Another thought... is it better to mount these from the front or the rear? From the rear, I can just round over the front face with a 1/2" or 3/4" bit. Then I don't need to scallop the rear. And the front acts a bit like a horn although I don't know if anyone has actually measured this. And it also makes grill cloth installation more straight forward.

Another thought... is it better to mount these from the front or the rear? From the rear, I can just round over the front face with a 1/2" or 3/4" bit. Then I don't need to scallop the rear. And the front acts a bit like a horn although I don't know if anyone has actually measured this. And it also makes grill cloth installation more straight forward.

If you mount from the rear you will need to have a removable baffle or access to get behind. A removable baffle is harder to seal, so you need lots of fasteners and something to make an airtight seal. Wesayso's aluminium baffle with layers of damping and neoprene does this very well but is pretty complicated.

Mounting from the front is the way I have chosen to go.

An option for you might be to put the cabinet as far into the corner as possible, pack the side gaps with rockwool, felt or other absorbent and then make a fabric grill panel to cover the whole lot.

The walls will provide a waveguide at lower frequencies, the damping will help to reduce or eliminate edge reflections and smooth the wall interface and it's all removable if it doesn't work the way you hoped.

If you mount from the rear you will need to have a removable baffle or access to get behind. A removable baffle is harder to seal, so you need lots of fasteners and something to make an airtight seal. Wesayso's aluminium baffle with layers of damping and neoprene does this very well but is pretty complicated.

Yes, I considered that but I don't think I'll need access very often (hopefully never) so I was willing to deal with the additional fasters and such. Also, I liked the clean look of having them mounted from the rear. Finally, front mounting means no steps from the frame to the baffle. That said, I can inset the drivers by the thickness of the frame so that step doesn't exist. And maybe fill in the gaps formed by the corners with some epoxy. I don't know that will make any difference in performance and it will be hidden by grill cloth anyway so perhaps a waste of energy.

An option for you might be to put the cabinet as far into the corner as possible, pack the side gaps with rockwool, felt or other absorbent and then make a fabric grill panel to cover the whole lot.

The walls will provide a waveguide at lower frequencies, the damping will help to reduce or eliminate edge reflections and smooth the wall interface and it's all removable if it doesn't work the way you hoped.

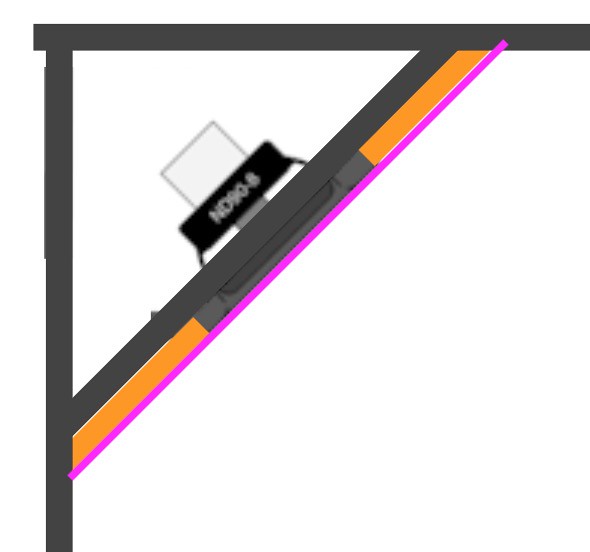

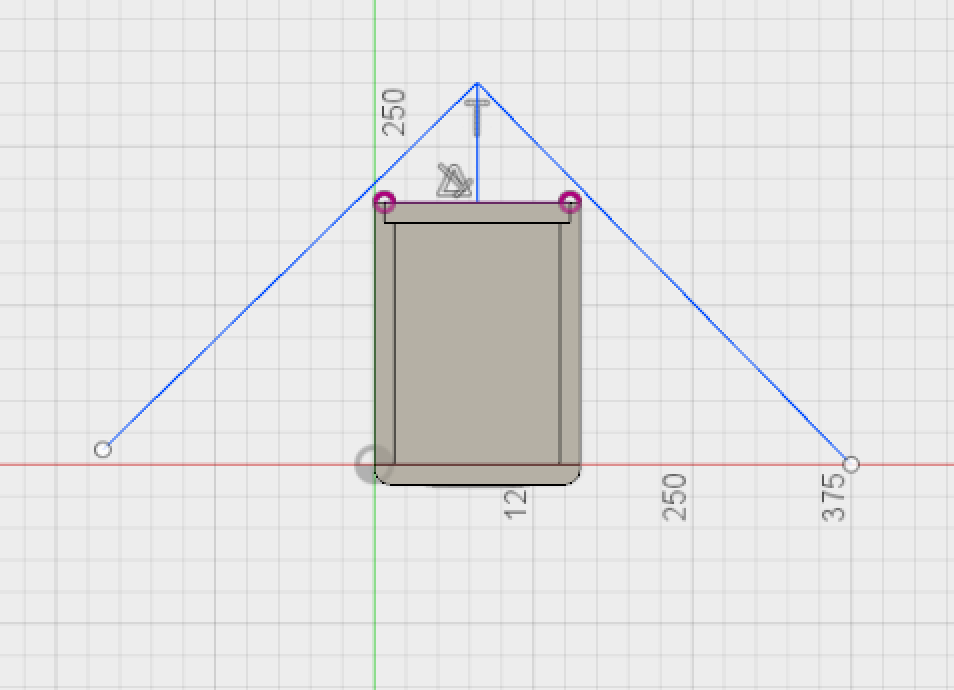

With the drivers front mounted, using 25 drivers where I have vertical room for 28, and planning for 2.0L per driver, I can get the 45 degree baffle to be just over 7". That just leaves ~1.5" on either side of the drivers. So maybe I can just use 1/4" thick felt for that 1.5" width with grill cloth over it. And I can literally tuck the grill cloth behind the baffle. Something like this:

Does that seem like enough felt to absorb the higher frequencies? Is the step from the wool an issue? Wesayso suggested "integrating" the wool into the baffle but that cuts into my volume and would space the drivers out further from the wall. I could make the wool wedge shaped so there was no step but seems like perhaps overkill?

Last edited:

Keep in mind that the surround will still move  .

.

Even at rest it's forward of the frame.

Wouldn't this be easy to test? Take one driver, mount it on a baffle and stick it into "a" corner. Measure it and look at the data.

Measure the baffle free from any wall to compare against. Add the felt and try again back in the corner...

Knowing is always better than gambling.

Even at rest it's forward of the frame.

Wouldn't this be easy to test? Take one driver, mount it on a baffle and stick it into "a" corner. Measure it and look at the data.

Measure the baffle free from any wall to compare against. Add the felt and try again back in the corner...

Knowing is always better than gambling.

Yes, of course you're right... perhaps the felt would be a little proud of the surround then. Also, Still have two months until we move back in and then some time to setup the shop and the rest of the house before I'm ready to make anything. So purely planning work for now.

And I thought maybe someone else had done this test before or the general wisdom would have an answer as often happens!

And I thought maybe someone else had done this test before or the general wisdom would have an answer as often happens!

Last edited:

Your desire to build the enclosures into the wall is a key consideration of the project, but wouldn't it be nice to have the ability to change the angle of the arrays in case you find that the fixed 45 degrees isn't exactly what you wanted? If you made the triangular cabinets free standing and made two extra floor to ceiling baffles to go on either side of the array you could change the angle and still have it be nicely integrated into the corners. Just a thought from someone who would love to do something like this someday!

Turns out I can't build directly into the walls since they ended up being shear walls. I like your idea though. The downside is that making the enclosure flexible while maintaining the volume I need means the drivers will be further away from corner. So I will likely go ahead and build as permanent. With 45 degree, they will cross right in front of my listening area so I think I should be good anyway. Also, the enclosures are pretty basic and I wouldn't be too hard pressed to just remake them if need be.

Let's be honest, no one ever wants to remake enclosures  Integrating them into the room is the best way, but I would still see myself wanting a bit of flexibility in placement or the ability to completely swap them out for other speakers in the future. A faux acoustic screen covering the whole corner would allow you to put anything behind it and do some listening experiments with unsuspecting moviegoers

Integrating them into the room is the best way, but I would still see myself wanting a bit of flexibility in placement or the ability to completely swap them out for other speakers in the future. A faux acoustic screen covering the whole corner would allow you to put anything behind it and do some listening experiments with unsuspecting moviegoers

Last edited:

Somewhat off topic - any recos for a HTPC? We'll have fiber to the house shortly (and CAT6 ethernet throughout to link to networked storage) so no need for local storage. So I'm thinking this would be primarily as the convolution engine. And secondarily as Netflix/streaming video player. I had been planning on using an old Macbook pro (circa 2013) but it seems the audio features on JRiver are still better on the PC version although it seems to be getting closer. Small, quiet, low power would be nice. The next gen Intel NUCs coming out shortly might be a good option? Doesn't have to be NUC sized though.

Are the stick PC's powerful enough? This one has an ethernet port.

Are the stick PC's powerful enough? This one has an ethernet port.

Last edited:

Flexibility would be nice. But I think the downsides outweigh the upsides to go in that direction.

Update on the status of the room:

Sheetrock is up... tape and mud next week probably.

For context, that front wall is about 11' wide and 93" tall.

it's come along way since finding burnt knob and tube wiring hasn't it !

I used the Goo systems product finder and they recommended the reference white screen Goo pairs.

My wife doesn't want a white rectangle on the wall so I'm thinking of just painting the whole wall with this stuff and it will be an "accent" wall sort of. (The other walls are Gallery Grey from Kelly Moore.) I won't have the black border which was the plan as I understand it offers better contrast perception. In which case, I'm thinking I can get the image to go right to the edge of the speakers and they'll sort of act as the border to the sides at least. This is slightly larger than I had originally planned (about 120" across vs. 120" diagonal), but I figure why not? I will need to position the projector a little farther back at 16'8" but that's fine.

Speaking of components, I need to figure out how I'm going to fit all the A/V equipment under the screen (receiver, 5-channel surround amp, mono blocks for mains, IB sub amp, HTPC, turntable, phono preamp, and PS4) but I'm not terribly worried about it. There will be some reflections from whatever that looks like but it will only be a couple feet tall and I'm not sure I have any good alternatives anyway. I could put some stuff on the other side of the wall in the garage, but the garage is going to be a very dusty environment. Sound about right?

My wife doesn't want a white rectangle on the wall so I'm thinking of just painting the whole wall with this stuff and it will be an "accent" wall sort of. (The other walls are Gallery Grey from Kelly Moore.) I won't have the black border which was the plan as I understand it offers better contrast perception. In which case, I'm thinking I can get the image to go right to the edge of the speakers and they'll sort of act as the border to the sides at least. This is slightly larger than I had originally planned (about 120" across vs. 120" diagonal), but I figure why not? I will need to position the projector a little farther back at 16'8" but that's fine.

Speaking of components, I need to figure out how I'm going to fit all the A/V equipment under the screen (receiver, 5-channel surround amp, mono blocks for mains, IB sub amp, HTPC, turntable, phono preamp, and PS4) but I'm not terribly worried about it. There will be some reflections from whatever that looks like but it will only be a couple feet tall and I'm not sure I have any good alternatives anyway. I could put some stuff on the other side of the wall in the garage, but the garage is going to be a very dusty environment. Sound about right?

Last edited:

Yes, I considered that but I don't think I'll need access very often (hopefully never) so I was willing to deal with the additional fasters and such. Also, I liked the clean look of having them mounted from the rear. Finally, front mounting means no steps from the frame to the baffle. That said, I can inset the drivers by the thickness of the frame so that step doesn't exist. And maybe fill in the gaps formed by the corners with some epoxy. I don't know that will make any difference in performance and it will be hidden by grill cloth anyway so perhaps a waste of energy.

With the drivers front mounted, using 25 drivers where I have vertical room for 28, and planning for 2.0L per driver, I can get the 45 degree baffle to be just over 7". That just leaves ~1.5" on either side of the drivers. So maybe I can just use 1/4" thick felt for that 1.5" width with grill cloth over it. And I can literally tuck the grill cloth behind the baffle. Something like this:

Does that seem like enough felt to absorb the higher frequencies? Is the step from the wool an issue? Wesayso suggested "integrating" the wool into the baffle but that cuts into my volume and would space the drivers out further from the wall. I could make the wool wedge shaped so there was no step but seems like perhaps overkill?

There are a few parts to this to consider for construction and then other considerations due to acoustics.

I doubt that 1.5" of 1/4" felt is enough to completely suppress the discontinuity between the driver and the wall. It is enough to significantly reduce edge diffraction but that is not the same phenomenon. I think wesayso is right that the only way to know will be to test it.

The image you show there doesn't seem to be a bad idea, but think of it like a horn where the driver doesn't quite match the horn, and you get reflection dips. Really early reflections (less than 6ms) are bad as your ear does not perceive them as separate and integrates them as the direct sound you hear making it coloured.

You could use an 1/8" layer to come right up to the edge of the driver and into the gaps to create a smooth surface and then put another layer of thicker material further away as you go outwards towards the wall. But do check on the price as that sort of pressed wool felt isn't cheap and you will quite need a lot of it due to the length of the lines.

I think that you either want the waveguide to start right at the edge of the driver basket or build in a bigger gap and fill that with damping material.

My suggestion before was more like this

Push the cabinet into the corner and then fill the space between the cabinet edge and the wall with a larger amount of damping like fibreglass or rockwool. You could use double sided tape or velcro to stick it to the edge of the cabinet and the wall to hold it in place. Putting fabric across the front could be done in many ways. You can then angle the cabinets to suit your listening position and adjust the damping.

That is my cabinet so I didn't have to draw a new one, but you could make it any shape you want.

One think to remember about constructing the cabinets is that they will be awkward, long thin pieces of material are a pain to work with. If the baffle is made out of any kind of wood when you cut the holes in it it will have no strength face on until you fix it. The panels need to be lifted on edge or they will bend and split. I have a whole set of them and they bend even more than I thought they would.

The aluminium baffle wesayso used has a benefit in that the material itself is much stiffer even with the holes cut in it.

As this is a sealed design it needs to be almost airtight. With edges over 2m long it is difficult to do. If you have great tools that can cut perfectly then it is easier but any deviation from flat will make it harder to seal. The cabinet internals are not that large either so getting in to put some sealer around the edges is harder than normal. A triangular cabinet is hard to join well as the 45 degree edge is awkward to screw into and end grain to glue against won't hold well by itself. A biscuit joiner with a 45 degree fence and band clamps would work well though.

As you have some time you might as well think over and do it right once

Attachments

You could use an 1/8" layer to come right up to the edge of the driver and into the gaps to create a smooth surface and then put another layer of thicker material further away as you go outwards towards the wall. But do check on the price as that sort of pressed wool felt isn't cheap and you will quite need a lot of it due to the length of the lines.

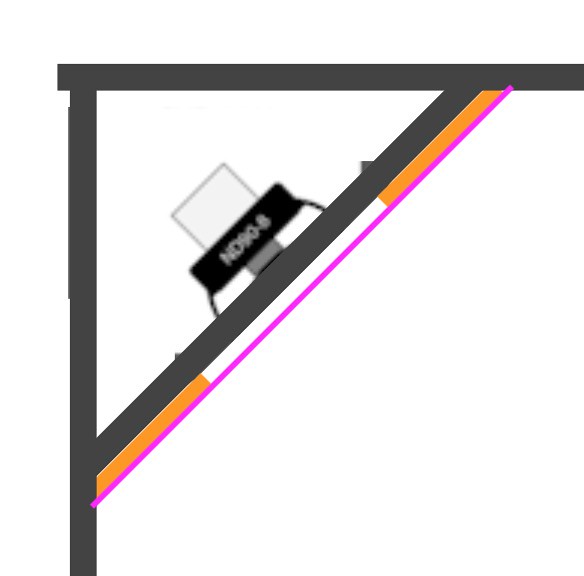

I like this idea. I would need about $50 worth of wool based on the 2 minute search I did for one 3/8" layer. Another $25 if I doubled up further away from the driver. And perhaps overlapping with the joint at the wall.

Like this?

I think that you either want the waveguide to start right at the edge of the driver basket or build in a bigger gap and fill that with damping material.

My suggestion before was more like this

Push the cabinet into the corner and then fill the space between the cabinet edge and the wall with a larger amount of damping like fibreglass or rockwool. You could use double sided tape or velcro to stick it to the edge of the cabinet and the wall to hold it in place. Putting fabric across the front could be done in many ways. You can then angle the cabinets to suit your listening position and adjust the damping.

I understand what you're saying. Thanks for the idea. I don't think I can convince the wife to allow that much of a presence... she's already not super happy about floor to ceiling speakers.

One think to remember about constructing the cabinets is that they will be awkward, long thin pieces of material are a pain to work with. If the baffle is made out of any kind of wood when you cut the holes in it it will have no strength face on until you fix it. The panels need to be lifted on edge or they will bend and split. I have a whole set of them and they bend even more than I thought they would.

The aluminium baffle wesayso used has a benefit in that the material itself is much stiffer even with the holes cut in it.

As this is a sealed design it needs to be almost airtight. With edges over 2m long it is difficult to do. If you have great tools that can cut perfectly then it is easier but any deviation from flat will make it harder to seal. The cabinet internals are not that large either so getting in to put some sealer around the edges is harder than normal. A triangular cabinet is hard to join well as the 45 degree edge is awkward to screw into and end grain to glue against won't hold well by itself. A biscuit joiner with a 45 degree fence and band clamps would work well though.

As you have some time you might as well think over and do it right once

Thanks for the input. Since I'm front mounting now, I'm thinking I'll make the baffle 3/4" birch ply. If it seems too wobbly, I can have two 3/4" square "stiffeners" along the length centered on each side of the baffle. And perhaps also some side to side window bracing too.

I do have nice tools thankfully and my Sawstop shouldn't have any problem cutting a precise 45 degree. I also do have a biscuit cutter but I don't think I'll need it as I'm going to pre drill holes in the baffle every 6" or so and then the baffle will screw directly into the wall through drywall and then into plywood. Those walls are nice and flat and I was planning on using foam weatherstripping to seal that interface to the drywall. I could use a few biscuits to help with keeping things in place while I screw it all in. But I was planning on having triangular "stops" on top and bottom that would also serve a similar purpose. I can always cut for biscuits at the end if I need to.

Once again, thanks for the input! Keep it coming!

Last edited:

I like this idea. I would need about $50 worth of wool based on the 2 minute search I did for one 3/8" layer. Another $25 if I doubled up further away from the driver. And perhaps overlapping with the joint at the wall.

Like this?

Yes just like that, check that it is actually wool and not some man made fibre as polyester is a really good reflector of sound and not what you want.

I understand what you're saying. Thanks for the idea. I don't think I can convince the wife to allow that much of a presence... she's already not super happy about floor to ceiling speakers.

If you make the cabinet small enough and put fabric over the front of the whole thing how will it look any different?

Thanks for the input. Since I'm front mounting now, I'm thinking I'll make the baffle 3/4" birch ply. If it seems too wobbly, I can have two 3/4" square "stiffeners" along the length centered on each side of the baffle. And perhaps also some side to side window bracing too.

3/4" birch ply is good, but it will still be extremely wobbly, the strength of the ply is the cross laminations, when you cut holes in it it has no strength in that direction. Once it is glued and fixed it is no problem it is just being able to manoeuvre it into place. Roger russell in his article recommends cutting the driver holes after the cabinet has been fixed for that very reason. Also the thicker the material the more you need to relieve the area around the cutout to let the driver breathe. This makes it even more wobbly...

I do have nice tools thankfully and my Sawstop shouldn't have any problem cutting a precise 45 degree. I also do have a biscuit cutter but I don't think I'll need it as I'm going to pre drill holes in the baffle every 6" or so and then the baffle will screw directly into the wall through drywall and then into plywood. Those walls are nice and flat and I was planning on using foam weatherstripping to seal that interface to the drywall. I could use a few biscuits to help with keeping things in place while I screw it all in. But I was planning on having triangular "stops" on top and bottom that would also serve a similar purpose. I can always cut for biscuits at the end if I need to.

Once again, thanks for the input! Keep it coming!

I'm not sure I understand how you plan to mount it, not that it matters as I don't need to!

The foam is a good idea that helps a lot with sealing everything tight.

If I am reading what you wrote correctly you plan to use the actual wall as the back of the cabinet?

If it was me I would make the cabinet separate and then mount it to the wall. Unless your outer wall surface is ply. If it is drywall/gyprock which it looks like in your pictures, I think you may have trouble with movement and resonances from your building. A cabinet of this length and shape is not easy to build like a small bookshelf speaker.

Somewhat off topic - any recos for a HTPC? We'll have fiber to the house shortly (and CAT6 ethernet throughout to link to networked storage) so no need for local storage. So I'm thinking this would be primarily as the convolution engine. And secondarily as Netflix/streaming video player. I had been planning on using an old Macbook pro (circa 2013) but it seems the audio features on JRiver are still better on the PC version although it seems to be getting closer. Small, quiet, low power would be nice. The next gen Intel NUCs coming out shortly might be a good option? Doesn't have to be NUC sized though.

Are the stick PC's powerful enough? This one has an ethernet port.

I use a full blown workstation with quad core Xeon processor, 16 GB of memory, dual SSD drives (Samsung 850 Pro) in raid mirror for OS, running Windows 7 Pro (no Win 8.1 or 10 for me, too much experience as a Sys Admin) and utilise it's Quadro graphics card (needed for my 3D modelling) to act as a renderer for picture quality. I calibrated the colors of my TV, which is running as a secondary monitor giving me all stream capabilities I could wish for and using 6 channels of audio convolution for Stereo and HT (different settings for each).

I just love tweaking I guess, JRiver has the excellent MadVR renderer which you can tweak to get crazy good results. So no stick PC for me, thank you

(by the way, My PC isn't in the same room (it's in the corridor), only monitor, keyboard an mouse are. So no fan noise etc. to ruin my enjoyment)

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- "Wall-integrated" corner loaded line array with Vifa TC9 drivers