Hello Esperado,

A quick google search for Earl Le Cleac'h gives:

Savourez la Bretagne - EARL Le Cleac'h

Notice : "EARL" in France stands for

"exploitation agricole à responsabilité limitée" which can be transalted as "limited liability farm "

reference:

L'exploitation agricole à responsabilité limitée (EARL) - Ministère de l'agriculture, de l'alimentation, de la pêche, de la ruralité et de l'aménagement du territoire

Best regards from Paris, France,

Jean-Michel Le Cléac'h

A quick google search for Earl Le Cleac'h gives:

Savourez la Bretagne - EARL Le Cleac'h

Notice : "EARL" in France stands for

"exploitation agricole à responsabilité limitée" which can be transalted as "limited liability farm "

reference:

L'exploitation agricole à responsabilité limitée (EARL) - Ministère de l'agriculture, de l'alimentation, de la pêche, de la ruralité et de l'aménagement du territoire

Best regards from Paris, France,

Jean-Michel Le Cléac'h

Did-you tried to make your Earl ? (bad joke)

I have send-you a PM.

I have made a CAD design for a small horn. I am very anxious to build a prototype. Will aluminium do? Or will it ring? Is MDF a better material?

MDF

MDF will cost less, but will require more work to finish.

Aluminum will ring. The question is at what frequency? For a prototype, if it rings, coat the exterior with an automotive sound damping material or enclose it in a box full of sand.

Regards,

WHG

I have made a CAD design for a small horn. I am very anxious to build a prototype. Will aluminium do? Or will it ring? Is MDF a better material?

MDF will cost less, but will require more work to finish.

Aluminum will ring. The question is at what frequency? For a prototype, if it rings, coat the exterior with an automotive sound damping material or enclose it in a box full of sand.

Regards,

WHG

Thought this may be the right place to ask. Does anyone know what T factor is used on the Autotech JMLC 200 horns for the 8"?

Thanks jzagaja. Is there any reason for this? Why is it so that you can run the 8" down lower towards the cut-off of the horn in the JMLC 200 compared to the JMLC 200T? Just trying to understand.

JMLC200 we made for particular order while JMLC200T is for compression drivers or can be cut to desired throat:

http://www.horns.pl/galeria/Zoltan_2.jpg

In both you can get good extension.

http://www.horns.pl/galeria/Zoltan_2.jpg

In both you can get good extension.

So, am I right to say that when T=0 the horn will be substanial deeper/longer, and therefore loading better down towards Fs? Is this the reason for using T=0 when the horn is made for a dome driver like a fullrange etc. and thereby have the possibility to go down to 250hz with the JMLC 200, compared to approximatly 350hz with the JMLC 200T that is used with a compression driver?

Hey Jack, What is the smallest available throat-area for the JMLC200?

280cm2.

Hello sanax,

With T = 0, the horn will compensate the reponse of a compression driver having a response a bit weak between 200 and 350Hz (as it is often the case, as seen on mesurements of certain drivers on the 200T having a T = 0.8).

This should allow a cut-off very near of 200Hz.

Best regards from Paris, France

Jean-Michel Le Cléac'h

With T = 0, the horn will compensate the reponse of a compression driver having a response a bit weak between 200 and 350Hz (as it is often the case, as seen on mesurements of certain drivers on the 200T having a T = 0.8).

This should allow a cut-off very near of 200Hz.

Best regards from Paris, France

Jean-Michel Le Cléac'h

So, am I right to say that when T=0 the horn will be substanial deeper/longer, and therefore loading better down towards Fs? Is this the reason for using T=0 when the horn is made for a dome driver like a fullrange etc. and thereby have the possibility to go down to 250hz with the JMLC 200, compared to approximatly 350hz with the JMLC 200T that is used with a compression driver?

Thank you Jmmlc!

Then again, if one looks at the JMLC 200T on the Autotech site, it seems to me that this particular horn has a T=0,8, and the other one, the JMLC 200 has a T=0. Shouldn't it be the other way around then, or am I missing something here? Just trying to figure this out 🙂

Then again, if one looks at the JMLC 200T on the Autotech site, it seems to me that this particular horn has a T=0,8, and the other one, the JMLC 200 has a T=0. Shouldn't it be the other way around then, or am I missing something here? Just trying to figure this out 🙂

Ok, so you would normally use a T=0,8 with a compression driver, but some of them need a horn that has T= 0, to compensate for the response between 200-350hz? Do you know which drivers?

What about a fullrange driver, that of course can be used in a horn? Is there any consensus to what T value one should use, and why? I would assume it is not that critical for a fullrange driver as with a compressiondriver (inner slot) regarding the throat of the horn.

What about a fullrange driver, that of course can be used in a horn? Is there any consensus to what T value one should use, and why? I would assume it is not that critical for a fullrange driver as with a compressiondriver (inner slot) regarding the throat of the horn.

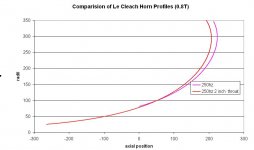

I am proposing to make some adaptors to reduce the throat of my 250Hz Le Cleach horns down from 160mm (for Lowther) down to 52mm for a 2" compression driver. When i used the Le Cleach calculator i have found that the profile does not simply extend backwards. Looking at the spreadsheet it looks as if the natural expansion routine it is using will give a different profile for every throat size. Attached is a graph showing how the profiles differ - what should i do, curve fit a profile "that smooth" from my current throat backwards or ?? suggestions please, as i dont know how sensitive the throat portion of the horn is.

i will be making flanged fibreglass extensions which will bolt on to the back of the existing horns.

i will be making flanged fibreglass extensions which will bolt on to the back of the existing horns.

Attachments

Vanilla Salmon

For the math you need to do this, see my post

http://www.diyaudio.com/forums/multi-way/140190-jean-michel-lecleach-horns-119.html#post2686127

Do not worry about the wave front dimensions in the neck, just apply Salmon's formula using ordinal dimensions. You will be primarly concerned with the radii (dia/2) and tangent angles at the driver and horn exits between which your adapter is to be placed.

Regards,

WHG

I am proposing to make some adaptors to reduce the throat of my 250Hz Le Cleach horns down from 160mm (for Lowther) down to 52mm for a 2" compression driver. When i used the Le Cleach calculator i have found that the profile does not simply extend backwards. Looking at the spreadsheet it looks as if the natural expansion routine it is using will give a different profile for every throat size. Attached is a graph showing how the profiles differ - what should i do, curve fit a profile "that smooth" from my current throat backwards or ?? suggestions please, as i dont know how sensitive the throat portion of the horn is.

i will be making flanged fibreglass extensions which will bolt on to the back of the existing horns.

For the math you need to do this, see my post

http://www.diyaudio.com/forums/multi-way/140190-jean-michel-lecleach-horns-119.html#post2686127

Do not worry about the wave front dimensions in the neck, just apply Salmon's formula using ordinal dimensions. You will be primarly concerned with the radii (dia/2) and tangent angles at the driver and horn exits between which your adapter is to be placed.

Regards,

WHG

Somebody in a previous post had stated that for jbl 2482's(which i am going to use) the throat exit angle should be 5 degs. Is this generic for JBL's as i could not find anything in the 2482 spec sheets? As this will add another variable.

All JBL 2" exit diameter drivers have the same throat dimensions.

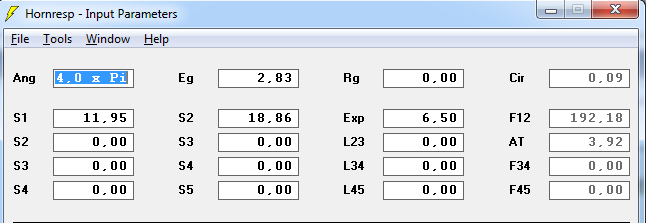

I have made a replacement throat for a 2440, and these are the measurements I get from it: The throat is 68,5 mm long. The entry diameter is 39 mm. The exit diameter is 49 mm. Most probably the expansion is exponential. Entering this in hornresp gives an exit half angle of 3,9 degrees and 192 Hz cutoff frequency.

I have made a replacement throat for a 2440, and these are the measurements I get from it: The throat is 68,5 mm long. The entry diameter is 39 mm. The exit diameter is 49 mm. Most probably the expansion is exponential. Entering this in hornresp gives an exit half angle of 3,9 degrees and 192 Hz cutoff frequency.

M10,

You have entered the wrong length! I measured entry to 38,5mm, but maybe you had a better chance to measure when you took you driver apart. Still gives a 183Hz exp flare whatever we use your figures or mine.

Vinylvalves,

Exit angle according to HR is 4,67 degrees so 5 degrees is what you could use.

You have entered the wrong length! I measured entry to 38,5mm, but maybe you had a better chance to measure when you took you driver apart. Still gives a 183Hz exp flare whatever we use your figures or mine.

Vinylvalves,

Exit angle according to HR is 4,67 degrees so 5 degrees is what you could use.

Last edited:

Well I did my new throat by measuring the old cracked one made from Bakelite. It is not the most stable of materials 🙂.

I measured only the throat piece, I guess the pole piece adds some length to the throat. You can see the parts on this thread: Refurbishing a pair of 2440

I measured only the throat piece, I guess the pole piece adds some length to the throat. You can see the parts on this thread: Refurbishing a pair of 2440

- Home

- Loudspeakers

- Multi-Way

- Jean Michel on LeCleac'h horns