Yes you put in the dimensions explicitly - PCB design files don't include this (PCBs can be any shape, not just rectangles).Am I supposed to put in the dimensions myself? I figured those would be auto populated.

Which PCB material are available with better thermal conductivity than the usual used epoxy glass fibre to get lower value for R-interface in fig.-1 ? - go toHow thick is that aluminum backed board? If it’s “thin” enough to sandwich between double row headers the second row can be glued to the aluminum backplane, giving it more mechanical support and making it less likely you’ll peel the pads off the board. Trim the back row off once it’s mounted if you‘re putting it in an existing device, leave them there for new construction where you’re making the motherboard anyway. I do this sort of mounting with double sided boards all the time, and it’s quite robust. .062 fits in between the rows quite nicely.

I would also suggest mounting ears on the sides, so it can be attached to a real heat sink (an old pentium CPU cooler comes to mind).

One of the weaknesses of these things is heat transfer - going thru thermal vias to a backplane is already a disadvantage, so any help you can give it will make it last that

much longer.

https://www.heatsinkcalculator.com/heat-sink-thermal-resistance-calculator.html

This would provide a huge increase in the reliability of those STK versions under

https://www.diyaudio.com/community/...-iv-v-looking-for-reliable-substitute.396173/

that run at high supply voltage.

check out also

https://resources.altium.com/p/thermal-resistance-of-pcb

Awesome, the answer I was looking for. Thank you for that, and I see the dimensions on the first page.Yes you put in the dimensions explicitly - PCB design files don't include this (PCBs can be any shape, not just rectangles).

Which PCB material are available with better thermal conductivity than the usual used epoxy glass fibre to get lower value for R-interface in fig.-1 ? - go to

https://www.heatsinkcalculator.com/heat-sink-thermal-resistance-calculator.html

This would provide a huge increase in the reliability of those STK versions under

https://www.diyaudio.com/community/...-iv-v-looking-for-reliable-substitute.396173/

that run at high supply voltage.

check out also

https://resources.altium.com/p/thermal-resistance-of-pcb

Do you have any recommendations as to the board? I don’t see alumina as an option at PCBWAY, I’ll have a read through that thread, but yeah, even getting the aluminum backed board I figured the actual fiberglass board (or whatever it’s made from) will have terrible conductivity and be the weak link.

Question for anybody, when it asks me for board thickness and gives me the options 1.0, 1.2, and 1.6 is that the thickness including the aluminum backplate? Or the thickness of the actual board material before it gets to the aluminum backing? If that’s the case then I’m getting the thinnest would be best for heat conducting. Or the thicker you go the thicker the aluminum backing? Basically which is best for driving the heat into a heatsink? I figure these will almost always be on a heatsink of somekind.

Dan

Last edited:

Just checked out the copper PCB, but the cost goes up substantially. Does anyone know of a Chinese PCB manufacturer that produces a alumina boards? I can’t seem to find any. I was thinking I’d like to get some of those as well. Cost per board and shipping it just makes sense to have 50 sent to me, I’ll never need 50, so if anyone was only wanting to buy one or two of them hit me up.

Dan

Dan

Just a quick question before I hit submit and buy these boards. Does the PCB thickness include the thickness of the aluminum? The options of 1.0, 1.2, and 1.6 would lead me to the thought that 1.0 would be best as there is less in between the components and the aluminum heat pad, that’s if the aluminum is the same thickness for each size. Now if the actual fiberglass board is the same thickness and as you go up in size the aluminum gets thicker than the 1.6 seems to be the best choice. Can anyone help me with that?

Dan

Dan

If anyone else is curious about this in the future this is the answer I got from JLCPCB

“For aluminium board, the Aluminium thickness will be the total thickness minus 0.1mm.

That means the 1.6mm Aluminium board will be with 1.5mm Aluminium.

The thicker and larger the Aluminium board, the better heat sinking it have.”

They then gave me some selling points on their new copper core boards and they definitely look good, but I’m thinking that the aluminum will be sufficient in almost any scenario as that’s really what most everyone else is using. So I went with the 1.6mm aluminum of course. I was VERY tempted to get the copper since I was getting 50 boards, but at 3 times the cost I eventually just decided on the aluminum. If I get to a point where I need to get more of these boards I may try the copper. Unless of course someone can point out a place that makes the ceramic.

Dan

“For aluminium board, the Aluminium thickness will be the total thickness minus 0.1mm.

That means the 1.6mm Aluminium board will be with 1.5mm Aluminium.

The thicker and larger the Aluminium board, the better heat sinking it have.”

They then gave me some selling points on their new copper core boards and they definitely look good, but I’m thinking that the aluminum will be sufficient in almost any scenario as that’s really what most everyone else is using. So I went with the 1.6mm aluminum of course. I was VERY tempted to get the copper since I was getting 50 boards, but at 3 times the cost I eventually just decided on the aluminum. If I get to a point where I need to get more of these boards I may try the copper. Unless of course someone can point out a place that makes the ceramic.

Dan

Are you sure it’s that way? and not the other way around?

I can’t see how the fibreglass is only 0.1mm thick, I would think it’s the aluminum

Guess I’ll see when it gets here, that answer was direct from JLCPCB product support. I guess if they messed up and got it the wrong way around that I’ll have proof and hopefully fix the issue and send the 1.0. You say that you think it’s the aluminum? I don’t thing 0.1mm of aluminum would do much, it would be saturated pretty quickly.

Edit: so yeah it looks like they were right. There is no fiberglass layer from what I can see, just the copper layer with solder mask on top of it, then a thin dielectric layer and then the aluminum making up most of the thickness.

Dan

Last edited:

Looks like it is as they say, I went through the online quote tool

0.1mm thick dielectric having 300V breakdown

interesting the price does not change with thickness

post a pic of the pcbs when you get them

Yeah I found that odd too, I figured the price would have gone up somewhat, even shipping for 50 boards basically stayed the same. I certainly will, even though this is more than I’d ever use in a lifetime, I may order a batch of the copper boards if I find that the transistors are getting warmer than I like, then compare the two.

Dan

As promised, here is a pic. They were delivered about an hour ago.Looks like it is as they say, I went through the online quote tool

0.1mm thick dielectric having 300V breakdown

interesting the price does not change with thickness

post a pic of the pcbs when you get them

The tag states 1.6mm, seem a bit shy of that, but my calipers aren’t precision I’m sure.

Only thing that will suck about these boards is their difficulty to solder over standard FR4, but that’s what makes it a better heat sink.

Dan

Looks good,

Could get a stencil made to deposit paste and reflow solder on a hot plate

You will find out how much heat gets conducted once you hand solder. Tabs on the sot-223 look to have some copper area to conduct heat, do you have a temperature controlled iron?

Yeah I considered getting a stencil, but I don’t have a hot plate and I know it isn’t expensive, but I also don’t have solder paste and figured I’d give it a go with my regular station. I use a Hakko FX-100 which is an induction style, identical to Metcal. The temperature is set by the tip itself and being induction has pretty incredible recovery. I generally use a micro wand and tips for SMD stuff, but I’m thinking that with this board I’ll need all the thermal mass I can get and should use the standard size.

Dan

I recall Gary Marsh, who designed the Weiner class D amp, saying he used his skillet and stove element to work as a hot plate when soldering up his protos

I do not use a stencil paste either, just twezzers, weller and AIM glowcore 15mil eutectic solder, good enough for 0.5mm pitch

So what are you driving with the STK3102? ie the rest of the amp? why did you need to buy 50?

Solder it up, bias it up measure the device temps, compare to what they are would be if you used just FR4.

Good luck

I do not use a stencil paste either, just twezzers, weller and AIM glowcore 15mil eutectic solder, good enough for 0.5mm pitch

So what are you driving with the STK3102? ie the rest of the amp? why did you need to buy 50?

Solder it up, bias it up measure the device temps, compare to what they are would be if you used just FR4.

Good luck

Hello Dan,

Very nice achievements!

I would like to repair my two Marantz PM-64 MK2 amps (with STK3102III inside). Could you sell me two Substitute STK3102 boards?

I live in France, which will allow you to determine the total price of this sale... if you agree.

Best regards,

Didier

Very nice achievements!

I would like to repair my two Marantz PM-64 MK2 amps (with STK3102III inside). Could you sell me two Substitute STK3102 boards?

I live in France, which will allow you to determine the total price of this sale... if you agree.

Best regards,

Didier

I designed this board with plenty of room around each pad, so a normal iron and 60/40 solder should work fine..As promised, here is a pic. They were delivered about an hour ago.

View attachment 1168034

View attachment 1168035

The tag states 1.6mm, seem a bit shy of that, but my calipers aren’t precision I’m sure.

View attachment 1168036

Only thing that will suck about these boards is their difficulty to solder over standard FR4, but that’s what makes it a better heat sink.

Dan

Don't use a too fine tip

I recall Gary Marsh, who designed the Weiner class D amp, saying he used his skillet and stove element to work as a hot plate when soldering up his protos

I do not use a stencil paste either, just twezzers, weller and AIM glowcore 15mil eutectic solder, good enough for 0.5mm pitch

So what are you driving with the STK3102? ie the rest of the amp? why did you need to buy 50?

Solder it up, bias it up measure the device temps, compare to what they are would be if you used just FR4.

Good luck

It’ll be going into a Crest Vs900 power amplifier. Nice amp with plenty of power, it used a STK3152III. I’ll get it built up and see how it goes. I only bought 50 because the price increase as I went up was minimal. It wasn’t until I jumped up to 75 boards that the price increase was substantial. I’ve seen plenty of people asking if they could buy a couple off of people so I figured I could help out the few that do. Plus I have multiple amps that use these and think that maybe it would be a good idea to replace them as preventative maintenance.

Hello Dan,

Very nice achievements!

I would like to repair my two Marantz PM-64 MK2 amps (with STK3102III inside). Could you sell me two Substitute STK3102 boards?

I live in France, which will allow you to determine the total price of this sale... if you agree.

Best regards,

Didier

Very cool, yeah, I can send you a couple. I figure $3 USD plus whatever actual shipping would be for the two boards. Maybe this should be taken to PM. I’ll see if I can’t get a shipping quote for you.

I designed this board with plenty of room around each pad, so a normal iron and 60/40 solder should work fine..

Don't use a too fine tip

Yeah, after looking at it I should be able to get in there with my standard iron tips no problem. Thank you.

Dan

Question, wanted peoples thoughts. I’m building this board now and as I mentioned I was a bit hasty when placing my order and didn’t see that there was a value changed to 18k. So I was like, oh well I’ll throw a could have 1/4w resistors in there. I didn’t notice that there are 6 in total. I will eventually order a 100 18k, but would like to wait until I have a decent parts order ready.

So these 3 18k per side are wired in series to get a final resistance of 54k, spread over 3 resistors to spread the heat around. I’m not sure how much these microscopic resistors dissipate, but what if I used a single 1/2w 56kohm resistors? Through hole part just soldered to the tabs. That would be a little over 3%, I could find one that measures 55.8 to get closer. Then I would just jumper the necessary pads. Would I need 1/2w or would 1/4w suffice?

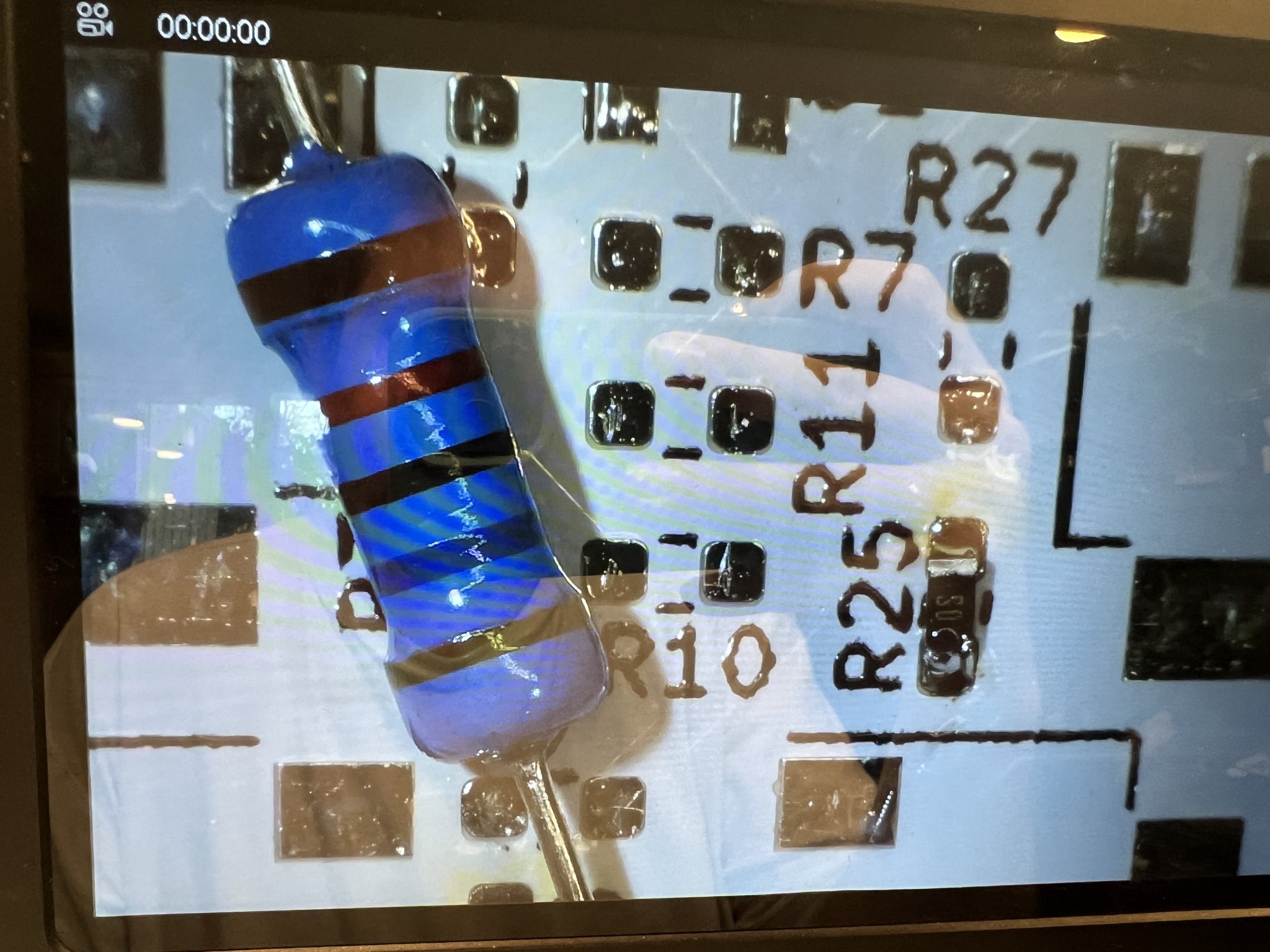

Here is 1/2w next to the 3 sets of pads it would need to be soldered to, as you can see it’s bigger than the sets of pads span. You can also see it next to one of the proper resistors at R25, this thing has like 50 times the mass so I don’t think heat would be an issue. If 1/4w would be more than enough I’d rather go that route. Thoughts on this idea? If I wait for the 18k smd components it’ll probably be a little while.

Dan

So these 3 18k per side are wired in series to get a final resistance of 54k, spread over 3 resistors to spread the heat around. I’m not sure how much these microscopic resistors dissipate, but what if I used a single 1/2w 56kohm resistors? Through hole part just soldered to the tabs. That would be a little over 3%, I could find one that measures 55.8 to get closer. Then I would just jumper the necessary pads. Would I need 1/2w or would 1/4w suffice?

Here is 1/2w next to the 3 sets of pads it would need to be soldered to, as you can see it’s bigger than the sets of pads span. You can also see it next to one of the proper resistors at R25, this thing has like 50 times the mass so I don’t think heat would be an issue. If 1/4w would be more than enough I’d rather go that route. Thoughts on this idea? If I wait for the 18k smd components it’ll probably be a little while.

Dan

- Home

- Design & Build

- Parts

- STK3152/STK3102 Clone for aluminium back PCB