I've also wondered about the very shallow drivers. The 2452 is certainly slim.

Some FaitalPro drivers are also shallow and have a bullet shaped phase plug sticking out of the throat. So do some BMS drivers, but they don't have shallow throats.

It seems this would mean you supply your own exit throat and do what you want, as @bappe mentioned earlier.

However I have some pretty shallow Radians, the throats can not be very deep, but they did not work well on my 803 or 1005 horns. The Radian 950 has a throat 4.2cm long, or shorter than it is wide. How shallow does the driver throat have to be to not make a significant difference or for its flare rate not to matter much to horn?

Some FaitalPro drivers are also shallow and have a bullet shaped phase plug sticking out of the throat. So do some BMS drivers, but they don't have shallow throats.

It seems this would mean you supply your own exit throat and do what you want, as @bappe mentioned earlier.

However I have some pretty shallow Radians, the throats can not be very deep, but they did not work well on my 803 or 1005 horns. The Radian 950 has a throat 4.2cm long, or shorter than it is wide. How shallow does the driver throat have to be to not make a significant difference or for its flare rate not to matter much to horn?

They would...would not other types horns that expect a different waveform shape benefit from an adapter?

But it is.Or is it a second order issue?

It has to be zero.How shallow does the driver throat have to be to not make a significant difference or for its flare rate not to matter much to horn?

I was struggling with exactly what is the topic for this thread. My approach was exactly what marco_gea describes, i.e. matching the horn throat expansion rate with the approximated one of the driver snout. I got tired of the lack of flexibility that gives and started to look for 4" VC drivers with an exit right at the end of the phase plug and found the JBL 2450SL, 2451 and 2452. The 2451 was dirt cheap used and i got a pair in good shape at $165. Initial tests were good enough to go for a pair of Be diaphragms and I have now stopped looking for driver improvements, the end result is up to me and how well i design and make the horns. The horn project will end up here on the forum eventually.

Last edited:

This has been a fascinating thread, but I am somewhat surprised that so many people seem surprised that matching geometry of driver to horn has such a great impact on performance.

First off, reading comments here it's clear to me that many of you are smarter and far more well versed in the minutia of measuring and theory than I. I had some good instruction and lots of smart people around me when I began messing with horns over 20 years ago, but I really tend to work on a more intuitive level.

But ultimately sound from a driver and horn is waves moving through a plastic medium: Like a plane in the air, a boat in the water, air through an engine's intake manifold or exhaust though headers, even water flowing down a gutter. Viewed like that anything causing any turbulence is probably going to have a deleterious effect. Because of the size if high frequency wavelengths they are far more susceptible to disruptions than longer, lower wavelengths. So when trying to convey high frequencies from a driver into a listening space the cleanest, smoothest path is probably going to be the best.

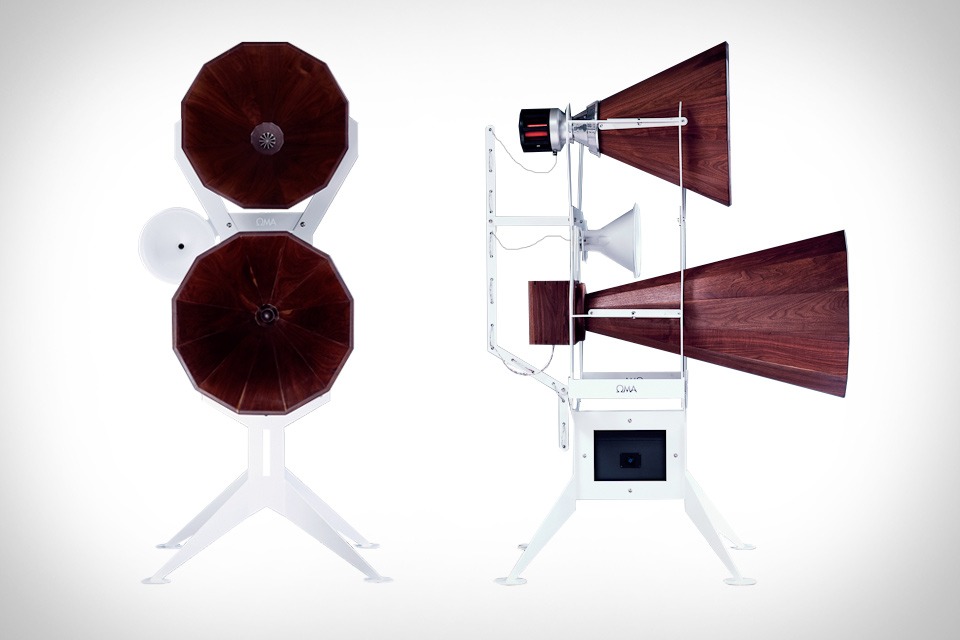

One example of this thinking in practice is the 12-sided conical horns used with Cogent midrange drivers. The conic midrange and mid bass horns used by both OMA (Oswald's Mill) and the Cogent/esodesignstudio were actually designed by former Yorkville Sound designer Bill Woods. OMA uses the driver exactly as designed by Bill including using the cast throat assembly. Rich from Cogent and I opted for a different system for mounting that we felt was cleaner and also allowed us to make the petals of the horns thicker which allowed for a bit of a mount radius to hopefully combat mouth refraction but also for a better visual balance of the horn to the mass of the drivers. But this digresses from the topic here.

Early in the Development of the Cogent drivers, Rich had purchased some Azura Horns from Martin in Australia. The mouth of the Cogent DS-1428 is an odd size–~2.7" if I recall correctly and the internal geometry if the phase plug is a pretty wide angle. The Cogent/Azura combination never worked well. The conflict in the throat created some congestion, and ultimately the long throat section of the horn led to considerable beaming at higher frequencies. But, round tractrix and Le'Cleach flares tend to match exceptionally well with the vintage 375/2440/2441/2482 style drivers as well as TAD 4001 and Gauss 4000 series compression drivers: the ~10˚ conic flare inside those drivers matches quite well with the throat of a typical Tractrix.

Bill woods designed horns in OMA Imperia:

Shorted version used by Cogent/esodesignstudio:

Back to the 12-sided conic horns, after initial prototypes built here, Rich and I noticed that the angle of the conic mid horn was slightly less than the most extreme angle inside the phase plug. We kept the mouth diameter but shortened the length by a couple inches, matching the conic angle to the angle in question in the phase plug. Again, the sound was more open. Now with the 118db sensitivity on the drivers we really do not need any support from horn loading. In the case of our implementation of this horn driver/combination we are only using it for pattern control and so in this case it is really just a wave guide.

Currently, I'm playing with some TAD drivers that I stumbled onto and looking at building a slight variation on the Exclusive 2401/TAD TSM-1 large monitor. Many years ago I built a pair of Yuichi A290 radial horns to play with. They are an exceptional radial design with performance very similar to the TAD TH-4001. But I don't like horns with vanes in them for hifi; I find they do great at even horzontal coverage, but the soundstage flattens as a result. The TAD TH-4003 horn has 80˚ X 30˚ pattern with no vanes, but that horn is designed for a 40mm throat driver. My TD-4001 has a 50mm throat (actually 49.2mm). So I decided to try to build a horn like the TD-4003 but for a 50mm driver.

Because I Know the Yuichi A290 has good frequency response I started with calculating an exponential expansion with a .7 hyperbolic influence for a 290Hz flare starting with a 49.2mm throat. This scenario does not have an adapter plate. The driver mounting plate is the mouth of the horn and the transition from 49.2mm round to a near rectangle is flowing the calculated expansion. And the horn itself is tedious to shape since it is asymmetrical, but initial tests are promising.

Not a perfect fit, but very close. This mounting plate is 1 3/4" thick, and the angles at the driver match the conic flare inside the driver before beginning the asymmetric expansion of the horn:

The prototype assembly:

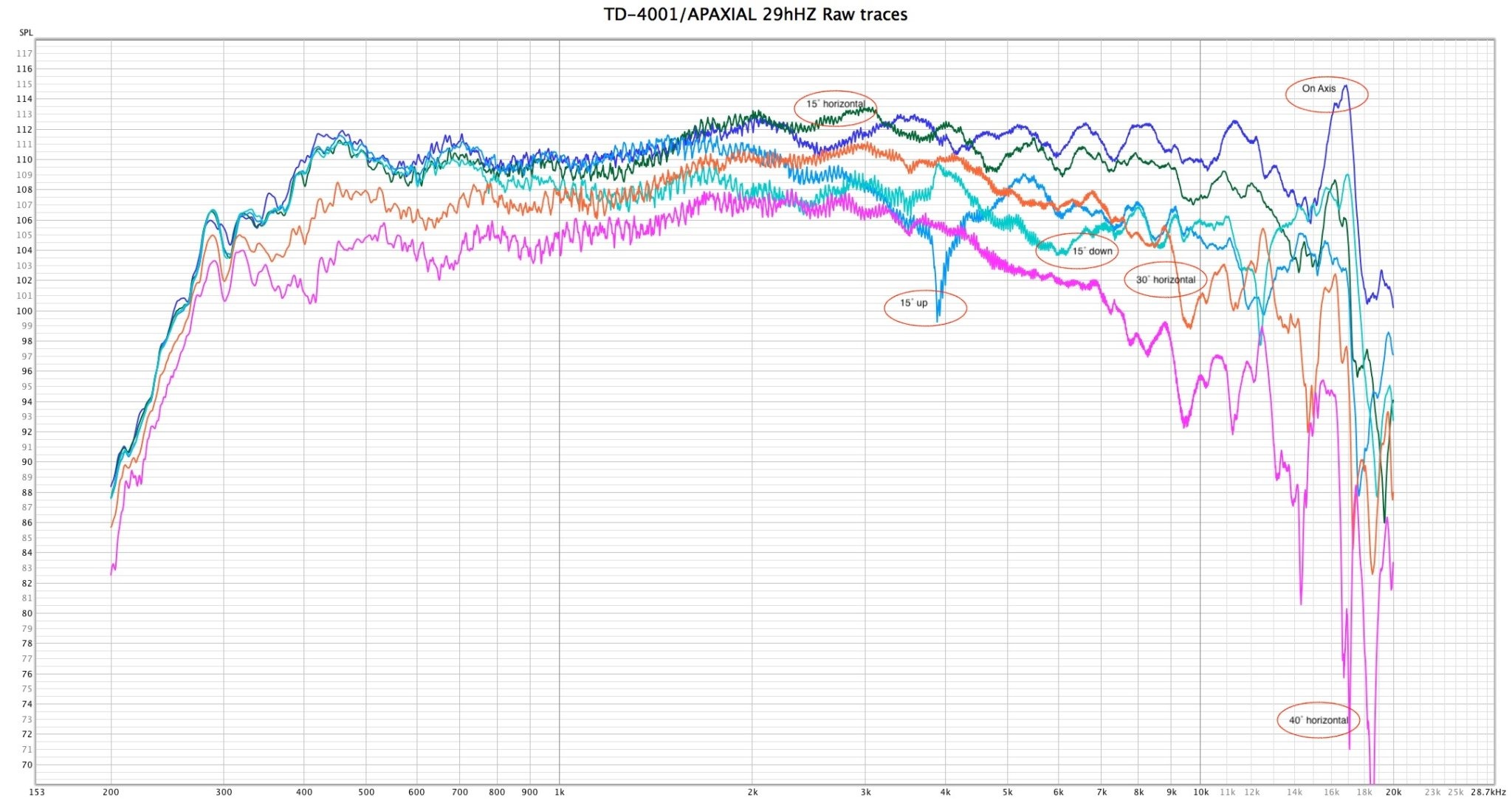

Rough plots on and off axis, no smoothing:

Still a lot of work to do on this one. Need to design the Helmholtz resonator that I believe will be adjusting the on-axis level to balance with the off-axis pattern a bit more closely. And I need to set up for taking impedance measurements... any input on that would be appreciated.

A lot of words there and meandering about, but hopefully not fully incoherent.

Cliff's Notes version: Don't adapt a 1" driver to a 2" horn, and don't even think about attaching a 2" driver to a smaller horn. Wherever possible start with a clean sheet of paper so you can work out the variable and possible conflicts ahead of time.

eso

First off, reading comments here it's clear to me that many of you are smarter and far more well versed in the minutia of measuring and theory than I. I had some good instruction and lots of smart people around me when I began messing with horns over 20 years ago, but I really tend to work on a more intuitive level.

But ultimately sound from a driver and horn is waves moving through a plastic medium: Like a plane in the air, a boat in the water, air through an engine's intake manifold or exhaust though headers, even water flowing down a gutter. Viewed like that anything causing any turbulence is probably going to have a deleterious effect. Because of the size if high frequency wavelengths they are far more susceptible to disruptions than longer, lower wavelengths. So when trying to convey high frequencies from a driver into a listening space the cleanest, smoothest path is probably going to be the best.

One example of this thinking in practice is the 12-sided conical horns used with Cogent midrange drivers. The conic midrange and mid bass horns used by both OMA (Oswald's Mill) and the Cogent/esodesignstudio were actually designed by former Yorkville Sound designer Bill Woods. OMA uses the driver exactly as designed by Bill including using the cast throat assembly. Rich from Cogent and I opted for a different system for mounting that we felt was cleaner and also allowed us to make the petals of the horns thicker which allowed for a bit of a mount radius to hopefully combat mouth refraction but also for a better visual balance of the horn to the mass of the drivers. But this digresses from the topic here.

Early in the Development of the Cogent drivers, Rich had purchased some Azura Horns from Martin in Australia. The mouth of the Cogent DS-1428 is an odd size–~2.7" if I recall correctly and the internal geometry if the phase plug is a pretty wide angle. The Cogent/Azura combination never worked well. The conflict in the throat created some congestion, and ultimately the long throat section of the horn led to considerable beaming at higher frequencies. But, round tractrix and Le'Cleach flares tend to match exceptionally well with the vintage 375/2440/2441/2482 style drivers as well as TAD 4001 and Gauss 4000 series compression drivers: the ~10˚ conic flare inside those drivers matches quite well with the throat of a typical Tractrix.

Bill woods designed horns in OMA Imperia:

Shorted version used by Cogent/esodesignstudio:

Back to the 12-sided conic horns, after initial prototypes built here, Rich and I noticed that the angle of the conic mid horn was slightly less than the most extreme angle inside the phase plug. We kept the mouth diameter but shortened the length by a couple inches, matching the conic angle to the angle in question in the phase plug. Again, the sound was more open. Now with the 118db sensitivity on the drivers we really do not need any support from horn loading. In the case of our implementation of this horn driver/combination we are only using it for pattern control and so in this case it is really just a wave guide.

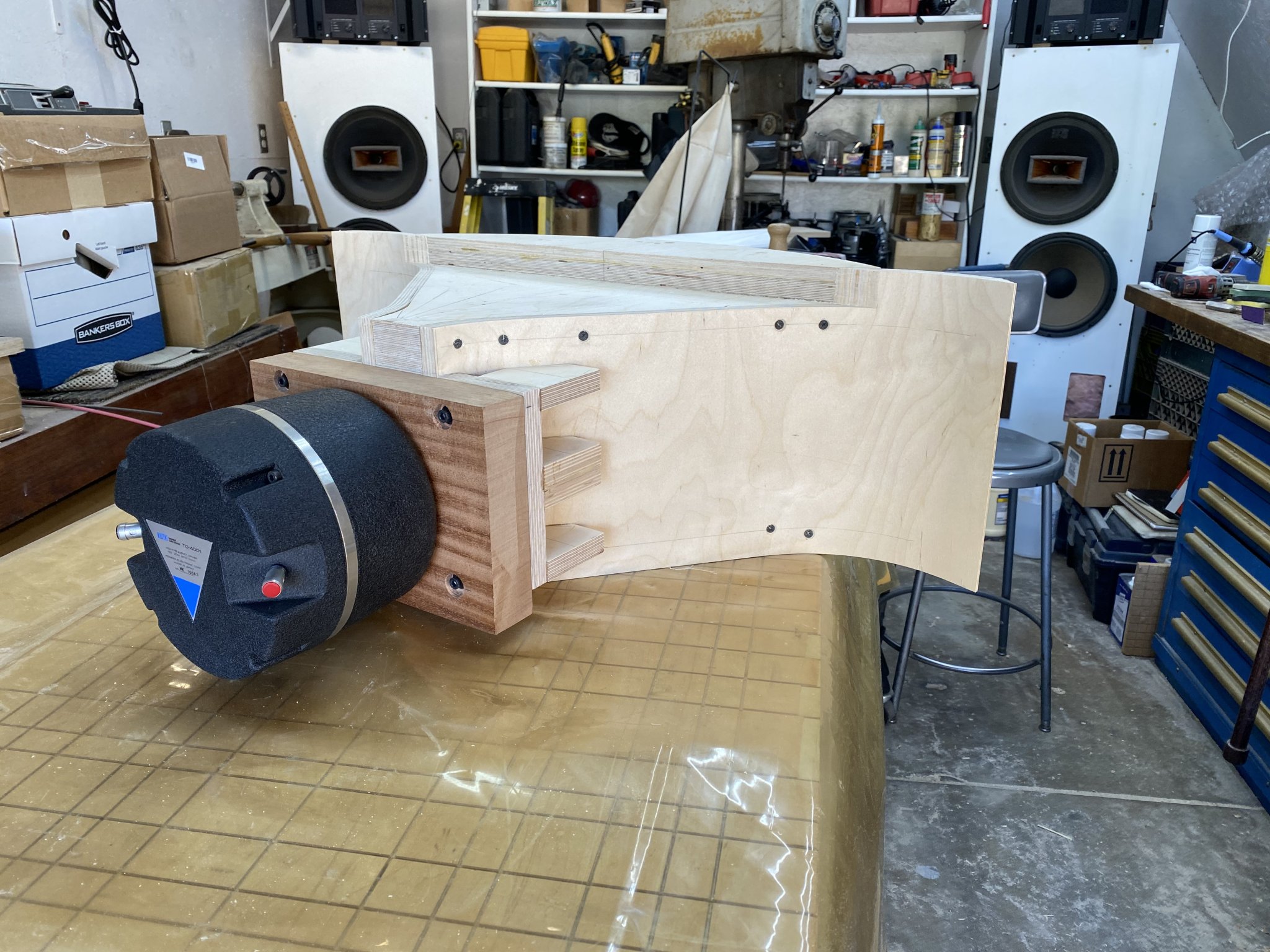

Currently, I'm playing with some TAD drivers that I stumbled onto and looking at building a slight variation on the Exclusive 2401/TAD TSM-1 large monitor. Many years ago I built a pair of Yuichi A290 radial horns to play with. They are an exceptional radial design with performance very similar to the TAD TH-4001. But I don't like horns with vanes in them for hifi; I find they do great at even horzontal coverage, but the soundstage flattens as a result. The TAD TH-4003 horn has 80˚ X 30˚ pattern with no vanes, but that horn is designed for a 40mm throat driver. My TD-4001 has a 50mm throat (actually 49.2mm). So I decided to try to build a horn like the TD-4003 but for a 50mm driver.

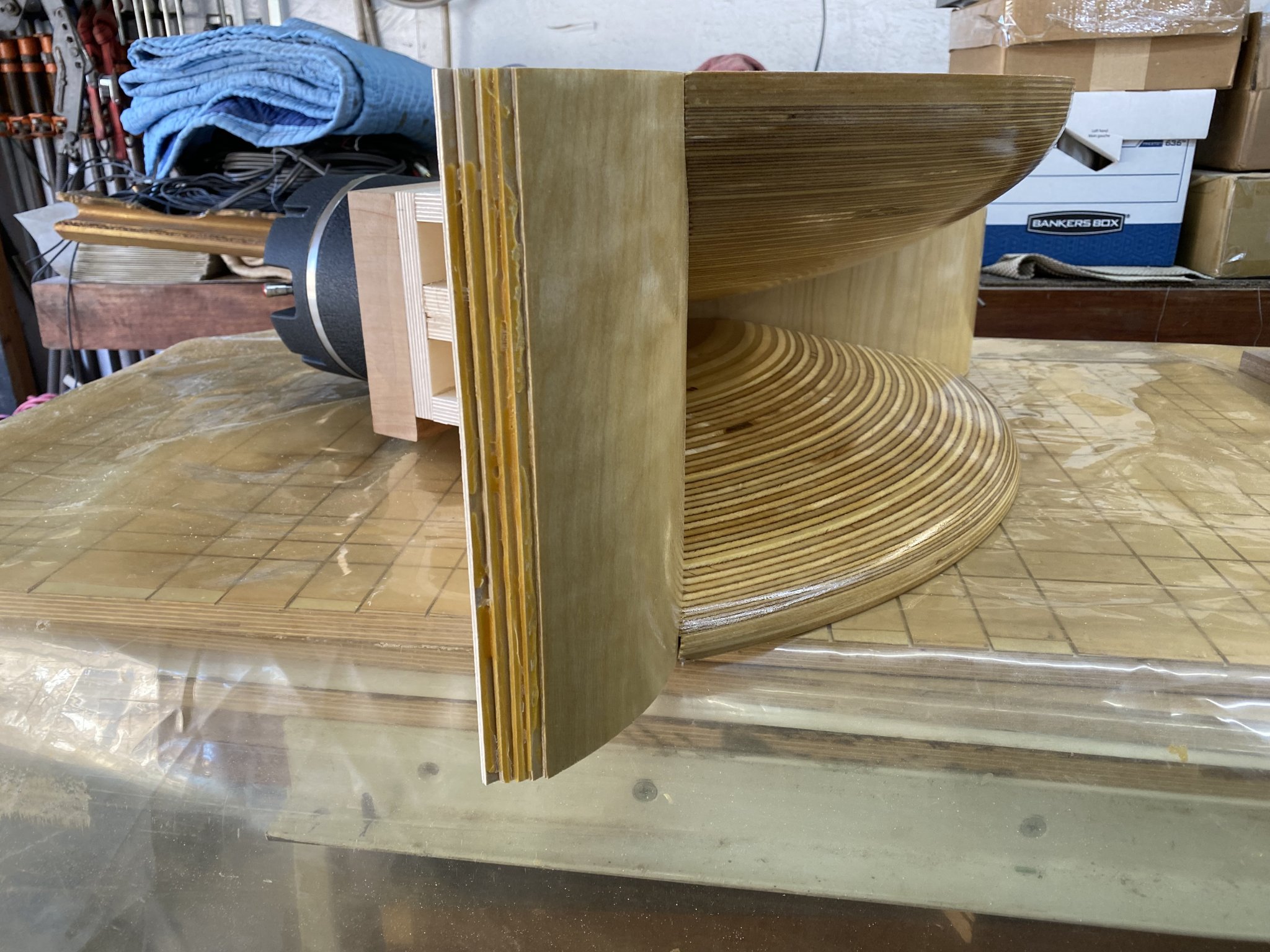

Because I Know the Yuichi A290 has good frequency response I started with calculating an exponential expansion with a .7 hyperbolic influence for a 290Hz flare starting with a 49.2mm throat. This scenario does not have an adapter plate. The driver mounting plate is the mouth of the horn and the transition from 49.2mm round to a near rectangle is flowing the calculated expansion. And the horn itself is tedious to shape since it is asymmetrical, but initial tests are promising.

Not a perfect fit, but very close. This mounting plate is 1 3/4" thick, and the angles at the driver match the conic flare inside the driver before beginning the asymmetric expansion of the horn:

The prototype assembly:

Rough plots on and off axis, no smoothing:

Still a lot of work to do on this one. Need to design the Helmholtz resonator that I believe will be adjusting the on-axis level to balance with the off-axis pattern a bit more closely. And I need to set up for taking impedance measurements... any input on that would be appreciated.

A lot of words there and meandering about, but hopefully not fully incoherent.

Cliff's Notes version: Don't adapt a 1" driver to a 2" horn, and don't even think about attaching a 2" driver to a smaller horn. Wherever possible start with a clean sheet of paper so you can work out the variable and possible conflicts ahead of time.

eso

I don't think it's a surprise, so to speak, as much as that fact that many of us don't know much about it. It's a topic I've heard discussed for about 40 years, and has to be about a century old. The difficulty is that the typical discussions of the topic haven't gone into much detail. "A smooth transition" is about all that is typically given as a parameter, not much beyond that. Finding clear guidelines to driver/horn matching have been hard to find and the goal here is to help define and clarify these guidelines.I am somewhat surprised that so many people seem surprised that matching geometry of driver to horn has such a great impact on performance.

Obviously some people like you and @marco_gea already understand how to calculate the matching, but many of us just know that it's important to do, but not the information of how to do it. They idea here is to acquire the tools and knowledge to do so.

"some people like you and @marco_gea already understand how to calculate the matching..."

@marco_gea may know how to calculate that, but certainly don't. I mostly observe and feel my way through these things. Luckily, visual cues can be quite informative.

I've been a member of this page since 2008, but participated very little. It seems that while "Under Moderation" I have a limited palette of tools and am unable to edit or even like posts... While I understand the reasoning behind the precautions it makes using this page awkward.

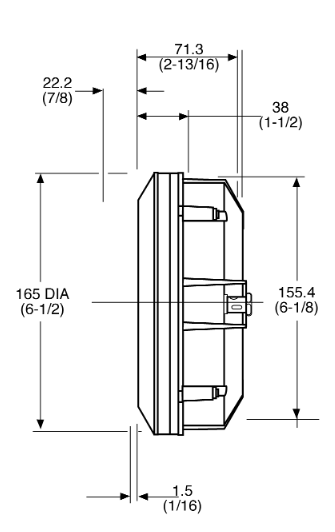

A small correction to the measurements for the JBL 2450J driver:Driver: JBL 2450J

diameter at phase plug exit = 3.8 cm, therefore S1 = 11.3 cm2;

diameter at internal throat exit = 4.9 cm, therefore S2 = 18.9 cm2

internal throat length L =6.3cm

Equivalent exponential cut-off frequency of internal throat: Fc = 343/(4*Pi*0.063)*ln(18.9/11.3) =220Hz

Equivalent exponential flare rate of internal throat: m = 4*Pi*221/343 =8.1

I actually measured the length of the internal throat again myself with a caliper, and it's L = 6.9 cm (not 6.3 cm)

This means that the equivalent exponential cut-off frequency of the internal throat is actually Fc = 200 Hz (not 220 Hz).

Not a large difference by any means, but I thought I'd mention it here for posterity ;-)

Marco.

Waves do not move like a plane or a boat.... sound from a driver and horn is waves moving through a plastic medium: Like a plane in the air, a boat in the water, ...

eso

Waves propagate without materia transport - the boat changes location. The boat hasa boundary layer which causes friction to the media it moves trough. A wave is pressure propagation with no boundary layer friction involved - only pressure loss to heat.

//

If pressure were the only driving factor, any form with the proper expansion would be an effective horn. Yet here we are with many different types of horns exhibiting different characteristics.A wave is pressure propagation with no boundary layer friction involved - only pressure loss to heat.

eso

@Pano

I have a pair of Celestion CDX1-1412 drivers. Let's start with exit angle, which isn't in the specs. Is that the angle of the exit "cone"? It appears to start at 5/8" diameter and expands to 1" diameter after about 1/2". Been a half century since my last Geometry class, but does that mean that the exit angle is around 20.5°? Does this mean that the horn entry should be 1" and initially expand at the same 20.5° before before reaching, say, 90°?

I hope my question makes sense. Here's a picture of the driver exit.

I have a pair of Celestion CDX1-1412 drivers. Let's start with exit angle, which isn't in the specs. Is that the angle of the exit "cone"? It appears to start at 5/8" diameter and expands to 1" diameter after about 1/2". Been a half century since my last Geometry class, but does that mean that the exit angle is around 20.5°? Does this mean that the horn entry should be 1" and initially expand at the same 20.5° before before reaching, say, 90°?

I hope my question makes sense. Here's a picture of the driver exit.

You are on the right track, my understanding is rather unsophisticated. While it is hard to tell it looks like the exit angle is significantly wider than the 20.5° you mention. I suspect and possibly mistakenly that this driver is intended for a very short horn. (They mention compact installations as a primary usage point.)

I have to say that is my first and last visit to Celestion since they force you to sign up for their newsletter before accessing the site. (I was a little inventive with email address and name.)

I have to say that is my first and last visit to Celestion since they force you to sign up for their newsletter before accessing the site. (I was a little inventive with email address and name.)

You could have just pressed the cross in the corner of the popup and carried on. There is no need to sign up to view the website.I have to say that is my first and last visit to Celestion since they force you to sign up for their newsletter before accessing the site. (I was a little inventive with email address and name.)

I had to shrink it from my normal 125% down to 50% before I found the circled x in the top right corner to delete it and now going back to the site I have to blow it back up, so 'kinda sorta' is a bit of a nuisance 'trap'.

Anyway, the specs pdf

Anyway, the specs pdf

I am a bit perplexed by this thread. Given that the discussion somewhat orbits around the question about how to consider the throat depth and exit angle of a CD compared to a horn profile, I am curious as to why Dr. Geddes treatment of this question has not been mentioned.

I believe the oblate spheroidal (OS) expansion is a member of the broader category of catenoid curves and the catenoid curve is a curve that finds the path of least 2nd derivative change in angle to join two points on a curve that have different tangent angles. Also called a "minimal surface". So, for example a if a CD has a 10 deg. exit angle and you would like to have a profile to terminate for a 90 degree directivity or mouth exit angle, the OS calculation methods gives the curve with the least rate of change and therefore diffraction distortion in the form of HOM's. The OSWG calculations explicitly solve the problem of a change in angle. But, of course that's only possible when designing a horn to match, instead of choosing a driver to match, which may be more about what folks are solving here.

One of the results of the OSWG approach to the design and analysis of horns is that it would be preferable to have the CD phase plug terminate as close to the mounting flange face as possible such that a horn might fully determine the wave propagation instead of requiring a transformation from the CD throat expansion to the final or dominant horn expansion, as is mentioned in this thread several times by others. Maybe there are intuitive reasons for this, but I think Geddes demonstrates why this is important explicitly and his work attempts to quantify the effect of this and also tested experimentally whether the HOM's are subjectively perceived. All to say, there appears to be wide acceptance at least at some level that this conclusion of the work is valid.

Unfortunately these methods may only really be explicitly useful for OSWG horns as I believe the math requires a horn expansion that can be modeled using the polar(?) coordinate system (only OS, maybe conical?). Without FEA, it's almost impossible to compute for other expansions. But, Dr. Geddes makes some general comments about the deleterious effects of rapid changes in expansion and I believe he's said that really it is only the distortions of wave propagation by diffraction within the horn profile that really matter. Even if that's exagerated (or misquoted), isn't the premise sound enough to provide a selection heuristic?

I know the whole OSWG thing is contentious for some folks, and conical horns are often just dismissed outright for some reason or the other, but many CD's have internal throats that are conical, so it seams like an obvious approach to match this cone to another cone or to the OSWG to minimize HOM's for those that accept that as a useful objective goal. I just can't see where anyone has offered any analytical approaches to matching the very short CD throat to the fully complex shape of a biradial or exponential horn, and Geddes has provided one analytical approach to look at this.

Sorry to intrude so verbosely, I just thought it strange that the OSWG analytical approach hasn't been mentioned yet on this thread. I haven't looked at other recent threads lately. Maybe there's a consensus already that this isn't applicable and I missed it.

Cheers,

Jamie

I believe the oblate spheroidal (OS) expansion is a member of the broader category of catenoid curves and the catenoid curve is a curve that finds the path of least 2nd derivative change in angle to join two points on a curve that have different tangent angles. Also called a "minimal surface". So, for example a if a CD has a 10 deg. exit angle and you would like to have a profile to terminate for a 90 degree directivity or mouth exit angle, the OS calculation methods gives the curve with the least rate of change and therefore diffraction distortion in the form of HOM's. The OSWG calculations explicitly solve the problem of a change in angle. But, of course that's only possible when designing a horn to match, instead of choosing a driver to match, which may be more about what folks are solving here.

One of the results of the OSWG approach to the design and analysis of horns is that it would be preferable to have the CD phase plug terminate as close to the mounting flange face as possible such that a horn might fully determine the wave propagation instead of requiring a transformation from the CD throat expansion to the final or dominant horn expansion, as is mentioned in this thread several times by others. Maybe there are intuitive reasons for this, but I think Geddes demonstrates why this is important explicitly and his work attempts to quantify the effect of this and also tested experimentally whether the HOM's are subjectively perceived. All to say, there appears to be wide acceptance at least at some level that this conclusion of the work is valid.

Unfortunately these methods may only really be explicitly useful for OSWG horns as I believe the math requires a horn expansion that can be modeled using the polar(?) coordinate system (only OS, maybe conical?). Without FEA, it's almost impossible to compute for other expansions. But, Dr. Geddes makes some general comments about the deleterious effects of rapid changes in expansion and I believe he's said that really it is only the distortions of wave propagation by diffraction within the horn profile that really matter. Even if that's exagerated (or misquoted), isn't the premise sound enough to provide a selection heuristic?

I know the whole OSWG thing is contentious for some folks, and conical horns are often just dismissed outright for some reason or the other, but many CD's have internal throats that are conical, so it seams like an obvious approach to match this cone to another cone or to the OSWG to minimize HOM's for those that accept that as a useful objective goal. I just can't see where anyone has offered any analytical approaches to matching the very short CD throat to the fully complex shape of a biradial or exponential horn, and Geddes has provided one analytical approach to look at this.

Sorry to intrude so verbosely, I just thought it strange that the OSWG analytical approach hasn't been mentioned yet on this thread. I haven't looked at other recent threads lately. Maybe there's a consensus already that this isn't applicable and I missed it.

Cheers,

Jamie

- Home

- Loudspeakers

- Multi-Way

- Matching horns to compression drivers, a discussion