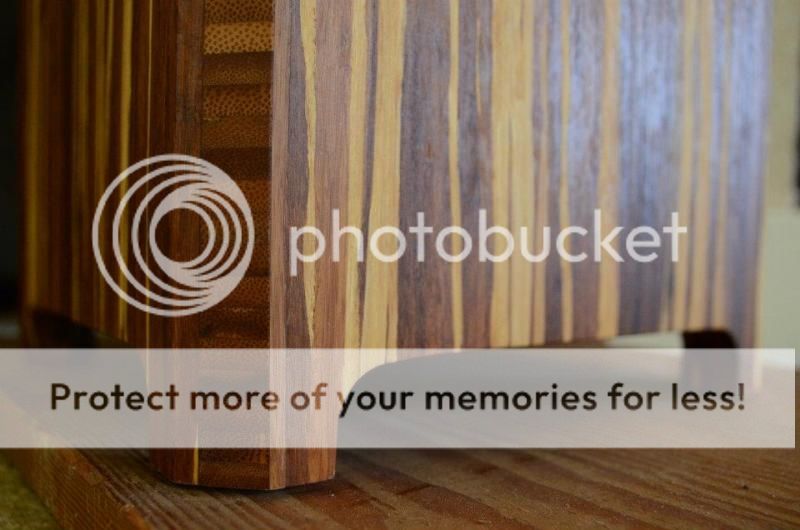

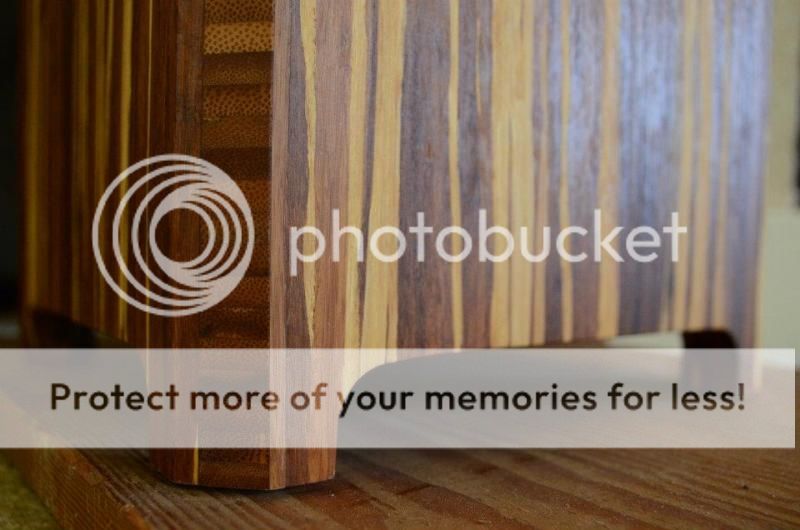

The wood is west African sapele with a unique interlocking grain. It's very dense and needs to be used up quickly before it starts to warp. For these two Valiants, the sapele alone was roughly $700-800.

Hi Storm

So you used hardwood instead of ply + veneer. Interesting... ¿Was this recommended by Scott or just a personal decision? Do you feel if the enclosures resonate? Did you use recommended damping or something else?

Gaston

Hi Storm

So you used hardwood instead of ply + veneer. Interesting... ¿Was this recommended by Scott or just a personal decision? Do you feel if the enclosures resonate? Did you use recommended damping or something else?

Gaston

It was more or less my decision. I did some research and found that a very hard dense wood would be suitable. Basically a hardwood that is approaching the density of MDF. A lot of people use Baltic birch ply, but it's really not a very dense material. Think of using lead as a sound dampener...it works really well, so I went with the nicest looking, most dense, cheapest wood I could afford. I also looked into using wenge, but could not fork over the $12/board foot that they wanted for it.

That and I have absolutely no idea how to veneer.😱

Scott and I went back and forth a little about my ideas and he didn't seem to object to anything. He said if anything, the sapele would have a superior stiffness/weight ratio than that of commercial ply. The empty voids in the speaker are filled to the brim with kitty litter to dampen them, and then the second side gets glued on to seal everything in.

I have both of them sitting on 303 stainless steel speaker spikes that I machined up at work.

Last edited:

I did some research and found that a very hard dense wood would be suitable. Basically a hardwood that is approaching the density of MDF. A lot of people use Baltic birch ply, but it's really not a very dense material.

Density by itself is not an asset. If 2 materials have the same stiffness, the less dense material will usually have the edge (there are other factors, like damping, which have me fudging)

dave

and with wenge, you'd be digging out splinters for days - if you found them all before they started to fester 😱

the sapele looks gorgeous

and as Dave says, mass/density is not always an advantage

and not all commercial or even "shop grade commodity" (read $hite) ply is created equal

the sapele looks gorgeous

and as Dave says, mass/density is not always an advantage

and not all commercial or even "shop grade commodity" (read $hite) ply is created equal

Last edited:

Here it is, all set up. It took my girlfriend approximately 10 seconds to throw halloween crap all over it.

Here it is, all set up. It took my girlfriend approximately 10 seconds to throw halloween crap all over it.

They are very nice, storm.

Don't complain too much about crap... you should see the kind of *it that I find on my BIBs every single time I dare to look inside their ceiling-firing mouths... big EVA letters, balls, marbles... Speakers are kind of a *it magnet when one has kids in the house. Metal grills in front of the drivers are a must too!

Thanks, I wasn't sure what that was all about.

FH3

Hi,

Finally finished my FH3's with A7.3 drivers. Fronts are American Black Walnut paper-backed veneer, which was grain filled & one coat of lacquer applied. Finished with a rub down using 00 steel wool. The rest is gloss paint with clear Acrylic Lacquer top coat ... wet sand at 600, 800 and 1200, fine cutting compound, polish and resin/wax finish. Not perfect but good enough for a first try.

Last thing to do is gluing the extra covers to the 7's 🙂

Big thanks to Collin Topps for making the kits and for some handy hints. Plus a

to the FH team for making them in the first place 😀

to the FH team for making them in the first place 😀

Next? 5 x mMarS for A7.3 then perhaps a pair of Pencil's for A10p ...

Paul.

Hi,

Finally finished my FH3's with A7.3 drivers. Fronts are American Black Walnut paper-backed veneer, which was grain filled & one coat of lacquer applied. Finished with a rub down using 00 steel wool. The rest is gloss paint with clear Acrylic Lacquer top coat ... wet sand at 600, 800 and 1200, fine cutting compound, polish and resin/wax finish. Not perfect but good enough for a first try.

Last thing to do is gluing the extra covers to the 7's 🙂

Big thanks to Collin Topps for making the kits and for some handy hints. Plus a

to the FH team for making them in the first place 😀

to the FH team for making them in the first place 😀Next? 5 x mMarS for A7.3 then perhaps a pair of Pencil's for A10p ...

Paul.

Attachments

A few pictures of the towers I built for a friend a few years back. They've since been set on granite bases. No more wood blocks. Built while I still had access to a full woodshop.

And then this is what happened when I moved away from aforementioned woodshop, but was too excited about my FF125wKeN drivers that something had to be built with the tools available after my move. It's ok, they're being painted. These drivers will eventually get cabinets that are worthy. 😉

A few pictures of the towers I built for a friend a few years back. They've since been set on granite bases. No more wood blocks. Built while I still had access to a full woodshop.

Nice. Do you have a photo of the entire finished speaker instead of small sections?

I'm having the owner take a few well-lit high-res photos of the Castles. Should have them soon. There is this one from shortly after they were first built.

Last edited:

I'm having the owner take a few well-lit high-res photos of the Castles. Should have them soon. There is this one from shortly after they were first built.

Wow, striking! Thanks.

- Home

- Loudspeakers

- Full Range

- Full Range Speaker Photo Gallery