I continue to search for the magic elixir that can recondition vinyl surface permanently without altering modulation, leaving a residue which gums, or damaging longevity of the record. My best results to date come from using very dilute solutions of siloxane, in an organic carrier.

By "siloxane" do you mean PDMS? That's been a very problematic material for stylus fouling since it doesn't bond to the vinyl. It will definitely lower the CoF.

Yes, PDMS is the polymer, and yes it does not bond so tends to accumulate on the stylus, especially after the initial application. It's no good really. Ideally, I imagine a designer polymer chain with one end that bonds and one end that lubricates. Or perhaps there's a natural constituent of the vinyl composition that would simply (re)condition the surface if re-applied? It's tribology of stylus-groove contact at the molecular level across a very small surface that is at issue I think.By "siloxane" do you mean PDMS? That's been a very problematic material for stylus fouling since it doesn't bond to the vinyl. It will definitely lower the CoF.

Gumming aside, lubricants (including water) work remarkably well in preserving (and improving) programme content IME. I think this is because what matters is that the base of the stylus follows the locus of the base of the groove, so riding on a thin layer doesn't much impair tracing accuracy.

Oddly, measured harmonic distortion @1kHz typically slightly improves with lubrication IME, and I really can't explain that. Low frequency stability (amplitude of resonant cart/arm movement), improves significantly, due to reduction in stimulus from variation in skate force, though Q remains unaltered. Unfortunately, each experiment burns a test record, I need a grant !

Aquaplaning?Gumming aside, lubricants (including water) work remarkably well in preserving (and improving) programme content IME. I think this is because what matters is that the base of the stylus follows the locus of the base of the groove, so riding on a thin layer doesn't much impair tracing accuracy.

Yes, I think so. And that's OK if the locus of the stylus base follows the locus of the groove base, which seems so.Aquaplaning?

When I got into vinyl wet playing was already out of fashion in UK and it was very much 'only a hunt brush and the stylus should touch the record'. It was only when I started collecting second hand stuff that I found ones that needed a deep clean. I' m still umming over trying an ultrasonic cleaner for the really filthy stuff.

So secondary question, if you buy a second hand record should you play first or clean first. Which comes down to, will the fact that the stylus melts the vinyl cause it to embed the dirt so it will never come out? (ignoring the fact that if its that dirty it may already have been ruined!)

So secondary question, if you buy a second hand record should you play first or clean first. Which comes down to, will the fact that the stylus melts the vinyl cause it to embed the dirt so it will never come out? (ignoring the fact that if its that dirty it may already have been ruined!)

It's a widespread myth that vinyl melts during playback. Frictional heat is mostly conducted away from the contact area because of the exceptional thermal conductivity of the diamond, and the small fraction that is left is dissipated by a perpetually changing vinyl surface. Typical frictional power equates to about 3.5mW dissipated as heat, distributed between stylus and groove. If you're lucky, vinyl wall heats by c 10 deg to a depth of 100nm of so. Stylus contact region might be a bit warmer, but not much, diamond is an exceptional conductor of heat away from the contact region - this is why stylus has to made from diamond, btw..... will the fact that the stylus melts the vinyl cause it to embed the dirt so it will never come out?

When a record is truly dirty, there's no alternative but to clean it. However, not much dirt is small enough to get into the part of the groove that matters, usually biological infiltration by molds is the cause of 'true grit'. Fluids from coughing or mucus from saliva spots is another common cause. It's best to avoid truly dirty records, IMO, if at all possible. Once you get into cleaning, then you're into the hazards that the vinyl surface may then need conditioning afterwards and its all a bit of a crapshoot IME.

No good can come of playing records which are known to have contaminated grooves - the contaminants are abrasive. If the record looks clean but still has pronounced crackle-pop noise, chances are it's not dirty, rather the surface has high friction. If the cleaning regime includes a lubricant, or if the vinyl surface tolerates the cleaning, the situation might improve. Still a crapshoot, IMO.

The records that I treated still sounded good about 10 years ago when I disassembled my vinyl playback system.

The records I treated with Last back in the 80's still sound good, but so do all the other "untreated" ones.

jeff

Well, ignoring random variation, friction force F = VTF*k, where k is coefficient of friction 0.2 - 0.55. So for a VTF of 2gf (c 0.02N), friction force is perhaps 0.006N, and applied at a radius of say 10cm is a torque of 0.0006Nm, which is pretty small. But still larger than spindle bearing drag/friction torque for decent bearings.3.5mW seems low for drag that can stop a platter in 20 seconds, but that's without me doing any calculations!

To get reasonably accurate friction coefficient measurements from 'the stopping method' needs stopping times > 90s really, with stylus up. Otherwise, spindle bearing torque tends to dominate and the method doesn't work very accurately.

Sorry to read about the hospital, Bill, hope you're OK. Yes, c 10mJ seems plausible for stored rotational energy in a platter.Yawn. Being stuck in a hospital all day drains the mind. I calculated kinetic energy for a platter. Was surprised how pathetically low it is. 10mJ for the platter used in the pardee paper. Just goes to show if you don't do the sums you think wrong!

Is LAST still around?

Personally, I just use a little distilled water and a good record brush.

I still have the remnants of a bottle and just found a couple of records that have only one side treated (35 yr. ago). Remember the little gold stickers? At the time I was not happy with the results, seemed a little quieter but something was missing. I should see what they look like now that I can actually do a hirez spectral analysis.

OTOH their stylus cleaner left a difficult to remove deposit.

EDIT - Bill, hope all is well.

Last edited:

Oddly, measured harmonic distortion @1kHz typically slightly improves with lubrication IME, and I really can't explain that. Low frequency stability (amplitude of resonant cart/arm movement), improves significantly, due to reduction in stimulus from variation in skate force, though Q remains unaltered. Unfortunately, each experiment burns a test record, I need a grant !

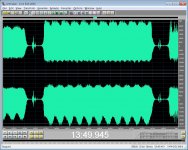

This might amuse you. This is 1/3 octave noise at 12kHz modulated by rotational artifacts. The surface crackle on a silent groove is also modulated. This TT has a spindle diameter well out of RIAA specs requiring careful centering of each LP, time for a sleeve shim.

Groove-T also claims a single play with a misaligned cart and the test record is toast, is this really measurably so?

Attachments

Last edited:

And in possibly the most offtopic update for a while. Appears SWMBO had managed to pick up a resistant strain of e-coli so will be in for another week. Apparently the lab boys say Meropenem will kill it. I do have an image of men in white coats staring at the culture going 'die you ******'!

Back on topic I often notice noisy vinyl gets quieter the further into the record you go. Is this

a) because the inner grooves are usually better protected

b) they are played less

c) linear velocity is less as you go in so the change of stylus induced damage as mentioned by lucky is less

d) its an illusion

?

Back on topic I often notice noisy vinyl gets quieter the further into the record you go. Is this

a) because the inner grooves are usually better protected

b) they are played less

c) linear velocity is less as you go in so the change of stylus induced damage as mentioned by lucky is less

d) its an illusion

?

Sorry to hear that Bill, yes I think the lab cultures the bug, works out what it is and then targets specific top shelf antibiotics, which are quite powerful. Meantime, I hope you can use a distraction, I've been through this with close family and it is not nice, so hope this helps somehow and all the best.And in possibly the most offtopic update for a while. Appears SWMBO had managed to pick up a resistant strain of e-coli so will be in for another week. Apparently the lab boys say Meropenem will kill it. I do have an image of men in white coats staring at the culture going 'die you ******'!

Back on topic I often notice noisy vinyl gets quieter the further into the record you go. Is this

a) because the inner grooves are usually better protected

b) they are played less

c) linear velocity is less as you go in so the change of stylus induced damage as mentioned by lucky is less

d) its an illusion

?

The answer is c), linear velocity is less as you go in. The noise component of friction varies directly with linear velocity, so further in the record where velocity is lower, peaks and troughs of random friction noise are reduced in amplitude and fewer of them cross the threshold where micromistracking occurs, leading to reduced crackle-pop noise.

And no to d) it's not an illusion !

Ha ! I wondered about that for years too......Good to know I wasn't imagining it!

By the way, I don't think the crackle-pop is strictly 'damage', just means that random variation in friction exceeds a certain threshold, enough to cause the stylus to lose contact momentarily. In a 'quiet' record, I suspect random variation still happens, but force does not exceed the threshold at which the stylus loses contact with groove wall. Neither do I think it is necessarily 'damaging' to playback records with high friction, other than it seems intuitive that wear of stylus and groove will be correspondingly higher.

Evidence of this is that such noise can often be reversed by playback under lubricated conditions. Near miraculous, sometimes IME.

Crackle-pop does not seem to degrade much with playback. Some records seem almost to be 'born' with a certain noise profile and stay that way for decades.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- vinyl coefficient of friction