If you're concerned about the water in the center of the flow not receiving heat, then turbulence is what you need; something to disturb the laminar flow. That said, there is something to be said for a smaller diameter. I used 1/2" pipe in my rig.

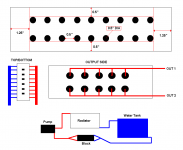

Bear in mind that I run two banks of six on the Alephs. One comprised of the gain devices, the other of the current sources. No, you don't see that in the pictures. I bring in one braided vinyl water line to a brass fitting, split the water flow in two with a T joint, the water runs through the two banks, then comes back together with another T, out through another brass fitting to the outgoing vinyl line.

Grey

Bear in mind that I run two banks of six on the Alephs. One comprised of the gain devices, the other of the current sources. No, you don't see that in the pictures. I bring in one braided vinyl water line to a brass fitting, split the water flow in two with a T joint, the water runs through the two banks, then comes back together with another T, out through another brass fitting to the outgoing vinyl line.

Grey

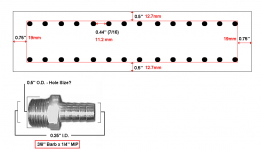

I won't show the rest of the message from that forum, but needless to say, he basically called me a moron.....oh well. But the fellow did point me to a sweet 762 page textbook dissertation on heat transfer. I'll attach it here in a zip, as its about 10MB. However the point of too fast water flow to allow proper heat transfer to the fluid got me thinking....see morons can think. I figured a redesign was in order. One thing I didn't mention; the drilled holes are 0.922", but thats to allow the fitting to be properly tapped. The fitting i'm using has a 0.75" I.D. entering the block, and 0.5" I.D. on the barbed fitting.

Edit: Looks like I cannot add the article, if anyone is interested i'll email it.

Edit: Looks like I cannot add the article, if anyone is interested i'll email it.

Attachments

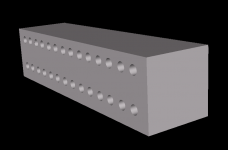

After mucking around in various engineering forums, I came up with what is my final iteration. I even joined a Physics forum, and they haven't chased me away....yet! A manifold design with 18, 1/2" holes (output side view in pic is just conceptual). The parallel flow pattern versus the series s-pattern hopefully will ensure the fets are at the same temp. As far as flow rates, I'll have to wing it; that infrared temp gun will come in handy. I've seen on various cooling set-ups from the over-clockers to Grey's setup, the utilization of a water-tank/bucket. Is this to relieve pressure, or prevent the chance of boiling over? Is it necessary? Hopefully my next attachment will be a photo of the darned thing. This theory business has to be put to rest, and the reality door needs to be opened! Thanks for the help!

-john

-john

Attachments

Hello Mega

I had looking at the tread. How big is your amplifier?

½" hole in the blok is for 10 to 15 kW amplifiers. Look at the radiator in cars. In the radiator alone there are below 2 liters, and it can remove 50 kW

Remember that the water in the mittel of the tube only fill. Only the water by the tube wall will remove heat. I would use 3 to 5 mm holes in the block.

Regards

Benny

I had looking at the tread. How big is your amplifier?

½" hole in the blok is for 10 to 15 kW amplifiers. Look at the radiator in cars. In the radiator alone there are below 2 liters, and it can remove 50 kW

Remember that the water in the mittel of the tube only fill. Only the water by the tube wall will remove heat. I would use 3 to 5 mm holes in the block.

Regards

Benny

Hojvaelde said:How big is your amplifier?

Dissipation may be anywhere from 300-1500 watts.

MEGA-amp said:.... I've seen on various cooling set-ups from the over-clockers to Grey's setup, the utilization of a water-tank/bucket. Is this to relieve pressure, or prevent the chance of boiling over? Is it necessary? ...

Absolutely necessary. The coolant will expand and blow apart your tubing as it heats up if there isn't any place for it to go. You don't need a flow through reservoir, an expansion tank like under the hood is fine. Notice the difference between the full hot and full cold lines.

I'd tap the expansion tank into the intake side of the pump and keep it higher than the intake to prevent cavitation. Probably not absolutely necessary in this case, but I used to sell liquid cooling systems for military aircraft applications.

I'll second Benny's comment - use more/smaller holes. if you've already made the cold plate, its not a show stopper, just keep the flow rate down. Smaller holes will allow a smaller pump.

You absolutely need away to purge the air out of your system. Trapped air will act as an insulator. Another reason for a tank at the high point - the air will eventually migrate there. Still fill the system open loop and tilt and shake your heat exchanger and cold plate with coolant flow to release trapped air.

MEGA-amp said:anywhere from 300-1500 watts.

Yeeha.

Think take-in pressure for the need of an expansion/storage tank.

OK, last pic. Luckily, I've resisted the drill press so far. I've looked around online at tap & drill charts, and i'm a little lost. The fitting entering the block is 1/4" MIP thread, what size hole should I drill, and what size tap should I use?

I remember Grey mentioning somewhere (maybe in his water-cooled thread) that he had an issue with the fets not properly biasing; something about over-cooling. With all this focus on super-duper cooling, i've been ignoring the fact that these fets might have an optimum running temp. I'll be using FQA19N20C for the outputs. Regardless of what Aleph output stage used or bias settings, what would be the optimal die temp? Because I haven't figured the Rth of the block, I'm stuck using an infrared temp gun to measure the outside of the fet case. The first iteration would possibly be an Aleph 5 config, 35V, 6A bias, 70W per fet, 420W dissipation, 840W total block dissipation.

I remember Grey mentioning somewhere (maybe in his water-cooled thread) that he had an issue with the fets not properly biasing; something about over-cooling. With all this focus on super-duper cooling, i've been ignoring the fact that these fets might have an optimum running temp. I'll be using FQA19N20C for the outputs. Regardless of what Aleph output stage used or bias settings, what would be the optimal die temp? Because I haven't figured the Rth of the block, I'm stuck using an infrared temp gun to measure the outside of the fet case. The first iteration would possibly be an Aleph 5 config, 35V, 6A bias, 70W per fet, 420W dissipation, 840W total block dissipation.

Attachments

Drilling is complete, I'll post a few pics in a day or so. However, the search continues, and I've think I've found a better idea. It's a variation on Grey's setup. It's cheaper to implement than my big block idea, less flying water tubes, less chance of leakage etc. I'd like to bias the crap out of the F5. Would I have to run F5 without thermistor and current limiting? Would the output fets even bias properly being watercooled?

I'd probably modify it a bit by drilling a couple hundred shallow dimples on both sides of the water exposed surface.

I'd probably modify it a bit by drilling a couple hundred shallow dimples on both sides of the water exposed surface.

Attachments

Hi, MEGA-amp

Not gas water and central heating mechanic your trade?

Good work!

Only not the copper would be in a golden price.

I received brainwaves whatever from you.

Myself installed some radiators finally some years of his, and does not leak yet.

This is not my trade though.

I am not know in English.

I know nothing actually.

But I say thank you for it because of that!

Gyuri

Not gas water and central heating mechanic your trade?

Good work!

Only not the copper would be in a golden price.

I received brainwaves whatever from you.

Myself installed some radiators finally some years of his, and does not leak yet.

This is not my trade though.

I am not know in English.

I know nothing actually.

But I say thank you for it because of that!

Gyuri

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Water-cooled Aleph idea