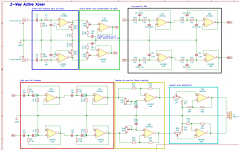

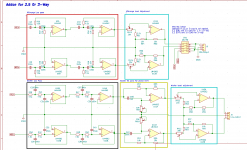

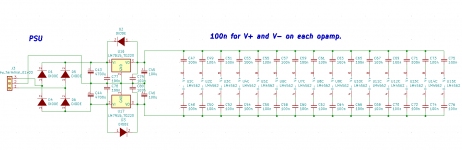

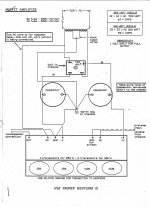

This is an experimental investigation into the feasibility of a very compact point source horn using a tractrix profile and a nice RAAL ribbon tweeter. The design follows earlier methodologies described in the

Trynergy thread and also the

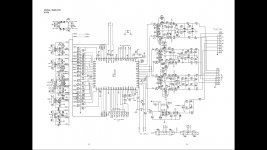

PRV 5MR450NDY thread. I used the PDF horn plans developed earlier and scaled the plans by a factor of about 0.33x to 0.35x in order to generate the profiles used here. I stretched the nominally square throat out in the vertical and horizontal directions to accommodate the rectangular aperture of the RAAL ribbon aperture. This is a private commissioned design so I have been asked to keep certain info private, such as the specific RAAL model number. But I think one can adapt this concept to almost any ribbon tweeter given appropriate crossover points.

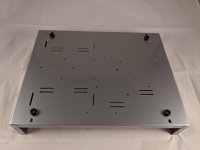

The horn dimensions are about the size of a sheet of letter paper (8.5in high x 11in wide x 7.5in deep). The envisioned frequency range is 500Hz to 20kHz+ with a crossover from 1.8kHz to 2.6khz. Integration with an externa woofer will provide bass below 500Hz.

The midrange will be handled by dual Faital Pro 3FE22 (8ohms) wired in parallel. However, I have found that this combo produces almost too much sensitivity. At 2.0Vrms and 0.5m, the microphone was clipping and my ears were ringing. I think the peak sensitivity was probably about 105dB at 2.83v. As a result, I had to back off the excitation to about 0.63Vrms to keep things bearable for measurements. An observation, consistent with my earlier efforts to use an AMT for a Synergy style horn was that there is very little horn-gain for the tweeter. Maybe 2dB... I think this results from the very small low mass diaphragm that does not pistonically "pump" the air column at the throat vs. a dynamic driver that acts more as a piston and hence experiences typically 10dB of horn gain.

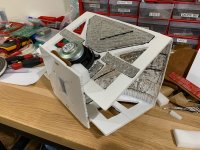

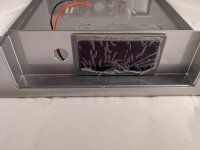

Here is the completed protoype Trynergy horn made out of Elmer's thick paper-faced foam core material. I tried the glossy finish foam core (vs matte) and although it looks great, the hot melt glue does not adhere well as the surface is glossy via a wax coat treatment. If I did it all over again, I would use the matte finish.

Rear view of the prototype showing open back stuffed with fiberglass in a manner similar to the microTrynergy. This provides enough of an enclosure to allow the mid range to go down to 500Hz with a -12dB/oct falloff. This is exactly where I wanted the crossover to be, so it worked out well. The bass drivers can be anything, but a pair of nice 8in woofers in open face saeled or reflex or TL etc can take this from 500Hz down to circa 50Hz easily. A set of woofers above and below for a WHW (woofer-horn-woofer) arrangemennt might work out real well for a point source system. The horn is surprisngly rigid once all glued together. The two top and bottom driver moutning plates serve large rib reinforcemnts to make the box quite stiff, yet surprisngly light weight.

Here are the construction details showing the liberal use of Noico mass-loaded butyl for resonance reduction. The panels and especially the horn walls are very dead sounding under the 'knuckle rapping' test. This will be evident in the very low THD vs frequency plots:

Noico on the side panels as well:

Lot's of pink fiberglass sound dampening is used throughout, some felt right behind the driver magents, and some use of melamine foam at strategic locations:

Here is a closeup of the throat and mid-range injection ports (20mm x 40mm at 23mm from throat plane). Throat is approx 40mm wide x 70mm tall. The location was made as close as physically possible given the bezel diameter of the 3FE22:

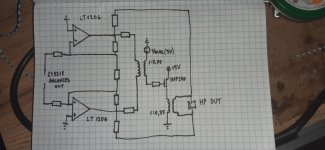

Getting measurements made using UMIK-1 at 0.5m to avoid room reflections:

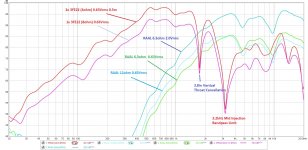

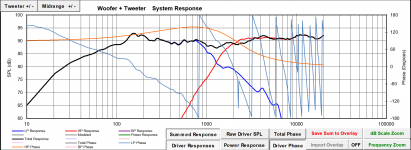

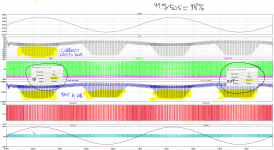

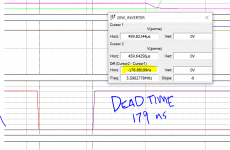

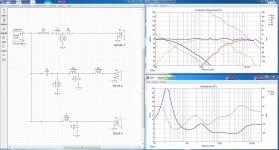

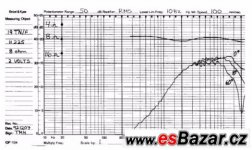

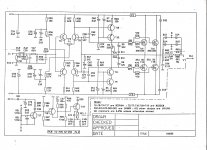

Measured response with freq dependent window (FDW) 6 cycles for mids and ribbon at various excitation levels and impedance taps:

The mid range has a sharp dip at 1.74khz, which I believe corresponds to the reflection cancellation from the top and bottom walls at the throat injection point (3.8in). The goal was to get up to 3kHz if possible.

Here is the THD vs frequency of one 3FE22 running at only 0.63Vrms - about 87dB at 1m ( a very comfortable SPL) and showing very low levels of distortion. Panel resonances look well controlled despite 3/16in thick foam core construction:

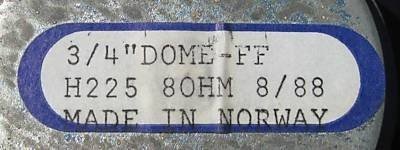

Here is the THD vs frequency for the RAAL running at 0.63Vrms, also showing very low distortion levels. This is equivalent to about 95dB at 2.83v and 1m. The 3FE22's could also be wired in series for 16ohms and that would help to match the sensitivities better and still keep a larger dynamic range and lower distortion:

Of interest is the acoustic slope of -18dB/oct on the high pass filter function. This could be very useful for a Harsch XO.

Next steps are to see if the nagging dips at 4.7khz and 10khz can be reduced or eliminated. I think they are wall reflections in the vertical (4.7kz) and horizonatal (10kHz) from the ribbon membrane to the horn side walls.

This will be interesting but certainly shows there is lots of work to be done, but there is promise here for a very compact point source horn. I will try to do some basic EQ and DSP crossover on the mid range. Let the RAAL run via passive high pass but maybe apply some EQ (cuts only, no boost). Will try maybe a 1.7kHz crossover to take advantage of the natural dip there.