did. This approach was also taken additionally because many of the vintage tables that are worth having have all been had, so a changer could substitute for a single play manual tt if all the automation is removed.

Ultimately if we could have all the parts made economically, we could even sell them, but if one is not a machinist, then the best we can do is pay the shop for materials and machining time and labour. and isn't this where we began?

Can you make an idler turntable from scratch? No you cannot buy any new parts or it cost to much so guys instead rebuild the Lenco.

Can you make a direct drive turntable from scratch? No you cannot buy any new parts. What about taking apart the Technics SL1200 and making a new turntable?

Can you make a belt drive turntable from scratch? Sure you can.

Can you make a direct drive turntable from scratch? No you cannot buy any new parts. What about taking apart the Technics SL1200 and making a new turntable?

Can you make a belt drive turntable from scratch? Sure you can.

Nanook,

Any progress on your turntable? I see big bang for the buck DIY amps, preamps,

speakers, dacs. Turntables are harder to do cheap and sound good. We need a diy

turntable using Nanook's tonearm built from scratch belt drive. Not including the tonearm, parts should be less than $1,000 or $500 for the scratch turntable.

Any progress on your turntable? I see big bang for the buck DIY amps, preamps,

speakers, dacs. Turntables are harder to do cheap and sound good. We need a diy

turntable using Nanook's tonearm built from scratch belt drive. Not including the tonearm, parts should be less than $1,000 or $500 for the scratch turntable.

Number two for this thread will hopefully be starting soon 🙂 I'm picking up later today three portable record players (the suitcase style type) all have Garrard turntables all direct drive.

One is a lovely Garrard 4SP that if I get running may end up in a ply based plinth. Something odd shaped to match/complement the Garrards design

One is planned to match with the linear arm I'm building and I may make a large plinth to accommodate the wtl as well. Neither will fit on the BSR as it sits on the new stereo rack. I need a test table to try out new projects so this may be the way to go with that.

The third one has a nice and tidy case so I'm thinking about doing a renovation job and keep it original. The other two cases are past it being much older although these may have tube amps so I may get to play with them 🙂

One is a lovely Garrard 4SP that if I get running may end up in a ply based plinth. Something odd shaped to match/complement the Garrards design

One is planned to match with the linear arm I'm building and I may make a large plinth to accommodate the wtl as well. Neither will fit on the BSR as it sits on the new stereo rack. I need a test table to try out new projects so this may be the way to go with that.

The third one has a nice and tidy case so I'm thinking about doing a renovation job and keep it original. The other two cases are past it being much older although these may have tube amps so I may get to play with them 🙂

Number two for this thread will hopefully be starting soon 🙂 I'm picking up later today three portable record players (the suitcase style type) all have Garrard turntables all direct drive.

One is a lovely Garrard 4SP that if I get running may end up in a ply based plinth. Something odd shaped to match/complement the Garrards design

One is planned to match with the linear arm I'm building and I may make a large plinth to accommodate the wtl as well. Neither will fit on the BSR as it sits on the new stereo rack. I need a test table to try out new projects so this may be the way to go with that.

The third one has a nice and tidy case so I'm thinking about doing a renovation job and keep it original. The other two cases are past it being much older although these may have tube amps so I may get to play with them 🙂

Direct drive ?

Idler, no ?

Can you post pics of the players intact ?

Hi Jay, I've disassembled them but could be reassembled if I wanted to. Are you looking for something in particular?

Not to take anything away from Nanooks 219 arm! I've tried the Aluminum arrow as the arm, but it never sounded better then my old Planar2 stock arm, so I am moving on to a carbon diy arm. Not that my new/old arm is carbon, but: I recently swapped out my stock tonearm for Thorens project arm and just love my music more. Even though this arm in old and out dated as my Planar2 arm was, it is better then any I have owned. I feel the arm on this gets out of the way better than the stock arm did, which says a lot given the rumble I heard at 3 O'clock on my volume dial.

But back to the Carbon arm: many of the upscale, upgrade arms advertised today use Carbon fiber as their arm material. So why not an old fishing rod? My son-in-law has several poles he does not use and when asked said "Help yourself!" So I'm going to try the carbon pole as a project tonearm! With my Planar2 arm sitting idle, the tangential assembly supporting the arm will be fashioned to support my carbon fishrod/tonearm! And of course it will be at least 12" long also! I'll get back to you on the progress.

But back to the Carbon arm: many of the upscale, upgrade arms advertised today use Carbon fiber as their arm material. So why not an old fishing rod? My son-in-law has several poles he does not use and when asked said "Help yourself!" So I'm going to try the carbon pole as a project tonearm! With my Planar2 arm sitting idle, the tangential assembly supporting the arm will be fashioned to support my carbon fishrod/tonearm! And of course it will be at least 12" long also! I'll get back to you on the progress.

A nice aspect of CF fishing rods or blanks is that the tube is tapered, as opposed to an arrow shaft which is cylindrical.

Bump thread with a new build!

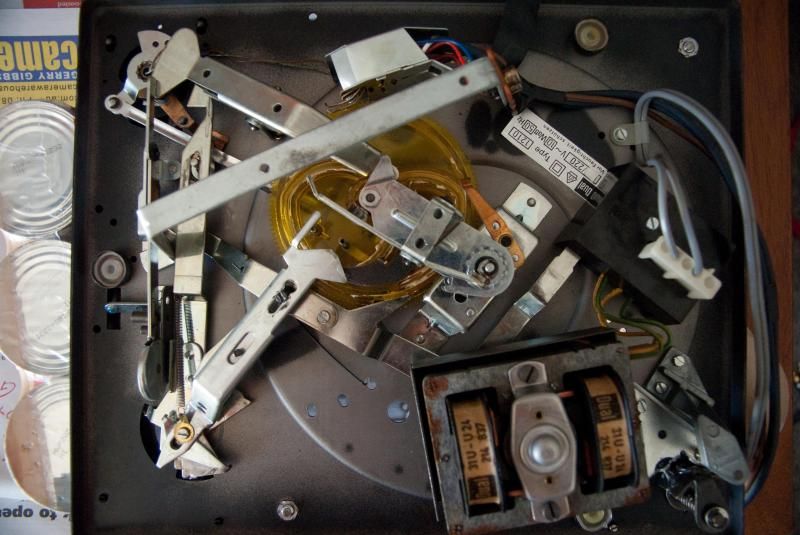

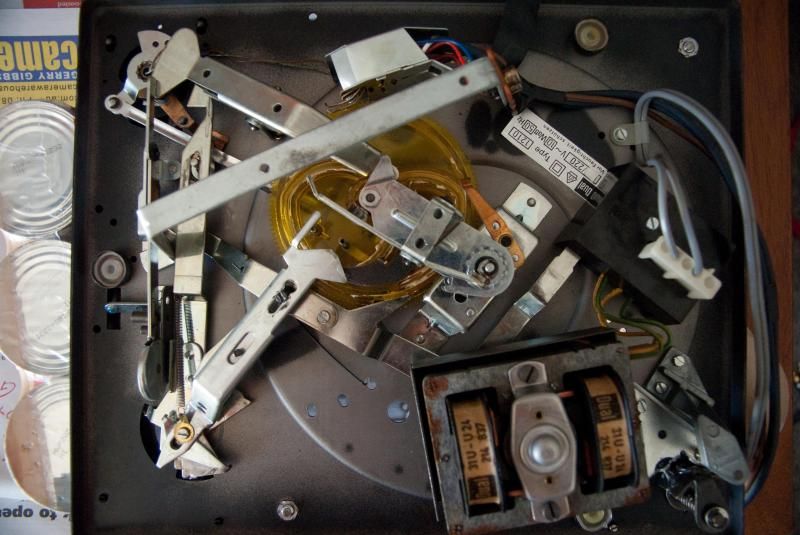

Decided to rebuild an old Dual and mount it in a plinth to complement my Nanook 219 tone arm... and here it is!

http://i113.photobucket.com/albums/n212/ecodan/_IGP0712_zpsa4845ab7.jpg

I started with a gumtree purchase of an old deck most likely from an old console

After a full clean and lube, everything worked perfectly

Next came the new plinth, cut one layer at a time by cutting a cardboard template then slowly tapering it down with each layer to build as much mass as possible into the plinth

Layers where glued, screwed and clamped before planing and sanding

and varnishing

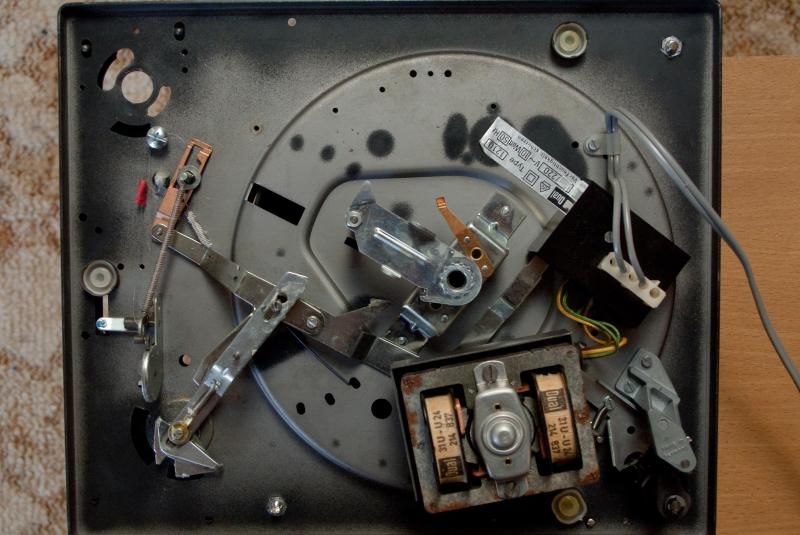

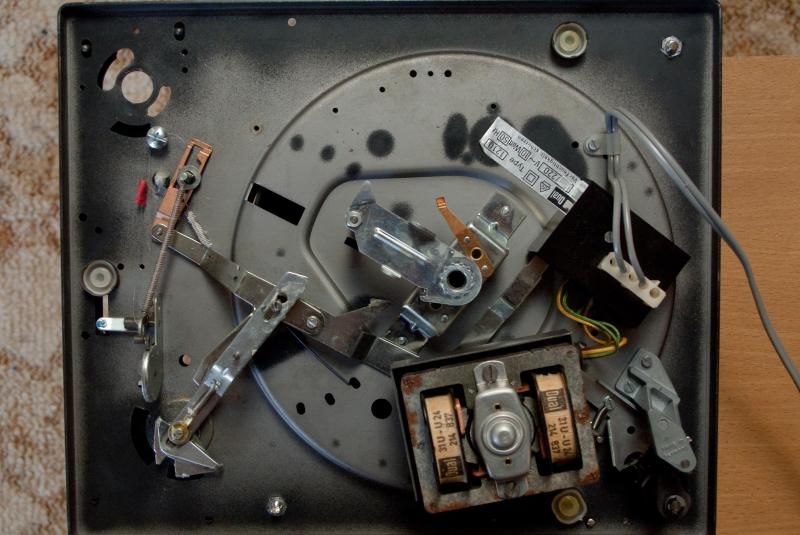

Next I took the existing Dual automatic mechanism

and stripped out all the automatic bits

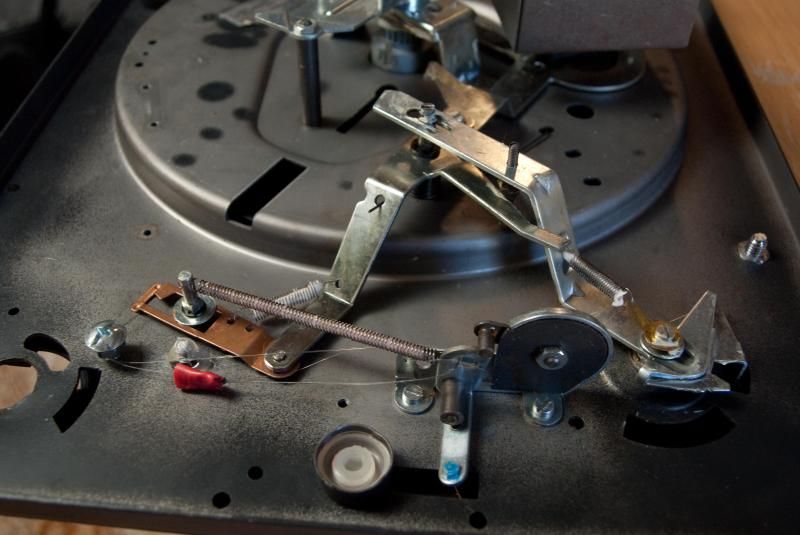

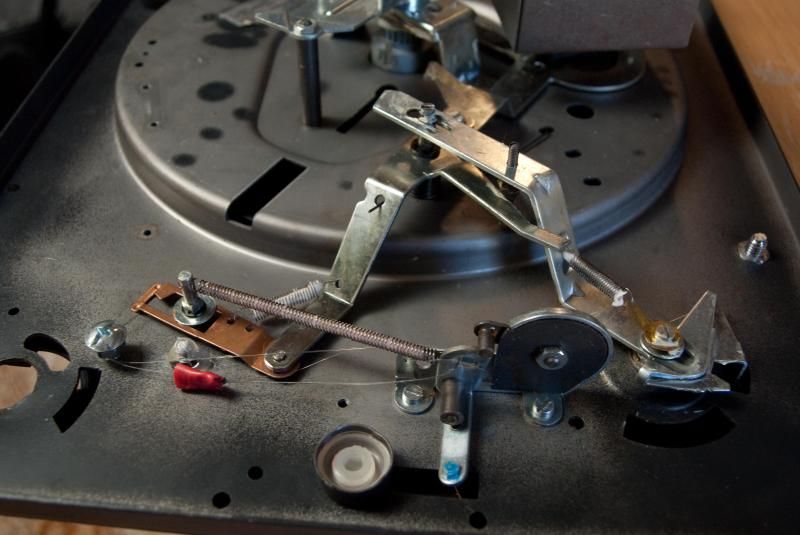

Note some of the leftover springs have been repurposed to allow the idler arm mechanism to engage and stay locked. To unlock I ran fishing line via a makeshift bolt pully to the now redundant tone arm lift.

So to start I pull the start lever to "start" and to stop I flick the tonearm lift lever and it disengages with a smart click. Its not the most prety solution, but it works well. Also note I stuffed the springs with wool to get rid of any spring noise.

Tonearm is a Nanook 219 with added antiskate (find build details here http://www.diyaudio.com/forums/anal...-latest-iteration-nanooks-219-tonearm-80.html ).

It works extremely well.

I'll add more detail later, but this should help a few people I hope.

Dan

Decided to rebuild an old Dual and mount it in a plinth to complement my Nanook 219 tone arm... and here it is!

http://i113.photobucket.com/albums/n212/ecodan/_IGP0712_zpsa4845ab7.jpg

I started with a gumtree purchase of an old deck most likely from an old console

After a full clean and lube, everything worked perfectly

Next came the new plinth, cut one layer at a time by cutting a cardboard template then slowly tapering it down with each layer to build as much mass as possible into the plinth

Layers where glued, screwed and clamped before planing and sanding

and varnishing

Next I took the existing Dual automatic mechanism

and stripped out all the automatic bits

Note some of the leftover springs have been repurposed to allow the idler arm mechanism to engage and stay locked. To unlock I ran fishing line via a makeshift bolt pully to the now redundant tone arm lift.

So to start I pull the start lever to "start" and to stop I flick the tonearm lift lever and it disengages with a smart click. Its not the most prety solution, but it works well. Also note I stuffed the springs with wool to get rid of any spring noise.

Tonearm is a Nanook 219 with added antiskate (find build details here http://www.diyaudio.com/forums/anal...-latest-iteration-nanooks-219-tonearm-80.html ).

It works extremely well.

I'll add more detail later, but this should help a few people I hope.

Dan

Last edited:

Looks great!

Dan,

The old Dual looks great. The only suggestion that I might suggest (and which should elevate the performance to the next level) is the removal of all springs. Even though you've damped the springs in the system, I would remove all of them (most notably the one which holds the idler against the platter). Just replace the spring with another 90 gram weight 🙂.

The plinth looks great, and the arm is pretty faithful to the original. I bet it sounds pretty amazing.

This is very similar to a 1219 that a friend and I did up for him. I started a plinth but my Dual was broken (by my wife "moving it into a safer place"). So the garrard is what I'll do instead.

Haven't done much for quite a while, mainly listening for last little bit. Headphones, speakers, other amplifiers, the list goes on and on...

Dan,

The old Dual looks great. The only suggestion that I might suggest (and which should elevate the performance to the next level) is the removal of all springs. Even though you've damped the springs in the system, I would remove all of them (most notably the one which holds the idler against the platter). Just replace the spring with another 90 gram weight 🙂.

The plinth looks great, and the arm is pretty faithful to the original. I bet it sounds pretty amazing.

This is very similar to a 1219 that a friend and I did up for him. I started a plinth but my Dual was broken (by my wife "moving it into a safer place"). So the garrard is what I'll do instead.

Haven't done much for quite a while, mainly listening for last little bit. Headphones, speakers, other amplifiers, the list goes on and on...

I'll do that starting with the idler spring Stew. Just going to ponder how for a few days first.

Question: I have removed most of the mains hum except for at loud volume by earthing everything back to the preamp and adding shielding where necessary. The counter weight at the end of the tone arm is steel, could this be my problem, even though it's away from the wires and pickup? I get no change in hum when I touch it and I must emphasis hum is only evident at high volume. After all the dual has steel all through it including the underside of the platter. This never caused a hum with its old arm. More I think about it I'll focus on the join in wires beneath the tone arm.

Yes it sounds wonderful! I lost a bit of its magic when I added the antiskate, however I have dropped the weight right back and the magic is back.

Thanks again for the thread Stew.

Question: I have removed most of the mains hum except for at loud volume by earthing everything back to the preamp and adding shielding where necessary. The counter weight at the end of the tone arm is steel, could this be my problem, even though it's away from the wires and pickup? I get no change in hum when I touch it and I must emphasis hum is only evident at high volume. After all the dual has steel all through it including the underside of the platter. This never caused a hum with its old arm. More I think about it I'll focus on the join in wires beneath the tone arm.

Yes it sounds wonderful! I lost a bit of its magic when I added the antiskate, however I have dropped the weight right back and the magic is back.

Thanks again for the thread Stew.

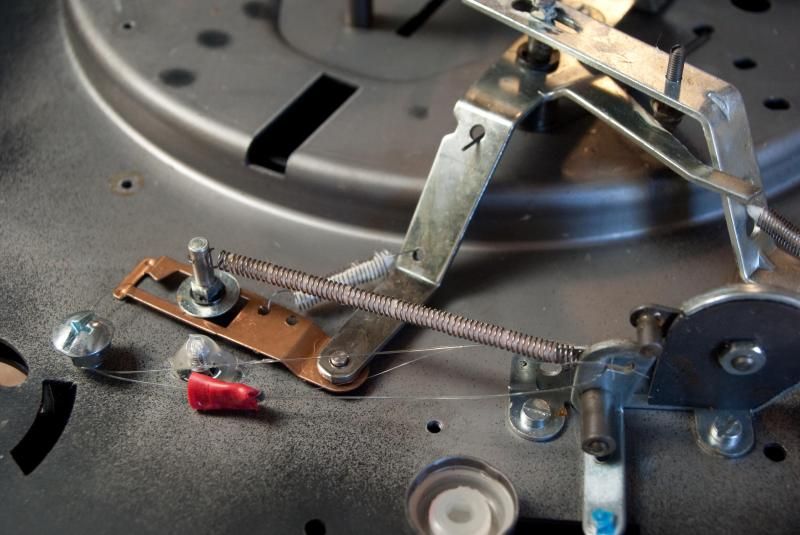

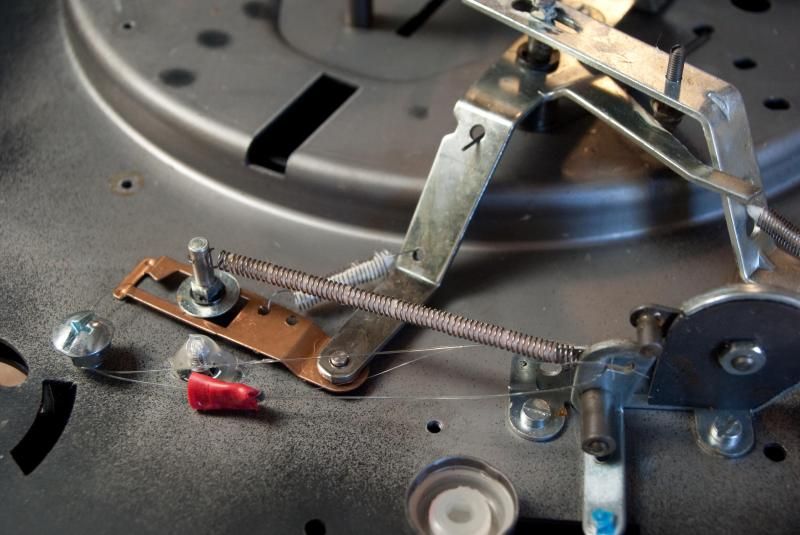

Sprung for a weight...

Okay Stew, I have implemented a rough counterweight mechanism to replace the idler tension spring:

Tension spring location

Entire mechanism

Weight attached instead of spring

close up

My weight substitute is an 80g fishing weight. I think its probably a tad heavy for the mechanism, so my next job is to install some nylon pulleys and possibly drop the weight by 10g or so.

It works!!! definite improvement in bass and pace of recording 😀

only downside is that the extra strain its putting on the mechanism, which I shall remedy as per the above.

Note: this implementation works as the weight has been adjusted so that the weight hits the base under the turntable at full stop so that the fishing line relaxes allowing the idler wheel to swing completely free of the drive mechanism and platter.

I think all other springs will most likely be replaced by elastic bands, as the above would be difficult to implement repeatedly. Any way one step at a time.

Okay Stew, I have implemented a rough counterweight mechanism to replace the idler tension spring:

Tension spring location

Entire mechanism

Weight attached instead of spring

close up

My weight substitute is an 80g fishing weight. I think its probably a tad heavy for the mechanism, so my next job is to install some nylon pulleys and possibly drop the weight by 10g or so.

It works!!! definite improvement in bass and pace of recording 😀

only downside is that the extra strain its putting on the mechanism, which I shall remedy as per the above.

Note: this implementation works as the weight has been adjusted so that the weight hits the base under the turntable at full stop so that the fishing line relaxes allowing the idler wheel to swing completely free of the drive mechanism and platter.

I think all other springs will most likely be replaced by elastic bands, as the above would be difficult to implement repeatedly. Any way one step at a time.

Friction aside, by using the lever as a pulley like that have i turned 80g of force into 160g? If so, no wonder its too heavy!

Friction aside, by using the lever as a pulley like that have i turned 80g of force into 160g? If so, no wonder its too heavy!

To answer my own question:

An externally hosted image should be here but it was not working when we last tested it.

(source wikipedia commons)

So as per #2 the force exerted is still 80g (less friction) and infact I'm reducing the effort required by the mechanism. Therefore I guess my first stop is to put some proper pulleys in to reduce friction.

yes?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- The Nanook turntable thread