Well, that's one end of the spectrum. That is certainly enough horsepower for audio!

The 2013 MBP should do just fine. It's not the audio side of JRiver that is behind the curve, it's the video. The Mac version doesn't have all the candy looking menus, and it doesn't use the MadVR engine either, but it's not terrible either... Still looks fine here, as I am using a 2012 Mac Mini (my 2008 MBP fried last year). When in audio mode, I use the Mini headless, using an iPad and VNC to control it.

I have been looking at those mini computers, quite cute indeed, although not on par for power as quad core Xeon stations!

The 2013 MBP should do just fine. It's not the audio side of JRiver that is behind the curve, it's the video. The Mac version doesn't have all the candy looking menus, and it doesn't use the MadVR engine either, but it's not terrible either... Still looks fine here, as I am using a 2012 Mac Mini (my 2008 MBP fried last year). When in audio mode, I use the Mini headless, using an iPad and VNC to control it.

I have been looking at those mini computers, quite cute indeed, although not on par for power as quad core Xeon stations!

Yes just like that, check that it is actually wool and not some man made fibre as polyester is a really good reflector of sound and not what you want.

It's F13 felt so I think it's ok.

If you make the cabinet small enough and put fabric over the front of the whole thing how will it look any different?

If I leave room for it maneuver, and I keep to the internal volume I need, then the drivers will sit farther away from the corner of the walls and also the fabric will also create a larger 45 degree impact than just the fixed cabinet alone. I haven't sketched it out, but let's assume I want to be able to aim the speakers 20 degrees in either direction. Roughly speaking, that cuts out almost half of the volume and the drivers will need to almost twice as far from the wall and the 45 degree fabric will need to be about twice as wide. I can do the geometry for more precision but that seems to be a lot to give up when I already know RA7 has had good results and this will already improve based on his experiences.

3/4" birch ply is good, but it will still be extremely wobbly, the strength of the ply is the cross laminations, when you cut holes in it it has no strength in that direction. Once it is glued and fixed it is no problem it is just being able to manoeuvre it into place. Roger russell in his article recommends cutting the driver holes after the cabinet has been fixed for that very reason. Also the thicker the material the more you need to relieve the area around the cutout to let the driver breathe. This makes it even more wobbly...

I'm not sure I understand how you plan to mount it, not that it matters as I don't need to!

Hmm, that's a thought. Will be harder to wire that way though. I think I can probably manage with some help. And maybe I will use the biscuits to help locate before screwing it in.

If I am reading what you wrote correctly you plan to use the actual wall as the back of the cabinet?

If it was me I would make the cabinet separate and then mount it to the wall. Unless your outer wall surface is ply. If it is drywall/gyprock which it looks like in your pictures, I think you may have trouble with movement and resonances from your building. A cabinet of this length and shape is not easy to build like a small bookshelf speaker.

Good point! I didn't think about that. Let me draw out exactly what I have planned including what the wall is made of and that will help us have a good discussion about the best path forward.

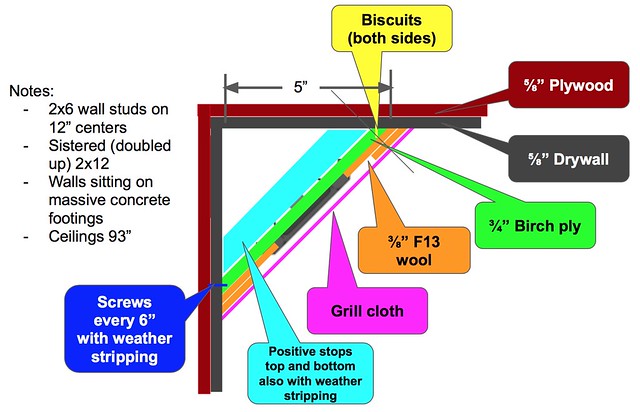

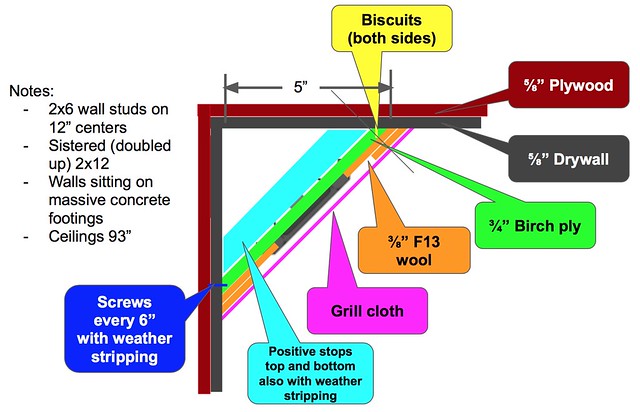

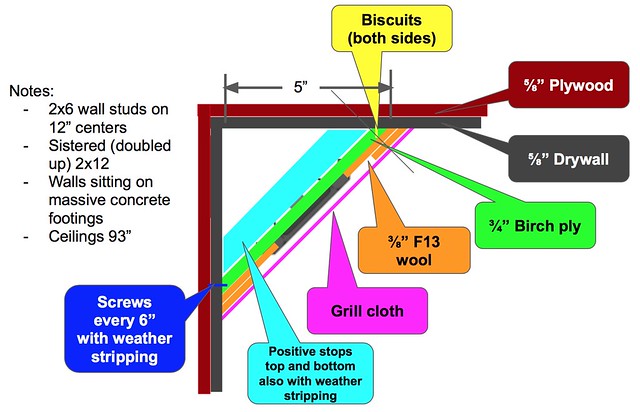

Here's a little more detail:

Also, I forgot to mention that there's a big post in the corners and the 2x4s also are bunched near the corners even though they're 12" centers for the rest of the wall. And also, I have sound isolation foam between the ceiling drywall and joists. Plus, all the walls are insulated. And the ceiling has rock wool.

EDIT: noticed there's a typo in the note section. The walls studies are 2x4. The ceiling joists doubled up 2x12s.

Also, I forgot to mention that there's a big post in the corners and the 2x4s also are bunched near the corners even though they're 12" centers for the rest of the wall. And also, I have sound isolation foam between the ceiling drywall and joists. Plus, all the walls are insulated. And the ceiling has rock wool.

EDIT: noticed there's a typo in the note section. The walls studies are 2x4. The ceiling joists doubled up 2x12s.

Last edited:

Well, that's one end of the spectrum. That is certainly enough horsepower for audio!

The 2013 MBP should do just fine. It's not the audio side of JRiver that is behind the curve, it's the video. The Mac version doesn't have all the candy looking menus, and it doesn't use the MadVR engine either, but it's not terrible either... Still looks fine here, as I am using a 2012 Mac Mini (my 2008 MBP fried last year). When in audio mode, I use the Mini headless, using an iPad and VNC to control it.

I have been looking at those mini computers, quite cute indeed, although not on par for power as quad core Xeon stations!

Good to know it's powerful enough. The one thing I noticed when I looked at the comparison was that loopback wasn't supported in OS X. And I think I need that to get my turntable through JRiver using my PS Audio ADC USB output via the WDM Virtual Audio Driver and Loopback System. I may be wrong though. I could skip JRiver with the turntable and just use the Dirac system in my Emotiva XMC-1 for that though. Or at some point I guess I could digitize my vinyl which kinda takes some of the fun out of the experience. I still have a lot to learn about all the JRiver and convolution stuff so definitely open to additional comments. There was some of this earlier in the thread, but I now have the XMC-1 and the PS Audio NuWave as known parts of the system.

EDIT: I also have a 10 year old Mac Pro. It's probably close in power to the Macbook. But it does have a ton of hard drive space and RAM as well as an optical port.

Here's a little more detail:

Also, I forgot to mention that there's a big post in the corners and the 2x4s also are bunched near the corners even though they're 12" centers for the rest of the wall. And also, I have sound isolation foam between the ceiling drywall and joists. Plus, all the walls are insulated. And the ceiling has rock wool.

EDIT: noticed there's a typo in the note section. The walls studies are 2x4. The ceiling joists doubled up 2x12s.

Here is my 2c.

I would build the cabinet separately for a few reasons.

1. It is easier to work with on the ground due to the length of it and the unstable nature of wood panels with holes cut in them.

2. You can make the cabinet perform as you want in terms of strength, bracing, damping etc.

3. I think it is better to fix the cabinet to the wall with some isolation rather than directly anchoring it or having the wall be the cabinet. This is how much sound reduction is achieved in dedicated buildings by reducing transmission from one surface to another by a damping layer.

4. You can take it outside to test it if you want, or remove it for servicing, wiring, driver replacement etc.

I would build the cabinet out of 3/4" ply to fit in the corner where your drywall layer is shown as you can still fix the front baffle in the same way to the actual cabinet.

Use enough bracing across the baffle and the cabinet to make it stiff enough. I designed in 9, 9mm braces across whole cross section dadoed into the sides and back. You could use 1/2" ply and screw through the cabinet sides to fix it. Just thin it out near the front or make cutouts to let the drivers fit through.

I would mount the cabinet to the wall by sinking tee nuts or other means into the plywood behind the drywall so that you can use bolts to secure it to the wall. Use as many as you need for it to be secure. Put a neoprene strip in between to provide some isolation and help to seal the cabinet from leaks.

By doing this way it will only be roughly 1.5" wider that if you screw the baffle direct to the wall.

Good to know it's powerful enough. The one thing I noticed when I looked at the comparison was that loopback wasn't supported in OS X. And I think I need that to get my turntable through JRiver using my PS Audio ADC USB output via the WDM Virtual Audio Driver and Loopback System. I may be wrong though. I could skip JRiver with the turntable and just use the Dirac system in my Emotiva XMC-1 for that though. Or at some point I guess I could digitize my vinyl which kinda takes some of the fun out of the experience. I still have a lot to learn about all the JRiver and convolution stuff so definitely open to additional comments. There was some of this earlier in the thread, but I now have the XMC-1 and the PS Audio NuWave as known parts of the system.

EDIT: I also have a 10 year old Mac Pro. It's probably close in power to the Macbook. But it does have a ton of hard drive space and RAM as well as an optical port.

Loopback in Jriver uses a wdm driver so it doesn't work outside of windows. On OSX you can use Soundflower a similar thing. There is also a commercial version of it now from Rogue Amoeba called loopback. As is always the case with OSX most good things end up moving away from open source.

You could use bootcamp to dual boot your mac with windows if you wanted to use the computer with windows. Being wedded to the MacOs will leaving you wanting with some software. Even with the core code being Unix based now it is different enough to make porting awkward. If the code for a program is written in Java or something else cross platform like that it is easy to create different versions.

I have all of the operating systems running. My laptop is a Macbook Pro, my server is Windows 8.1, the Cubox-i runs openelec which is a linux based media centre using Kodi and the NUC has Windows 10. The Macbook has virtual versions of Windows XP and Ubuntu for the occasions I can only use those systems to get something done. Now I've got over the transition with windows 8.1 I actually like that version of windows the best. I find windows 7 to be terribly slow and windows 10 wants everything to be automatic which is terrible for a dedicated media computer.

I have been looking for an all in one computer solution for music and movies for a long time and have used most of them. None of them get everything right for me but Jriver actually comes the closest. The windows version is the one to use though that is where all the development is done first.

For movies and TV, Kodi (formerly XBMC) is a really good piece of software. I use it on Cubox-i for playing TV shows and movies to my TV over wifi and it is really user friendly. I don't know if they have got to support atmos yet but it is only a matter of time. The lossless movie audio formats are already supported. There are versions for all platforms and it can be controlled across the room with an IR remote or tablet etc. There is DSP addon to allow convolution but not for MacOS. You can always pipe the audio from Kodi through another program to get convolution but it starts to get more complicated at that stage.

Dirac is good as far as point and shoot room correction is concerned but it will not do what wesayso has achieved through manual tweaking in DRC FIR and I imagine that it would work much better if you used some pre EQ to get the lines in the ballpark of flat which they won't be without it.

As always, thanks for the input. All your points are valid of course. My thoughts below:

Entirely agree. But I think I can make it work. Also, I can get everything wired with drivers installed which actually will help add a little stability to it. And then I just need to get it a few feet from the shop to the corner where it will be much more stable once in place. The other thing is, if I make a stand alone speaker that is nearly the height of the room, I may not be able to stand it up (might get stuck). Whereas standing up just a baffle will be easy.

This is actually the biggest concern I have. However, with the relatively small size of the triangular cross section, I'm not sure I'll need that much bracing. The other thing I could do is to brace similar to what you had shown with dados into the front baffle. And then screw into the rear from the other side of the wall. Or just apply some foam tape to the faces that would touch the walls and count on the compression from screwing the baffle into the walls to provide the support. I don't love either of those ideas, but perhaps they will spur on some better ideas.

This is a new one I had not thought about. And I'm not sure I understand it. Are you saying that there may be a problem transferring sound through the walls and that will disturb the rest of the house? In which case, I actually don't care. Or perhaps other things will vibrate and that will cause problems with overall sound quality? That would be a problem! Given the energy is distributed across so many drivers though, I wonder if that would ever be an issue. Just an open question... I don't know. The reason I bring it up is that it seems like the drivers do not work very hard even at high SPL so I'm extrapolating from that.

Or perhaps other things will vibrate and that will cause problems with overall sound quality? That would be a problem! Given the energy is distributed across so many drivers though, I wonder if that would ever be an issue. Just an open question... I don't know. The reason I bring it up is that it seems like the drivers do not work very hard even at high SPL so I'm extrapolating from that.

Absolutely true. But testing in place is kinda necessary for this application. I should be able to service in place too in terms of driver replacement at least. Besides, in all the speakers I've ever built, I've never had to service anything (knock on wood) so even if I do, I don't think it would be frequent enough to drive a design decision IMHO.

I hope you don't think I'm discounting your ideas. I really appreciate the input! And the debate is part of the fun for me so I sincerely hope you think so too.

Here is my 2c.

1. It is easier to work with on the ground due to the length of it and the unstable nature of wood panels with holes cut in them.

Entirely agree. But I think I can make it work. Also, I can get everything wired with drivers installed which actually will help add a little stability to it. And then I just need to get it a few feet from the shop to the corner where it will be much more stable once in place. The other thing is, if I make a stand alone speaker that is nearly the height of the room, I may not be able to stand it up (might get stuck). Whereas standing up just a baffle will be easy.

2. You can make the cabinet perform as you want in terms of strength, bracing, damping etc.

This is actually the biggest concern I have. However, with the relatively small size of the triangular cross section, I'm not sure I'll need that much bracing. The other thing I could do is to brace similar to what you had shown with dados into the front baffle. And then screw into the rear from the other side of the wall. Or just apply some foam tape to the faces that would touch the walls and count on the compression from screwing the baffle into the walls to provide the support. I don't love either of those ideas, but perhaps they will spur on some better ideas.

3. I think it is better to fix the cabinet to the wall with some isolation rather than directly anchoring it or having the wall be the cabinet. This is how much sound reduction is achieved in dedicated buildings by reducing transmission from one surface to another by a damping layer.

This is a new one I had not thought about. And I'm not sure I understand it. Are you saying that there may be a problem transferring sound through the walls and that will disturb the rest of the house? In which case, I actually don't care.

4. You can take it outside to test it if you want, or remove it for servicing, wiring, driver replacement etc.

Absolutely true. But testing in place is kinda necessary for this application. I should be able to service in place too in terms of driver replacement at least. Besides, in all the speakers I've ever built, I've never had to service anything (knock on wood) so even if I do, I don't think it would be frequent enough to drive a design decision IMHO.

I hope you don't think I'm discounting your ideas. I really appreciate the input! And the debate is part of the fun for me so I sincerely hope you think so too.

Last edited:

A separate enclosure is what I would do too. With neoprene between it and the wall. Even though each driver hardly does anything you don't want to couple the low frequencies to the walls. There's still a lot of force behind it all. You don't want to add resonances.

Make the enclosure shorter and fill up the bottom and top, or just have the baffle in the right size and the enclosure the length that's needed. No problems to set it upright.

Make the enclosure shorter and fill up the bottom and top, or just have the baffle in the right size and the enclosure the length that's needed. No problems to set it upright.

As always, thanks for the input. All your points are valid of course. My thoughts below:

No problem, I don't want to come off as if I am telling you what to do. As I am in the final process of assembling mine I have been thinking and reading about this for some time so I have weighed up a few pro's and con's myself. What is important to me might not be to you, either way I will respond to your responses!

Entirely agree. But I think I can make it work. Also, I can get everything wired with drivers installed which actually will help add a little stability to it. And then I just need to get it a few feet from the shop to the corner where it will be much more stable once in place. The other thing is, if I make a stand alone speaker that is nearly the height of the room, I may not be able to stand it up (might get stuck). Whereas standing up just a baffle will be easy.

I actually think that having all the drivers and wiring will make it much worse. If you do it that way you will need some extra strength to the sides of the baffle.

The size is a fair point to consider, two options, a 25 driver line should be no problem and you can build a cover plate for the extra. If you decide for a total floor to ceiling line cut a small recess in the ceiling so you can lift it in and drop it down.

This is actually the biggest concern I have. However, with the relatively small size of the triangular cross section, I'm not sure I'll need that much bracing. The other thing I could do is to brace similar to what you had shown with dados into the front baffle. And then screw into the rear from the other side of the wall. Or just apply some foam tape to the faces that would touch the walls and count on the compression from screwing the baffle into the walls to provide the support. I don't love either of those ideas, but perhaps they will spur on some better ideas.

Apart from the reduction in internal volume it almost isn't possible to have too much bracing. Do not underestimate that or you will create a resonant cabinet.

This is a new one I had not thought about. And I'm not sure I understand it. Are you saying that there may be a problem transferring sound through the walls and that will disturb the rest of the house? In which case, I actually don't care.Or perhaps other things will vibrate and that will cause problems with overall sound quality? That would be a problem! Given the energy is distributed across so many drivers though, I wonder if that would ever be an issue. Just an open question... I don't know. The reason I bring it up is that it seems like the drivers do not work very hard even at high SPL so I'm extrapolating from that.

Both I suppose as energy will transfer either way, but it was vibrations and movement from the house transferring to the cabinet that would make it worth isolating. The amount of energy dissipated into the cabinet won't reduce just because it is spread over 25, the peak of it will be different due to excursion and being being spread but the overall amount won't change.

Absolutely true. But testing in place is kinda necessary for this application. I should be able to service in place too in terms of driver replacement at least. Besides, in all the speakers I've ever built, I've never had to service anything (knock on wood) so even if I do, I don't think it would be frequent enough to drive a design decision IMHO.

I disagree with the testing in place somewhat. You really want to know what is coming from your speaker and what is coming from your room. The best way to do that is to make an outdoor measurement with sufficient distance to give you clean results. Gating and frequency dependant windowing are things you can use indoors but a clean outdoor result is the closest you will get to an anechoic response. The final result in room is the most important factor but good outdoor measurement would make the process easier. How practical it is to measure a full length line array outdoors is a totally different question.

I hope you don't think I'm discounting your ideas. I really appreciate the input! And the debate is part of the fun for me so I sincerely hope you think so too.

Not at all, just throwing out suggestions as to what I would do, if they don't work for you no harm done. Some of it is actual experience of doing something very similar to what you propose

Where is your build thread!? Would love to see your progress.

I'm thinking about building the "simple" baffle-only version first to see how that goes and what I can learn from that journey. And if it doesn't work out, it will be easy to simply repurpose that into a fully independent stand alone speaker as it would basically mean cutting a couple lengths of plywood and screwing into those instead of the walls. And if it doesn't work out, I can save someone else the pain by saying definitively that one way is better than the other.

I'm thinking about building the "simple" baffle-only version first to see how that goes and what I can learn from that journey. And if it doesn't work out, it will be easy to simply repurpose that into a fully independent stand alone speaker as it would basically mean cutting a couple lengths of plywood and screwing into those instead of the walls. And if it doesn't work out, I can save someone else the pain by saying definitively that one way is better than the other.

I'd be very concerned about having any of the cabinet attach directly to walls in my room. I use speakers up very close to the wall, but there is undeniably bad degradation when the cabinet even touches the wall behind it. The walls at least here aren't that "dead" (quite the opposite in fact), and these are even old lathe and plaster walls for the most part with some drywall where doorways were covered and changes were made over the years.

Do you think there's a difference between speakers touching the walls versus being intimately part of the wall? I'm thinking about in-wall speakers where the walls are actually part of the cabinet. It seems those designs do fine. Even the infinite baffle subwoofers with manifolds built into the walls seem to do ok. Some of them are designed to cancel each other out, but some are not.

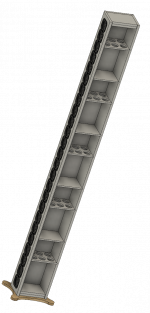

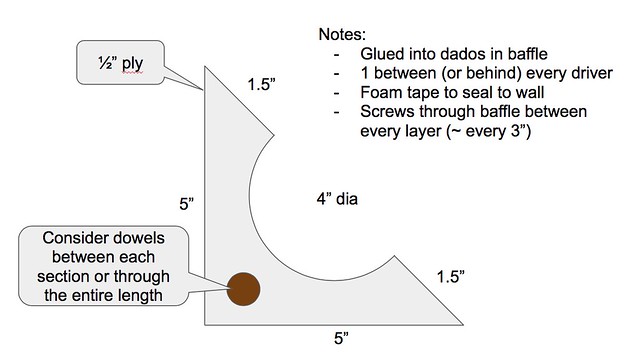

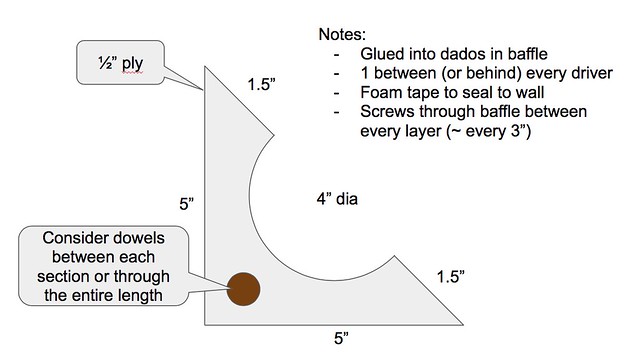

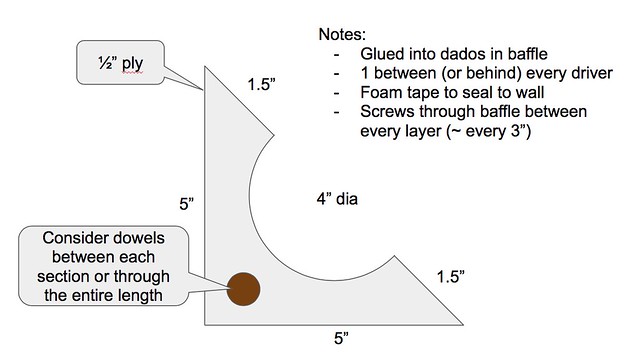

Independent of separate enclosure or part of the wall, I took the rigidity of the cabinet to heart. Here's an idea for bracing (dimensions approximate).

I could do one between every driver at the expense of either less volume or a larger cabinet. Maybe one every two would be a good compromise but I'm leaning towards one per driver. Also, if I build to the wall, I can use pocket screws to secure directly to the wall vs the foam tape to seal and relying on the screws from the baffles to keep everything tight. I might need to go to 3/4" thick in that case to have enough material for the pocket screws to work well. Alternatively, I could try to biscuit and glue them in but that's an assembly nightmare. If I build a standalone cabinet, I would likely just dado and glue (and the dowels wouldn't necessary at all then.)

Question... do you think it makes more sense to space them between drivers or directly behind the center of the drivers? I'm leaning towards between the drivers as that could reduce the size of the circular cutout for a stronger brace. Also, would it make sense to offset the drivers to one side? Not sure if baffle step compensation concepts apply for this situation directly, but thought it was worth asking.

I could do one between every driver at the expense of either less volume or a larger cabinet. Maybe one every two would be a good compromise but I'm leaning towards one per driver. Also, if I build to the wall, I can use pocket screws to secure directly to the wall vs the foam tape to seal and relying on the screws from the baffles to keep everything tight. I might need to go to 3/4" thick in that case to have enough material for the pocket screws to work well. Alternatively, I could try to biscuit and glue them in but that's an assembly nightmare. If I build a standalone cabinet, I would likely just dado and glue (and the dowels wouldn't necessary at all then.)

Question... do you think it makes more sense to space them between drivers or directly behind the center of the drivers? I'm leaning towards between the drivers as that could reduce the size of the circular cutout for a stronger brace. Also, would it make sense to offset the drivers to one side? Not sure if baffle step compensation concepts apply for this situation directly, but thought it was worth asking.

Last edited:

Yes, I think this came up in a previous section of this thread. I'll try this first when the time comes.Loopback in Jriver uses a wdm driver so it doesn't work outside of windows. On OSX you can use Soundflower a similar thing. There is also a commercial version of it now from Rogue Amoeba called loopback. As is always the case with OSX most good things end up moving away from open source.

I've used Kodi for some basic streaming but nothing fancy. I'm likely to just use my existing video sources for now.For movies and TV, Kodi (formerly XBMC) is a really good piece of software. I use it on Cubox-i for playing TV shows and movies to my TV over wifi and it is really user friendly. I don't know if they have got to support atmos yet but it is only a matter of time. The lossless movie audio formats are already supported. There are versions for all platforms and it can be controlled across the room with an IR remote or tablet etc. There is DSP addon to allow convolution but not for MacOS. You can always pipe the audio from Kodi through another program to get convolution but it starts to get more complicated at that stage.

Yes, I'm thinking that Dirac will be what I use for most of the home theater stuff until I get my feet wet with convolution for 2-channel. That said, why would I need to pre-EQ? Shouldn't Dirac do EQ as part of it's black box stuff? (I do plan on playing with Room EQ outputs and manually entering into the parametric EQ just to see how close I get with that regardless.)Dirac is good as far as point and shoot room correction is concerned but it will not do what wesayso has achieved through manual tweaking in DRC FIR and I imagine that it would work much better if you used some pre EQ to get the lines in the ballpark of flat which they won't be without it.

It's coming but I keep getting distracted on other peoples threadsWhere is your build thread!? Would love to see your progress.

I'm thinking about building the "simple" baffle-only version first to see how that goes and what I can learn from that journey. And if it doesn't work out, it will be easy to simply repurpose that into a fully independent stand alone speaker as it would basically mean cutting a couple lengths of plywood and screwing into those instead of the walls. And if it doesn't work out, I can save someone else the pain by saying definitively that one way is better than the other.

Bill has given you some more advice against it too but if you want to give it a try you are now aware of what the issues might be. Run an impedance test when you are done and that will show you where the issues lie as cabinet problems show up as wiggles in the impedance response.

Independent of separate enclosure or part of the wall, I took the rigidity of the cabinet to heart. Here's an idea for bracing (dimensions approximate).

I could do one between every driver at the expense of either less volume or a larger cabinet. Maybe one every two would be a good compromise but I'm leaning towards one per driver. Also, if I build to the wall, I can use pocket screws to secure directly to the wall vs the foam tape to seal and relying on the screws from the baffles to keep everything tight. I might need to go to 3/4" thick in that case to have enough material for the pocket screws to work well. Alternatively, I could try to biscuit and glue them in but that's an assembly nightmare. If I build a standalone cabinet, I would likely just dado and glue (and the dowels wouldn't necessary at all then.)

Question... do you think it makes more sense to space them between drivers or directly behind the center of the drivers? I'm leaning towards between the drivers as that could reduce the size of the circular cutout for a stronger brace. Also, would it make sense to offset the drivers to one side? Not sure if baffle step compensation concepts apply for this situation directly, but thought it was worth asking.

If you are going to brace the void that much then I really can't understand why you wouldn't build an enclosure isolated from the wall. You could build it in situ it doesn't actually have to be separate. Cut the pieces as if they were going to be a separate cabinet and then assemble them on the wall. That way you can use some neoprene between the panels and the wall. That's my last attempt to persuade you, you decide now

The triangular cabinet will have a reduced volume and you need to know how much you will have, a brace every driver will reduce that down even further. A linkwitz transform can help to restore that but it also burns power. The bigger the cabinet the more it does the work instead of the amp. I settled at a Q of 0.8 when the damping is taken into consideration.

If you give me your exact internal dimensions I can put it into Bassboxx Pro and it will give me the volume numbers for you. It subtracts the volume the driver occupies and accounts for the damping to get a more realistic number.

I separated my cabinet into 5 sections and used solid braces to seal them. Each section of 5 drivers then has a cut out brace placed between the 3rd and 4th driver. This makes every section exactly the same in terms of volume an layout so it should minimize any discontinuity from the drivers not occupying a common volume.

If you mount the drivers with the terminals to the side there is enough room to fit a 9mm ~3/8" brace in between with the drivers mounted frame to frame. If you mount them terminals towards the brace there isn't enough room. 1/2" would fit but it would be very close to the magnet and restrict the backwave quite a bit.

Here are some 3D shots to show what I mean

Attachments

I would actually build something but I keep getting distracted by other peoples' advice.It's coming but I keep getting distracted on other peoples threads

Yes indeed... well informed folly is better than uninformed folly I suppose! What's good for an impedance test? Fuzzmeausure works on Mac...Bill has given you some more advice against it too but if you want to give it a try you are now aware of what the issues might be. Run an impedance test when you are done and that will show you where the issues lie as cabinet problems show up as wiggles in the impedance response.

Yes, I'm thinking that Dirac will be what I use for most of the home theater stuff until I get my feet wet with convolution for 2-channel. That said, why would I need to pre-EQ? Shouldn't Dirac do EQ as part of it's black box stuff? (I do plan on playing with Room EQ outputs and manually entering into the parametric EQ just to see how close I get with that regardless.)

Dirac will have built in limits as to how much it can cut and boost. Remember it is room correction software and you are trying to get it to do speaker correction and room correction at the same time. The closer you get the speaker to be flat before the better. If you try and do it all with dirac in one go I think you might be disappointed but hey I have never tried it.

The more processing that Dirac has to do makes it more likely that it will only be correct for one point where you measured. To get a better off axis spread you want to limit the amount of room correction.

Wesayso's use of room correction software is a really good way of using a fine grain FIR filter to adjust frequency and phase response of the speaker in the mid to higher frequencies and progressively more room as the frequency goes down. You cannot get the same result with an automated system yet.

Frequency response issues in the modal region respond well to EQ, acoustic issues or non minimum phase problems do not. Room correction will try to fix both because it is a machine trying to fit a response to a curve. It doesn't know that by doing that it will sound wrong.

The overriding thing I have taken from wesayso's journey is that to get the best result you need to go the extra mile as far as you can. Every time you compromise for the sake of making it easier to build or easier to eq the result gets worse. How much worse is hard to say but try and do as much as are willing to as it will pay you back.

I would actually build something but I keep getting distracted by other peoples' advice.

Very true, lol

Yes indeed... well informed folly is better than uninformed folly I suppose! What's good for an impedance test? Fuzzmeausure works on Mac...

I would use REW works on a mac too

https://www.roomeqwizard.com/help/help_en-GB/html/impedancemeasurement.html#top

If you are going to brace the void that much then I really can't understand why you wouldn't build an enclosure isolated from the wall. You could build it in situ it doesn't actually have to be separate. Cut the pieces as if they were going to be a separate cabinet and then assemble them on the wall. That way you can use some neoprene between the panels and the wall. That's my last attempt to persuade you, you decide now

I want my cake and eat it too! Perhaps I'm putting too much value in the concept of having the drivers as close to the wall as possible, in the simplicity of just building out the baffle with the rest of the cabinet in the walls, and the lesser visual footprint of a somewhat narrower baffle. And there's also the curiosity of seeing if I can make it work this way. In addition to the minimal downside risk as I can always adapt this work to the stand alone if need be.

I'd like each driver to have 2.0L of space. The resulting dimensions if I did my math correctly was a right isoceles triangle with interior dimensions of about 125mmx125mm. This was not accounting for braces and driver volume but did include extra space because the vertical length was able to accommodate 28 drivers vs the 25 I planned on (93" floor to ceiling). I would also assume mounting the drivers on a 3/4" baffle from the outside.If you give me your exact internal dimensions I can put it into Bassboxx Pro and it will give me the volume numbers for you. It subtracts the volume the driver occupies and accounts for the damping to get a more realistic number.

Understood. Perhaps 1/2" solid bracing for every five drivers and then cut out braces everywhere else.If you mount the drivers with the terminals to the side there is enough room to fit a 9mm ~3/8" brace in between with the drivers mounted frame to frame. If you mount them terminals towards the brace there isn't enough room. 1/2" would fit but it would be very close to the magnet and restrict the backwave quite a bit.

Thanks for checking my math with Bassbox!

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- "Wall-integrated" corner loaded line array with Vifa TC9 drivers