I have previously built amplifiers dissipating over 32W of heat using porous ceramic heatsinks.

https://www.diyaudio.com/community/...and-heatsinks-using-ceramic-heatsinks.380763/

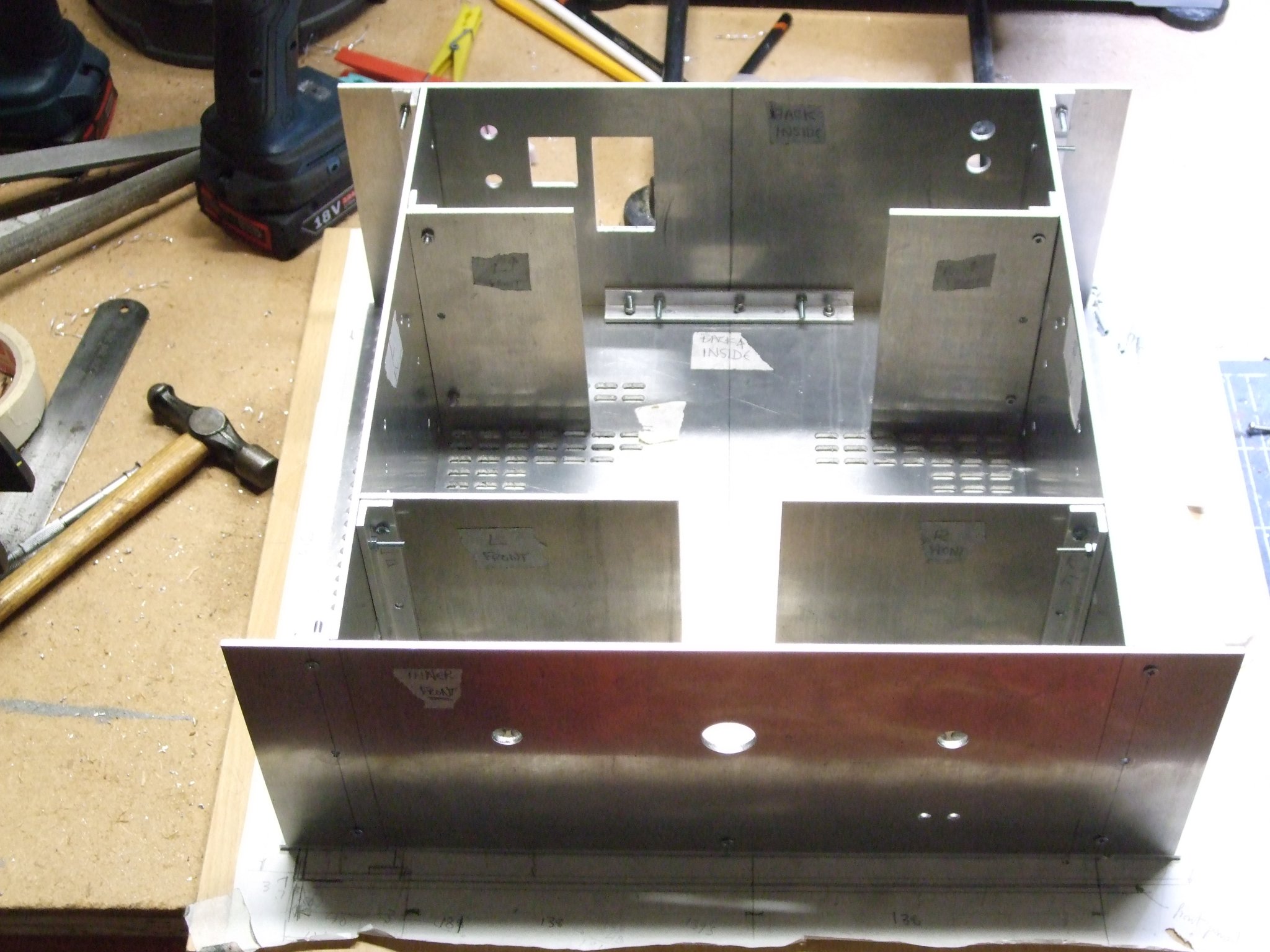

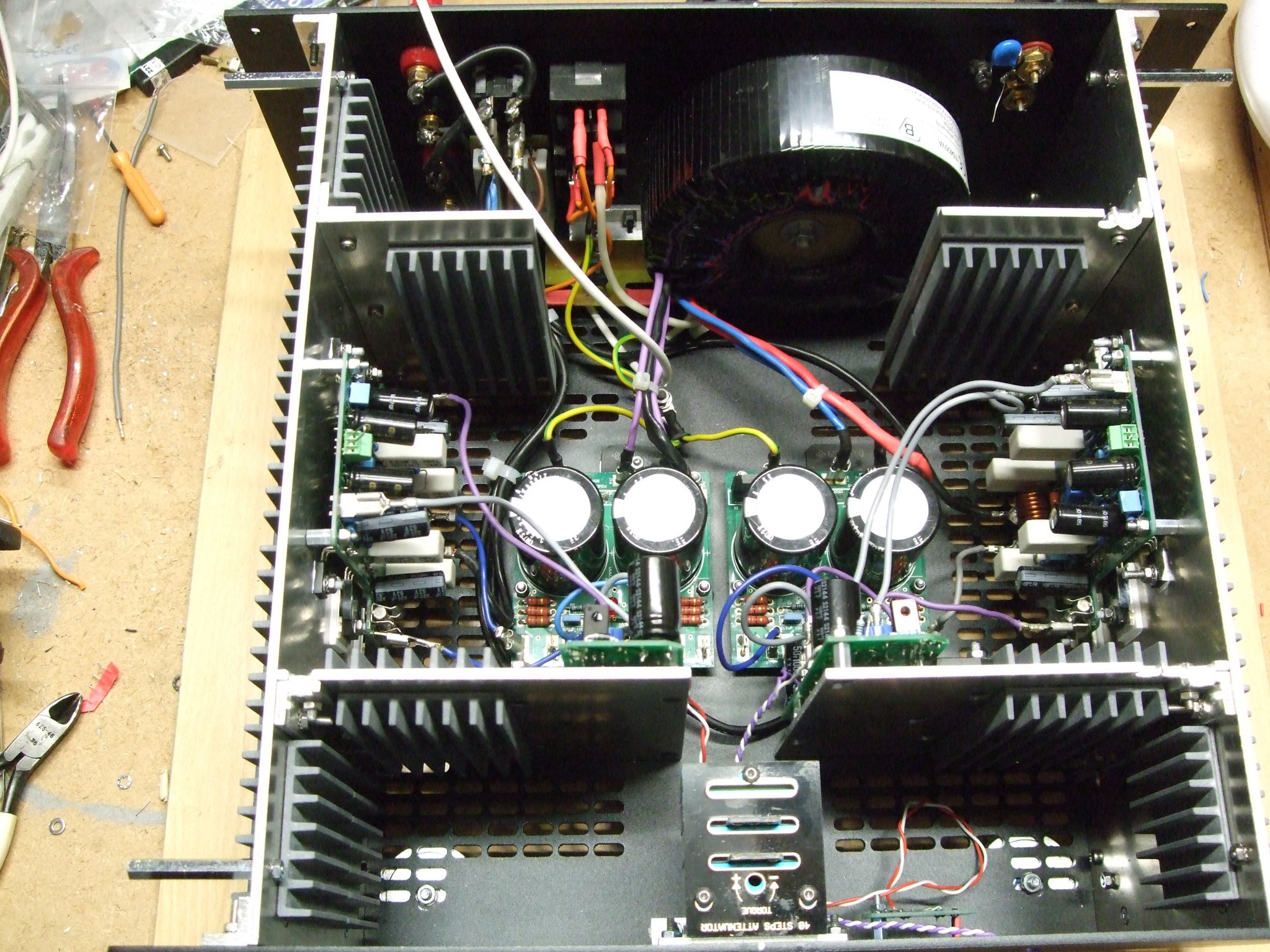

I wanted to rebuild my Ovation SX 15W per channel class-A amplifier which dissipates 120W as heat. The original SX build used an off the shelf case which was large and heavy so I designed a new one using the technique I previously used in my “headinclouds” KGSShv Carbon ES headphone amplifiers dissipating about 32W. The cases are all 3mm sheet aluminium alloy and the heatsinks are porous ceramic with adhesive pads. The SX rebuild adds two ripple eaters, volume and balance controls and headphone feed while being smaller and lighter.

I allowed 3W dissipation for each Amec Thermasol FCH505010T, so 22 dissipate 66W per channel for a reasonable temperature rise. They are simply stuck on to aluminium plates holding the power transistors and forming part of the case. Of course the heatsinks are now internal so the case needs a good updraught to allow the heat to escape. In practice the temperature rise is similar to the original large aluminium finned amplifiers. The area near to the power transistors runs at around 50°C and the outer heatsinks 44°C.

The case is 375W x 320D x 170H (inc. feet) [14.75 x 12.6 x 6.75in]

The case is 375W x 320D x 170H (inc. feet) [14.75 x 12.6 x 6.75in]

https://www.diyaudio.com/community/...and-heatsinks-using-ceramic-heatsinks.380763/

I wanted to rebuild my Ovation SX 15W per channel class-A amplifier which dissipates 120W as heat. The original SX build used an off the shelf case which was large and heavy so I designed a new one using the technique I previously used in my “headinclouds” KGSShv Carbon ES headphone amplifiers dissipating about 32W. The cases are all 3mm sheet aluminium alloy and the heatsinks are porous ceramic with adhesive pads. The SX rebuild adds two ripple eaters, volume and balance controls and headphone feed while being smaller and lighter.

I allowed 3W dissipation for each Amec Thermasol FCH505010T, so 22 dissipate 66W per channel for a reasonable temperature rise. They are simply stuck on to aluminium plates holding the power transistors and forming part of the case. Of course the heatsinks are now internal so the case needs a good updraught to allow the heat to escape. In practice the temperature rise is similar to the original large aluminium finned amplifiers. The area near to the power transistors runs at around 50°C and the outer heatsinks 44°C.

Last edited:

I think it's pretty -the old big case was not so nice. Friend Julian Hoyes is a great help with the appearance of the design.Mmmmmm. Heatsinks look to be aluminum.

Howeverthe appearance is marvelous.

Yes they have sticky pads. I thought they might drop off but they are hard to get off.Stick on heatsinks you say. Double sided tape? Maybe a thin coat of special adhesive.

In strength? Ceramic is brittle and bolting down would not be a good idea.I can see where the over enthusiastic might tighten mounting bolts over the limit of the ceramic. Can you give a comparison between aluminum and ceramic or is there much difference to be had?

I would mention that the method of dissipating heat is interesting with the porous ceramic, the structure has a mass of airways in the material so the heat escapes through a large area.

Amec Thermasol info;

https://mec-uk.co.uk/new-admin/uploads/pdf/Ceramic Heat sink presentation.pdf

Not a comparison in strength but in cooling ability. Now that I have read the information in the provided link my questions are answered. Very impressive!

I really like the idea of using ceramic material for heat dissipation. The process of introducing air into the ceramic is impressive. It makes me wonder if the same could be done with some metals if the gas was nitrogen, that way eliminating the problems associated with oxygen.

I really like the idea of using ceramic material for heat dissipation. The process of introducing air into the ceramic is impressive. It makes me wonder if the same could be done with some metals if the gas was nitrogen, that way eliminating the problems associated with oxygen.

Yes, oxygen is quite corrosive.... Nitrogen as we used while welding of aluminum pipe, was the gas shield used to keep this from happening. That is why I am wondering if a metal, such as aluminum could be injected when meting/molding by nitrogen. Maybe the same result could be achieved as was for the ceramic heatsink.

I have previously built amplifiers dissipating over 32W of heat using porous ceramic heatsinks.

https://www.diyaudio.com/community/...and-heatsinks-using-ceramic-heatsinks.380763/

I wanted to rebuild my Ovation SX 15W per channel class-A amplifier which dissipates 120W as heat. The original SX build used an off the shelf case which was large and heavy so I designed a new one using the technique I previously used in my “headinclouds” KGSShv Carbon ES headphone amplifiers dissipating about 32W. The cases are all 3mm sheet aluminium alloy and the heatsinks are porous ceramic with adhesive pads. The SX rebuild adds two ripple eaters, volume and balance controls and headphone feed while being smaller and lighter.

I allowed 3W dissipation for each Amec Thermasol FCH505010T, so 22 dissipate 66W per channel for a reasonable temperature rise. They are simply stuck on to aluminium plates holding the power transistors and forming part of the case. Of course the heatsinks are now internal so the case needs a good updraught to allow the heat to escape. In practice the temperature rise is similar to the original large aluminium finned amplifiers. The area near to the power transistors runs at around 50°C and the outer heatsinks 44°C.

View attachment 1118140 View attachment 1118141 View attachment 1118142 View attachment 1118143 The case is 375W x 320D x 170H (inc. feet) [14.75 x 12.6 x 6.75in]

The heat sinks need to radiate heat as well as produce air flow. There is not enough ventilation by having small slots in the top of the case and sides covering the heat sinks on each side.

You would do better to use aluminium extrusions for the sides of the case. This was my approach with a JLH 15Watt Class A design where the dissipation per channel is 88W and case temperatures of the output transistors is limited to 60 degrees Celcius.

These heat sink extrusions are 300 mm long and anodised black which helps heat dissipation and I recommend having this paint process done for your project. All the same there is a large ventilation hole in my case bottom with cross hatch aluminium cover on the inside to prevent entry of insects and vermin and a similar pattern sheet on the cover for the top.

I am using a 300 VA power transformer to power this system and it gets quite hot. This resides in a separate case with heat sink and voltage regulators for the whole two channels. This is mounted horizontally in the separate case and there is an umbilical supply cord and plug connection to the amplifier case. This removes a heat source and any source of mechanical vibration/ noise from operation of the toroid. The supply rails are +/- 22V and the regulators are electronicallshort circuit protected. These are mounted on a heat sink forming part of the back of this separate case. I drilled small holes in the bottom of this case to allow air to flow around the toroid.

Absolutely!placebo

Even the datasheet provided shows Aluminium being superior on all counts and they don't even talk about anodized aluminium:

https://www.gabrian.com/anodized-aluminum-heatsinks-what-you-need-to-know/

Anodized aluminium has a thin porous layer of aluminium oxide on top of it which technically is one of the finest ceramic outhere.

By the way..Peltier effects have alumium oxide plates for thermal contact and electrical isolation.Guess why?

Then 66watts dissipation for headphones amplifiers looks like one more overkill and utterly useless application ...

Ridiculous...but that's the world we're living in.

https://m.pt.aliexpress.com/item/10...ppclist.product.2&gatewayAdapt=gloPc2braMsite

Last edited:

- Home

- Amplifiers

- Solid State

- SS amplifier dissipating 120W using internal porous ceramic heatsinks.