Hey there DIY-Audio-community

I’m a total beginner when it comes to Hifi-Projects but since my current setup is in desperate needs of some upgrades and I’m traditionally on the DIY-approach when it comes to “new” things, I thought about constructing my own speakers… how hard can it be? During my research with a lot of detours, the World Wide Web finally lead me to Charlie’s infamous jazzman design and I’m in quite in awe about the community surrounding the project, that is mainly based on this board. So into the rabbit-hole I went…

In a first instance, I was simply impressed by the aesthetics of this ESL, which is why I got completely lost in the project. After a first attempt to simply copy the design and therefor understand the design-choices made, I had a bit of an idea while researching for appropriate wires...

Since this is a one of a kind and my workshop is quite limited in size, I want to avoid the tensioning-jig that is usually necessary for the elongation of the single-stranded wire, by tensioning the wires within the actual Speaker.

So, in short this is the attempt to have a segmented wire-ESL with tensioned stranded wires.

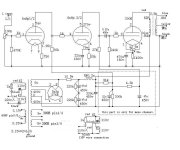

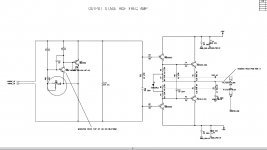

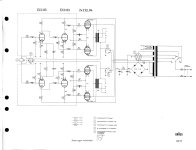

By putting tension on the wires, one could also avoid a lot of the horizontal segmentation. The wire tensioning would be achieved by simple harp-pegs, that are screwed in the top of the speaker. This of course results in an odd number of wires per electrical segment. In my case 5 instead of 6 in the Jazzman-design, so my active diaphragm width is actually a bit smaller than the Jazzman-design. Nevertheless, I hope to be able to copy as much as possible from the original design, especially when it comes to electronics… Really not my expertise yet

🙁

This will be a hybrid design with open-baffle speakers. I do have four Peerless SLS 8 (830667) left, which I hope to be able to use. One idea is to use two dual speakers per speaker, the other idea is to integrate 1 per speaker and build a sub out of the remaining two. But I haven’t checked if the spl would be sufficient for an open-baffle design. Since this is really in the early stages of research, feedback is very welcome!

I’m probably in way over my head with this as a first project but maaaaaaaybe there is a chance for me to actually get these things running

🙂 And even if this is a dead end, it was quite a fun journey so far.

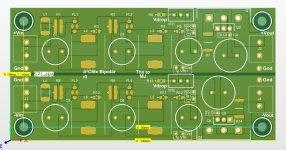

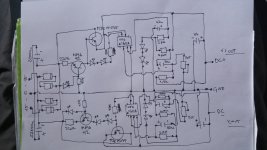

I have some drawings of the project attached.

Where I am at the moment:

I started a first prototype based on some leftover 22mm wood, some FLRY-A 0,5mm2, 1,55mm OD cables and some harp pegs. I build a quick router jig and milled one vertical segment. constant wire distance as well as looping of the cables is achieved by some 3D-printed parts.

After having tensioned a first loop, things look promising, after 3 days under tension the wires are still as straight as they can be. I had some problems with the wire snapping at the top in the beginning, which is in my opinion mainly due to friction in the 3D-printed parts and the loops around the nails. I’ll have to redesign this part in order to allow the wire to distribute its tension over the whole length. But I’m optimistic that I’ll achieve this in the next try.

![20241209_113825[1].jpg](/community/data/attachments/1298/1298946-121bde104f98289c92a64421acbc07af.jpg?hash=bsXMCiKY8O)

![20241208_184122[1].jpg](/community/data/attachments/1298/1298948-588b321abc6f9d537fb5e89e74c41685.jpg?hash=4sgNwmacOw)