.....

What is the "height" of your t'former? ....

pmchoong, great to learn that the Toroidy shipment has apparently reached you safely.

Techn. data of the AUX transformer: See here

http://www.diyaudio.com/forums/group-buys/204203-f5x-transformers-2.html#post2858642

and the website of the manufacturer (the core of a 20VA transformer seems to have been used for our AUX):

TOROIDY.PL Transformatory Toroidalne Producent, Audio, Separacyjne, Trójfazowe, 230/110V, 110/230V, Na zamówienie

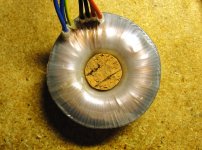

auxillary transformer

Hi

Thanks Heinz.

Attached is the photo. The transformer is about 34-35mm including the metal piece and the pvc rings that comes with it. Without those, I guess it is about 28mm according to the specs given by Toroidy, as attached by Heinz.

There are pieces of foams (for protection during shipping) in between the transparent sheets that wrap around the transformers. Is the transparent sheet necessary? Shall I remove it to dislodge the foams?

Thanks.

PMChoong

Hi

Thanks Heinz.

Attached is the photo. The transformer is about 34-35mm including the metal piece and the pvc rings that comes with it. Without those, I guess it is about 28mm according to the specs given by Toroidy, as attached by Heinz.

There are pieces of foams (for protection during shipping) in between the transparent sheets that wrap around the transformers. Is the transparent sheet necessary? Shall I remove it to dislodge the foams?

Thanks.

PMChoong

Attachments

Having previously ordered from Toroidy, I know what are you referring to: those little white balls stuck between the thin transparent sheet. I removed them with the help of a pencil.Hi

Thanks Heinz.

Attached is the photo. The transformer is about 34-35mm including the metal piece and the pvc rings that comes with it. Without those, I guess it is about 28mm according to the specs given by Toroidy, as attached by Heinz.

There are pieces of foams (for protection during shipping) in between the transparent sheets that wrap around the transformers. Is the transparent sheet necessary? Shall I remove it to dislodge the foams?

Thanks.

PMChoong

I would not recommend removing it, at it is part of the transformer, with the end of protecting the enamel coated winding.

Now I am switched on.

The transparent tape is wound around the secondary to keep the electricity in.

And to keep your hands and tools out.

Do not remove that tape !!!

The little balls are expanded polystyrene. Often used for packaging and transport protection.

If you can carefully prise them out with a toothpick, then go ahead.

They are very squidgy (soft). Bolting up the transformer using the kits parts will squash those balls to insignificant thickness.

The transparent tape is wound around the secondary to keep the electricity in.

And to keep your hands and tools out.

Do not remove that tape !!!

The little balls are expanded polystyrene. Often used for packaging and transport protection.

If you can carefully prise them out with a toothpick, then go ahead.

They are very squidgy (soft). Bolting up the transformer using the kits parts will squash those balls to insignificant thickness.

Capacitor GB for North American Case Buyers

So the price of the 35V/22000uF capacitors drops significantly when ordered in quantities of 100 or more. Each F5X stereo build requires (16) of these Panasonic TSHA capacitors (per fitzfish BOM). The price drops from $6.01/ea to $3.97/ea when you order 100. That is a savings of roughly $32 per F5X.

I am offering to organize a mini group-buy for the North American participants who purchased cases. I would purchase the capacitors in bulk, and distribute them out to the group buy participants. Unfortunately, I'd like to limit this GB to NA persons only to avoid the whole customs and international shipping hassle.

Total cost would be actual price of the resistors plus shipping to be determined later. If you are interested, please put you name below.

NA Capacitor GB Interest (1 set = 16 capacitors):

Horio (2 sets)

So the price of the 35V/22000uF capacitors drops significantly when ordered in quantities of 100 or more. Each F5X stereo build requires (16) of these Panasonic TSHA capacitors (per fitzfish BOM). The price drops from $6.01/ea to $3.97/ea when you order 100. That is a savings of roughly $32 per F5X.

I am offering to organize a mini group-buy for the North American participants who purchased cases. I would purchase the capacitors in bulk, and distribute them out to the group buy participants. Unfortunately, I'd like to limit this GB to NA persons only to avoid the whole customs and international shipping hassle.

Total cost would be actual price of the resistors plus shipping to be determined later. If you are interested, please put you name below.

NA Capacitor GB Interest (1 set = 16 capacitors):

Horio (2 sets)

Horio, I was thinking the same thing. The Big parts GB was to be drop-shipped to you. If you do not wish to deal with the administration I would be happy to help. I am also arranging a similar drop-ship arrangement for European buyers and as such this will help to reduce time used for shipping.

I am also arranging the other larger parts including the relays, switches XLR connectors and fuseholder. I think that having these all organized centrally would be beneficial.

I am also arranging the other larger parts including the relays, switches XLR connectors and fuseholder. I think that having these all organized centrally would be beneficial.

Horio, I was thinking the same thing. The Big parts GB was to be drop-shipped to you. If you do not wish to deal with the administration I would be happy to help. I am also arranging a similar drop-ship arrangement for European buyers and as such this will help to reduce time used for shipping.

I am also arranging the other larger parts including the relays, switches XLR connectors and fuseholder. I think that having these all organized centrally would be beneficial.

Alexis,

Sorry, I didn't realize you were already organizing a GB for the larger parts. Was it to include the big caps? I definitely agree that we should have things centrally organized is possible.

I'd be more than happy to accept a large parcel (or parcels) and distribute out the parts to the US/Canadian participants.

For the big caps, it may be best for me to purchase these in the US and ship these with your GB parts when they arrive.

Last edited:

Alexis,

Sorry, I didn't realize you were already organizing a GB for the larger parts. Was it to include the big caps? I definitely agree that we should have things centrally organized is possible.

I'd be more than happy to accept a large parcel (or parcels) and distribute out the parts to the US/Canadian participants.

Hi Horio.

Yes it was to include the large capacitors. Thankyou for the offer. The problem here I think is that the large part GB was not well advitised. In reality the only real saving for the other parts at the moment is that in shipping and that they need to be sourced from multiple suppliers this is significant.

PM Choong,

Your (our) problem of the AUX Transformer comes from the fact the the transformer is not potted with epoxy in the centre, with a mounting hole drilled.

This then requires the steel washer and the rubber gasket which adds to the thickness and creates the volume conflict.

In our original prototype, we used a transformer that is potted, so we had sufficient clearance.

Give me a couple of days to see whether I can find a solution for you for the least trouble.

e.g. potting the centre with epoxy putty is a simple way out.

Patrick

Your (our) problem of the AUX Transformer comes from the fact the the transformer is not potted with epoxy in the centre, with a mounting hole drilled.

This then requires the steel washer and the rubber gasket which adds to the thickness and creates the volume conflict.

In our original prototype, we used a transformer that is potted, so we had sufficient clearance.

Give me a couple of days to see whether I can find a solution for you for the least trouble.

e.g. potting the centre with epoxy putty is a simple way out.

Patrick

A dished washer plate will help. But still leaves the compressed thickness of the rubber protector washer and the plate............Give me a couple of days to see whether I can find a solution for you for the least trouble.

e.g. potting the centre with epoxy putty is a simple way out.

Be careful with a homemade epoxy fill. The Mylar tape will resist adhesion to most glues. The fill must also use the mechanical lock of the non parallel sides of the "hole" to give a reliable grip.

I had a look at my own examples of the AUX Tx from Toroidy.

The centre hole is about 13~16mm.

A couple of quick solutions :

1) Use a 2-part epoxy compound and pot the centre hole yourself. When dried, drill a hole 5.5mm, and use a nut at the other end. There is no need to pot full hieght.

2) Use a rubber Well Nut of the correct outside diameter at the free end, and the M5 mounting screw to expand the rubber nut to grip the Tx. See :

Rubber well nuts M5, M6 and M8

The high end solution would be a machined flanged plug from Delrin with a threaded hole sized to the Tx. Probably also the most expensive (5~10 Euros a piece). But if one of you has a lathe, it is very easy to DIY. Wood will also do.

I personally would try the rubber nut first.

Patrick

The centre hole is about 13~16mm.

A couple of quick solutions :

1) Use a 2-part epoxy compound and pot the centre hole yourself. When dried, drill a hole 5.5mm, and use a nut at the other end. There is no need to pot full hieght.

2) Use a rubber Well Nut of the correct outside diameter at the free end, and the M5 mounting screw to expand the rubber nut to grip the Tx. See :

Rubber well nuts M5, M6 and M8

The high end solution would be a machined flanged plug from Delrin with a threaded hole sized to the Tx. Probably also the most expensive (5~10 Euros a piece). But if one of you has a lathe, it is very easy to DIY. Wood will also do.

I personally would try the rubber nut first.

Patrick

I tried something even simpler tonight. A sherry bottle cork will fit perfect.

You then need to drill a small hole (say 1.5mm), and use a wood screw to secure this in place at the rear bracket.

Do not over-tighten.

Patrick

You then need to drill a small hole (say 1.5mm), and use a wood screw to secure this in place at the rear bracket.

Do not over-tighten.

Patrick

Attachments

Last edited:

If you, like me, use sherry for cooking, you do not need the cork.

I already tried Bordeaux. They put too much stress on the windings.

Definitely be bad for the sound, the stress being coupled from the Aux Tx back to the IEC Socket and then to the main Tx for the F5X.

Patrick

I already tried Bordeaux. They put too much stress on the windings.

Definitely be bad for the sound, the stress being coupled from the Aux Tx back to the IEC Socket and then to the main Tx for the F5X.

Patrick

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Group Buys

- Potential EUVL F5X designed case user distribution check