1) What can I do to warm up the sound.

Also plan to stuff with ~1/2# of polyfill stuffing. And am going to experiment with adding 2-6 ohms resistance.)

2) Is it possible to measure the frequency response of the cabinet without spending a small fortune on equipment? If so, how? I do have a microphone.

Greets!

Normally one either tunes the cab higher and/or adds series resistance. FWIW, since I quit tubes in '70, have typically preloaded nearly all later high DF P-P tube, SS amps with a matching impedance non inductive resistor when driving typical consumer, DIY HIFI speakers since at normal SPLs the amps are usually outputting down in their non-linear/'noisy' BW, though occasionally can still need more.

If you're listening with no cab damping, this too will make a big difference, though best to damp after preloading the amp since less is required IME.

Folks swear by REW and you can't beat the price: REW - Room EQ Wizard Room Acoustics Software

GM

Here's some pics of the prototype.

No can see, get Google 403 error.

GM

No can see, get Google 403 error.

GM

Attachments

Until all the panels are sealed (oe glued) any comments or evaluation are probably premature.

The A10.3 really takes a long time to break ins 100 hrs is not near enuff and just enuff to get you to the point where they can start to be turned up.

Hard to say what you mean by warm, but in my mind i think A10p.

dave

On Sealing panels: obviously the best way to seal would be glue + some sort of caulk all the way round. What do you do when you want to still have access to the inside, say if you plan to tinker with stuffing etc.? Do you use a gasket sealer with wax paper between the sealer and the removable panel? Or is it enough to just use a bunch of screws?

On "warm": vinyl vs compressed blutooth mp3; listening to a real violin vs a bad youtube recording on laptop speakers; a Strad vs a $40 walmart special; My sennheiser momentum 2 headphones or my altec lansing 605B's vs bose anything.

The above is a lot of extremes, and the alpair 10.3Ms in my prototype aren't "bad" per se, just lacking some warmth.

OBTW: speaker is surface mounted. So far, I have only made one cabinet and have not yet glued up. So, if it is uber critical to flush mount, that can be done.

On Sealing panels: obviously the best way to seal would be glue + some sort of caulk all the way round. What do you do when you want to still have access to the inside, say if you plan to tinker with stuffing etc.? Do you use a gasket sealer with wax paper between the sealer and the removable panel? Or is it enough to just use a bunch of screws?

We use close cel daft exclusion tape/weather strip. The black stuff from Home Depot. Then a ton of screws to compress it. With a Metronome a removable bottom panel and thru the driver hole + a tool to extend your arm are likely best. Since none of the Met joins are exactly square you do have to take care.

On "warm": vinyl vs compressed blutooth mp3; listening to a real violin vs a bad youtube recording on laptop speakers; a Strad vs a $40 walmart special; My sennheiser momentum 2 headphones or my altec lansing 605B's vs bose anything.

I don’t lixten to MP3 of youtube, and it has been a long time since i have listened to bose so i still have no reference I will say that all of those are missing scads of information..

dave

We use close cel daft exclusion tape/weather strip. The black stuff from Home Depot. Then a ton of screws to compress it. With a Metronome a removable bottom panel and thru the driver hole + a tool to extend your arm are likely best. Since none of the Met joins are exactly square you do have to take care.

Interesting. I wonder if I did something wrong because all the joints for my side panels are 90 degrees or near as makes no difference. The top and bottom pieces have a 3 or 5 degree slant depending on which side though. My build is in effect a 4 sided pyramid with the top cut off.

I don’t lixten to MP3 of youtube, and it has been a long time since i have listened to bose so i still have no reference I will say that all of those are missing scads of information..

dave

Ok, sorry for the ambiguity. "Warmth" is an extremely subjective term....Soon I will finish the prototype, seal, glue, stuff, etc. Then have another listen. If I still feel it's lacking "warmth" we'll have another go at finding a common definition and/or taking proper measurements.

Interesting. I wonder if I did something wrong because all the joints for my side panels are 90 degrees or near as makes no difference.

True, but it isn’t quite 90° if you wanted to be perfect.

dave

Isn't all the 'warmth' removed from such recordings? Sure sounds that way to me.

GM

Perhaps... especially when those recordings are heavily compressed like with streaming mp3s, and youtube. Blutooth just makes it worse. Listening to a CD or Vinyl on my set of Altec-Lansing 605B speakers is the closest thing I've experienced to the real thing (a live performance), and a big part of my career is performing with the symphony. Also, I've noticed a big difference from recording to recording. Some seem to better represent the live performance than others.

But that's only at the top and bottom, right?

GM

I have an Incra Machinist square and measured the middle of the panel at the joint when I assembled. It looked near enough as equal to 90 to me. I was quite surprised. As for "perfect" it's what I would call "wood perfect." Since wood moves in a way that other materials don't you lose a small amount of precision. I will take more pictures and measurements when I assemble again.

But that's only at the top and bottom, right?

The sides are not quite square. When i 1st did detailed drawings i did the auxiluary views so that i could measure and they were something like 89.9 something degrees.

dave

What do ya'll like to use to seal the inside joints of a cabinet? I have GE silicone 1 on hand, but can get something else easy enough it would be better.

Pretty much anything that sticks to wood, i.e impervious to trapped moisture content, doesn't shrink, dry out over time, so oil based or silicone latex variant adhesive.

No experience with this GE product, though it advertises 'right', but IME GE's products have fallen short on its exterior construction performance over time, so YMMV unless your app has a much better controlled humidity than I do.

I've always used construction grade caulks, sealers, adhesives with Pliobond PL400 adhesive being my fave construction/sealer since it came out decades ago, though in recent years I've had [too many] occasions to try other brands due to ongoing weather, bugs, etc., damage on a severely limited budget and of the bunch, Sherwin-Williams' NR4000 pro grade caulk has proven to be the superior performer in every way plus IME, the cheapest if you know a paint contractor that buys in bulk and will pass the savings on.

GM

Perhaps... especially when those recordings are heavily compressed like with streaming mp3s, and youtube. Blutooth just makes it worse. Listening to a CD or Vinyl on my set of Altec-Lansing 605B speakers is the closest thing I've experienced to the real thing (a live performance), and a big part of my career is performing with the symphony. Also, I've noticed a big difference from recording to recording. Some seem to better represent the live performance than others.

Considering how much [euphonic] distortion the 604 series 'color's the music, am very familiar with how close to 'live' Altec's products can be, especially their studio monitor series. Drive them with period correct tube electronics to get them even closer.

For sure, recordings are 'all over the map', with small venue live RTR, vinyl recordings being by far the best IME.

GM

What do ya'll like to use to seal the inside joints of a cabinet? I have GE silicone 1 on hand, but can get something else easy enough it would be better.

Don't know why you would need anything beyond the glue on the joint as long as the box is built properly.

I do a dry fit-up before getting the glue out. Below is a photo from my BIB build showing the LED work light sitting on top of the the BIB. I shine the light into the cabinet to see if there are any light leaks. If there are light leaks, then either the clamps need repositioning or a sanding block needs to be used. (I use masking tape to mark where the clamps will be positioned when I do the glue-up.) Once there are no light leaks, then the glue should provide an air-tight seal.

Cheers, Jim

Attachments

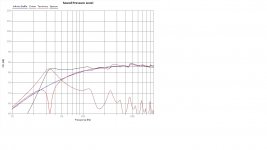

I built a single speaker prototype, not too happy with it. No mid-bass and muffled. Maybe I have too much stuffing?. Maybe it has too long a transmission line for this driver? I used Leonard Audio software to design it and here is what it predicted:

Attachments

Leonard Audio Model

60.5" line length

Driver at 29"

Top 2"x4"

Bottom 8"x10"

Vent 1.75" ID by 3"

The model is divided into 3 sections:

Rear.0 Top half with stuffing

Rear.1 Bottom half, no stuffing

Rear.2 Vent

3.6

# This is a model file for Leonard Audio Transmission Line Modelling Software

#-----Amplifier Settings-----#

AmplifierPower 1

AmplifierRg 0.1

#-----Filter Settings-----#

FilterLowPassActive False

FilterLowPassQ 0.707

FilterLowPassfo 100

FilterLowPassOrder 0

FilterHighPassActive False

FilterHighPassQ 0.707

FilterHighPassfo 20

FilterHighPassOrder 0

#-----Driver Settings-----#

DriverTitle MA Alpair 10 Gen.3

DriverFilePath C:\Users\GM\Downloads\LA TL\Drivers\MA Alpair 10 Gen.3.lsd

DriverSd 0.008825

DriverQes 0.378

DriverQms 1.93

DriverLvc 0.0007137

DriverRe 7.2

DriverFs 38.266

DriverVas 0.02632

DriverIsobaric False

DriverSeries True

#-----Enclosure Settings-----#

TLWidth 0.126514478045725

TLTappedHorn False

TLTappedHornPosition 1

TLDriverPosition 0.73152

TLNode Path=Rear.0 Length=0.75 StartArea=0.0019 EndArea=0.01887 Taper=3 StuffingDensity=3 OpenEnd=True Angle=0

TLNode Path=Rear.1 Length=0.77513688 StartArea=0.01887 EndArea=0.0516 Taper=3 StuffingDensity=0 OpenEnd=False Angle=0

TLNode Path=Rear.2 Length=0.0886968 StartArea=0.00155 EndArea=0.00155 Taper=3 StuffingDensity=0 OpenEnd=True Angle=0

60.5" line length

Driver at 29"

Top 2"x4"

Bottom 8"x10"

Vent 1.75" ID by 3"

The model is divided into 3 sections:

Rear.0 Top half with stuffing

Rear.1 Bottom half, no stuffing

Rear.2 Vent

3.6

# This is a model file for Leonard Audio Transmission Line Modelling Software

#-----Amplifier Settings-----#

AmplifierPower 1

AmplifierRg 0.1

#-----Filter Settings-----#

FilterLowPassActive False

FilterLowPassQ 0.707

FilterLowPassfo 100

FilterLowPassOrder 0

FilterHighPassActive False

FilterHighPassQ 0.707

FilterHighPassfo 20

FilterHighPassOrder 0

#-----Driver Settings-----#

DriverTitle MA Alpair 10 Gen.3

DriverFilePath C:\Users\GM\Downloads\LA TL\Drivers\MA Alpair 10 Gen.3.lsd

DriverSd 0.008825

DriverQes 0.378

DriverQms 1.93

DriverLvc 0.0007137

DriverRe 7.2

DriverFs 38.266

DriverVas 0.02632

DriverIsobaric False

DriverSeries True

#-----Enclosure Settings-----#

TLWidth 0.126514478045725

TLTappedHorn False

TLTappedHornPosition 1

TLDriverPosition 0.73152

TLNode Path=Rear.0 Length=0.75 StartArea=0.0019 EndArea=0.01887 Taper=3 StuffingDensity=3 OpenEnd=True Angle=0

TLNode Path=Rear.1 Length=0.77513688 StartArea=0.01887 EndArea=0.0516 Taper=3 StuffingDensity=0 OpenEnd=False Angle=0

TLNode Path=Rear.2 Length=0.0886968 StartArea=0.00155 EndArea=0.00155 Taper=3 StuffingDensity=0 OpenEnd=True Angle=0

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Metronome for Alpair 10.3m and 12p