Hi Community,

Is there any progress on reviving this project?

TBH, I am very interested in having on of them for my designs.

Gabriel

Is there any progress on reviving this project?

TBH, I am very interested in having on of them for my designs.

Gabriel

Loki never responded…

Well, I took the project from Uwe and completely revamped the client software by writing a Python GUI -which btw. runs on every platform (successfully tested on MacOS and Windows). It’s mostly for small signal transistors and it does what it is supposed to do. The software is GNU public incl. all source code. The heart is an Arduino Nano. Firmware source is also available… Drop me a PM if you are interested. In the meantime you can grab the hard- and software plans here. Be warned, only windows and a bit buggy. Otherwise Uwe did an awesome work!

http://diy.ucborgmann.de/index.php/en/audio-messtechnik-2/characteristic-curve-recorder

Some curves from my GUI attached. It also has a rudimentary matching function (incl. complementary pairs).

Well, I took the project from Uwe and completely revamped the client software by writing a Python GUI -which btw. runs on every platform (successfully tested on MacOS and Windows). It’s mostly for small signal transistors and it does what it is supposed to do. The software is GNU public incl. all source code. The heart is an Arduino Nano. Firmware source is also available… Drop me a PM if you are interested. In the meantime you can grab the hard- and software plans here. Be warned, only windows and a bit buggy. Otherwise Uwe did an awesome work!

http://diy.ucborgmann.de/index.php/en/audio-messtechnik-2/characteristic-curve-recorder

Some curves from my GUI attached. It also has a rudimentary matching function (incl. complementary pairs).

Attachments

Last edited:

Yes, it is, on request from Uwe. He didn’t made it public on his page but if you ask politely you’ll get it (I got it because it was a big help while developing the Python GUI…)So, firmware is also Open source. Something that Locy_Z development lacks. Very interesting Tube Kiddo. Thanks for the head-up!

If you look into my Python code you’ll see howto communicate which the Arduino.

Many people have a currently working Locky_z curve tracer. Including me. So the answer to your question is: Yes.I just wonder if somebody have a curve tracer (Locky_z) currently working.

The answer to your second question is, yes I will sell it to you for USD 2500. No I will not offer a money back guarantee against shipping damage or software incompatibility.

I see TubeKiddo!Yes, it is, on request from Uwe. He didn’t made it public on his page but if you ask politely you’ll get it (I got it because it was a big help while developing the Python GUI…)

If you look into my Python code you’ll see howto communicate which the Arduino.

First glance of schematics, it seems to me a 'refined' design. For instance, using a 3uV OpAmp to 'fabricate' a kind of isolated digital ground apart from analog one.

So, you have contributed in the design programming the python code you showed me at the pics. Nice GUI, BTW!!!

It starts to be eager of this design. If you and Uwe are keen to improve the project, I can contribute with my double peltier fine controlled temperature environment for the DUT with a BTL design. Not only for semiconductor but for NTC alike...

Let's se how things are evolving!

Gabriel

Hi Mark,Many people have a currently working Locky_z curve tracer. Including me. So the answer to your question is: Yes.

The answer to your second question is, yes I will sell it to you for USD 2500. No I will not offer a money back guarantee against shipping damage or software incompatibility.

Thank yu for your answer.

Indeed, you guessed I am looking for a working device. On the other hand, I respect your gentle offer, but regrettably is far out of my budget, even to start a bargain.

But, let's see the bottle half full. The fact of knowing that you have a device, it can be interesting to make a win-win between us.

When I have the chance to do a PM with you (Now the platform won't let me because I'm new) I'll share my idea in case you're interested (with little effort on your side!).

Gabriel

Madrid

LolMany people have a currently working Locky_z curve tracer. Including me. So the answer to your question is: Yes.

The answer to your second question is, yes I will sell it to you for USD 2500. No I will not offer a money back guarantee against shipping damage or software incompatibility.

Sounds nice!If you and Uwe are keen to improve the project, I can contribute with my double peltier fine controlled temperature environment for the DUT with a BTL design. Not only for semiconductor but for NTC alike...

In the meantime if you are looking for a curve tracer wit temperature control for the DUT, see here:

https://pypsucurvetrace.readthedocs.io/en/latest/

I was aware of this, dear mbrennwa.In the meantime if you are looking for a curve tracer wit temperature control for the DUT, see here:

https://pypsucurvetrace.readthedocs.io/en/latest/

It is based on a heavy block of cooper with a lot of temperature intertia and a kind of temperature resistor heaters.

Mine, is based on peltier. It has some advantages (and maybe some drawbacks).

But, in theory, it is possible to maintain a target temperature for a discrete DUT with a reasonable size and temperature load.

Attached, it is the PCB design based in a double push-pull stages, 16 bits AD, 12 bits DA, precision current generator (For tracing NTCs, this is the original purpose) and 5V 2A (Reversible and continuous) hot-cold peltier stage.

Also, some SPICE curves showing linearity from -5V to 5V Peltier feeding. Power supply is only +5V due to the Bridge Tied Load final stage without zero cross distorsion.

Attachments

All source code is available. Everybody can start improving. I am satisfied with the result it does what I need!(…)If you and Uwe are keen to improve the project, I can contribute with my double peltier fine controlled temperature environment for the DUT with a BTL design. Not only for semiconductor but for NTC alike...

Let's se how things are evolving!

Gabriel

If you need help to improve beyond and modify to fit your specific needs, PM me…

If your ADC/DAC (s) can be addressed via SDI, EVERYHTING you need to control this via a PC is available. E.g. there are ready made Arduino libraries to control this. And IK that an Arduino can be addressed rather easy by a Python client software. The Arduino FW source code is available and there’s enough flash space available to add add’l functions. There are also some add’l I/O ports available.I was aware of this, dear mbrennwa.

It is based on a heavy block of cooper with a lot of temperature intertia and a kind of temperature resistor heaters.

Mine, is based on peltier. It has some advantages (and maybe some drawbacks).

But, in theory, it is possible to maintain a target temperature for a discrete DUT with a reasonable size and temperature load.

Attached, it is the PCB design based in a double push-pull stages, 16 bits AD, 12 bits DA, precision current generator (For tracing NTCs, this is the original purpose) and 5V 2A (Reversible and continuous) hot-cold peltier stage.

Also, some SPICE curves showing linearity from -5V to 5V Peltier feeding. Power supply is only +5V due to the Bridge Tied Load final stage without zero cross distorsion.

I took windows VB GUI source code and re-wrote it to Python incl. all communication protocols, implemented threading (‘pseudo paralleled’ code execution) and added a modern GUI which can be rather easy extended.

If you need any help at any stage PM me. I be able to guide you howto compile the FW source and howto edit it…

I am not experienced enough to touch a hardware close C++ source code. I have a good idea how everything works together and how the Arduino addresses the ADCs and DACs but wouldn’t feel confident to add add’l functions.

Last edited:

Some curves from my GUI attached. It also has a rudimentary matching function (incl. complementary pairs).

Nice shots.

Which Python libs did you use for GUI and data communication?

PyCharm CE as IDE with QT DesignerNice shots.

Which Python libs did you use for GUI and data communication?

GUI:

Python 3.9+

PySide6

serialtools, serial

statistics, random

json

time

matplotlib

numpy

Scipy

sys, threading

PM and I’ll send you the source code, incl. the Designer files.

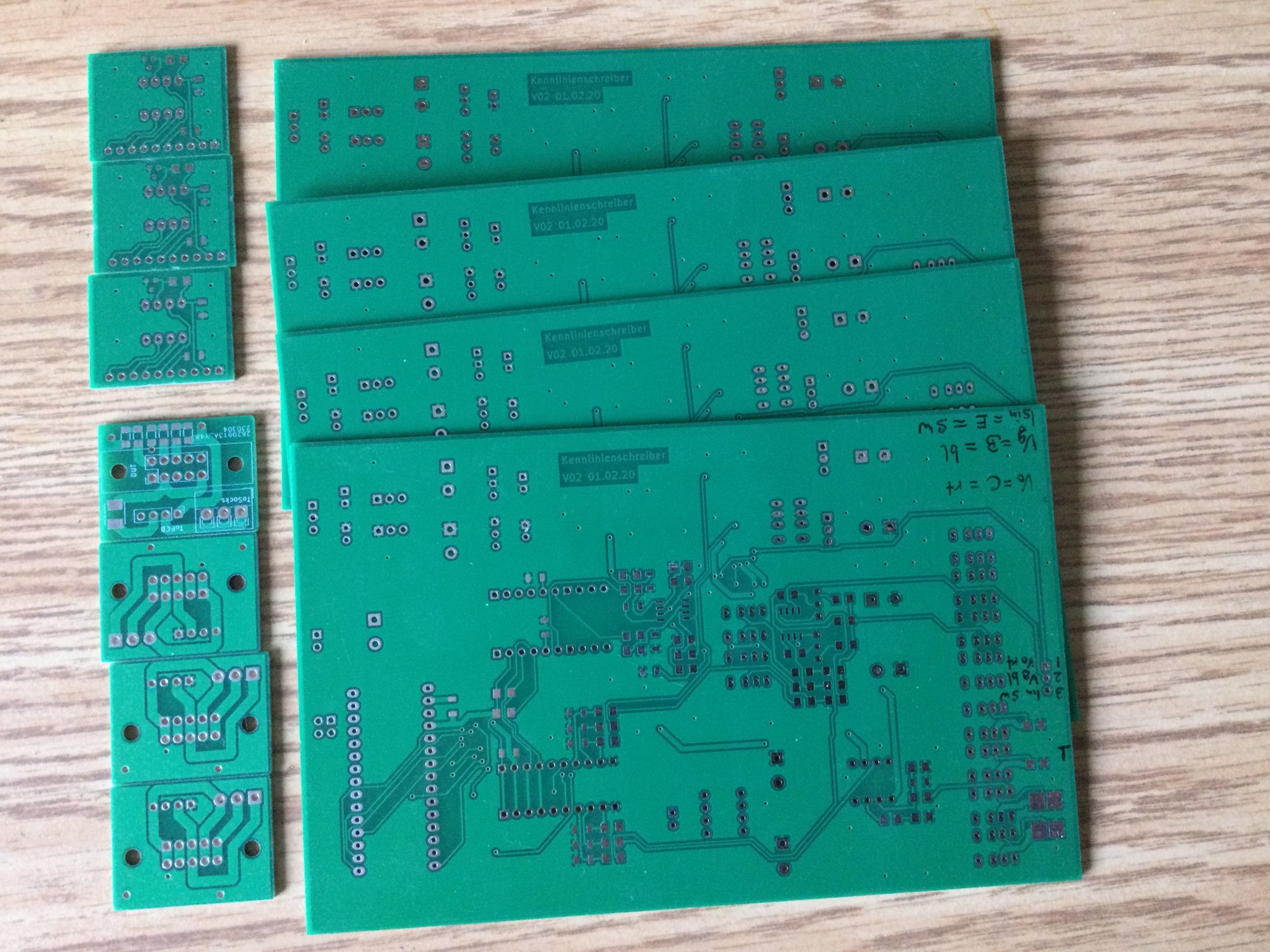

I have a few leftover in Canada. Unfortunately only one complete set, since you need two for the DAC adapter (can be assembled on a prototype board, only 6 parts).

Also, you can PM me in case you’re interested in the Python GUI…

Also, you can PM me in case you’re interested in the Python GUI…

- Home

- Vendor's Bazaar

- Intelligent Curve Tracer 3.0 release