OPS asymmetry

- By Raichu

- Solid State

- 2 Replies

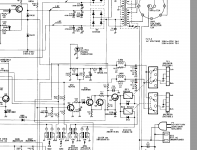

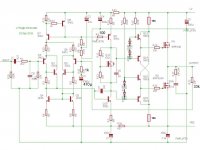

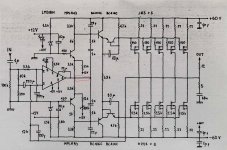

I am modeling an amplifier with Multisim using an EF3 OPS with 6 pairs of MJL3281A/MJL1302A driven by MJE15032/MJE15033.

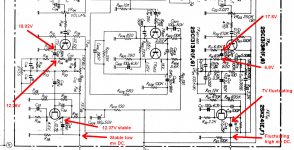

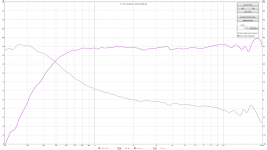

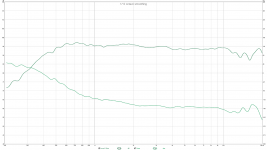

With a 1KHz input signal and an output voltage of 34.6VRMS into a 4 ohm load (300WRMS), the Fourier analysis of the output node shows a THD of less than 0.0001% (9 harmonics) so the closed loop behavior seems OK.

I do a Fourier analysis of the VAS (the test node is the connection of the VAS collector to the bias spreader) to get an idea of the "correction" applied to the OPS.

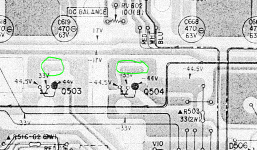

With 0.2R emitter resistors, the VAS THD is 0.054% with a dominant 2nd harmonic (0.026%).

Changing the emitter resistors *only* on the PNP output devices (MJL1032A) to 0.26R (empirically determined) lowers the VAS THD substantially to 0.011%, now with a very low second harmonic. (<0.0002% = much better symmetry)

The bias is set for best THD (approx. 70mA).

I thought that something may be wrong with the models but I also tried MJL21194/MJL21193 with similar results.

Looking at the data sheets, I see that these PNP devices tend to have a higher current gain which seems to explain this.

Your thoughts and/or experiences please.

With a 1KHz input signal and an output voltage of 34.6VRMS into a 4 ohm load (300WRMS), the Fourier analysis of the output node shows a THD of less than 0.0001% (9 harmonics) so the closed loop behavior seems OK.

I do a Fourier analysis of the VAS (the test node is the connection of the VAS collector to the bias spreader) to get an idea of the "correction" applied to the OPS.

With 0.2R emitter resistors, the VAS THD is 0.054% with a dominant 2nd harmonic (0.026%).

Changing the emitter resistors *only* on the PNP output devices (MJL1032A) to 0.26R (empirically determined) lowers the VAS THD substantially to 0.011%, now with a very low second harmonic. (<0.0002% = much better symmetry)

The bias is set for best THD (approx. 70mA).

I thought that something may be wrong with the models but I also tried MJL21194/MJL21193 with similar results.

Looking at the data sheets, I see that these PNP devices tend to have a higher current gain which seems to explain this.

Your thoughts and/or experiences please.