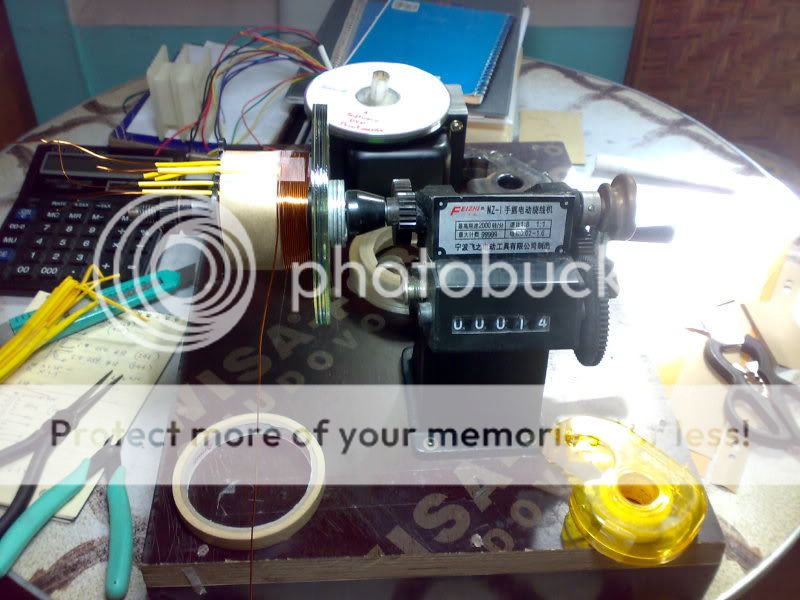

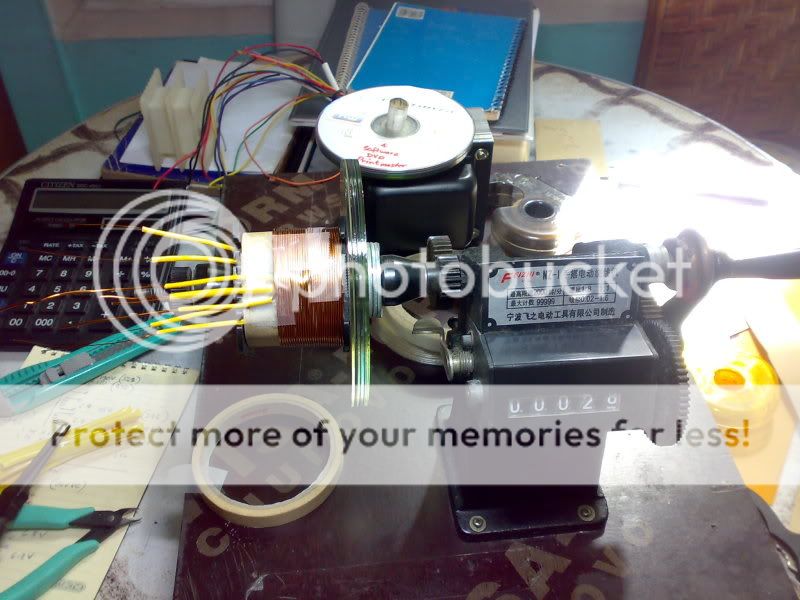

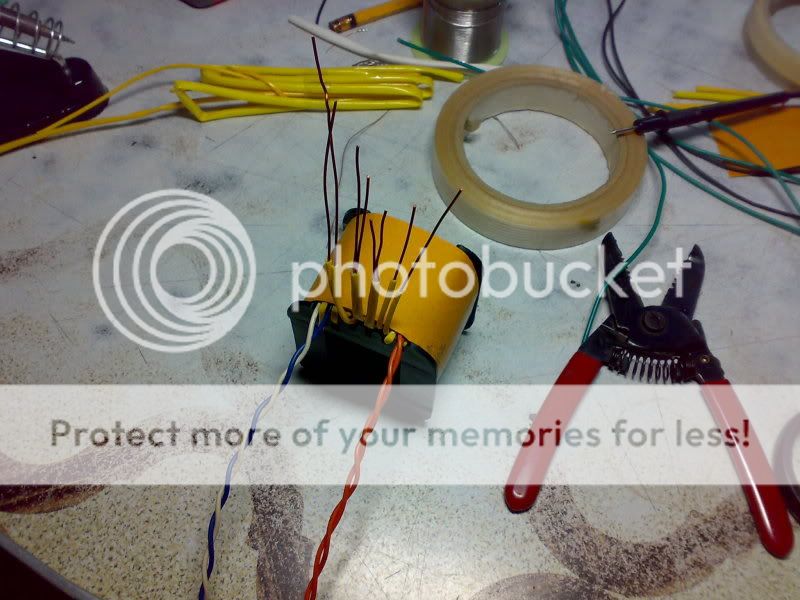

this is a power traffo using a 2inch center leg stacked to 3 1/4 inch DEECO silicon steel (noss) irons..

specs are as follows:

primary: 220 volts 60hz.

secondary1: 250volts at 2amps.

secondary2: 100volts at 0.5amps

secondary3: 12.6volts at 10 amps

secondary5&6: 6.3 volts at 3 amps

completed, there are 3 chokes sitting on top, 1/2inch, 5/8 inch, aqnd 3/4 inch.

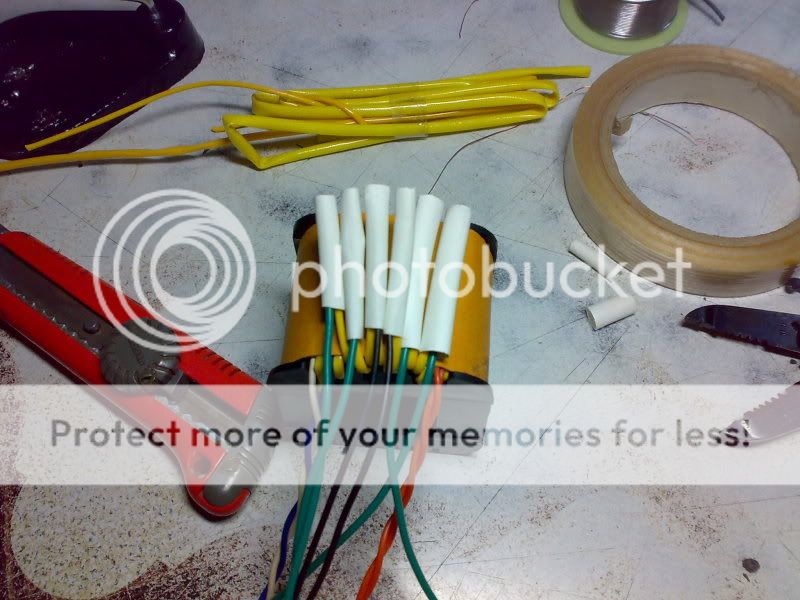

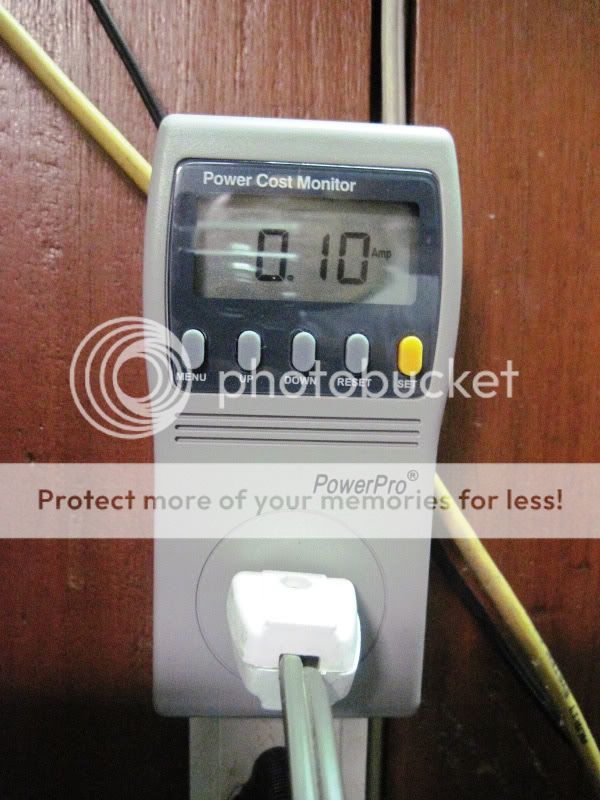

testing prior to dipping in polyuretahne varnish

line voltage:

magnetizing current:

unloaded core apparent power:

actual unloaded power in watts:

power factor:

specs are as follows:

primary: 220 volts 60hz.

secondary1: 250volts at 2amps.

secondary2: 100volts at 0.5amps

secondary3: 12.6volts at 10 amps

secondary5&6: 6.3 volts at 3 amps

completed, there are 3 chokes sitting on top, 1/2inch, 5/8 inch, aqnd 3/4 inch.

testing prior to dipping in polyuretahne varnish

line voltage:

magnetizing current:

unloaded core apparent power:

actual unloaded power in watts:

power factor:

Very nice work! I wound 1000s of stators for my company but this is truly a work of art. Where can I get parts and is there a site that shows how to wind these?

Thanks

WO

Thanks

WO

Very nice work! I wound 1000s of stators for my company but this is truly a work of art. Where can I get parts and is there a site that shows how to wind these?

Thanks

WO

parts are all available locally in manila, the irons used costs P110 per kilo, this traffo used about 9.5kgs. so total cost of irons is P1045 or U$24...

stateside, you can get then from Thomas and Skinner.........Thomas and Skinner

this is a good read: http://www.geofex.com/Article_Folders/xformer_des/xformer.htm

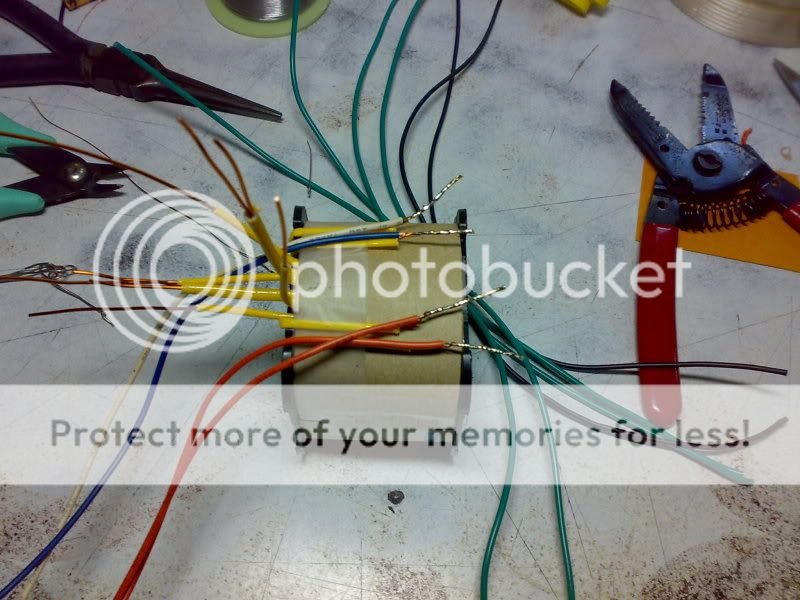

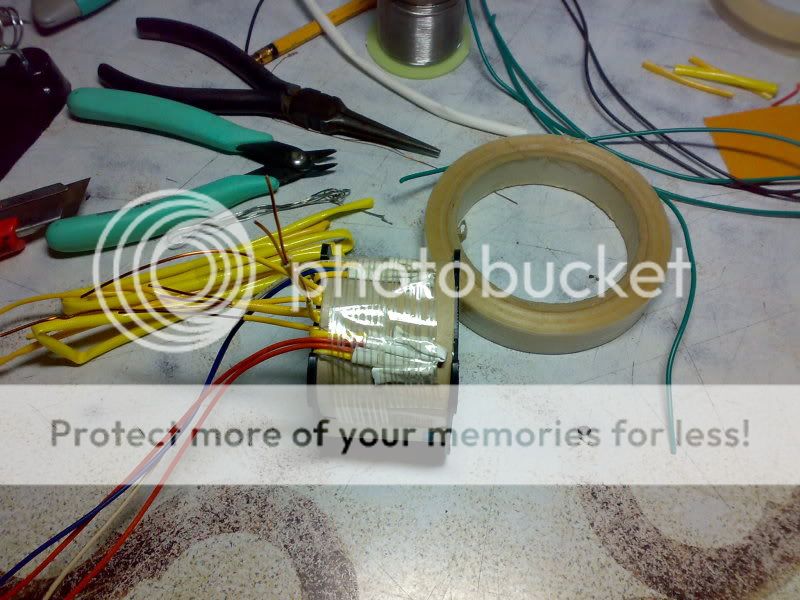

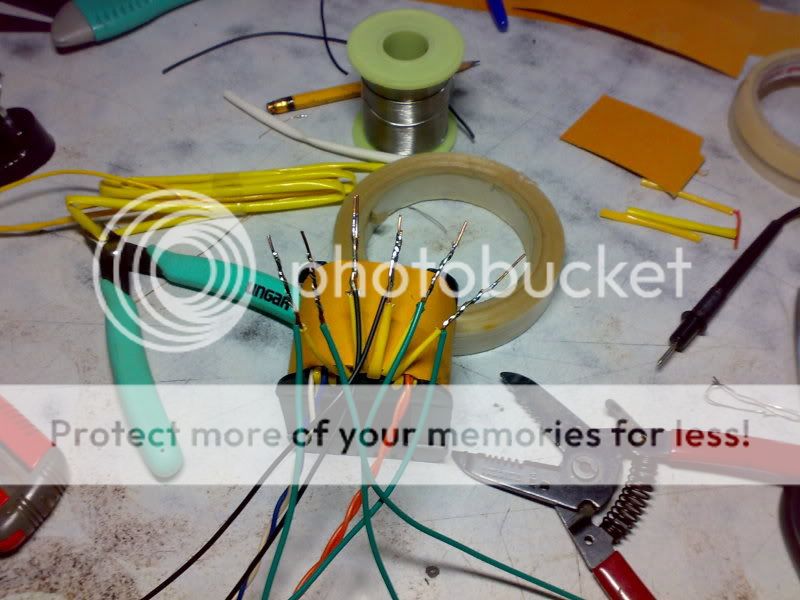

^in case you are wondering, secondary #4 is the "electrostatic shield" made out of a single layer of copper foil sheet...

I get the impression it is quite big !

Give details of size, weight, VA, Vac, windings, turns or turns ratios, etc.

Give details of size, weight, VA, Vac, windings, turns or turns ratios, etc.

Big? not really, core is a 1 1/4inch squared, core rating of about 75VA,

primary at 220volts,60hz, 950 turns of #24 magnet wire, layer wound.

secondary1 at 120volts, 0.4 amps, 570 turns of #27 magnet wire, layer wound

secondary2&3 at 6.3volts center tapped, 3.0amps, 28turns of #18 magnet wire..

primary at 220volts,60hz, 950 turns of #24 magnet wire, layer wound.

secondary1 at 120volts, 0.4 amps, 570 turns of #27 magnet wire, layer wound

secondary2&3 at 6.3volts center tapped, 3.0amps, 28turns of #18 magnet wire..

Last edited:

update:

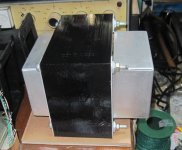

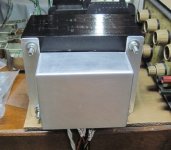

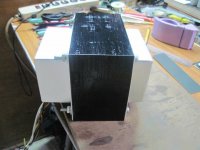

after painting the traffo, i had some aluminum covers made, since no end bells can be found anywhere for 2inch cores that i know of:

after painting the traffo, i had some aluminum covers made, since no end bells can be found anywhere for 2inch cores that i know of:

Attachments

wow...nice build sir....it's really nice building your own trafo especially if u have those equipments....customizing trafo for you own use is really a factor and sometimes cost saving rather than buying ready made trafo that not exactly as u want...some store sell trafo of false VA rating just voltage and amperage and you dont know wether it for a single wind rating or dual...if you not familiar with the core size you can be fooled.

thanks, one reason i build my own traffos is so that i get what i want and not be limited in that sense.....

not really, still a hobby for me, but fire me an email with your requiements and i may be able to help.....

- Home

- Amplifiers

- Power Supplies

- Tony's latest traffo DIY build