[Quote = KCMO_One; 2024303] Sandt nok. Nogle metal film lyder godt, blot afhænger af, hvor de bruges i en circiut og hvad fabrikanten anvendes. [/ QUOTE]

What kind of metal resistors do you recommend ? Some nonmagnetic could be ok sometimes but never in the feedback and never in series with signal.

What kind of metal resistors do you recommend ? Some nonmagnetic could be ok sometimes but never in the feedback and never in series with signal.

Hi Martin, i did not try the Texas resistor but the Charcroft is so much clearer in sound then everything i tried that even 25,- pounds is a bargain. And they make it in any value and tolerance you need. I use them sparingly for example in the shunt volume control of my preamp. I had a Dale RS55 nm there and like that resistor much but the Charcroft made such a big difference in terms of clarity and speed without spit that i know no other modification that gives that effect. So if i want that sound i have to put my money where my mouth is.

My rule of merit in resistors is lowest temperature coefficient and lowest voltage coefficient. This immediately rules out any carbon resistor, especially composition which are actually piezoelectric in nature. There may be better carbon films than others, but I'm looking for the most stable type of resistor I can afford, without any coloration.

Most metal films use some variation on nickel-chromium alloy (as do most wirewounds), but there are other types such as tantalum nitride. I look for 100 ppm Tc at a very minimum. The very best resistors by this criteria may be Vishay bulk metal foil, but they are also expensive; Tc runs below 1 ppm in the Z foils and voltage coefficient is vanishingly small.

Realistically, most of the time I have to go with the 100 ppm metal films I can obtain, but 50 and 25 ppm metal films are not that expensive. I like to use these parts in the most critical circuit areas like feedback and front ends, especially when carrying the direct audio signal. 1% tolerance is standard, .1% is generally available, and .01% or better is possible with the foil and a few film types. I hand match if necessary for the circuit, but the tighter tolerance also have better stability and should have less coloration, if there's any at all.

That's my opinion on a completely generalized basis; yours may vary greatly. Consult data sheets closely; Vishay sources a wide range of well-documented types of resistors.

Consult data sheets closely; Vishay sources a wide range of well-documented types of resistors.

I have no experience at all using tantalum nitride resistors; they're very rare and expensive and little documentation but are considered "best" by many, even as others such as myself consider bulk metal foils to be "best", at least within the resistance range available.

(What, you wanted a clear and concise engineering evaluation on Christmas Day?)

Most metal films use some variation on nickel-chromium alloy (as do most wirewounds), but there are other types such as tantalum nitride. I look for 100 ppm Tc at a very minimum. The very best resistors by this criteria may be Vishay bulk metal foil, but they are also expensive; Tc runs below 1 ppm in the Z foils and voltage coefficient is vanishingly small.

Realistically, most of the time I have to go with the 100 ppm metal films I can obtain, but 50 and 25 ppm metal films are not that expensive. I like to use these parts in the most critical circuit areas like feedback and front ends, especially when carrying the direct audio signal. 1% tolerance is standard, .1% is generally available, and .01% or better is possible with the foil and a few film types. I hand match if necessary for the circuit, but the tighter tolerance also have better stability and should have less coloration, if there's any at all.

That's my opinion on a completely generalized basis; yours may vary greatly.

I have no experience at all using tantalum nitride resistors; they're very rare and expensive and little documentation but are considered "best" by many, even as others such as myself consider bulk metal foils to be "best", at least within the resistance range available.

(What, you wanted a clear and concise engineering evaluation on Christmas Day?)

Damon i agree with you. Tantalum non magnetic are hard to get and were my reference before the Charcroft came. They sound slightly fuller and rounder but without loss of detail

so can help a system that is on the border of sharp and edgy. Of cause compensating flaws has limits if you go for the most transparent and honest sound.

so can help a system that is on the border of sharp and edgy. Of cause compensating flaws has limits if you go for the most transparent and honest sound.

Back in the early 90s I had a lot of the original Japanese tantalum resistors given to me by Be Yamamura. They were superb, but had magnetic caps, and he was then working on some new amps. One factor he was insistant on was that the possibility of inductance was lowered to the absolute minimum. The consequence was that the Boss of Vishay in the UK came to my house in LOndon and we sat around the kitchen table whilst Be briefed him on his requirements and resistor design ideas. Eventually these resistors were made up by Sfernice in France - the closest Vishay owned company with the machinery necessary - and tested by Be. They are truly suberb and have that solidity of tone which is lacking in so much equipment. It is known that these are higly valued by the extremists in Japan and it is a great pity that they were produced in such limited quantity.

I have not heard todays top money resistors such as used by Joachim so cannot give my opinion on the differences in sound. But compared to the tantalum resistors they have a solidity - as I have said - which gives them an automatic first place against any others I have heard. I have a few still in the smaller wattage (1 Watt) and I see that Percy still list a few higher wattages. There may still be a few found in Italy and amongst Be's American friends, but they are no longer produced. They are marked with the letters "YAM". smash:Joachim: I see you are up late again! Send me a PM with your address and I will send you a couple at 100R to test!...It is still Christmas!!)

smash:Joachim: I see you are up late again! Send me a PM with your address and I will send you a couple at 100R to test!...It is still Christmas!!)

I have not heard todays top money resistors such as used by Joachim so cannot give my opinion on the differences in sound. But compared to the tantalum resistors they have a solidity - as I have said - which gives them an automatic first place against any others I have heard. I have a few still in the smaller wattage (1 Watt) and I see that Percy still list a few higher wattages. There may still be a few found in Italy and amongst Be's American friends, but they are no longer produced. They are marked with the letters "YAM".

Last edited:

Brian, i worked with the YAM2 and they are superb. I own a passive BALANCED pre that Be build for me with that resistors. Of cause i would be more then happy to get more of those.

I send you a note.

To work with Be was fascinating. The 90th were my golden time for shure.

If i get those 100 Ohm i could do a comparison with the Charcroft. I think before Be Vishey had no idea that an AUDIOPHILE resistor would even exist but shure they have the technology.

I send you a note.

To work with Be was fascinating. The 90th were my golden time for shure.

If i get those 100 Ohm i could do a comparison with the Charcroft. I think before Be Vishey had no idea that an AUDIOPHILE resistor would even exist but shure they have the technology.

Joachim, I suspect the Charcroft and the Texas Components resistors are identical. Texas Components merely has a Vishay licence and receives their resistive material from Vishay direct. TC merely laser etches these bulk products for target resistances and tolerances. Charcroft probably has the same arrangement.

Vishay Zs are truly superior resistors. Nothing like them, in my books at least.

Btw, how much $$ are the Charcroft versions? Texas Components sells a Z resistor for about $10.

Vishay Zs are truly superior resistors. Nothing like them, in my books at least.

Btw, how much $$ are the Charcroft versions? Texas Components sells a Z resistor for about $10.

Well, that is much less then Charcroft at 25,- english pounds. They mount the resistor on something that looks like bakelite. I do not know if that is important for sound. As i said, i heard things with this resistors that i did not know they exist. I just designed a commercial phonostage for Spiral Groove that has MANY in them. I do not think we can make it under 15.000,-$ beause there are also Teflon caps and other goodies in it.

Joachim, I think everything you see in a resistor before you was supplied by Vishay. It for sure meets Vishay's tolerances. In either case, you have a Vishay resistor.

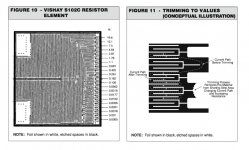

The contractor (TC or Charcroft) merely, I think, "burns" the appropriate resistance in the bulk resistive material. Burning just severs microscopic traces, which increases resistance the more is burned. Tolerance is similarly set.

Charcroft's products are overpriced IMO.

The contractor (TC or Charcroft) merely, I think, "burns" the appropriate resistance in the bulk resistive material. Burning just severs microscopic traces, which increases resistance the more is burned. Tolerance is similarly set.

Charcroft's products are overpriced IMO.

Last edited:

That's my new phono stage with "Teflon caps and other goodies in it"

http://www.diyaudio.com/forums/audio-sector/151938-phono-stage.html

http://www.diyaudio.com/forums/audio-sector/151938-phono-stage.html

my phonostage has 18 expensive opamps only in one inputstage and it has two input stages. For that input alone i need 40 z foils so do not make jokes about it although i find your post a bit funny myself. As always i will try the Charcroft against other z foils and will decide which one i will use on sound alone. if they are the same they should sound the same.

Vishay has a good bit of information here on bulk foil resistor technology:

Resistors, fixed discrete - Bulk Metal Foil - Vishay

Their latest Z-foil technology has vanishingly tiny temperature coefficient, it's practically nothing in typical consumer electronics applications, as is voltage coefficient and noise, and long-term stability.

The foil is produced by Vishay and sold to qualified vendors; it's applied to an alumina substrate via lithography (I think) with a very specific pattern to minimize inductance and configured so that the trim areas don't see current when cut out with a laser. Everything about the basic resistor element is optimized to make as absolute a resistor as possible and it ends up not looking much at all like the tiny cylinders we are used to seeing.

Related Documents - Vishay Resistors, fixed discrete, Bulk Metal Foil

The downside of foil technology besides expense is the limited upper range of resistance, so we can still argue about the merits of relative technologies for anything above 100k ohms or so. Having no comparable information on tantalum nitride, I can only assume that the technology didn't meet a large enough market demand to sustain it, although I think some surface mount resistors are made with the material.

Having no comparable information on tantalum nitride, I can only assume that the technology didn't meet a large enough market demand to sustain it, although I think some surface mount resistors are made with the material.

While the naked Z-foil resistors may now be the absolute best audio resistor, Vishay provides a "cheap" VSH encapsulated Y-foil; Percy has them for around $4. I suspect they're plenty good enough for most applications compared to generic metal film resistors.

http://www.vishay.com/docs/63087/vshvsc.pdf

I've been picking up an occasional bargain on Ebay and at Nebraska Surplus. I grabbed a box of 100 2k ohm RNC90Y resistors for $14. Search on terms like "RNC90*" "S102*" "Vishay bulk foil" "foil resistor" including in the descriptions. Or bite the bullet via the vendors or Percy to get the exact values you need.

There's still a need for more high quality and affordable "generic" metal film resistors; Vishay Dale has a good variety and PRP has a good audio line. My rule of thumb remains temperature coefficient and tolerance: the lower the better (and the more you'll pay). "Better" might be described as .1% and 50 or 25ppm (search for RN55E, for example). The very best metal films such as Dale PTF can get close to Y-foil specs, but they're quite rare.

Isn't it fun how a lowly component like the resistor has its own complex little world yet to be fully explored by the DIYer? I've been at this for a few years and I'm still learning about the technologies and choices. We'll know the bulk foil technology has arrived when the counterfeiters get busy with their 'wares'. As always, know your source.

Resistors, fixed discrete - Bulk Metal Foil - Vishay

Their latest Z-foil technology has vanishingly tiny temperature coefficient, it's practically nothing in typical consumer electronics applications, as is voltage coefficient and noise, and long-term stability.

The foil is produced by Vishay and sold to qualified vendors; it's applied to an alumina substrate via lithography (I think) with a very specific pattern to minimize inductance and configured so that the trim areas don't see current when cut out with a laser. Everything about the basic resistor element is optimized to make as absolute a resistor as possible and it ends up not looking much at all like the tiny cylinders we are used to seeing.

Related Documents - Vishay Resistors, fixed discrete, Bulk Metal Foil

The downside of foil technology besides expense is the limited upper range of resistance, so we can still argue about the merits of relative technologies for anything above 100k ohms or so.

While the naked Z-foil resistors may now be the absolute best audio resistor, Vishay provides a "cheap" VSH encapsulated Y-foil; Percy has them for around $4. I suspect they're plenty good enough for most applications compared to generic metal film resistors.

http://www.vishay.com/docs/63087/vshvsc.pdf

I've been picking up an occasional bargain on Ebay and at Nebraska Surplus. I grabbed a box of 100 2k ohm RNC90Y resistors for $14. Search on terms like "RNC90*" "S102*" "Vishay bulk foil" "foil resistor" including in the descriptions. Or bite the bullet via the vendors or Percy to get the exact values you need.

There's still a need for more high quality and affordable "generic" metal film resistors; Vishay Dale has a good variety and PRP has a good audio line. My rule of thumb remains temperature coefficient and tolerance: the lower the better (and the more you'll pay). "Better" might be described as .1% and 50 or 25ppm (search for RN55E, for example). The very best metal films such as Dale PTF can get close to Y-foil specs, but they're quite rare.

Isn't it fun how a lowly component like the resistor has its own complex little world yet to be fully explored by the DIYer? I've been at this for a few years and I'm still learning about the technologies and choices. We'll know the bulk foil technology has arrived when the counterfeiters get busy with their 'wares'. As always, know your source.

Last edited:

I feel for both sides of the argument. Yes, it's true that no recipe is any better than the sum of its ingredients, but the "diminishing returns" argument is just as considerable. No one wants to be the fool who empties his wallet for no good reason (read: 'audio grade' power cables, audio enhancing pot knobs -yes, KNOBS-, etc.). But when it comes to components that arguably affect the character of an amp, I will at least entertain the thought. In the case of resistors, it seems obvious to me that different qualities and especially materials will produce different results in analog audio circuits. Resistors are found all over a circuit, in and out of the signal path, unlike those overpriced power cables.

To insult someone for having a personal preference of resistor is a waste of time and emotion, but I digress.

Of the hi fi amps I've heard, the ones with carbon comp resistors did sound slightly noisier at full gain/volume, yet they delivered a more enjoyable, musical, natural, and pleasing tone. The others with metal films did sound great, but were more flat and had more piercing 'metallic' treble... to a VERY noticable degree... through the same speakers. Hearing the former and then switching to the latter was almost depressing even. I'm sure, however, that this was far more due to amp design and the other components (tubes vs. transistors/IC's, caps, etc.) than the resistor types. Of all of the components involved in amplification, the resistor seems to be the least effective in changing the character of an amp... But there is still a difference, and I'm sure there's SOME reason McIntosh charges an arm and a leg for their amps which still feature carbon comp resistors.

When breadboarding projects and swapping out components to hear the difference, I do find carbon comp's a little more enjoyable for guitar amps, old fashioned tube stereos, and high voltage preamps. Ultimately my decision is up to my wallet, because the differences just aren't that significant.

*For hi fi audiophiles, I understand perfect linearity and reproduction is the ultimate goal, but there is one thing that no one seems to discuss...: Recording studio engineers understand that all amplifiers add at least SOME color through their delivery of sound. 'Perfect' replication through 'perfectly' linear speakers will not reproduce recordings the way they are intended. This is the beauty of amplifier and speaker combinations. Each has its own character, and after a certain point of quality, it's all a matter of opinion. Like sports stars, vehicles, musicians, etc. once you compare the greats, there really is no best.

Sorry for the rant.

To insult someone for having a personal preference of resistor is a waste of time and emotion, but I digress.

Of the hi fi amps I've heard, the ones with carbon comp resistors did sound slightly noisier at full gain/volume, yet they delivered a more enjoyable, musical, natural, and pleasing tone. The others with metal films did sound great, but were more flat and had more piercing 'metallic' treble... to a VERY noticable degree... through the same speakers. Hearing the former and then switching to the latter was almost depressing even. I'm sure, however, that this was far more due to amp design and the other components (tubes vs. transistors/IC's, caps, etc.) than the resistor types. Of all of the components involved in amplification, the resistor seems to be the least effective in changing the character of an amp... But there is still a difference, and I'm sure there's SOME reason McIntosh charges an arm and a leg for their amps which still feature carbon comp resistors.

When breadboarding projects and swapping out components to hear the difference, I do find carbon comp's a little more enjoyable for guitar amps, old fashioned tube stereos, and high voltage preamps. Ultimately my decision is up to my wallet, because the differences just aren't that significant.

*For hi fi audiophiles, I understand perfect linearity and reproduction is the ultimate goal, but there is one thing that no one seems to discuss...: Recording studio engineers understand that all amplifiers add at least SOME color through their delivery of sound. 'Perfect' replication through 'perfectly' linear speakers will not reproduce recordings the way they are intended. This is the beauty of amplifier and speaker combinations. Each has its own character, and after a certain point of quality, it's all a matter of opinion. Like sports stars, vehicles, musicians, etc. once you compare the greats, there really is no best.

Sorry for the rant.

it seems obvious to me that different qualities and especially materials will produce different results in analog audio circuits.

100%.... but some times its a double edged sword... There are times when breakthroughs in materials & processes lead to things that could never be achieved before.

Sometimes it leads to cheaper processes that are just that, cheaper but not better... Other times the new processes lead to performance levels that simply could not be achieved previously.

Driven by the Military guys, Resistors have come a long way.

It has been said that the major periods of progress in society can be trace to breakthroughs in material science.... Said differently "I could rule the world, if I could only get the parts...."

jk

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- Resistor Sound Quality?