I have some experience with the 5100. I have one sitting on my desk at home currently. It will handle more power thermally and with just as good of cooling as these other drivers despite the ratings. I would have no qualms putting a 2-4kw rated amp on it if you use some care to set it up right. It has probably twice the vc mass of most of these other drivers mentioned and 1.5-2x the linear displacement. Power handling specs are some of the most worthless in my experience. It has so much dependancy on the cabinet loading on the driver, the content run through it and the duration of it. It is a very good driver but very very expensive now. Unless you are going to go for real 25-30hz extension and maximum output per cubic foot of cab it is a little bit under utilized. You can get 90% of the performance for less than half of the price. YMMV, FWIW and all of that.

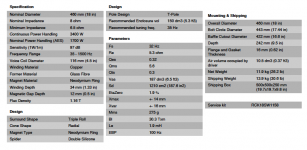

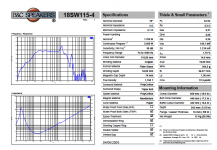

There are quite a few minor differences in the specifications.Both should be working in the Xoc1 fine although there could be a small difference in Group Delay. I haven't seen any PDF about the 4 ohm version but I'm working on it. Maybe Art has the Thiele-Small for the 4Ohm version since he uses them.

The heat dissipation the BC-18SW115-4 is quite impressive, in side by side high power testing of some Eminence drivers the ceramic magnets would be hot to the touch, while the BC seemed to not have raised in temperature hardly at all.

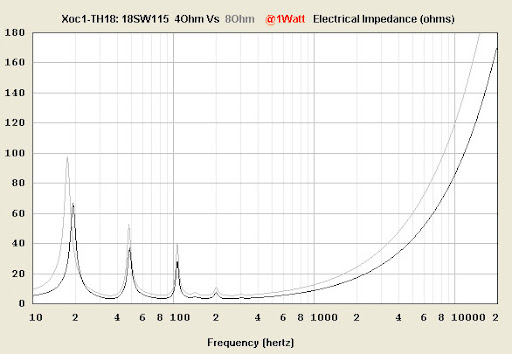

There are very few amps (unless bridged mono) that have enough power to utilize the peak potential of the 8 ohm version.

The 4 ohm version is not really half the impedance of the 8 ohm, I am using Crest CA-9 bridged mono into a single speaker, but it is just tickling the speaker at clip levels (perhaps 3000 watt peaks). I think amps capable of 7000+ watt peaks would not be at all out of line for this speaker.

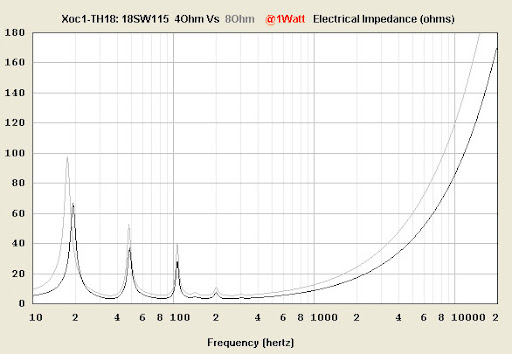

Here are both the 8 ohm and 4 ohm versions:

Attachments

Last edited:

Thanks Art for the info. There seems to be no difference in the gap between the 4 and 8 ohm version which means some distributors  need to correct their Thiele-Small parameters.

need to correct their Thiele-Small parameters.

I made both HornResp to compare the difference between the 8 and 4 Ohm version. Based on 1 watt calculated for each driver.

Eg for the 4Ohm version = 1,8V

Eg for the 8Ohm version = 2,3V

As you can see there is no difference between sensitivity and a very minor difference in response. As suspected the minor differences you only will see back in Group Delay and impedance.

need to correct their Thiele-Small parameters.

need to correct their Thiele-Small parameters. I made both HornResp to compare the difference between the 8 and 4 Ohm version. Based on 1 watt calculated for each driver.

Eg for the 4Ohm version = 1,8V

Eg for the 8Ohm version = 2,3V

As you can see there is no difference between sensitivity and a very minor difference in response. As suspected the minor differences you only will see back in Group Delay and impedance.

Last edited:

Quick question for Djim / Xoc1 or the many experienced horn men on this thread...

I noticed many of the other drivers proposed for the design show a smoother and more extended response than the BMS18n850V2- albeit the model response are for 4 cabs. As size is not an issue for me should i look at tweaking the design to better suit this driver? Or as a horn novice am i wasting my time and opening a can of worms trying to improve on this? - i definately want to try a tapped horn and have the BMS units sitting on the shelf.

I have been trying to learn about horns and playing with hornresp and will get stuck in if there is a chance adaption of the design will help get the driver / cab combo to start rollling of at 40hz rather than 45hz as it does currently. I am guessing i need more effective lenght?

Sorry for the basic questions and not contributing anything useful to this thread!

Once its built i will post measuremens - have an earthworks mic and smaart live.

I noticed many of the other drivers proposed for the design show a smoother and more extended response than the BMS18n850V2- albeit the model response are for 4 cabs. As size is not an issue for me should i look at tweaking the design to better suit this driver? Or as a horn novice am i wasting my time and opening a can of worms trying to improve on this? - i definately want to try a tapped horn and have the BMS units sitting on the shelf.

I have been trying to learn about horns and playing with hornresp and will get stuck in if there is a chance adaption of the design will help get the driver / cab combo to start rollling of at 40hz rather than 45hz as it does currently. I am guessing i need more effective lenght?

Sorry for the basic questions and not contributing anything useful to this thread!

Once its built i will post measuremens - have an earthworks mic and smaart live.

Quick question for Djim / Xoc1 or the many experienced horn men on this thread...

I noticed many of the other drivers proposed for the design show a smoother and more extended response than the BMS18n850V2- albeit the model response are for 4 cabs. As size is not an issue for me should i look at tweaking the design to better suit this driver? Or as a horn novice am i wasting my time and opening a can of worms trying to improve on this? - i definately want to try a tapped horn and have the BMS units sitting on the shelf.

I have been trying to learn about horns and playing with hornresp and will get stuck in if there is a chance adaption of the design will help get the driver / cab combo to start rollling of at 40hz rather than 45hz as it does currently. I am guessing i need more effective lenght?

Sorry for the basic questions and not contributing anything useful to this thread!

Once its built i will post measuremens - have an earthworks mic and smaart live.

Longer path length and a bigger cabinet will go lower.

I could not find any specs for the BMS18n850V2, so hard to speculate how big, or long, or how low.

Hornresp shows multiple TH cabinets having a lower LF corner, while in reality that simply does not happen.

Hi sense, like Art already pointed out, stacking TH’s wont lower the Fb of the system. In this case it is set out at 37,6Hz and the knee (where the signal starts to drop off) will always stay above this point.

But I have checked 4cabs response to be sure. Although maybe the sound of the BMS will have a German accent 🙄 for the rest it will perform just like any other high quality driver in the Xoc1. The bumps in the response from the prediction will be less in reality so you don’t have to worry about that either.

But I have checked 4cabs response to be sure. Although maybe the sound of the BMS will have a German accent 🙄 for the rest it will perform just like any other high quality driver in the Xoc1. The bumps in the response from the prediction will be less in reality so you don’t have to worry about that either.

As size is not an issue for me...

...i definately want to try a tapped horn and have the BMS units sitting on the shelf.

I have been trying to learn about horns and playing with hornresp and will get stuck in if there is a chance adaption of the design will help get the driver / cab combo to start rollling of at 40hz rather than 45hz as it does currently.

Since size is not an issue, check this thread where Xoc1, epa and others have already modeled a few enclosures around the 18N850v2 to play 30-35Hz and up! 🙂

http://www.diyaudio.com/forums/subwoofers/178029-c-e-x-pa-flat-30-ft30-pa-th-awesomeness.html

Hope this helps!

Left: 18Sound 18LW2400 vs Pro 5100 (SPL)

Center: B&C 18SW115 vs Pro 5100 (SPL)

Right: B&C 18SW115 vs Pro 5100 (Group Delay)

(In Hornresp, the Pro 5100 reaches its AES power rating of 1000W way before xmax)

Correction: the Pro 5100 is currently $1270, not $900..

Thanks guys, i did look at the 30hz thread and will give it some more attention - will probably opt for this 38hz version as i can see quite a lot of work has gone into it so far and design has evolved.

Either way will post pics and measurement results once i have completed the first cab.

Cheers

Either way will post pics and measurement results once i have completed the first cab.

Cheers

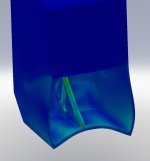

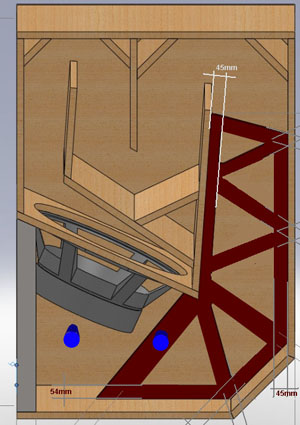

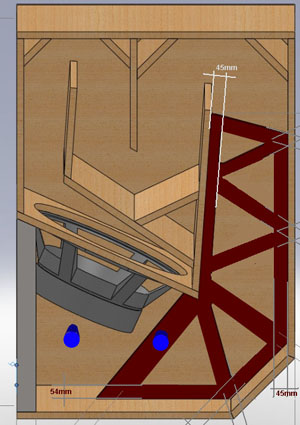

Quick question...are these all strips of 18mm ply? Or is this brace cut from a single piece then the triangles are cut out to reduce the volume the bracing takes up?

Of course the best way is to use one single piece as it gives the highest strength but I think Martin also wants to use left over parts. (Btw the cut outs are not only for reducing volume or weight)Quick question...are these all strips of 18mm ply? Or is this brace cut from a single piece then the triangles are cut out to reduce the volume the bracing takes up?

Just read over the design and ran it through Akabak for fun. I'm still learning in Akabak so forgive me if its way off. I used a HP and LP filters to keep excursion and bandwidth under control

An externally hosted image should be here but it was not working when we last tested it.

I have some experience with the 5100. I have one sitting on my desk at home currently. It will handle more power thermally and with just as good of cooling as these other drivers despite the ratings. I would have no qualms putting a 2-4kw rated amp on it if you use some care to set it up right. It has probably twice the vc mass of most of these other drivers mentioned and 1.5-2x the linear displacement. Power handling specs are some of the most worthless in my experience. It has so much dependancy on the cabinet loading on the driver, the content run through it and the duration of it. It is a very good driver but very very expensive now. Unless you are going to go for real 25-30hz extension and maximum output per cubic foot of cab it is a little bit under utilized. You can get 90% of the performance for less than half of the price. YMMV, FWIW and all of that.

If you trust the T-S values, also try the Ficaraudio BTL N218:

https://ssl.perfora.net/www.ficaraudio.com/sess/utn;jsessionid=154dfcc4d52a9e6/shopdata/0050_Speakers/0010_BTL/0060_N2/product_overview.shopscript

28mm Xmax, 2000W claimed handling -- which is plausible even with a 3" coil given that it's about 2.5" tall -- and about £500 in the UK (less than $500 in the USA). The dual 2 ohm version with coils in series would be a very good match for amps in the 3-4kW/4ohm class.

If you look at the page 3 of the cut sheet drawing. there is plenty of material left over to cut a one piece brace. This is the 1/2 sheet in the cutting plan for a single cabinet, so You would need to nest the 2 braces to get the pair from this sheet.Quick question...are these all strips of 18mm ply? Or is this brace cut from a single piece then the triangles are cut out to reduce the volume the bracing takes up?

I have been using stress analaysis to try to optimise the bracing but of course the more complicated I make it the more difficult it is to cut.🙁

I have applied forces to the base, and the reflector where castors are likely to be fitted and I have eliminated most of the stress concentrations.

The thin braces in the back triangulate to the centre of the unsupported back panel area.

Regards

Martin

Attachments

Martin, try to model them with the 'broomsticks' that are side-to-side mounted. One cuts trough the big first brace half way between driver panel and bottom panel.

The other one should be sits somewhere under the magnet.

Btw the one piece brace looks great, as usual...

The other one should be sits somewhere under the magnet.

Btw the one piece brace looks great, as usual...

Last edited:

Straight cuts done...

Angle Cuts done...

This wood is REALLY stiff! Now I see why it's recommended. It is very nice to work with!

An externally hosted image should be here but it was not working when we last tested it.

Angle Cuts done...

This wood is REALLY stiff! Now I see why it's recommended. It is very nice to work with!

Nice looking project, but a tiny word of advice. Think carefully about where you drill the mounting holes for the driver bolts, you don't want to end up with them being in places where you can't get a socket in easily. 😉

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)