Came across this 1982 JAES article on record friction http://www.audiomods.co.uk/papers/pardee_recordfriction.PDF (note as available on web hope this not any sort of Copyright infringement).

Now record lube has a bad name these days for many reasons, but the part I found interesting was the increase in friction for a cleaned new record. I had always assumed that, whilst mould release agent is slippy, the vinyl plasticizers were also quite slippy and would ooze out to the surface after cleaning.

Any polymer experts care to comment (you know who you are!)

Now record lube has a bad name these days for many reasons, but the part I found interesting was the increase in friction for a cleaned new record. I had always assumed that, whilst mould release agent is slippy, the vinyl plasticizers were also quite slippy and would ooze out to the surface after cleaning.

Any polymer experts care to comment (you know who you are!)

Came across this 1982 JAES article on record friction http://www.audiomods.co.uk/papers/pardee_recordfriction.PDF (note as available on web hope this not any sort of Copyright infringement).

Now record lube has a bad name these days for many reasons, but the part I found interesting was the increase in friction for a cleaned new record. I had always assumed that, whilst mould release agent is slippy, the vinyl plasticizers were also quite slippy and would ooze out to the surface after cleaning.

Any polymer experts care to comment (you know who you are!)

I would love to know where the mold release meme comes from- it's just not used for records or CDs. As many times as that urban legend is knocked down, it keeps getting repeated.

Yes, the vinyl compounds have plasticizers in them which you don't want to remove.

In any case, there's a lot of chemical treatments which can alter the CoF and most have been used somewhere or other. The question then is, does that bring a net benefit? The best ones I've seen use reactive surfactants, generally short-chain fluorocarbons, but I was unconvinced that the changes in the sound were actually improvements or that they actually prolonged vinyl life. Most of these potions have disappeared over the years. Is LAST still around? The worst ones built up gunk on the record surface or (like the wet-play systems) seemed to actually damage the grooves. I remember one spray system much loved by certain reviewers which was based on fatty aliphatic quats, and would leave a nice permanent varnish on the stylus.

Personally, I just use a little distilled water and a good record brush.

So why would cleaning some records with the same fluid as others make such a difference? 40% increase in some cases and one where it doubled (although I suspect that may have been an experimental error as such as outlier). I don't know where I picked this possible wrongness up but I had read that the plasticisers can migrate so IF the friction increase was caused by the detergent removing them they would return over time.

I suppose I am still confused in this case what is increasing CoF when normally one considers clean to be more slippery! Its one of those expectation things.

I suppose I am still confused in this case what is increasing CoF when normally one considers clean to be more slippery! Its one of those expectation things.

Actually, the opposite. Clean is often much less slippery than dirty. Think of glass with some grease on it versus glass that has been fully and carefully degreased.

If you remove plasticizers from the surface, indeed you will have more bloom up. That will eventually embrittle the vinyl, which leads to increased noise and surface damage.

If you remove plasticizers from the surface, indeed you will have more bloom up. That will eventually embrittle the vinyl, which leads to increased noise and surface damage.

yes realised that after posting. I was mixing up the 'squeaky clean' of say removing limescale from a window vs 'lubricated'.

So following this up (and thinking about an experiment) If you cleaned a record and CoF went up (new record no atmospheric glorp on it) would it go back down over a period of hours/days?

Do I also read that 0 or 1 are the SY recommended cleaning cycles a record should dgo through?

So following this up (and thinking about an experiment) If you cleaned a record and CoF went up (new record no atmospheric glorp on it) would it go back down over a period of hours/days?

Do I also read that 0 or 1 are the SY recommended cleaning cycles a record should dgo through?

Yes, if you remove the plasticizer from the surface, more will bloom back over a few hours or so. If you play the record immediately, the damage will unfortunately be permanent.

The goal of washing should be to only remove external contaminants, and there's some very good ways to do that- I'm sure many have been commercialized. I use distilled/deionized water with a tiny bit of a proprietary surfactant. Something like Photoflo (if that's still around) could work quite well also, but it should be HIGHLY diluted (100:1 at least).

The goal of washing should be to only remove external contaminants, and there's some very good ways to do that- I'm sure many have been commercialized. I use distilled/deionized water with a tiny bit of a proprietary surfactant. Something like Photoflo (if that's still around) could work quite well also, but it should be HIGHLY diluted (100:1 at least).

Thank you. Good to get a considered view rather than the nonsense that is spoken. I have a bit of an ebay habit as cannot resist grab bags. Some are pristine, like the 1979 delos I just put on (soundstream recording but mighty fine and only 10p). and others are filthy. I use disk doctor and DI water with a vac dry but not found something for the serious basket cases.

I would use a very mild detergent, highly diluted, then rinse with the water-wetting agent combo. I have been thinking about a really effective record cleaning solution (I've learned a lot in the past 3 years about the chemistry of cleaners since taking my most recent job), but I'm cursed with a terminal case of Project Backup.

Stylus-groove friction is the most important unmentioned factor in vinyl playback IMO. The classic co-efficient of friction ranges from 0.2 - 0.55 (JVC, Yamamoto), depends on stylus profile, alignment and very much on vinyl composition.

Yes, cleaning vinyl often results in higher friction IME, and this is bad news.

Friction is not constant, but has a strong random element following a flicker noise law (1/f) so very low frequency loaded. This represents a stick-slip model, and because the applied force has an upward component can cause momentary loss of contact between stylus and groove. This is the commonly heard 'crackle noise' or 'pop' on certain pressings, it is seldom dirt especially on new pressings.

Cleaning with detergents and other agents alters the vinyl surface, typically increasing friction. Adding a lubricant can offset this, so the outcome depends closely on the exact formulation of the 'cleaning' agent, but without a lubricant many pressings end up with a background crackle-pop noise due to friction flicker noise.

Stylus profile and alignment critically affect friction. This is why azimuth and VTA affect performance, especially noise, so much. Stylus wear increases friction, again why the onset of wear can be marked by increase in crackle-pop and mistracking.

So, it's fascinating IMO. And, if one is into getting the best from vinyl playback, friction is worth minimising and certainly worth thinking about.

Interesting ?

I spent a few years reading and analysing it.

Yes, cleaning vinyl often results in higher friction IME, and this is bad news.

Friction is not constant, but has a strong random element following a flicker noise law (1/f) so very low frequency loaded. This represents a stick-slip model, and because the applied force has an upward component can cause momentary loss of contact between stylus and groove. This is the commonly heard 'crackle noise' or 'pop' on certain pressings, it is seldom dirt especially on new pressings.

Cleaning with detergents and other agents alters the vinyl surface, typically increasing friction. Adding a lubricant can offset this, so the outcome depends closely on the exact formulation of the 'cleaning' agent, but without a lubricant many pressings end up with a background crackle-pop noise due to friction flicker noise.

Stylus profile and alignment critically affect friction. This is why azimuth and VTA affect performance, especially noise, so much. Stylus wear increases friction, again why the onset of wear can be marked by increase in crackle-pop and mistracking.

So, it's fascinating IMO. And, if one is into getting the best from vinyl playback, friction is worth minimising and certainly worth thinking about.

Interesting ?

I spent a few years reading and analysing it.

Lower tracking force reduces total friction, but that does not help much because it is the ratio of friction to VTF that matters, in terms of keeping the stylus in contact with the groove and thus avoiding crackle-pop noise. Since friction is approx. proportional to VTF, changes to VTF don't significantly change that ratio, so effect is small in practice.How about cartridge which require less tracking force ? Will reduce friction I guess.

Regards.

Here's some detail on the relationship between friction and crackle-pop noise.

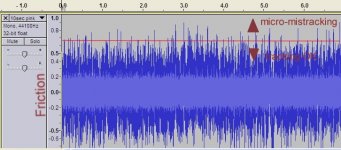

The first attachment below is not from vinyl playback, but nicely shows how measured friction between a stylus and a surface varies randomly with time. There is an average friction level (1) and noise variation resulting in peaks and troughs (2) which are prominent at very low repetition rates, following a 1/f energy law (flicker noise).

Random variation in friction force means random variation in stylus upforce, acting against VTF to lift the stylus, there being a vertical component to applied friction forces (reaction) because of involved angles. It also means random variation in skate force, which acts to make the headshell move inward, applied tonearm reaction force is applied at tracking offset angle (c 22 deg).

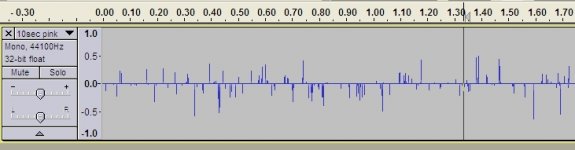

The second attachment shows synthesised pink noise (1/f), representing variation in stylus-groove friction force. It also shows a threshold, arbitrarily, at -5dB representing the force at which VTF is overcome and the stylus loses contact with one of the groove walls. This is micro-mistracking, very short term loss of contact between stylus and at least one of the groove walls.

The third attachment shows simulated cartridge output arising from micro-mistracking when the friction force momentarily randomly exceeds the threshold set out in the example above. You can see it has the appearance of random pops and crackles, and an audio file of these events sounds exactly like the familiar crackle-pop of vinyl surface noise.

So friction force, especially random variations in it, often plays a dominant role in crackle-pop surface noise. Methods which reduce friction reduce surface noise, and vica versa.

The first attachment below is not from vinyl playback, but nicely shows how measured friction between a stylus and a surface varies randomly with time. There is an average friction level (1) and noise variation resulting in peaks and troughs (2) which are prominent at very low repetition rates, following a 1/f energy law (flicker noise).

Random variation in friction force means random variation in stylus upforce, acting against VTF to lift the stylus, there being a vertical component to applied friction forces (reaction) because of involved angles. It also means random variation in skate force, which acts to make the headshell move inward, applied tonearm reaction force is applied at tracking offset angle (c 22 deg).

The second attachment shows synthesised pink noise (1/f), representing variation in stylus-groove friction force. It also shows a threshold, arbitrarily, at -5dB representing the force at which VTF is overcome and the stylus loses contact with one of the groove walls. This is micro-mistracking, very short term loss of contact between stylus and at least one of the groove walls.

The third attachment shows simulated cartridge output arising from micro-mistracking when the friction force momentarily randomly exceeds the threshold set out in the example above. You can see it has the appearance of random pops and crackles, and an audio file of these events sounds exactly like the familiar crackle-pop of vinyl surface noise.

So friction force, especially random variations in it, often plays a dominant role in crackle-pop surface noise. Methods which reduce friction reduce surface noise, and vica versa.

Attachments

Thank you, very interesting (and makes complete sense when you think about it. Do you have any practical experience on what lubricant to use and how? On records that need cleaning I tend to use disk doctor on an orbitrac followed by DI rinse and vac dry. Sounds like that might be wrong.

In my youth (1991 ish) there was a fad of using armourall. I tried it once. Baaaaaad move! Luckily on tried on one nearly dead album

In my youth (1991 ish) there was a fad of using armourall. I tried it once. Baaaaaad move! Luckily on tried on one nearly dead album

Last edited:

LAST

Back in the early 80s I would clean each new record as thoroughly as I could with the Discwasher felt pad, then spray and buff it with, I think "Sound Guard" then "LAST."

Seemed to work fine: the records were very shiny and generally had pretty low surface noise. I never did any controlled experiments, though.

My vinyl playback was the best domestic one I had heard up to that time: Thorens TD160 with a Pickering XSV-3000. The records that I treated still sounded good about 10 years ago when I disassembled my vinyl playback system.

Back in the early 80s I would clean each new record as thoroughly as I could with the Discwasher felt pad, then spray and buff it with, I think "Sound Guard" then "LAST."

Seemed to work fine: the records were very shiny and generally had pretty low surface noise. I never did any controlled experiments, though.

My vinyl playback was the best domestic one I had heard up to that time: Thorens TD160 with a Pickering XSV-3000. The records that I treated still sounded good about 10 years ago when I disassembled my vinyl playback system.

Hi Bill. I found my simulation of crackle-pop noise, attached it as a wav file within the .zip folder below. It's a 10 second simulation of crackle-pop noise, generated entirely synthetically simply by taking 1/f noise through a noise gate set at an arbitrary threshold. It simulates micromistracking as described above, the mechanism by which friction influences crackle-pop surface noise.Thank you, very interesting (and makes complete sense when you think about it. Do you have any practical experience on what lubricant to use and how? On records that need cleaning I tend to use disk doctor on an orbitrac followed by DI rinse and vac dry. Sounds like that might be wrong.

In my youth (1991 ish) there was a fad of using armourall. I tried it once. Baaaaaad move! Luckily on tried on one nearly dead album

I continue to search for the magic elixir that can recondition vinyl surface permanently without altering modulation, leaving a residue which gums, or damaging longevity of the record. My best results to date come from using very dilute solutions of siloxane, in an organic carrier. But I have nothing really worthy to write about.

A temporary and tantalising demonstration of the excellent benefits available is very easy to show by playing with a layer of distilled water as a lubricant. However, the act of doing this often results in permanent degradation of friction & crackle-pop noise when subsequently played dry IME.

So, philosophically, I try hard to avoid cleaning records at all, rather aim to minimise friction by selection of stylus profile, quality, and alignment. I try to buy copies which are already quiet, and for records which have intolerable surface noise I either use a home-brew siloxane treatment or play back wet.

I feel sure one day someone will come up with an elixir that reconditions vinyl surface for the purpose of minimising playback friction.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- vinyl coefficient of friction