That's an erm 'dense' webpage. Given it mainly quotes 60s work before microline stylii were the norm not sure its universally applicable.

Swdedish Analog Technologies - SAT this guy claims his antiskate 'does' work across the whole record, but at $28k for the arm I am not about to find out.

Swdedish Analog Technologies - SAT this guy claims his antiskate 'does' work across the whole record, but at $28k for the arm I am not about to find out.

I look at 'SAT' arm and Swedish Analog TEchnologies - ARTICLES, and see nothing new; it still is a big stiff mass, with a little bob over a pulley for anti-skating. And of course not a single bit of measurement; let alone comparison to other arms.

The article is void of content:

Wow! From 'potentially' in first sentence to 'has a bigger effect' in the second sentence.

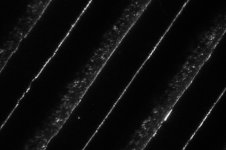

The SEM photo tells a lot more in the context of friction. A series of such photos of fresh cut master, of master after plating, of master after etching, and follow ups of photos for 1st pressing, mid run of pressing and of final pressing. As is the previously posted SEM looks like canyon walls withered with erosion, with scale of ruts much finer than what 20kHz sine modulated onto grove walls looks like.

The electron cloud about the locus of stylus tip v cloud of electrons at surface of record groove in motion; a perfect storm replete with cloud to cloud lightning and wind.

Surely modern polymer science could/has produce better vinyl, but not much point if you've got a master recording worthy of distribution. But finding treatments for existing vinyl devoid of snake oil seems possible too. Synthetic motor oil revolutionized engine life expectations, why not real deal equivalent for vinyl records?

For the truly priceless recordings for which no master recording exist, techniques such as employed by Smithsonian may be used. There goals aren't to retrieve audio from discs for purpose of stamping more discs.

The article is void of content:

The arm is potentially responsible for far more distortion than it is the turntable. An improvement in the performance of the arm has a bigger effect on the overall reproduction accuracy of the system.

Wow! From 'potentially' in first sentence to 'has a bigger effect' in the second sentence.

The SEM photo tells a lot more in the context of friction. A series of such photos of fresh cut master, of master after plating, of master after etching, and follow ups of photos for 1st pressing, mid run of pressing and of final pressing. As is the previously posted SEM looks like canyon walls withered with erosion, with scale of ruts much finer than what 20kHz sine modulated onto grove walls looks like.

The electron cloud about the locus of stylus tip v cloud of electrons at surface of record groove in motion; a perfect storm replete with cloud to cloud lightning and wind.

Surely modern polymer science could/has produce better vinyl, but not much point if you've got a master recording worthy of distribution. But finding treatments for existing vinyl devoid of snake oil seems possible too. Synthetic motor oil revolutionized engine life expectations, why not real deal equivalent for vinyl records?

For the truly priceless recordings for which no master recording exist, techniques such as employed by Smithsonian may be used. There goals aren't to retrieve audio from discs for purpose of stamping more discs.

Yes - strictly it is the stylus rake angle, SRA, which has influence on friction. Hence, in some circumstances, very sensitive variation in performance for small changes in SRA (ie VTA). VTA and SRA are linked because the stylus is fixed at a set angle in the cantilever, of course.Re VTA issue, see VTA

Yosh's collated resources are just great. AFAIK there is nothing about variation in friction though, eg short term dynamic variation, but then there is very little written on the subject. And yet it remains a profound influence on performance, pretty much uncharted after all these decades.........

There is a common lore that SRA is optimal at 92 deg, but the exact number and how much benefit there is available from precise setting depends on the specific stylus, and can vary widely IME.

Anti-skate has to be a compromise, dependent on vinyl formulation, groove profile, maybe stamper lifecycle, stamper generation, groove pitch and so many other possibilities.

It would be interesting to see SEM images of the groove "texture" from a new stamper and a worn one. How much is from the vinyl and how much is from the stamper itself

It would be interesting to see SEM images of the groove "texture" from a new stamper and a worn one. How much is from the vinyl and how much is from the stamper itself

Last edited:

Yes. It's momentary variation in friction that is the performance issue, because it creates dynamic variation in tonearm pull. In an offset arm, this in turn creates moment to moment variation or modulation of skate force, which is a stimulus to move the headshell and excite the cart/arm resonance. In a linear tracking arm, although the variation in friction force is still there, there is no skate force so there can be no modulation of skate force. Thus lateral stability benefits from reduced stimulus for a linear tracking arm - which is just as well, because lateral stability can be a weak point in linear arms.Could the variable in skating force be one of the reasons that linear tracking arm advocates claim such audible improvements?

However the gains aren't total, because the fundamental moment-moment variation in tonearm pull remains, and it is still applied via the cantilever at a vertical angle (VTA). This is true for both linear tracking arms and offset arms. So there's still variation in upforce, and which (amongst other things) is also a stimulus for headshell motion.

Yes it would !It would be interesting to see SEM images of the groove "texture" from a new stamper and a worn one. How much is from the vinyl and how much is from the stamper itself

Here's one of my own optical micrographs which is lit and contrasted to view the grainy surface of one vinyl wall. This was always a particularly noisy example I should say, so somewhat exaggerates......nevertheless the grain structure of the wall is just about visible with optical microscopes for normal records. Note the random nature of the grain.

Attachments

Last edited:

Wasn't there a Denon tonearm which corrected dynamic bias with some kind of electronics at the base of the tonearm ?

Denon DP-35F

Yes. The DP-35F has a servo which can apply torque to the tonearm - definitely by way of providing damping, and quite possibly also to provide antiskate torque. In any event, tonearm damping is the only known antidote for instability caused by friction noise variation in skate force, so it must help I think.

There are two separate effects of noise variation in friction:reminds me, I had an offer of a townsend silicon trough I had to pass on recently. Hadn't considered how it might effect noise.

One is to be a stimulus for tonearm motion, exciting the cart/arm resonance instability - this can be treated to an extent by tonearm damping.

The other is to cause the stylus to momentarily mistrack, ie lose contact with one groove wall, and so produce familiar crackle pop noise. Or, below the threshold of mistracking, the familiar background roar. This noise isn't treatable by tonearm damping, unfortunately.

Yes, this is true.ok. On inspection the damping would seem to keep the cartridge more stable which should give an increase in the resistance to mistrack.

Thanks Barleywater and Lucky.

Damping is interest subject. Tonearm while playing moves towards the center and some people don't prefer antiskate. So having a high precision lowest resistance bearing may not be the end of the story. If we put viscous liquid damping trough near pivot which would resist the skating force we can benefit with both i.e. it would serve as antiskate and damp resonance. With proper equipment and measurements we can adjust viscosity of the liquid or put in an adjustable paddle which can be lowered in and out of liquid to achieve nearly perfect antiskating. Right ?

Damping is interest subject. Tonearm while playing moves towards the center and some people don't prefer antiskate. So having a high precision lowest resistance bearing may not be the end of the story. If we put viscous liquid damping trough near pivot which would resist the skating force we can benefit with both i.e. it would serve as antiskate and damp resonance. With proper equipment and measurements we can adjust viscosity of the liquid or put in an adjustable paddle which can be lowered in and out of liquid to achieve nearly perfect antiskating. Right ?

Indeed. Precision is needed, yes. Low viscous drag is not ideal, no. The correct amount of the right type of resistance to motion is needed. Yes an oil paddle can help supplement and provide damping. Most standard tonearm/cart combinations are sub-optimal in this respect IME.So having a high precision lowest resistance bearing may not be the end of the story.

Damping can help treat symptoms of noise variation in skateforce. Static antiskate though, is a waste of good drinking time, unless it is done by a servo which can sense and correct momentary variations. A steady torque doesn't help much, might as well press up VTF by 10% and save the antiskate mechanism IMO. Yes, damping better addresses the symptoms.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- vinyl coefficient of friction