Good morning and happy Monday, y'all! I hope everyone had an excellent Thanksgiving this year. 🙂

Before I get into it, I want to thank Victor Kung @ VKAudio for his assistance and patience in answering my questions, particularly about Capacitor upgrades. His knowledge is invaluable and he's a good guy to have in your corner when you need help. I also want to thank TubeDepot which is where I purchased my kits from. Honestly, if I'd have spotted Victor's store earlier, I probably would have purchased directly through him. However, I have no complaints whatsoever with my transaction as TubeDepot has always provided me with great products at fair prices.

With that done, I'll move on.

I've been an audiophile for more than 35 years. Music is the one thing I can depend on to get me through each day. It make a bad day turn good and make a good day even better.

Now, I'm not an audiophile in the "I own a set of Infinity IRS-V speakers powered by 3 Macintosh Amplifiers" sort of sense. I would love to be there, but that's a financial commitment I'm simply just not able to justify. However, I absolutely love how a quality sound system can bring out deep emotions, stir up memories of people and places, and transport you to another time. It has that much influence.

Until recently, I've always been a solid state kind of guy. Part of the reason is that the generation I grew up in was on the leading edge of Transistor technology with vacuum tube well on their way out the door. In fact, about the only thing you could buy with vacuum tubes in the '80s were guitar amps, and even those were rapidly declining in favor of the less expensive, sturdier solid state equipment. I do remember as a younger child, my parents and grandparent having old vacuum tube equipment, and I would spend many hours listing to records on this equipement. This probably set my mental bar for audio quality.

I guess that the other reason I was into solid state was that I was very big into car audio in the '80s and '90s, and there just isn't any place for vacuum tubes in car audio! I see there are companies that actually specialize in this kind of equipment, but that all seems a bit gimmicky. LOL

A couple years ago, I really started getting back into the idea of analog sound. I have always love vinyl and actually had an impressive collection until our house burned down in 2015 and we lost everything. Almost 40 years of collecting lost forever. Anyway, while I enjoy the analog nature of vinyl, it's always been through solid state amplification. Not that it was bad... In fact it's quite the opposite. It's just that I always did feel like something was lacking. Some level of depth or warmth that I remembered from my childhood that I just couldn't seem to reproduce. So decided to start looking around at what's available.

Vacuum tube audio equipment is clearly big business these days, with companies building preamps, amps, active crossovers, and other stuff that vary in range from hundreds to hundreds of thousands of dollars. The array is as dizzying as it is almost endless. Reviews leave you with more questions than answers, and almost anything with decent reviews will empty your wallet in short order. But the question at the end of the day is, "Is a $10,000 amplifier any better than a $1,000 one?" I'm sure that at the end of the day the answer would be, "Yes, the $10,000 amp is better." But the next question would logically be, "Is it $9,000 better?" In many cases the answer would be solidly, "No."

With this in mind, I started looking at many different amplifiers in the "under $5,000" range. There are a number of what I presume to be quality products on the market in this price range, but still couldn't make heads or tails of what was actually worth dropping my hard-earned cash on. Oddly enough, while researching different amplifiers, I came across a DarkVoice 336SE headphone amplifier in a pawn shop and scooped it up. Even before I plugged it in and turned it on, I was already looking at reviews, schematics, and upgrades to this unit. My first 20 hours into it, I had already order a variety of tubes so that I could start rolling as time permitted. I do realize that this little amp met with mixed reviews, but was mostly positive. I also discovered that there were some very easy improvements that could improve the quality and reduce the idle noise of the amp. I, personally, love this little amp. It brought back that sound I so vividly remember from my youth. The depth and presence that I felt I was missing was restored. Even with high quality digital recordings, there was a sonic improvement. That's was it. I'm now hooked on tube amplifiers!

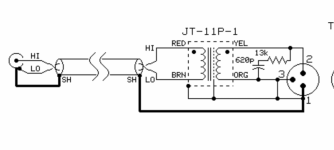

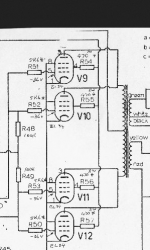

I figured the best place to start would be at the bottom of the chain and slowly work my way up. After digging around for several months, I came across the TU-8200R Amp kit along with the TU-8500 Pre-Amp kit. I found it intriguing as it was a full-on, build-it-yourself sort of kit that came with everything. The reviews on it were outstanding, and the documentation on component upgrades was well defined and easy to follow. The only pitfall was that some of the upgrade components were no longer available, such as the AMTRANS components, but c'est la vie. The biggest improvements seemed to come from using Mundorf coupling caps and Lundahl transformers anyway, so that was what I opted with for the final build. Tube rolling will come later. Ordered through TubeDepot and then waited for the brown Santa to show up in his trusty delivery van.

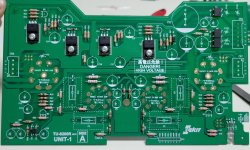

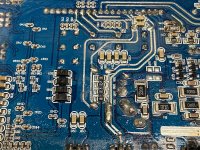

I did my process a little backwards, starting with the pre-amp first as I was waiting for my Lundahl transformers to come from VKAudio. Out of the box, this thing is a solid work of engineering. The chassis was remarkably clean in design and fit together well. I may, at some point, disassemble and have the chassis powder coated a different color, but it's great as it is. The PCB is laid out very well, all the components were grouped in nice, organized baggies, and the instructions were very clear to understand. Now, I'm an electronics engineer by trade (digital, not analog), so following a schematic and PCB layout is a simple thing for me. Not to mention that I have a helluva soldering station. PCB assembly and soldering didn't take long, and within a couple hours I had the whole thing put together. Slapped in the J/J tubes, connected my Technics 1200 turntable to it, and hooked it up to an old Pioneer SX-980 with Kenwood KL-777A speakers and then let 'er rip.

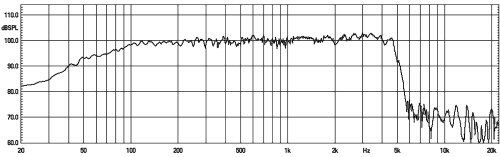

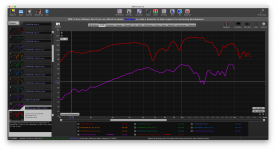

I let the pre-amp run for about 2 hours just to let things settle in and then dropped Tom Petty on the platter. Even with the tubes barely even run, the difference was immediate. The sound was warmer with vocals that were more in the foreground. I played this album and then moved on to my next favorite, Pink Floyd - Wish You Were Here. Shine On You Crazy Diamond (Parts 1-5) is my quintessential sound system test. For me, this track reveals the soundstage and depth of a sound system, or even the capability of individual components, and let me tell you, the TU-8500 did not disappoint. I went with this setup for several days, and with each passing hour the pre-amp continued to provide subtle improvements in sonic and tonal quality. I now realized I needed to get the amplifier built!

Thanksgiving intervened and I had to do all that family stuff. While I always enjoy being with family, I was quietly preoccupied with wanting to put the amp together. Our office was closed for Black Friday so I headed in and began the process of assembling the amplifier in peace and quiet. Again, all the details were impeccable and assembly was completed in a matter of hours. I'm a bit of a perfectionist, and since the tubes are exposed in this unit, I spent a little extra time making sure that the tube sockets were level and even. Unfortunately, during my final assembly of all the PCB units, I forgot to solder the bridges on the bottom of the input/output board which left me a little perplexed when I fired up the amp and had no sound. A few muttered curse words and 45 minutes later, all was good.

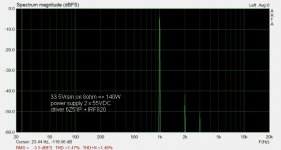

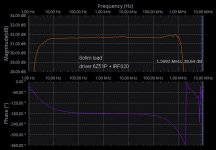

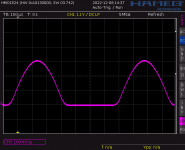

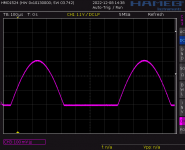

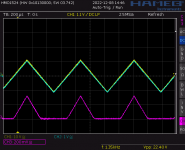

I've always heard from people that 10 watts of power from a tube amp is like 50 watts of power from a solid state amp. I always took these comments with a large degree of skepticism since I've always argued that "Watts is watts." I guess that it's true that wattage is a pretty stable measure of audio output. But let me tell you right now... This little amplifier that only runs 8 watts per channel sounds better than my 100 watt per channel Onkyo receiver (in stereo mode) running through a set of B&W 603 S2 speakers! Of course, the Onkyo running in 7.1 will simply outmatch almost any 2 channel amplifier for range and soundstage, but in 2 channel mode I would take the little tube amp every time. There is no absolutely no hint of hiss or hum at idle with no input, even with headphones on. It is dead quiet until you feed the signal back into it and then it just fills the room.

I just couldn't believe the quality of the sound the TU-8200R produces at a pretty solid listening level. It's certainly loud enough that I can feel immersed in the music, and that even with the TU-8500 pre-amp on a flat 1x gain on the inputs. I haven't even turned it up to 3x yet, and from what I've read so far, the amplifier can certainly handle the higher input levels without becoming too distorted. I may give that a try tonight and see how well it handles. I expect it may pick up some signal noise, but I can't say until I give it a spin.

As an aside, the amplifier works great with a set of high quality, high impedence headphones. My Sennheiser HD-650, which works fantastic with my DarkVoice 336SE, sounds fantastic with the TU-8200R. Of course, you don't buy an amp like this just to plug in a set of headphones. It's just nice to know I'm not losing anything in sonic quality. My DarkVoice picks up stray interference with the volume turned up and no live signal coming in, but I think that has more to do with being pretty close to my monitors on my computer desk. I've moved it to another location and that noise disappeared. However, I do not get any noise with this combination of pre-amp and amp sitting in the same location, so the DarkVoice might need a little more input filtering. I did install the PS-3249 DAC module and that works just as I would expect. I don't expect to use it much, but it's there if I need it and it doesn't take away from anything when it's not plugged in.

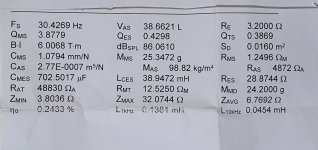

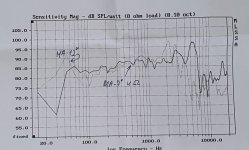

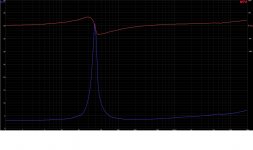

Overall, this has been an absolutely fantastic kit build. It's a pretty easy go, provided you have a resonable level of skill with soldering. The rest is just following instructions. I did take the amp apart and installed the original transformers just for a quick listen, and the sound did have a little bit of dryness to it. I can't quite explain it, but it felt like some of the low frequencies were a little muddled and washed out which took away from some of the depth of the soundstage. I can't say for highs since I have tinnitus (too many years of concerts and loud car audio) and can't hear anything above about 12,000 Hz, but the range I can hear still seemed to be pretty clear and sharp.

Tube equipment is clearly the way I need to go in the future. I got my feet wet and I'm now ready to jump in. Just for grins, I've already ordered and received the TU-8550 pre-amp and will soon order the TU-8900 amplifier. I'm ejoying the building of these kits and have been absolutely floored by the sound quality of both the pre-amp and amplifier. I mean, for the price you just can beat it. And with the ability to swap power tubes in the TU-8200 between the 6L6, KT88, EL34, 6550, and possibly even the KT90 (I don't know if KT120 would work), all with auto biasing, it makes tube rolling a fun (albeit potentially expensive) adventure. But if you're going to tube roll, then this is a great way to start out.

Again, many thanks to Victor Kung, TubeDepot, and also to Elekit and the infamous Mr. Fujita. Excellent work by everyone in bringing this exceptional product to market and making it affordable to the average hobbyist. It provides entry level access to quality tube audio equipment as well as a platform in which to build a solid foundation of understanding how tube audio equipment works. Well done!!!

TL;DR

I bought the Elekit TU-8200R amp and TU-8500 pre-amp kits along with Lundahl transformers and Mundorf caps for the amp. I assembled them and they are *******' AWESOME! Do yourself a favor and get these for yourselves. You can't beat the quality, especially for the price.