I finished my F5 build yesterday and wanted to document it before I lost motivation and moved on to another project. This was a great project, and I was happy to be making the most of my time in isolation creating something. My background is in software, and I don't expect to ever be able to fully understand or design analog electronics. But I really enjoy the process of building, customizing, refining, and chasing details.

Parts:

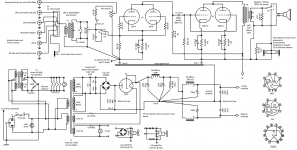

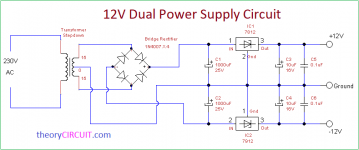

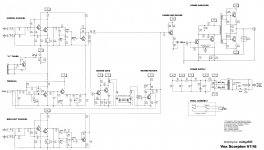

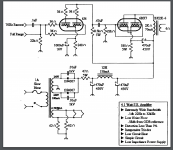

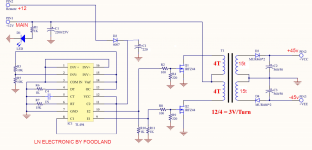

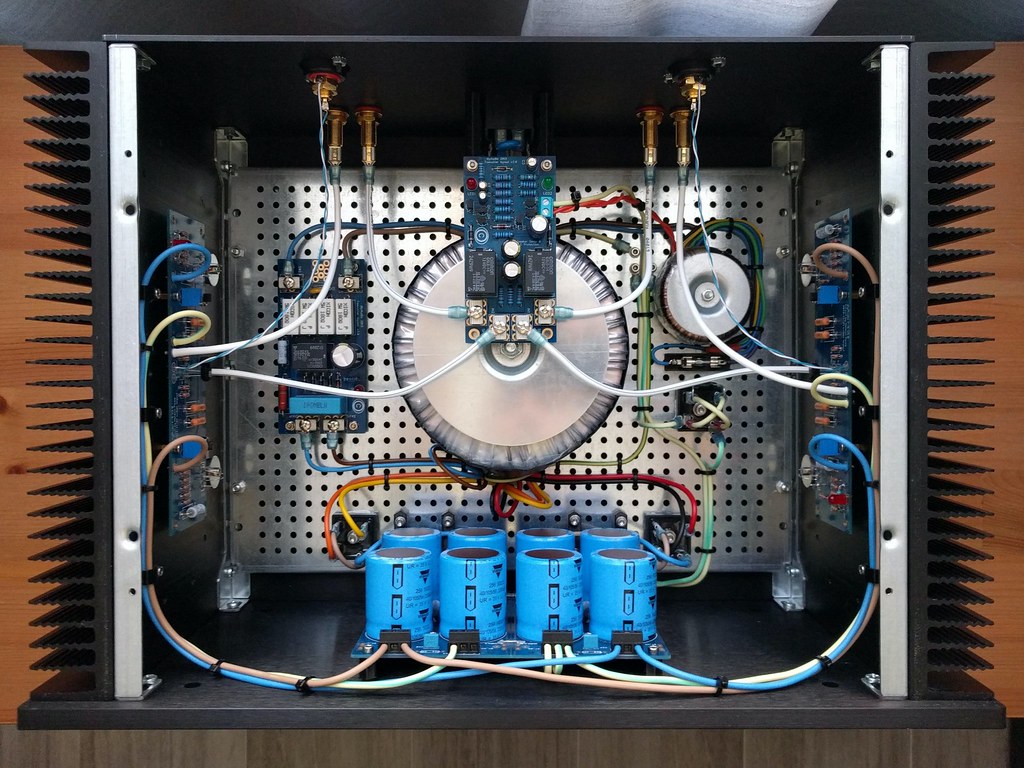

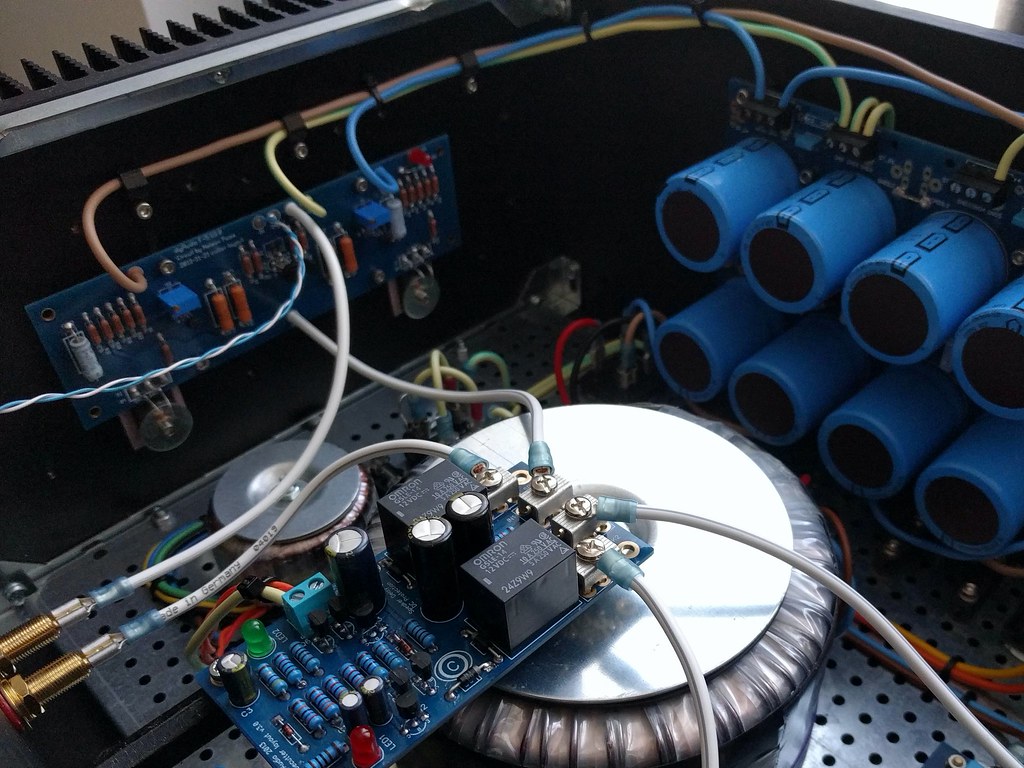

All PCBs are DiyAudio including the Universal Power Supply, F5, and Soft Start & Speaker Turn-On Delay / DC Protector Combo. I also purchased the F5 parts Kit, the LSK170/LSJ74 +/-0.1ma Matched Quad and Back panel parts kit plus PCB / Transistor / Diode mounting parts kit for the Deluxe Chassis.

The large transformer is a CM0500218 230V (2x115V) 500VA 2x18V audio grade toroid from Airlink. It's ok, but the finish was a tad sloppy, and the shipping was high. I would probably gibe Toroidy a try for a future project. The small transformer powers the speaker protection boards and is an RS 230V (2x115V) 15VA 2x12V.

All components (aside form the DiyAudio kit parts and transformers) came from Mouser. Shipping from Texas to Spain was free and was only 3 business days from placing the order to arrival.

For wire I used what I had nearby. Power (e.g. IEC -> terminal -> soft start) is 1.5mm2 taken from an IKEA extension cord. The same was used for the PSU to amp boards, chassis grounding, audio ground lift, etc. For amp boards to speaker protection and speaker terminals I borrowed an unneeded foot or two from my speaker cables, which are DCSk 2.5mm2. Signal inputs to amp boards is twisted pair stripped from CAT5 cables.

I also made a dim-bulb tester from an IEC cable, a ceiling lamp socket kit, and a 100w incandescent bulb. It never actually saved me from any mistakes, but it did make switching it on the first time and after each change less stressful.

Build:

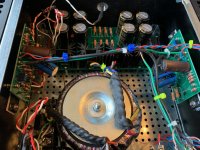

I was expecting more room in this big 4U chassis, but it's actually compact inside once I added the 500VA PSU, soft start, and speaker protection boards, second transformer, etc. I ordered the black 10mm aluminum faceplate which doesn't have convenient tapped holes like the silver version. So I had to get creative some of the layout and decided to design and 3D print some parts to make it cleaner and easier to work on.

I designed and printed L-shaped brackets to hold the PSU PCB against the faceplate. The bracket only anchors to the bottom plate which makes it convenient when removing the faceplate for better access. The soft start board is on the bottom plate next to the transformer. The speaker protection board is on 3D printed inverted L-shaped brackets I designed that attach to the back panel by sharing the IEC inlet/fuse mounting hardware. The board is only supported from one end at the moment, but I plan to create a second bracket that will anchor to the transformer mounting plate. I also designed and printed some cable guides that attach to the heat sinks via some of the spare tapped holes.

I spent quite a lot of time on layout of boards, transformers, wires, etc. because I enjoy it, and I've had a lot of time recently. I left all the primaries and secondaries at full length just in case I want to make changes, try a different amp build, convert to 115V, etc.

Sound:

No idea! To be honest I did this project more for the journey than the end result. I will definitely put it to use soon, but I don't have a preamp at the moment -- just a couple integrated amps (Rega Brio-R and Sony TA-F3000ES). I have a ChromeCast Audio and a couple Raspberry Pi DACs with variable outputs, but there's something to be said for having a potentiometer in between a source and amp in case there's a 'glitch'.

So I don't have more to say on this at the moment, but will add to this thread when I build or buy a preamp for it. My current plan is to build the Mezmerize B1 Buffer, which would give me another couple of weeks of entertainment value.

Photos:

Below are a few shots I took today, and more high-res ones can be found in

this album.

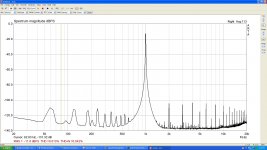

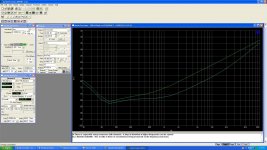

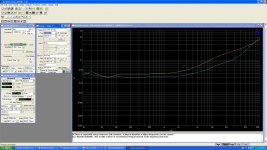

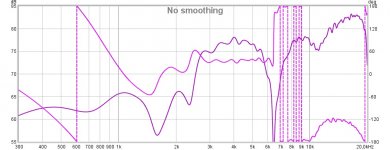

ugh it hurts my brain.

ugh it hurts my brain.