You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Filters

Show only:

Serial LC filter on a low Q subwoofer in order to use it in a dipole configuration

- By silverprout

- Analog Line Level

- 14 Replies

Hello, could you tell me why it should not be desirable to use a serial LC filter on a low Q subwoofer in order to use it in a dipole configuration ?

The main advantage it that the subsonic register is still damped and the drawbacks are inaudible if the center frequency is under 30Hz.

Why please ?

The main advantage it that the subsonic register is still damped and the drawbacks are inaudible if the center frequency is under 30Hz.

Why please ?

Technics SL-1100: Possessed? (Platter rotates at power on)

- By dbxdx5

- Analogue Source

- 5 Replies

I could use some brain power, as mine apparently isn't up to the task. Here's the situation: I'm working on a Technics SL-1100. When the power switch is moved to On, the platter begins spinning. Of course, it isn't supposed to do that, but rather instead wait for Start to be pressed. Once the platter is spinning, pressing Stop will often (but not always) stop it, but usually only for a few seconds, and then it will often begin spinning again. During those times when the platter stops and stays stopped, pressing Start will have no effect.

I've replaced both mini snap switches used for Start/Stop. I've also tested the following transistors in circuit, all were ok (not shorted), though I'll pull any that folks think warrant out-of-circuit testing.

TR9

TR11

TR12

TR13

TR14

All electrolytic caps tested with my Peak ESR70 Plus--nothing out of the ordinary. I checked all of the solder joints and touched up a few. In terms of voltages. I've measured around TR11, TR12, TR13, and TR14, and everything is close to what's shown on the schematic. One odd thing is that all voltages are showing negative with my common lead connected to pin 7, per the instructions in the SM.

I feel like I'm missing an obvious culprit here. . . .

I've replaced both mini snap switches used for Start/Stop. I've also tested the following transistors in circuit, all were ok (not shorted), though I'll pull any that folks think warrant out-of-circuit testing.

TR9

TR11

TR12

TR13

TR14

All electrolytic caps tested with my Peak ESR70 Plus--nothing out of the ordinary. I checked all of the solder joints and touched up a few. In terms of voltages. I've measured around TR11, TR12, TR13, and TR14, and everything is close to what's shown on the schematic. One odd thing is that all voltages are showing negative with my common lead connected to pin 7, per the instructions in the SM.

I feel like I'm missing an obvious culprit here. . . .

Drop THX 789 protection mode

- Headphone Systems

- 0 Replies

Has anybody successfully fixed this issue? It seems to be pretty common.

I picked one up and would like to bring it back to life. All I know right now is that it powers on but the light remains red, so it doesn't click on and turn white.

I picked one up and would like to bring it back to life. All I know right now is that it powers on but the light remains red, so it doesn't click on and turn white.

Thermal Interface - Aluminium Nitride (AlN)

- By selwe

- Solid State

- 7 Replies

I've searched through pages about aluminium nitride plates, but couldn't find someone who actually used them (we know the numbers).

There are some vendors on aliexpress and the 0.6mm ones could be promising, at least if it is AlN as stated. Anyone used AlN pads sourced from Aliexpress?

To me this seem to be the best solution performance and robustness wise (with a high performing grease, of course)

There are some vendors on aliexpress and the 0.6mm ones could be promising, at least if it is AlN as stated. Anyone used AlN pads sourced from Aliexpress?

To me this seem to be the best solution performance and robustness wise (with a high performing grease, of course)

Question about 6P31S

- By Ryssen

- Tubes / Valves

- 50 Replies

I just built a se amp with these tubes,BUT I just realized that I designed the amp to run with EL 36,just found out that 6P31S only can stand 13w

and the EL36 about 15w,so I get a little just a little (hardly can se it)red glow.

Now the qeustion -> will this be a problem?

and the EL36 about 15w,so I get a little just a little (hardly can se it)red glow.

Now the qeustion -> will this be a problem?

IGBT Conversions for Forte Audio Amps?

- By Nexus9

- Solid State

- 86 Replies

My trusty Forte Model 5 and Model 6 are starting to show their age, and during a scheduled maintenance, I found an emitter resister completely blown (more than two VOLTS across the resistor when biasing), which, of course was caused by a bad IGBT. This led me to test all the output transistors (Very nicely matched within each amp, BTW) and I found one of the model 5 transistors to be bad as well!

Both were P-channel GT20D201, which (if you can find them) are only available as used pulls for around $20 each.

Which led me to start thinking about updating the entire board(s) with newer parts, and might not cost much more. I know the circuitry was designed around the IGBTs, and I really don't want to start rebuilding that. The latest version of Toshiba's IGBT is the GT50J121, which is faster, and has a higher current and voltage rating.

That's the background, here's the question(s): has anybody ever actually changed out a full set of IGBTs with a different model? Would the output circuitry be so carefully chosen that it would only sound right with the original transistors? Or, is there anything else you have learned from experience that would be a caution here?

Thanks for sharing your knowledge!

Both were P-channel GT20D201, which (if you can find them) are only available as used pulls for around $20 each.

Which led me to start thinking about updating the entire board(s) with newer parts, and might not cost much more. I know the circuitry was designed around the IGBTs, and I really don't want to start rebuilding that. The latest version of Toshiba's IGBT is the GT50J121, which is faster, and has a higher current and voltage rating.

That's the background, here's the question(s): has anybody ever actually changed out a full set of IGBTs with a different model? Would the output circuitry be so carefully chosen that it would only sound right with the original transistors? Or, is there anything else you have learned from experience that would be a caution here?

Thanks for sharing your knowledge!

Coupling capacitor dac.

- By Sagen

- Digital Line Level

- 29 Replies

Hi, im building a DDDac1543. Its going to a preamp with 50k input impedanc. What is the smalest output cap I can use on the dac and not loose any bass? Im looking at Solen film/foil teflon to use in dac, Im a fan of V-cap ODAM but have them as output cap in preamp and in crossover so think that is good for now. I also before have bypassed caps in signal way but dont do that anymore, dont like “smearing” of the sound, but that is just my experiance. Frank

Adcom GFA 555 power switch behavior. Need advice

- By tonester

- Solid State

- 15 Replies

I was given an Adcom GFA-555 that was reported to be not working. I checked all fuses and wiring and components visually for burned resistors bulging caps etc BEFORE plugging into the DBT. I am using a 100W bulb. When I plugged into the DBT to test the amp the lamp lit bright and slowly dimmed but not completely dim, with the power button in both the on or off position. How should I begin to proceed with this repair, and should I assume the switch is fried or that something in the amp is shorted?

New member and new to DIY!

- By mjhill1234

- Pass Labs

- 15 Replies

Hello everyone, I am new to the forum and am looking for some advice where to start with building a DIY amplifier!

I have Avantgarde Duo (103dB sensitive) speakers and I currently run an Audion SET tube amp that can take 300b or 2A3 valves. I love the sound of the valve amplifier but it’s had a couple of wobbles recently that has resulted in gong in for repair.

The first time this was in for repair I purchased an Amptastic Mini-1 and while it didn’t have the wonderful musicality of the Audion I was rather shocked with how quiet it was and how fast the bass was.

This has got me thinking about building something solid state that will give me the fast bass response but hopefully match the lush musical sound of the 300b/2a3

I really have no idea where to start! I am not too shabby with a soldering iron though!

Thank you

I have Avantgarde Duo (103dB sensitive) speakers and I currently run an Audion SET tube amp that can take 300b or 2A3 valves. I love the sound of the valve amplifier but it’s had a couple of wobbles recently that has resulted in gong in for repair.

The first time this was in for repair I purchased an Amptastic Mini-1 and while it didn’t have the wonderful musicality of the Audion I was rather shocked with how quiet it was and how fast the bass was.

This has got me thinking about building something solid state that will give me the fast bass response but hopefully match the lush musical sound of the 300b/2a3

I really have no idea where to start! I am not too shabby with a soldering iron though!

Thank you

Home made tube socket

- By mashaffer

- Tubes / Valves

- 2 Replies

Anyone ever play with making your own tube sockets? I could foresee a time when some of the less common compactron sockets could become hard to find.

Does anybody know anything about RCL drivers?

RCL 'made' some fairly robust budget drivers in the late 90s. I can't speak to their quality but they were pretty indestructible. Later they introduced their 'hi-fi' series of bass drivers: PP8 & PP10 with concave dust-caps. But a little birdie told me RCL never manufactured drivers - simply branded them, and the H-Fi series were made by SEAS. SEAS have an excellent reputation, and their drivers ain't cheap.

I only ask because I have acquired a pair of PP8 drivers and have cannot find any information on them.

Does anybody have any further information?

I only ask because I have acquired a pair of PP8 drivers and have cannot find any information on them.

Does anybody have any further information?

Broken Sony SRS ZR7

- Everything Else

- 7 Replies

Hello all! I have a Sony SRS ZR7 speaker that fell the other day. Unfortunately, since the fall the speaker produces a buzzing noise when playing louder music. I have taken the grill off and noticed that there is a scratch on the thing (cone? sub?) second from the right. Seems that the buzzing is coming from that one as when I touch it when music is playing and sound no longer comes out the buzzing stops. I have tried to open the unit to no success, as even when removing all screws the front plate is really wedged on there. Does anyone have any suggestions for DIY fixes or advice on how the unit can be opened or is this the end of my dear speaker’s life? Thanks!

Sinclair-Peterson based power Amp.

Works stable and sounds more than just fine with triode tubes but I`m wonder if this old OTL amp concept from early 50` is applicable for modern various J-Fets and SIT power devices ? ,

short circuit description ; Q1 is the input transistor which achieve major voltage gain and is AC coupled to Q2 gate , Q2 is phase inverter where its drain is 100% positive bootstrapped from loudspeaker output line which achieve dynamic asymmetric drive for SEPP output power pair , Q2 drain drives Q3 gate and in the same time Q2 source out of phase drives Q4 gate , P1 trim-pot regulate current via Q2 and in the same time regulate Iq of the output Q3 & Q4 SEPP power pair , B+=48V is chosen for deep A class of operation of SEPP- OPS ,

yours suggestion and critics are welcomed , guys with Spice skills also is welcomed .

short circuit description ; Q1 is the input transistor which achieve major voltage gain and is AC coupled to Q2 gate , Q2 is phase inverter where its drain is 100% positive bootstrapped from loudspeaker output line which achieve dynamic asymmetric drive for SEPP output power pair , Q2 drain drives Q3 gate and in the same time Q2 source out of phase drives Q4 gate , P1 trim-pot regulate current via Q2 and in the same time regulate Iq of the output Q3 & Q4 SEPP power pair , B+=48V is chosen for deep A class of operation of SEPP- OPS ,

yours suggestion and critics are welcomed , guys with Spice skills also is welcomed .

Attachments

Orion HCCA 2000.4 Problem with channel 1 and 4

This amp suffered multiple problems including failed opamps and channel 4 output TIP35/36 failures. Open base (3.3ohm) and emitter (0.1ohm) resistors. Someone previously bought ST brand TIP35/36 but likely got stuck close to where I'm stuck now. The previous repair removed all the drivers which are TIP41/TIP42, B600/B631 and 1023/1027.

I'm working on Channel 4 now. There is no bottom waveform. I tried swapping out many parts and testing parts and cannot find the solution.

Is there a schematic available for this amp by chance?

Audio signal comes in clean on the base of Q403/Q404/Q405/Q406 but then immediately gets clipped at the emitters. I swapped out FR with 3B. BR Im not sure what that is. I tried 1B transistors but the amp stayed muted.

I'm working on Channel 4 now. There is no bottom waveform. I tried swapping out many parts and testing parts and cannot find the solution.

Is there a schematic available for this amp by chance?

Audio signal comes in clean on the base of Q403/Q404/Q405/Q406 but then immediately gets clipped at the emitters. I swapped out FR with 3B. BR Im not sure what that is. I tried 1B transistors but the amp stayed muted.

Mid-bass horn 100-1k?

For 100 (150?)-1k (900?)

Can I do better than:

https://volvotreter.de/downloads/Conical_77Hz_Midbass_1.0.pdf

A bit taller (1,3m?) would be OK - folded?

HiFi is goal.

//

Can I do better than:

https://volvotreter.de/downloads/Conical_77Hz_Midbass_1.0.pdf

A bit taller (1,3m?) would be OK - folded?

HiFi is goal.

//

Speaker simulation of AMT with basta?

- By Herbie70

- Software Tools

- 8 Replies

Hi all,

how do I simulate AMT's with basta!? I want to build an open baffle speaker using Mundorf AMT's but it seems

that there are no T/S parameters for these drivers. I assume that it is not possible to "derive" them as the speaker

principle is so different...... Is there a workaround?

how do I simulate AMT's with basta!? I want to build an open baffle speaker using Mundorf AMT's but it seems

that there are no T/S parameters for these drivers. I assume that it is not possible to "derive" them as the speaker

principle is so different...... Is there a workaround?

WTB WTB Mofo pcb pair

Hi, Im looking to buying a pair of original Mofo amp pcb or also Mofo pcb from member Prasi. Plese for offer only from member from Europe, becose of lower shipping costs and no tax to pay. Thanks!

Find schematic diagram of Danish Bush arena a220

- By jacky-bb

- Solid State

- 5 Replies

I need the schematic diagram of Danish Bush arena a220. I hope I can get help. Thank you. Have a nice work,

Over/Under & Right-Sized Rectifier PS

- By coolcity

- Power Supplies

- 1 Replies

A few expensive small-signal components utilize two rectifier tubes, including 5AR4s; each supplying one stereo channel. This sometimes includes massive filtering capacity. OTOH, most high-end power amps have only one rectifier and much less filtering. I realize this may be for marketing purposes, to some extent, for those pre & phono amps with "over-sized" power supplies. But if there are valid reasons for this, why don't more power amps use larger a PS?

Orion hcca 1000.4

HI all

Amp had shorted outputs changed them and the amp is working but there a resistor in-between output terminals and power terminals that is burnt. I would like to know the value of it. It is connected in-between main power ground and speaker ground.

Amp had shorted outputs changed them and the amp is working but there a resistor in-between output terminals and power terminals that is burnt. I would like to know the value of it. It is connected in-between main power ground and speaker ground.

Positive Feedback Meets the Amazing Circlotron

I wanted to build a variation of the Amazing Circlotron with Exicon Mosfets and positive current feedback. I emailed Mike and have his blessing. I came up with the circuit below but I have a nagging feeling it wouldn't work. I suspect that the PCF should be cross-coupled to the load and the ends of the 0R33 resistors grounded, but don't want to blow up my working amp with the modification. Sorry poor man's workshop, no Spice etc and a solid state beginner. Would like some advice as to the connection of the positive current feedback.

Regards Tony

Regards Tony

Resolved - Feedback noted Forum doesn't accept HEIF format for images.

- By kodabmx

- Forum Problems & Feedback

- 22 Replies

Can we add HEIF to the image formats? Smaller and better than jpeg.

https://en.wikipedia.org/wiki/High_Efficiency_Image_File_Format

https://en.wikipedia.org/wiki/High_Efficiency_Image_File_Format

add 12v trigger to Elekit TU-8500

- By Mrdrewk

- Tubes / Valves

- 16 Replies

I'm looking to add a 12v trigger to my Elekit TU-8500. I can hunt around in there for some volts until I find something close - but I don't want to impact the sonic quality. Is there a place that makes sense to solder in the trigger jack? thanks!

https://tubedepot.com/products/elekit-tu-8500-stereo-tube-preamplifier-kit

another post

audiosciencereview guys had some decent suggestions, a Niles Current Sensing 12v trigger. I could put that inline with the AC into the preamp and that might do the trick.

12v trigger cable amazon

female (stereo) 3.5mm jack amazon, to hook up and hack into chassis.

https://tubedepot.com/products/elekit-tu-8500-stereo-tube-preamplifier-kit

another post

audiosciencereview guys had some decent suggestions, a Niles Current Sensing 12v trigger. I could put that inline with the AC into the preamp and that might do the trick.

12v trigger cable amazon

female (stereo) 3.5mm jack amazon, to hook up and hack into chassis.

Bookshelf MLTL Enclosure for W3-881SJF

- By yljhao

- Full Range

- 17 Replies

Hello everybody

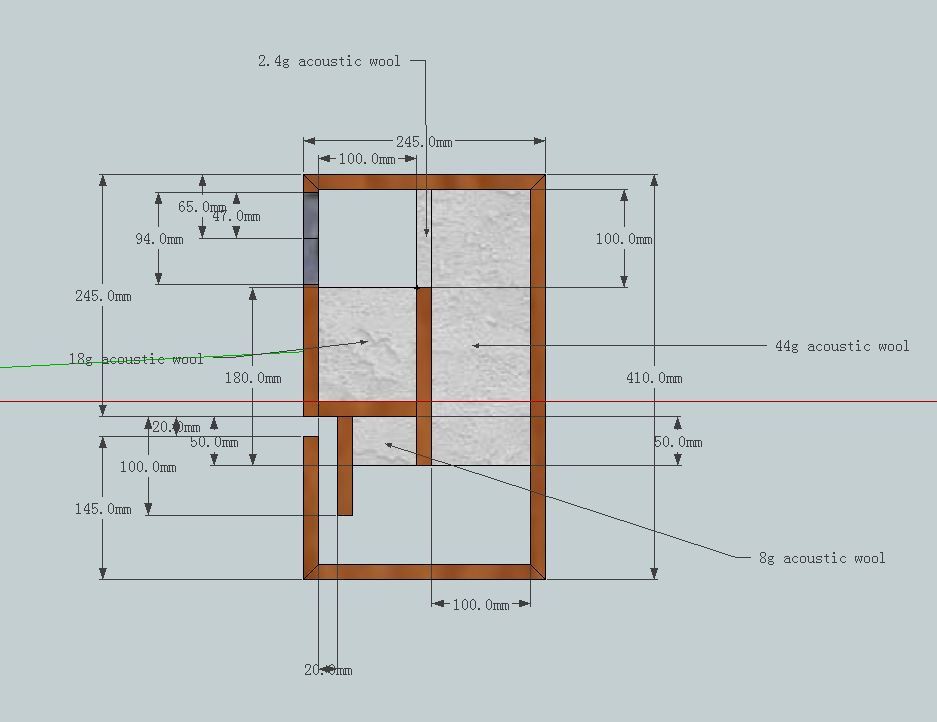

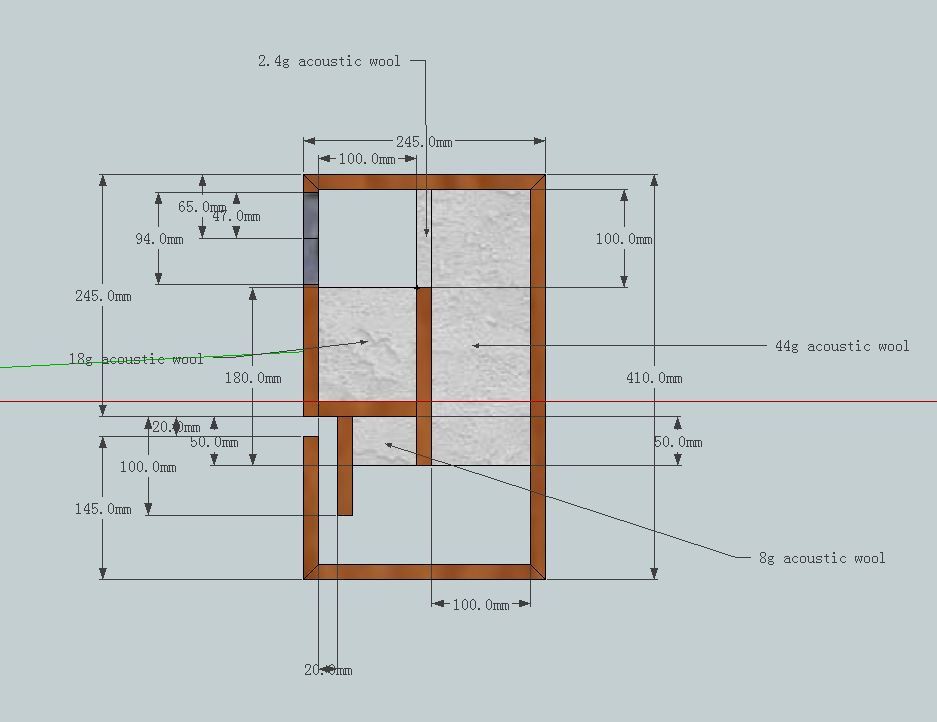

I design a new MLTL bookshelf speaker for tangband W3-881SJF.

The W3-881SJF design with 3" p.p. cone, the piston area is smaller than W4-1320.

Cross section area in W3-881SJF MLTL cabinet will smaller W4-1320 MLTL cabinet, that means smaller speaker enclosure.

That's good to me, I can saving more desktop space. 😀

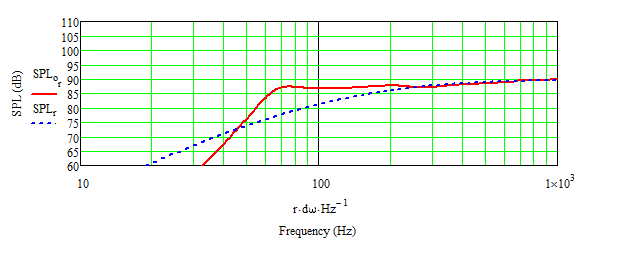

Here is the simulate SPL results, this enclosure extension bass response close to 60hz :

Enclosure 2D structure:

Enclosure 3D structure:

Speaker 3D plane sketch file : Plane

MJK worksheet analysis result : PDF(2013/08/02 updated, fix geometry and port offset parameter.)

I found a local store in Taiwan that provides enclosure manufacture and sells some models of Tang Band driver.

This is really helping me to build this project, so I ask their help to build this enclosure.

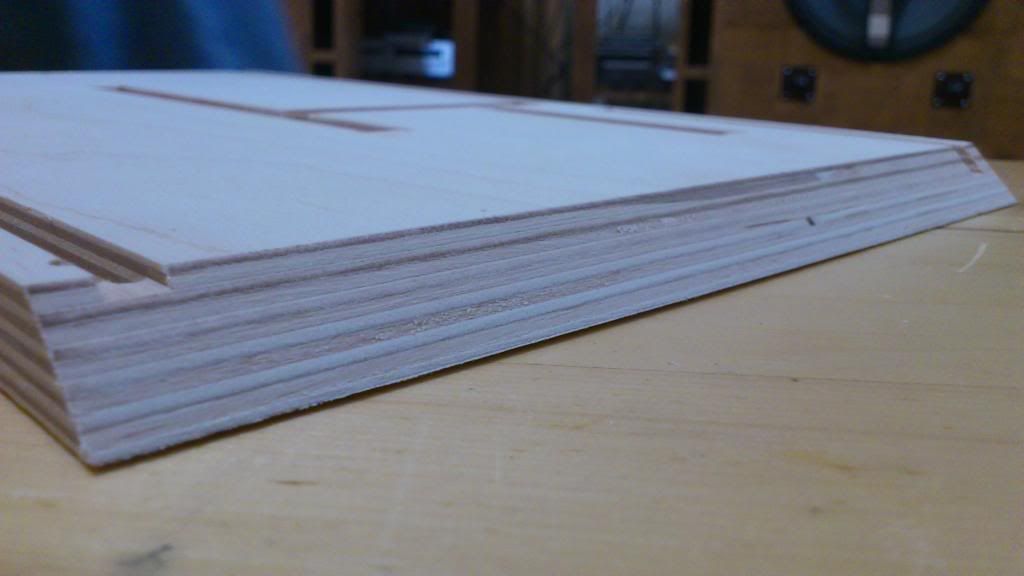

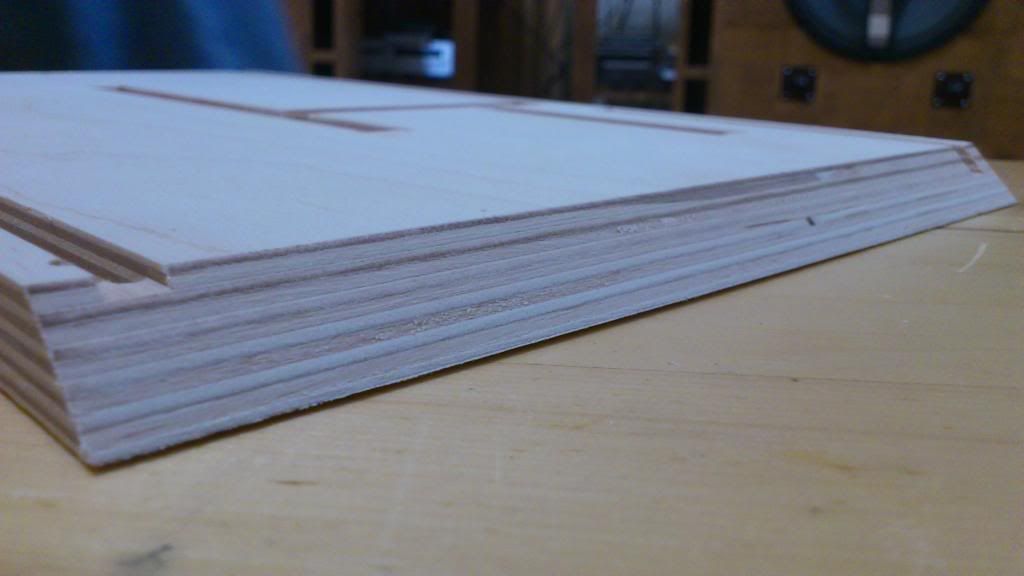

I use 15mm thick Birch plywood to build this enclosure, here are some build picture:

Cnc cutting with joint.

I love Birch plywood. 😀

Port output.

Driver placement.

W3-881SJF FIT!!! 😀

W3-315E FIT!!! 😀

Finish!

Compare with W4-1320 MLTL, the new one is smaller.

Thank you read this thread and reply.

Hope you will like it. 😀

I design a new MLTL bookshelf speaker for tangband W3-881SJF.

The W3-881SJF design with 3" p.p. cone, the piston area is smaller than W4-1320.

Cross section area in W3-881SJF MLTL cabinet will smaller W4-1320 MLTL cabinet, that means smaller speaker enclosure.

That's good to me, I can saving more desktop space. 😀

Here is the simulate SPL results, this enclosure extension bass response close to 60hz :

Enclosure 2D structure:

Enclosure 3D structure:

Speaker 3D plane sketch file : Plane

MJK worksheet analysis result : PDF(2013/08/02 updated, fix geometry and port offset parameter.)

I found a local store in Taiwan that provides enclosure manufacture and sells some models of Tang Band driver.

This is really helping me to build this project, so I ask their help to build this enclosure.

I use 15mm thick Birch plywood to build this enclosure, here are some build picture:

Cnc cutting with joint.

I love Birch plywood. 😀

Port output.

Driver placement.

W3-881SJF FIT!!! 😀

W3-315E FIT!!! 😀

Finish!

Compare with W4-1320 MLTL, the new one is smaller.

Thank you read this thread and reply.

Hope you will like it. 😀

-

Poll

Baffle step compensation sizing

This is just a poll to get a general view on preference regarding Baffle step compensation amount.

Please feel free to mention in the comments your speaker type, -3/-6/-10 dB point, room size and placement from rear and side wall.

Hope this poll will helpful to someone.

Please feel free to mention in the comments your speaker type, -3/-6/-10 dB point, room size and placement from rear and side wall.

Hope this poll will helpful to someone.

egg crate foam vs flat foam?

- Multi-Way

- 21 Replies

I'm putting together the HI-VI swans 3.1 DIY kit. They give you a bunch of regular flat 1.5'' foam to cut into pieces for the box. Would I be better with egg crate foam to help diffuse the sound waves inside the box better?? or should I just use the stuff they gave me ? 🙂

Those magnificent and easy to use cassette recorders.

- By edbarx

- Everything Else

- 43 Replies

This thread is a consequence of my nostalgia for what I still consider one of the best and simplest to use of audio equiqment: the cassette recorder and its sibling the radio cassette recorder.

Sadly, technology has taken from users their ability to record audio to a very high quality with simple and easy to access electronics these days are no longer in production. I will not go into the merits and the reasons why modern audio equipment lacks the ability of recording.

Progress has taken away the simplicity of cassette recorders and replaced it with complex digital systems which are mostly not accessible to the home user. For instance, how would anyone record audio without expensive equipment but with the same quality that was offered by humble cassette recorders?

A press of A SINGLE BUTTON was enough.

Sadly, technology has taken from users their ability to record audio to a very high quality with simple and easy to access electronics these days are no longer in production. I will not go into the merits and the reasons why modern audio equipment lacks the ability of recording.

Progress has taken away the simplicity of cassette recorders and replaced it with complex digital systems which are mostly not accessible to the home user. For instance, how would anyone record audio without expensive equipment but with the same quality that was offered by humble cassette recorders?

A press of A SINGLE BUTTON was enough.

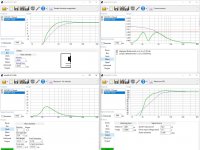

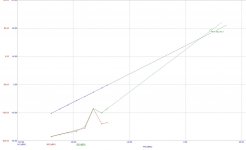

Making sense of Tang Bands W4-1720 (DIY Speedsters) in WINISD

- By v3locity

- Software Tools

- 4 Replies

Hello all!

I'm fairly new to the world of DIY audio and currently working on my first pair of 2-way desktop/bookshelf speakers. I hope this thread is not misplaced, since I don't know yet whether my problem is software-, speaker- or brain-related... probably the latter 🙂

Browsing for a suitable chassis, I read a lot about Paul Carmody's DIY Speedsters, which I'm sure are well known around here (perhaps even a DIY classic?).

I won't replicate this exact build, but I have my eyes set on the Tang Band W4-1720 in vented a 6 litre enclosure paired with Dynavox AMT-2.

As per the official pages:

A 40ish F3 with a 4" woofer in cabinet that small? Impressive! Surely I can aim for a similar result, once I get a hang of this whole DIY thing? And so I decided to feed the T/SP, box and vent data into WINISD to verify that this could actually work. WINISD won't let me specify the port length but everything else, and in fact recommends an even longer port. This is how it looks:

That's nice and smooth graph for sure, but with a steep and early dropoff. Nowhere near 45 Hz at -3dB! The Speedster's crossover doesn't seem to play a role in that (or does it? I'm only just learning how crossovers work, with XSim and SPL trace and everything, so keep in mind that I am exactly as clueless as it seems). Anyway, I've looked for other explanations. Incorrect TSP (or units) were the prime suspects. But they are all in line with the specsheet.

That's nice and smooth graph for sure, but with a steep and early dropoff. Nowhere near 45 Hz at -3dB! The Speedster's crossover doesn't seem to play a role in that (or does it? I'm only just learning how crossovers work, with XSim and SPL trace and everything, so keep in mind that I am exactly as clueless as it seems). Anyway, I've looked for other explanations. Incorrect TSP (or units) were the prime suspects. But they are all in line with the specsheet.

Except... this posting on parts express' techtalk caught my attention:

Not that smooth anymore, but it looks more in line with that infamous F3. Air speed looks good... cone excursion not so much, but that also applies to the original VAS. Now, all this reeks of confirmation bias. A woofer so widely used and nobody except one dude noticed this? Don't think so. What am I missing?

Not that smooth anymore, but it looks more in line with that infamous F3. Air speed looks good... cone excursion not so much, but that also applies to the original VAS. Now, all this reeks of confirmation bias. A woofer so widely used and nobody except one dude noticed this? Don't think so. What am I missing?

Maybe I should just call it a day, move on to a different chassis and work it from there. But I'm trying really hard to understand the basics and not go by feel. Can you help me with that? 🙂

Thank you kindly,

v3

I'm fairly new to the world of DIY audio and currently working on my first pair of 2-way desktop/bookshelf speakers. I hope this thread is not misplaced, since I don't know yet whether my problem is software-, speaker- or brain-related... probably the latter 🙂

Browsing for a suitable chassis, I read a lot about Paul Carmody's DIY Speedsters, which I'm sure are well known around here (perhaps even a DIY classic?).

I won't replicate this exact build, but I have my eyes set on the Tang Band W4-1720 in vented a 6 litre enclosure paired with Dynavox AMT-2.

As per the official pages:

(Alas, there is very little on that later.)The enclosure for the Speedster is 5.5 Liters. It has a 1.375" dia port that is 4.5" long (mounted directly behind the tweeter). This tunes the box to about 55 Hz. The -3 dB point of the W4-1720 in this size box is in the mid 40 Hz range, which is quite satisfying (more on that later).

A 40ish F3 with a 4" woofer in cabinet that small? Impressive! Surely I can aim for a similar result, once I get a hang of this whole DIY thing? And so I decided to feed the T/SP, box and vent data into WINISD to verify that this could actually work. WINISD won't let me specify the port length but everything else, and in fact recommends an even longer port. This is how it looks:

Except... this posting on parts express' techtalk caught my attention:

Changed the VAS in WINISD, and sure enough:I measured 4 of these W4s about 5 yrs. ago. The T/S specs actually were quite close to factory, eXcept Vas - it was considerably smaller (less than half of TB's spec), so much so that even Paul's 5-6L Speedster box looked a tad large! ... Vas 0.07cf (some were closer to .08, but NONE close to TB's 0.2 !)

Maybe I should just call it a day, move on to a different chassis and work it from there. But I'm trying really hard to understand the basics and not go by feel. Can you help me with that? 🙂

Thank you kindly,

v3

Xkitz 2-way Active Crossover Kit

- By Mickatroids

- Analog Line Level

- 10 Replies

I just stumbled across this crossover kit. It looks works off a single DC supply (if I have read the product manual correctly) and can be ordered with parts for different frequencies. It is listed under their 'new products for August' in their audio kits section which may explain why I had not seen it before.

Anyone have any experience with building one of these? They are only mono and I was thinking of using one for an active-crossover center speaker perhaps.

Anyone have any experience with building one of these? They are only mono and I was thinking of using one for an active-crossover center speaker perhaps.

Duelund Cu-Sn and Silver bypass capacitors Thanks!

- By Geluidloopt

- Swap Meet

- 11 Replies

Selling:

2x Duelund Tinned Copper 0.01uf/600V bypass capacitors, used 35€/pair

2x Duelund JDM Pure Silver 0.01uF/600V bypass capacitors, SOLD

Items are in Belgium, will ship worldwide

2x Duelund Tinned Copper 0.01uf/600V bypass capacitors, used 35€/pair

2x Duelund JDM Pure Silver 0.01uF/600V bypass capacitors, SOLD

Items are in Belgium, will ship worldwide

Attachments

Looking for cabinet ideas for Mark Audio drivers

- By audi0

- Full Range

- 7 Replies

I am considering building a small pair of full range bookshelf size speakers using (most probably) Mark Audio CHR70 drivers.

Anybody got any cabinet design ideas I could use?

Anybody got any cabinet design ideas I could use?

Misinterpretation of Measuremenets

- By ruffrecords

- The Lounge

- 19 Replies

It is now quite easy to make measurements of frequency response, distortion and noise using a PC and a good quality soundcard but misinterpretation of the graphs produced has led to some performance claims that sometimes defy the laws of physics especially when it comes to noise.

Here is an example from the "The Wire" thread:

https://www.diyaudio.com/forums/headphone-systems/179298-wire-ultra-performance-headphone-amplifier-pcbs.html

The second post includes an FFT plot from which the author states "the noise floor is down at -145dB" which at first sight appears to be the case as the noise seems to bump along at about -145dB. But the FFT plot is of the noise per root Hz. To get the total rms noise over the entire audio spectrum (which is what you hear and measure with a regular meter) you need to integrate these measurements over the 20KHz bandwidth. This is not complicated to do but if you assume the noise is more or less constant over the entire audio spectrum you can simplify it considerably. All you need do is multiply each measurement by the square root of the bandwidth. The square root of 20,000 is 141 so the rms noise over 20KHz is 141 times the value on the graph or 43dB higher. So the rms noise is -102dB which is still a very good result but not as incredible as the stated -145dB.

Cheers

Ian

Here is an example from the "The Wire" thread:

https://www.diyaudio.com/forums/headphone-systems/179298-wire-ultra-performance-headphone-amplifier-pcbs.html

The second post includes an FFT plot from which the author states "the noise floor is down at -145dB" which at first sight appears to be the case as the noise seems to bump along at about -145dB. But the FFT plot is of the noise per root Hz. To get the total rms noise over the entire audio spectrum (which is what you hear and measure with a regular meter) you need to integrate these measurements over the 20KHz bandwidth. This is not complicated to do but if you assume the noise is more or less constant over the entire audio spectrum you can simplify it considerably. All you need do is multiply each measurement by the square root of the bandwidth. The square root of 20,000 is 141 so the rms noise over 20KHz is 141 times the value on the graph or 43dB higher. So the rms noise is -102dB which is still a very good result but not as incredible as the stated -145dB.

Cheers

Ian

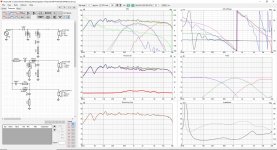

New Project Critique Please

I am about to launch into a new 3 way project and would like to hear views/comments etc. form the forum members before I commit to the driver buy.

- 3 Way initially active with Minidsp (Nanodigi + 4xKardas Toneboard + Rotel RMB1066) then maybe passive later

- Box size - Re-use Akai SW125 with extra bracing and sound deadening panels (bitumen) plus 25mm MDF baffle level with box edge - external 350 x 560 x 295mm (13-7/8" x 21" x 11-5/8") - approx 40litres net volume

- Drivers - SB WO24P-4 + Morel EM1308 + Morel ET448

- Crossovers - doing some modelling in Boxsin 2.0, Vituixcad and Jeff Bagby's PCD I get good consistent result with the published data (obviously will measure and re-do) with very good phase tracking with all LR2 electrical at 700hz and 3600hz plus a tank/notch on the woofer at 3500hz and a notch on the tweeter at 4500. Mid out of phase. The crossover point are also fairly consistent with the couple of papers that Jeff Bagby produced on the EM1308 and ET448 which gave me some confidence I was on the right track.

- Alignment - for the WO24P-4 40l is pretty much spot on for a sealed box and also can be used as a BR tuned to 28hz giving a very slight lift at 75hz, F3/6/10 are 52/38/28.5hz and 38/28.5/24hz respectively according to WinISD.

Attachments

Design to bamboozle you.

- The Lounge

- 10 Replies

Been learning Python programming language.

A bit of steep curve to start with but managed to create an small ecommerce website.

SO next step is to get the site hosted online.

Azure is very expensive so took a look at AWS.

Eventually worked out I needed AWS SDK to send website up to AWS.

I had to store a key and a security key in AWS which was done using command prompt.

So managed to upload my website but it all i get is error 403 credentials are wrong message.

SO i uploaded a node js project and that uploads and runs fine so that suggests my credentials/logon data are fine.

I had a dig around on AWS and the website is stored in a S3 container but for some reason AWS arent unzipping the output from Visual Studio.

AWS dont support "free tier" users so that was a waste of a day or two trying to get it to work. The forums seem to get very few replies.

I complained to AWS sales that their website isnt working right and they just say I have to upgrade my service package to get help.

My view of AWS is its bloated, far too complicated and extremely slow.

Azure is much better but expensive.

A bit of steep curve to start with but managed to create an small ecommerce website.

SO next step is to get the site hosted online.

Azure is very expensive so took a look at AWS.

Eventually worked out I needed AWS SDK to send website up to AWS.

I had to store a key and a security key in AWS which was done using command prompt.

So managed to upload my website but it all i get is error 403 credentials are wrong message.

SO i uploaded a node js project and that uploads and runs fine so that suggests my credentials/logon data are fine.

I had a dig around on AWS and the website is stored in a S3 container but for some reason AWS arent unzipping the output from Visual Studio.

AWS dont support "free tier" users so that was a waste of a day or two trying to get it to work. The forums seem to get very few replies.

I complained to AWS sales that their website isnt working right and they just say I have to upgrade my service package to get help.

My view of AWS is its bloated, far too complicated and extremely slow.

Azure is much better but expensive.

Lost faith in my tube tester+

- By campsquire

- Equipment & Tools

- 21 Replies

I have an early 60s Philco tube tester. It's a beautiful piece of industrial art if you ask me. The quality of the components is top notch. It looks really steam-punk too.

However.....I was fixing a friends guitar amp. Kind of a hybrid - a solid state reverb driver and effects loop implemented with op-amps, but all the rest is tube and circuit board mounted everything to my chagrin. (The Chinese have figured out how to make a tube amp inexpensive)

By the third stage the gain dropped off dramatically. In fact, on ten, the amp whispered. This was apparent using my o-scope.

This thing was giving me da bizness!

I removed all tubes and tested them - all good according to trusty Philco.

Finally I decided to measure bias voltages.

The third stage plate read 1.3 volts - ahah ---I measured the plate resistor in circuit- infinite R, it had gone open I ASSumed. I replaced the resistor and still a whisper. I measure the plate resistor it read 150k properly...what? Ok, you can't measure resistance in circuit - I should know better.

Finally in desperation I replaced the tube and voila all was good.

I took the tube (12AX7) and tested in my Philco. All measurements were good. The gain ws as good as other 12AX7s. I put the tube back in the amp - no sound. I put the tube in another amp - no sound. I put the tube int he tube tester again - measure good.

My world is rocked!

So much for my Philco.

Anyone care to comment on tube testers?

It is now industrial art only and has no other value.

I will hang it on my lab wall.

However.....I was fixing a friends guitar amp. Kind of a hybrid - a solid state reverb driver and effects loop implemented with op-amps, but all the rest is tube and circuit board mounted everything to my chagrin. (The Chinese have figured out how to make a tube amp inexpensive)

By the third stage the gain dropped off dramatically. In fact, on ten, the amp whispered. This was apparent using my o-scope.

This thing was giving me da bizness!

I removed all tubes and tested them - all good according to trusty Philco.

Finally I decided to measure bias voltages.

The third stage plate read 1.3 volts - ahah ---I measured the plate resistor in circuit- infinite R, it had gone open I ASSumed. I replaced the resistor and still a whisper. I measure the plate resistor it read 150k properly...what? Ok, you can't measure resistance in circuit - I should know better.

Finally in desperation I replaced the tube and voila all was good.

I took the tube (12AX7) and tested in my Philco. All measurements were good. The gain ws as good as other 12AX7s. I put the tube back in the amp - no sound. I put the tube in another amp - no sound. I put the tube int he tube tester again - measure good.

My world is rocked!

So much for my Philco.

Anyone care to comment on tube testers?

It is now industrial art only and has no other value.

I will hang it on my lab wall.

Flyback diode choice

- Parts

- 59 Replies

Hi. Will it be ok to use this diode 1n5711as a flyback diode on a 12V relay ?

If you had to choose the best diode for a flyback use, which one woul it be ? no matter the cost.

Thank you.

If you had to choose the best diode for a flyback use, which one woul it be ? no matter the cost.

Thank you.

Luxman R-2040 idle current?

- By iMac

- Solid State

- 0 Replies

Cant find anything about setting of the idle current for a Luxman R-2040 in the SM

Can a 60Hz woofer enclosure tune to about 40Hz?

- Subwoofers

- 17 Replies

Hi I am working on a Bluetooth stereo system, please help me with these doubts.

1. Fs of my woofer speaker is 63Hz, so can I tune the enclosure to 40Hz or low?

If no, at what frequency should I design!

2. Two woofers can share the same enclosure volume, since they are same spec and receiving the same signal?

3. Adding a speaker cloth cover in front of the port hole will affect the bass output and tuning!!?

Woofer spec: 6inch 4ohm woofer, 40Watt RMS, Peak 80Watt, 2Nos

Fs= 63Hz, Qes= 0.5, Qms= 4.77, Qts= 0.45, Vas= 15.94ltr

Tweeter: 10Watt, 4ohm, 2Nos

Amplifier: tpa3116d2, 2*80Watt

Thank you

1. Fs of my woofer speaker is 63Hz, so can I tune the enclosure to 40Hz or low?

If no, at what frequency should I design!

2. Two woofers can share the same enclosure volume, since they are same spec and receiving the same signal?

3. Adding a speaker cloth cover in front of the port hole will affect the bass output and tuning!!?

Woofer spec: 6inch 4ohm woofer, 40Watt RMS, Peak 80Watt, 2Nos

Fs= 63Hz, Qes= 0.5, Qms= 4.77, Qts= 0.45, Vas= 15.94ltr

Tweeter: 10Watt, 4ohm, 2Nos

Amplifier: tpa3116d2, 2*80Watt

Thank you

The Infinite Improbability Audio Rack

- By peppennino

- Everything Else

- 27 Replies

Hi All,

I had the necessity of a bigger audio rack for my setup, wich now includes a 4U/400 Dissipante from Hifi2000. Since I have almost zero carpentry skills, I needed a simple project but the result had to be a sturdy cabinet, since the power amp is very heavy and I needed at least 4 shelves...

And it had to be a quick project, as I have gear everywhere, faster than a warp engine...

Thanks to the plans sent to me by Syrius Cybernetics Corporation 😀 I had a way to proceed!!!

Yes, It’s time for an Infinite Improbability Drive Rack!

So, I bought some Marine Pine Plywood (or, if you prefer, Military Pangalactic Police) in form of 60X50cm boards, I used some aluminium tubes oxidized with caustic soda that I had from a previous project (something with Impulse Drive Engine ), M8 threaded rods, washers and nuts. Obviously the golden drive had to be stolen using robots… 😀

), M8 threaded rods, washers and nuts. Obviously the golden drive had to be stolen using robots… 😀

With a Point Of View Gun on hand, I started the build!

I made some wooden discs with the internal diameter of the tubes...

...holes in plywood for the threaded rods...

...and glued 'em to the shelves

I had the necessity of a bigger audio rack for my setup, wich now includes a 4U/400 Dissipante from Hifi2000. Since I have almost zero carpentry skills, I needed a simple project but the result had to be a sturdy cabinet, since the power amp is very heavy and I needed at least 4 shelves...

And it had to be a quick project, as I have gear everywhere, faster than a warp engine...

Thanks to the plans sent to me by Syrius Cybernetics Corporation 😀 I had a way to proceed!!!

Yes, It’s time for an Infinite Improbability Drive Rack!

So, I bought some Marine Pine Plywood (or, if you prefer, Military Pangalactic Police) in form of 60X50cm boards, I used some aluminium tubes oxidized with caustic soda that I had from a previous project (something with Impulse Drive Engine

), M8 threaded rods, washers and nuts. Obviously the golden drive had to be stolen using robots… 😀

), M8 threaded rods, washers and nuts. Obviously the golden drive had to be stolen using robots… 😀With a Point Of View Gun on hand, I started the build!

I made some wooden discs with the internal diameter of the tubes...

...holes in plywood for the threaded rods...

...and glued 'em to the shelves

BSC on full range

- By peterpan

- Full Range

- 5 Replies

I want to engage in single driver speakers, my only concern is, what happens to baffle step compensation? I have not seen this spoken about. Is it considered in the design of the cabinet?

Monarchy Deluxe cleaning?

- Solid State

- 7 Replies

I just bought a set of monarchy 100 watt monoblock class a amplifiers that the guy had not used for 12 years is there any cleaning methods on that type of amp thats different from a normal power amp? Ive never had a mono block or class a amp before

APPJ1601A

- By gotan

- Tubes / Valves

- 18 Replies

After ruining my Miniwatt N3 amp well, I was excited by the experience it gave me while I was listening rather than soldering, well based on that I felt the urge to get a similar one. At the time, N3 was not for sale, and I had already purchased excellent TUNGSRAM pieces from EL84, so the APPJ 1601A, which also uses EL84 power valves, came in handy.

What he says, I also love the new composition.

All I know about it is that like the N3, in principle, it is also an ultra linear SE amplifier. But how about SET or SEP? Maybe it doesn't matter.

It sounds great, I like that it consists of two units, and of course I'm not resting, I had to look at what's going on in the field of capacitors. There are one or two "suspicious" pieces, e.g. the 16V 1500 uF Rubycon RX30, which speciel I can't find in a vendor, but not even in the brochures.

I also don't understand the need for a 4.7uF 400V capacitor "400V" with the Rubycon YXG 16V 1000uF.

What he says, I also love the new composition.

All I know about it is that like the N3, in principle, it is also an ultra linear SE amplifier. But how about SET or SEP? Maybe it doesn't matter.

It sounds great, I like that it consists of two units, and of course I'm not resting, I had to look at what's going on in the field of capacitors. There are one or two "suspicious" pieces, e.g. the 16V 1500 uF Rubycon RX30, which speciel I can't find in a vendor, but not even in the brochures.

I also don't understand the need for a 4.7uF 400V capacitor "400V" with the Rubycon YXG 16V 1000uF.

Control Output Transistor with Emitter Resistor?

- By Nexus9

- Solid State

- 7 Replies

I have an array of IGBT output transistors on a heatsink (four pair), and in setting the bias for that side, I noticed that one particular transistor reads a little more than double what all the rest average. Considering that Toshiba stopped making these transistors more than ten years ago, is there any problem with doubling the emitter resistor from .47 ohm to 1 ohm to control the current flow from that one transistor? Obviously, the voltage drop over that transistor would increase, so we wouldn't use that resistor to calibrate that side, but the current should be more in line with the other transistors, so I could bias the whole group up without burning out the emitter resistor for that one wild card.

Does that make sense? Anything I'm not aware of here, like distortion effects or instability?

Thanks for your input. 👍

Does that make sense? Anything I'm not aware of here, like distortion effects or instability?

Thanks for your input. 👍

Sony preamp capacitor choices

- By Chrisr3521

- Solid State

- 27 Replies

So, going to recap this sony pre, it's a ta-86 but wanted to run through the circuit diagram to spend my money in the right places, so in the pic below have I circled all the signal caps? Thanks

Newby question about parafeed OPT

- By Windcrest77

- Tubes / Valves

- 9 Replies

The parafeed topology couples the OPT using a capacitor. Doesn't this then mean that the primary impedance of the OPT is pretty much a moot point? As long as the capacitor is sized properly for LF cutoff does the output tube really care any more what load it is working into?

For example lets say I had a 45 tube and I had three OPT's, one has a 10K primary another has a 7K primary and the last one has a 5K primary. If it was not parafeed then the 5K would be the best choice for the tube to work into and the 10K and 7K the poor choice. With parafeed is that still true?

For example lets say I had a 45 tube and I had three OPT's, one has a 10K primary another has a 7K primary and the last one has a 5K primary. If it was not parafeed then the 5K would be the best choice for the tube to work into and the 10K and 7K the poor choice. With parafeed is that still true?

STK439 Internal Component Values

Hey all, the title pretty much sums it up. All the higher wattage amps seem to get all the love but I am looking for the values of the internal components of the STK439. I have the datasheets which give an equivalent circuit but no values. I was thinking of using TIP31/TIP32 for output trannies and 2N3904 and 2N3906 for the driver section. I know TIP29 and TIP30 would be a closer match but I got a deal on the others, so was gonna give them a shot. I also have, what I am sure is a fake STK439, since I just bought it on ebay, though it seems to work ok. I suppose I could cut it open but I would hate to ruin what I paid money for. I would rather build my own as a more permanent solution. I have the original STK439 with one dead channel. I cut it open but I am not sure I can get all the right values with the connections all still in tact. Maybe I could cut the traces before and after each component?

My other option is to use the circuit shown on Fig 16 at the following link.

https://www.nutsvolts.com/magazine/article/bipolar_transistor_cookbook_part_7

Not the same output power but at 38V input it may be OK .

STK439 Datasheet: https://datasheetspdf.com/pdf/944755/Sanyo/STK439/1

I plan to release my final schematic, PCB gerber files, etc when I am done. Any help would be appreciated.

My other option is to use the circuit shown on Fig 16 at the following link.

https://www.nutsvolts.com/magazine/article/bipolar_transistor_cookbook_part_7

Not the same output power but at 38V input it may be OK .

STK439 Datasheet: https://datasheetspdf.com/pdf/944755/Sanyo/STK439/1

I plan to release my final schematic, PCB gerber files, etc when I am done. Any help would be appreciated.

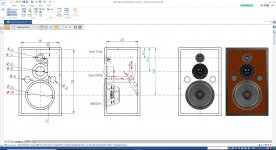

3-way speaker used as studio monitor - vertical or horizontal arrangement of drivers?

Hello,

I am building a speaker similar the to the Troels Gravesen SBAcoustics 3-Way Classic, using the same drivers. 8" woofer, 4" mid, 1" tweeter. These will be active speakers (no passive crossover).

http://www.troelsgravesen.dk/SBAcoustics-3WC.htm

These will be placed on a desk for use as monitors, similar to this photo:

Question is about the arrangement of the drivers. Either all three vertically aligned, or the mid and tweeter vertically aligned with the woofer on the side - a lot of 3-way professional studio monitors are designed like this. For example:

https://en-de.neumann.com/kh-310-a

Vertical 3-way

Pro - looks more like a conventional speaker, and can be used in other settings eg living room

Con - tweeter and mid are higher than ear height (when seated)

Horizontal 3-way

Pro - can put a riser underneath to adjust the height of the mid and tweeter to ear height

Pro - drivers closer together (more like a point source), which is better for a close listening distance.

Con - drivers are not in a line vertically

Con - narrower sweet spot due to horizontal dispersion different to vertical arrangement?

Any thoughts on this?

I am building a speaker similar the to the Troels Gravesen SBAcoustics 3-Way Classic, using the same drivers. 8" woofer, 4" mid, 1" tweeter. These will be active speakers (no passive crossover).

http://www.troelsgravesen.dk/SBAcoustics-3WC.htm

These will be placed on a desk for use as monitors, similar to this photo:

Question is about the arrangement of the drivers. Either all three vertically aligned, or the mid and tweeter vertically aligned with the woofer on the side - a lot of 3-way professional studio monitors are designed like this. For example:

https://en-de.neumann.com/kh-310-a

Vertical 3-way

Pro - looks more like a conventional speaker, and can be used in other settings eg living room

Con - tweeter and mid are higher than ear height (when seated)

Horizontal 3-way

Pro - can put a riser underneath to adjust the height of the mid and tweeter to ear height

Pro - drivers closer together (more like a point source), which is better for a close listening distance.

Con - drivers are not in a line vertically

Con - narrower sweet spot due to horizontal dispersion different to vertical arrangement?

Any thoughts on this?

Technics SL-1310 automatic doesn't function. SM needed

- By Jan Dupont

- Analogue Source

- 2 Replies

Got this Technics SL-1310 on the workbench, as the automatic doesn't work. Plays fine as manual turntable.

A look under the hood shows an automatic function (levers, wheels etc.) far more complicated than I would think was necessary.....

I can't seem to find the Service Manual anywhere online, so if you have it then please share it with me.

Thanks it advance

A look under the hood shows an automatic function (levers, wheels etc.) far more complicated than I would think was necessary.....

I can't seem to find the Service Manual anywhere online, so if you have it then please share it with me.

Thanks it advance

B&k pro10 mc preamp adjustment potentiometers?

- By Royxc800

- Analog Line Level

- 0 Replies

I just put together a power supply for the above mentioned preamp and it is working. However there are 4 little blue potentiometers mounted on the board and I’m wondering if anyone knows what they are for. I checked over the board with an infrared thermometer and the negative regulator is running a little warmer than the positive. Maybe that’s normal or maybe it needs adjustment. I haven’t run any signal through it yet just powered it up. If anyone could help it would be appreciated greatly. Thank you Mike

DIY Cables - Sourcing True OCC Copper Wire

- The Lounge

- 156 Replies

After a few bad experiences with poorly constructed cables, I am now in the process of putting together my own cables of all sorts; interconnects, speaker cable, phono leads, you name it. I believe that smart geometries, rock-solid physical connections, and high quality materials are of the utmost importance.

That being said, I am looking to source highly pure copper wire fabricated using the Ohno Continuous Casting (OCC) process, as I believe the theory behind single crystal structure is sound (pun intended).

The issue is that there is no easy way to verify that copper is ultra pure, or even cast using the OCC process. The best bet is to find a good trusted source.

Any help is truly appreciated.

That being said, I am looking to source highly pure copper wire fabricated using the Ohno Continuous Casting (OCC) process, as I believe the theory behind single crystal structure is sound (pun intended).

The issue is that there is no easy way to verify that copper is ultra pure, or even cast using the OCC process. The best bet is to find a good trusted source.

Any help is truly appreciated.

Monitor Audio ASW100 SUB schematics needed

- By NIXIE62

- Subwoofers

- 2 Replies

For the MA ASW100 SUB I need a schematics or service manual for possible repairs and maintenance in the future. The device is old, and malfunctions are possible. Without a schematics, it would be difficult for me to fix it if needed.

Bought used for my sister. Refresh was done by replacing all electrolytic capacitors, replacing thermal paste, and some damping material was added to the box. Removed bipolar electrolytic capacitors 150uF 100V (first order high pass filter for satellites), jumpers were installed. All small capacitors were in poor condition, increased ESR, some deviate a lot from the rated capacity. The big ones are still good.

Now it sounds much better than the original. Much has been gained on the naturalness of low frequencies. The bass is no longer just a boom-boom, it has a nice rounded character and sounds more natural. It is used in one modest 2+1 system, with Wharfedale Diamond 11.1 modified minimonitors.

Bought used for my sister. Refresh was done by replacing all electrolytic capacitors, replacing thermal paste, and some damping material was added to the box. Removed bipolar electrolytic capacitors 150uF 100V (first order high pass filter for satellites), jumpers were installed. All small capacitors were in poor condition, increased ESR, some deviate a lot from the rated capacity. The big ones are still good.

Now it sounds much better than the original. Much has been gained on the naturalness of low frequencies. The bass is no longer just a boom-boom, it has a nice rounded character and sounds more natural. It is used in one modest 2+1 system, with Wharfedale Diamond 11.1 modified minimonitors.

Attachments

For Sale Pathaudio resistors

- By Geluidloopt

- Swap Meet

- 2 Replies

New and unused Pathaudio resistors, bought for a Hiraga Altec VOTT A5 crossover

2x 68ohm

2x 6ohm

2x 9ohm

2x 12ohm

12€/piece

80€ for the lot

2x 68ohm

2x 6ohm

2x 9ohm

2x 12ohm

12€/piece

80€ for the lot

Attachments

JL Audio 250/1v2 idle current cycling maxing out PS every 3 seconds, video included.

Just got this in, went to test it and noticed soon as it’s turned on it starts cycling between low/normal idle current to very high, actually maxing out PS into CC mode, back down to low and back up about every 3 seconds. I have never seen an amp do this before, would like to find out if anyone has seen this before I give it some real power to test it as I don’t want to make the problem worse. There was some ?dried soda gunk? near knobs/terminals but nothing on the boards inside, doesn’t look like it’s ever been serviced either. Was told it worked.

Login to view embedded media

Any insight greatly appreciated, searching the net didn’t result in any answers :/

Login to view embedded media

Any insight greatly appreciated, searching the net didn’t result in any answers :/

Any simple DIY music server based on a Pi3?

- By Giovanni1968

- PC Based

- 1 Replies

Hello,

at this moment in time I am using an old MacMini 2010 which streams lossless music to a Beresford Caiman SEG DAC, it is ok, I can run it headless through Audirvana and I does pretty well, the software is not the simplest and most comfy to create playlists etc but it does fine, what I miss is web radio and I'd also like to use the Raspberry Pi3+ I used to run Volumio with, I didn't like to have the board flying around the desk, another AC adapter and too many cables so I am wondering if there is some DIY project which fits in a single box a Pi, it's power supply and, eventually, a DAC which might be as good or better than the MacMini otherwise I'd leave the world as it is and just miss web radios which are nice to discover new music.

Grazie

at this moment in time I am using an old MacMini 2010 which streams lossless music to a Beresford Caiman SEG DAC, it is ok, I can run it headless through Audirvana and I does pretty well, the software is not the simplest and most comfy to create playlists etc but it does fine, what I miss is web radio and I'd also like to use the Raspberry Pi3+ I used to run Volumio with, I didn't like to have the board flying around the desk, another AC adapter and too many cables so I am wondering if there is some DIY project which fits in a single box a Pi, it's power supply and, eventually, a DAC which might be as good or better than the MacMini otherwise I'd leave the world as it is and just miss web radios which are nice to discover new music.

Grazie

Rockford 4020DSM

I've got a Rockford 4020DSM with one blown channel. The outputs are BUZ11A and IRF9530 with 10ohm gate resistors. Can I sub IRF540 and IRF9540?

Does anyone have the schematic for this? I'm also getting a little noise on the speaker negatives. Whole amp could likely use a recap...

Does anyone have the schematic for this? I'm also getting a little noise on the speaker negatives. Whole amp could likely use a recap...

Fender FM212R Tone Pots Acting As Volume

- By xtwentyseven

- Solid State

- 0 Replies

Current Issue is that clean channel tone pots R10, R11 and R12 all feed completely to ground when set to 1. As they are raised the volume goes up, but so does some noise (more noise on the high, medium noise on the mid and lower for the low. If any of those three pots are raised a slight amount past 1, the signal comes in. I have studied the schematic and am having trouble figuring out where the problem is.

Some background: a few years ago my overdrive channel pot was not reliable (sound was very low. If I moved the volume back and forth it would work, but not while staying still. Last year I cleaned all the pots and the overdrive started working again, but the clean channel began to have some distortion.

Last week I started trying to find the issue. Opened up the amp and checked for bad solder joints. I re-flowed anything that looked a bit suspect. Afterward, I had no sound from clean channel at all. Reflowed some more joints and got to the issue I’m currently experiencing.

I have confirmed the FX Return works, Footswitch also works. I’m pretty sure the issue is in the tone circuit, but would appreciate any direction from experienced guys. Attached is the schematic.

Some background: a few years ago my overdrive channel pot was not reliable (sound was very low. If I moved the volume back and forth it would work, but not while staying still. Last year I cleaned all the pots and the overdrive started working again, but the clean channel began to have some distortion.

Last week I started trying to find the issue. Opened up the amp and checked for bad solder joints. I re-flowed anything that looked a bit suspect. Afterward, I had no sound from clean channel at all. Reflowed some more joints and got to the issue I’m currently experiencing.

I have confirmed the FX Return works, Footswitch also works. I’m pretty sure the issue is in the tone circuit, but would appreciate any direction from experienced guys. Attached is the schematic.

Attachments

Looking for a couple of decent 6V6G tubes for a project, as much about 'form' as 'function'.

- By Wharf_Creek

- Parts Connexion

- 0 Replies

As per the title, I'm looking for a couple (2, 3, 4, ??) of the 6V6G 'coke-bottle' type tubes for a project I'm working on.

This project will be a 'clone' of the Fender Tweed 'Champ' amp, but a 'chassis only' unit, no speaker or enclosure. So, the chassis will sit atop what ever speaker cabinet gets chosen. As it will be fully visible, I'd like to give it some 'aesthetic' value as well, so I thought using a 6V6G might be kind of 'interesting'.....from a 'looks' standpoint.

So, if anyone can help, please email me at Wharfcreek at Outlook dot com.

Many thanks,

Tom D.

This project will be a 'clone' of the Fender Tweed 'Champ' amp, but a 'chassis only' unit, no speaker or enclosure. So, the chassis will sit atop what ever speaker cabinet gets chosen. As it will be fully visible, I'd like to give it some 'aesthetic' value as well, so I thought using a 6V6G might be kind of 'interesting'.....from a 'looks' standpoint.

So, if anyone can help, please email me at Wharfcreek at Outlook dot com.

Many thanks,

Tom D.

Capacitors for Crossover

Hi, I am wanting to do a minor upgrade of the caps and resistors in a pair of PSB B6 speakers just for fun. The crossover uses 15uf 100v and 12uf 100v electrolytics.

My question is, can I use non electrolytic film caps with the same capacitance but higher voltage, say 250v to 400v?

I am also replacing the cheap sandcast resistors with Mills of the same values.

Thanks!

My question is, can I use non electrolytic film caps with the same capacitance but higher voltage, say 250v to 400v?

I am also replacing the cheap sandcast resistors with Mills of the same values.

Thanks!

Resistor position in passive crossover

I'm adding a few Mills MRA-12 resistors to my crossovers and there isn't room to secure them to the board. Would they work just as well with the leads solderd to connections and the resistors suspended above the board?

Open Baffle Speakers

Hi guys

Has anyone build or heard Troels Gravesen's OBL-15 open baffle speakers?

OBL-15

http://www.troelsgravesen.dk/OBL-15/OBL-15-1-large.jpg

If so what are your thoughts on these, or Open Baffles's in general?

Cheers

Has anyone build or heard Troels Gravesen's OBL-15 open baffle speakers?

OBL-15

http://www.troelsgravesen.dk/OBL-15/OBL-15-1-large.jpg

If so what are your thoughts on these, or Open Baffles's in general?

Cheers

Orchard Audio Annual Pi Day Sale -- 3.14

- By orchardaudio

- Vendor's Bazaar

- 1 Replies

Discount Codes:

"40pi" - $125.6 off PecanPi Streamer Ultra

"20pi" - $62.8 off PecanPi Streamer

"10pi" - $31.4 off PecanPi DAC

Sale ends on 3/15/2022, offer only valid while supplies last.

Acurus RL-11 rebuild

- By shawnra

- Analog Line Level

- 12 Replies

Well I haven't posted for a while so I thought I'd share my latest project of rebuilding an Acurus RL-11. I rebuilt an A-150 a while back and I was looking to find a RL-11 to match it, and honestly I just can't live without remote volume anymore :=) so the RL-11 was my only option in the Acurus line.

So some of the improvements I saw that could be made were in the power supply for the preamp section, maybe improve the circuitry a bit, and the volume control on this unit had seen better days so it needed replacing.

The biggest problem I see with this preamps power supply is that the transformer is undersized, the regulator for the preamp looks pretty good and it is mostly separate from the volume control voltage. The only place where they are tied together is for the relay that ungrounds and mutes the input signal. I had an parallel regulated power supply already so I decided to go a bit overboard on it but I would of been happy with just upgrading the transformer if I didn't already have the supply. So I put the parallel regulator and a 25 VA transformer in a case I had from an old frequency counter and used XLR jacks to connect it to the preamp. I tried to match the old voltage of 17.5-0-17.5 volts as closely as possible.

So some of the improvements I saw that could be made were in the power supply for the preamp section, maybe improve the circuitry a bit, and the volume control on this unit had seen better days so it needed replacing.

The biggest problem I see with this preamps power supply is that the transformer is undersized, the regulator for the preamp looks pretty good and it is mostly separate from the volume control voltage. The only place where they are tied together is for the relay that ungrounds and mutes the input signal. I had an parallel regulated power supply already so I decided to go a bit overboard on it but I would of been happy with just upgrading the transformer if I didn't already have the supply. So I put the parallel regulator and a 25 VA transformer in a case I had from an old frequency counter and used XLR jacks to connect it to the preamp. I tried to match the old voltage of 17.5-0-17.5 volts as closely as possible.

Attachments

How many times could you remove/install the wood screws that mount the speaker driver?

- By Kiq8787

- Full Range

- 6 Replies

Hi,

This more of general question with wood screws and the wood for loudspeakers. For retail speakers, if you were to remove the screws and then later

put them back on, how many times could you do that before the wood gets messed up?

I’m pretty sure it’s MDF wood. I was planning to remove the drivers so I can add different color vinyl wrap then put the drivers back on.

This more of general question with wood screws and the wood for loudspeakers. For retail speakers, if you were to remove the screws and then later

put them back on, how many times could you do that before the wood gets messed up?

I’m pretty sure it’s MDF wood. I was planning to remove the drivers so I can add different color vinyl wrap then put the drivers back on.

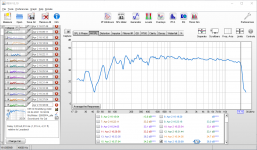

Digital BSC question

Some trade-offs of a 2-Way Waveguide Speaker played through

# # # # # # # # # # # # # # # # # # # # # # # # # # # # # # #

Today, I quickly assembled digital filters for my Hypex FA123 driven Econowave prototype. I meassured indoors gated with Arta and REW, the speaker on a "stand" (table on a table) and corrected the observed FR with Hypex Filter Designer. I was happily listening to the very 'clear sound' until I saw a video on youtube where someone showed his 3-way which was allegedly playing down to only f3 @55, but it sounded fuller than my speaker which was calculated to reach f3 of 35 to 38. Then I realised I forgot baffle step compensation!

I have not done near-field or mic-in-box measurements of the bass response yet so tried a free hand BSC on the go. I ask for your opinions if this is a legit exploit, this is what I did. All corrections up to step 3 concern the woofer channel only:

The speaker has a lot of foundation now, so as a side issue I also reduced the bass boost by 2 dB. WinISD suggest f3 is now at 38 instead of 35 and shows a gentler slope to f6=32 and f10=27. I did this because at low volumes there was already a lot of energy in the room now and I was limiting it so to not get problems with the neighbors, but I was missing presence.

Some introductory remarks in the meantime said:This thread was started to tackle my first and most pressing questions I had when I began working on an Econowave-inspired, Hypex-powered digital 2-Way speaker. Throughout the course of my trials and errors, reading and simultaneous developements elsewhere, I learned some assumptions that where stated by the original developers had to be discarded. Most noteworthy the asymmetric waveguide and the close center-to-center distancing. Using the speakers from a floor level also does not make sense and a much more aggressive EQ-ing could be done. If one is not in pursuit of absolute audio perfection, on could state the question whether it is actually neccessary to use such big boxes. Given that power is cheap and active solutions with DSP abilities are readily at hand and many big commercial manufacturers implement heavy DSPing in ther Pro grade products. Without a doubt, if a passive solution was intended, I would now pursue a floor standing, tall but shallow box, as this is needed for a good position of the image anyway and also due to volume considerations, and would possibly implement a free-stand waveguide on top. With DSP and ample power at hand, I will instead look into minimizing the footprint. This is why my endeavour has not ended and is still in the making. Please understand this thread as an ongoing elaboration of what is actually needed by a certain user-type and what can be achieved with some compromises. Over the time, I will annotate my findings in this post as a list and resource.

# # # # # # # # # # # # # # # # # # # # # # # # # # # # # # #

Today, I quickly assembled digital filters for my Hypex FA123 driven Econowave prototype. I meassured indoors gated with Arta and REW, the speaker on a "stand" (table on a table) and corrected the observed FR with Hypex Filter Designer. I was happily listening to the very 'clear sound' until I saw a video on youtube where someone showed his 3-way which was allegedly playing down to only f3 @55, but it sounded fuller than my speaker which was calculated to reach f3 of 35 to 38. Then I realised I forgot baffle step compensation!

I have not done near-field or mic-in-box measurements of the bass response yet so tried a free hand BSC on the go. I ask for your opinions if this is a legit exploit, this is what I did. All corrections up to step 3 concern the woofer channel only:

- Step 0) REW frequency response shows good crossover (1,2 kHz), cannot see bass response because of room

- Step 1) Taking a baffle step simulation from vituixCAD

- suggested values: -6 dB high shelf with center ~ 175 Hz, -2 dB cut at 500 Hz

- Step 2) what I did in Hypex Filter Designer:

- 2a) high shelf, center frequency 160 Hz, Q=0,7, -4 dB

- 2b) cut, center frequency 500 Hz, Q =4, -2 dB

- Step 3) in Hypex Filter Designer:

- add -4 dB gain to compression driver channel to realign both drivers at crossover frequency.

The speaker has a lot of foundation now, so as a side issue I also reduced the bass boost by 2 dB. WinISD suggest f3 is now at 38 instead of 35 and shows a gentler slope to f6=32 and f10=27. I did this because at low volumes there was already a lot of energy in the room now and I was limiting it so to not get problems with the neighbors, but I was missing presence.

Attachments

Problem rec out Sony TA-AX44

Hi guys, I'm new around here.

I have a problem with an old amplifier that I inherited from my father, it is the sony ta-ax44.

I use it mainly to listen to some vinyl records but I have the problem that the rec out does not work. When i connect the output rca cable, I see some small sparks come out in the channel mass, and this causes the signal to clip and a protection click is heard inside the amplifier.

After moving the rca connector for a while, I managed to make it sound on both channels well when i push the mass of the rca connector so it touches the chassis, but as soon as I released and stopped pressing the conector, this would work badly again.

I have a welder, so I've opened it in case the welds were cold and I have not seen anything strange.

maybe someone can guide me, as i think it should be pretty simple to repair.

I have a problem with an old amplifier that I inherited from my father, it is the sony ta-ax44.

I use it mainly to listen to some vinyl records but I have the problem that the rec out does not work. When i connect the output rca cable, I see some small sparks come out in the channel mass, and this causes the signal to clip and a protection click is heard inside the amplifier.

After moving the rca connector for a while, I managed to make it sound on both channels well when i push the mass of the rca connector so it touches the chassis, but as soon as I released and stopped pressing the conector, this would work badly again.

I have a welder, so I've opened it in case the welds were cold and I have not seen anything strange.

maybe someone can guide me, as i think it should be pretty simple to repair.

Attachments

Overly Large Sub Build

- By cobrettie

- Subwoofers

- 6 Replies

Hello all, I know there is quite a few posts about jbl 2242 builds and originally I was going to build a pair of 4645C clones... However I ended up purchasing a pair of Altec 817a from my local school district recently (couldn't pass them up, also with a pair of mrii 594 and 291 drivers!!! They were pretty much giving away that "junk").

So right now I'm thinking of putting the 2242s under the 817 cabinets but results in a huge box. (exterior dimensions around 26.5"x33.75"x37.5") I was just planning on maybe filleting the corners with sonotube and adding an additional interior rear baffle, then pack it all with sand. Targeting the internal volume of the box back to around 8 CF. I have a pretty decent sized listening area but the layout won't really allow the subs to placed adjacent unless I got rid of my vinyl storage. The 817s replaced my pair of jbl 2226s in a 4507 boxes which were much smaller.

Before I commit to the build, I was just wanted to see if there were any other ideas people may have. I know it's all PA stuff, but I'll be using it mainly for home hifi listening.

Thank you in advance!

So right now I'm thinking of putting the 2242s under the 817 cabinets but results in a huge box. (exterior dimensions around 26.5"x33.75"x37.5") I was just planning on maybe filleting the corners with sonotube and adding an additional interior rear baffle, then pack it all with sand. Targeting the internal volume of the box back to around 8 CF. I have a pretty decent sized listening area but the layout won't really allow the subs to placed adjacent unless I got rid of my vinyl storage. The 817s replaced my pair of jbl 2226s in a 4507 boxes which were much smaller.

Before I commit to the build, I was just wanted to see if there were any other ideas people may have. I know it's all PA stuff, but I'll be using it mainly for home hifi listening.

Thank you in advance!

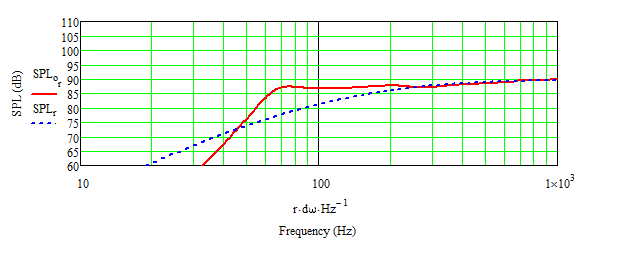

Boundary gain compensation

I like the idea of having the option to place my speakers either far away or very close to the front wall, whatever the situation demands, with the convenience of a flick of a switch. I didn't know if it was actually possible until I saw the 'Normal/ Boundary' adjustment knob at the back panel of Revel F208.

Does anyone have any idea how this could be implemented? One of the photo I saw suggests this is done with resistors only.

I have attached some photos of what the boundary compensation actually does. Basically, it reduces the level by 4dB around 100Hz in a gradual slope from 400Hz.

It does not attenuates the very low frequencies by much.

Does anyone have any idea how this could be implemented? One of the photo I saw suggests this is done with resistors only.

I have attached some photos of what the boundary compensation actually does. Basically, it reduces the level by 4dB around 100Hz in a gradual slope from 400Hz.

It does not attenuates the very low frequencies by much.

post's send-time

- By myleftear

- Forum Problems & Feedback

- 2 Replies

Here’s a funny issue: the post appear to come from the future? (Watch the time on the first 2 notifications; the second screenshot was made after refreshing the page…)

Attachments

Raspberry Pi 4 Linear Power Supply

- Power Supplies

- 27 Replies