Howard,

I make all my speakers out of foam core, it is actually quite stiff when used as separator ribs in compression. The closest speaker would be the Cornu which uses a lot of foam core dividers. The structure that results is very stiff with the foam core holding the front and back together.

I make all my speakers out of foam core, it is actually quite stiff when used as separator ribs in compression. The closest speaker would be the Cornu which uses a lot of foam core dividers. The structure that results is very stiff with the foam core holding the front and back together.

I have a lot of wood and saws, so wood is easy for me. What kind of glue do you prefer for the foam core-to-wood application?

The horn in the pictures I posted came into the house and is standing in a corner of the bedroom. The ceiling and the corner do boost the bass response, according to my ear. In the shop I have been making measurements on another mocked up/prototype horn that should be acoustically like the one in the pics. The very low bass was impressive, considering the driver, but 40hz is stronger than 50 and 60hz, which makes it sound thin. So---

I have been playing around with shortening the mocked up horn. I made a version that is pretty close in CSA at appropriate points to the Austin A-166, with pretty close to the same length-about 120". I made measurements with pink noise bands from a CD and a R.shack meter. It rolls off higher than the one in the pics, so has less deep bass, but is overall more realistic and balanced sounding. On the bench, the response is definitely still a rising response. Hopefully the room and corner location will help with that.

The Fe 166e is not actually my favorite driver. But I have them already, this is an in wall installation(and so kind of compromised), and I like to see how much I can extract from a driver.

Looks like if I shorten the horns, I will end up with an extra 20x20x3.5" cavity (about .8 cuft). Any good ideas out there about a driver that would make a nice little plate-amp-powered sub-woofer in that shape/size of a cabinet/ volume? Low bass would be best, but I know that is a small volume.

The horn in the pictures I posted came into the house and is standing in a corner of the bedroom. The ceiling and the corner do boost the bass response, according to my ear. In the shop I have been making measurements on another mocked up/prototype horn that should be acoustically like the one in the pics. The very low bass was impressive, considering the driver, but 40hz is stronger than 50 and 60hz, which makes it sound thin. So---

I have been playing around with shortening the mocked up horn. I made a version that is pretty close in CSA at appropriate points to the Austin A-166, with pretty close to the same length-about 120". I made measurements with pink noise bands from a CD and a R.shack meter. It rolls off higher than the one in the pics, so has less deep bass, but is overall more realistic and balanced sounding. On the bench, the response is definitely still a rising response. Hopefully the room and corner location will help with that.

The Fe 166e is not actually my favorite driver. But I have them already, this is an in wall installation(and so kind of compromised), and I like to see how much I can extract from a driver.

Looks like if I shorten the horns, I will end up with an extra 20x20x3.5" cavity (about .8 cuft). Any good ideas out there about a driver that would make a nice little plate-amp-powered sub-woofer in that shape/size of a cabinet/ volume? Low bass would be best, but I know that is a small volume.

Foam core to wood can be glued with hot melt or PVA (or tacked with hot melt and sealed with PVA). Gorilla glue works well I hear but makes a mess.

Are you looking for a combo of amp and driver for the 20x20x3.5 cavity to put a subwoofer? That is not a lot of volume for a sub (23 liters). Also, you are limited in the depth of the driver magnet. Maybe one of those super long throw subwoofer drivers (like the TB W6-1139SIF 6-1/2 - maybe with a passive rad? Use a compact 100 watt class D amp - they take no space at all.

Are you looking for a combo of amp and driver for the 20x20x3.5 cavity to put a subwoofer? That is not a lot of volume for a sub (23 liters). Also, you are limited in the depth of the driver magnet. Maybe one of those super long throw subwoofer drivers (like the TB W6-1139SIF 6-1/2 - maybe with a passive rad? Use a compact 100 watt class D amp - they take no space at all.

Hi xrk971,

Yeah, a small sub that would use that space and compliment the low end was the idea. I should probably wait till I have the pair of horns in place(with removable front panels) to see if I really want a pair of little subs. I think that I am going to have a rising response up into the 300 hz range. May have to live with that, if the room response doesn't compensate entirely.

Folks might like to know this way of making a rattle proofing gasket for removable panels:

Put acrylic caulk on the edges of the "box" and any dividers, lay thin plastic sheeting over the whole thing, then screw the removable panel down. When the caulk dries, and you remove the panel, peel away the plastic and you have a nice caulk gasket.

I thought a little about using the(possible sub-woofer) space as some kind of resonant chamber off of the horn, with a port to the outside, but that sounds like more of a design problem than the horn itself. The chamber would be where the original 180 degree turn was(which was moved up about 20" when the horn was shortened).

Yeah, a small sub that would use that space and compliment the low end was the idea. I should probably wait till I have the pair of horns in place(with removable front panels) to see if I really want a pair of little subs. I think that I am going to have a rising response up into the 300 hz range. May have to live with that, if the room response doesn't compensate entirely.

Folks might like to know this way of making a rattle proofing gasket for removable panels:

Put acrylic caulk on the edges of the "box" and any dividers, lay thin plastic sheeting over the whole thing, then screw the removable panel down. When the caulk dries, and you remove the panel, peel away the plastic and you have a nice caulk gasket.

I thought a little about using the(possible sub-woofer) space as some kind of resonant chamber off of the horn, with a port to the outside, but that sounds like more of a design problem than the horn itself. The chamber would be where the original 180 degree turn was(which was moved up about 20" when the horn was shortened).

Hi xrk971

It is comforting to know that a compensating circuit is an option.

I looked at your flute pipe thread, and I am a little behind the curve with the math and the terminology, but from my cut/drill/play experimenting, I have a decent sensory feel for how a pipe resonates. The nulls, by virtue of being "not there" are more elusive to the senses.

On the 120" horn, I drilled 2) 2" holes in tandem at about 100". I can hear quite a bit of 50-80hz bass coming from the holes, but when they are open(sometimes I have them covered) I think that there is somewhat less coming from the mouth; while the overall bass response seems greater with them open.

Is there any generalizable rule for the spacing of holes along a pipe, possibly in lieu of a mouth, or is it always a unique distance between holes that needs to be calculated? If there was a predictable spacing, I might make some kind of sliding piece to move up and down the tube length.

It is comforting to know that a compensating circuit is an option.

I looked at your flute pipe thread, and I am a little behind the curve with the math and the terminology, but from my cut/drill/play experimenting, I have a decent sensory feel for how a pipe resonates. The nulls, by virtue of being "not there" are more elusive to the senses.

On the 120" horn, I drilled 2) 2" holes in tandem at about 100". I can hear quite a bit of 50-80hz bass coming from the holes, but when they are open(sometimes I have them covered) I think that there is somewhat less coming from the mouth; while the overall bass response seems greater with them open.

Is there any generalizable rule for the spacing of holes along a pipe, possibly in lieu of a mouth, or is it always a unique distance between holes that needs to be calculated? If there was a predictable spacing, I might make some kind of sliding piece to move up and down the tube length.

Neat idea with sliding hole to tune. It will follow similar physics of woodwind instruments for hole placement. Akabak can model a flute of course. There are closed form solutions for straight tubes. Google flute calculator and Ohio State University. There is an excel worksheet with all equations.

Sorry wrong Ohio school. I meant Baldwin Wallace College.

P Hoekje's MUSICAL ACOUSTICS page

Program is very accurate and lets you design nice flutes in interesting ranges with simple pvc pipes.

P Hoekje's MUSICAL ACOUSTICS page

Program is very accurate and lets you design nice flutes in interesting ranges with simple pvc pipes.

xrk971,

Thank you for that info. Seems like there are two issues with a speaker pipe, vis a vi the flute holes and other termini in the pipe:

1)Evening-out ragged response.

2)Producing enough bass response, especially in the low end.

My observation that some output from the mouth was lost when I opened up other holes closer to the driver, would seem to indicate that the mouth size might change when other holes are opened.

Thank you for that info. Seems like there are two issues with a speaker pipe, vis a vi the flute holes and other termini in the pipe:

1)Evening-out ragged response.

2)Producing enough bass response, especially in the low end.

My observation that some output from the mouth was lost when I opened up other holes closer to the driver, would seem to indicate that the mouth size might change when other holes are opened.

Progress on the In-Wall project:

I added an 8" woofer and PR to the .8cu ft space that was created when I shortened the pipe to 120". The driver/PR were rubber surround units from old KOSS CM/530 2way's. I had made a note years ago when I tossed the original 1.3 cu ft cabinets that, overall, the speakers(with a soft dome tweeter) sounded good, but had "loose(sloppy) bass"----I made a note to try a smaller cabinet(like this one!). I wired the sub up to a plate amp, and fired up the system. I was then smiling and rocking out!

A sub will do the trick to fill in the bass for rock and movies, and can be switched off for acoustic music if need be. I am thinking that the sub will integrate like a LF driver in a multi-way installation, being in the same plane as the FR drivers.

The bedroom wall that I am installing these speakers into is multipurpose with space for a 32" flat screen above the wardrobe cabinets, a bookshelf to the right, and component shelves to the left.

The subwoofer success is good news for those who would like to do a project like this for a family room or theater. If the wall one is working with is already built with 2x4's, the drywall could be removed, and the studs furred out to 2x6 depth to accommodate the wood enclosure. Maybe a decent installation could be made with 5/8" drywall and wood or foam core dividers over 3.5" deep stud bays . I do wonder if that would be rigid enough for the subs though. I know that drywall mounted subs are done by home theater installers all the time, but my purist side has long wanted to do something more sophisticated and rigid.

no photos yet.

And I played it kinda loud with some really low notes, and saw that something was wildly wrong with the PR----the surround is rubber but the spider WAS foam---now it is in fragments( If I had noticed it was foam before it got destroyed-I think it was basically all there- I could have used flowable silicone windshield sealer to make it strong agian). Woofer probably has the same spider-had to leave home/shop about then-the PR looks like the woofer frame sans-magnet structure/voicecoil, which of course most are. So the woofer may be toast too. At least I know that sub+PR is a good way to go!

And I played it kinda loud with some really low notes, and saw that something was wildly wrong with the PR----the surround is rubber but the spider WAS foam---now it is in fragments( If I had noticed it was foam before it got destroyed-I think it was basically all there- I could have used flowable silicone windshield sealer to make it strong agian). Woofer probably has the same spider-had to leave home/shop about then-the PR looks like the woofer frame sans-magnet structure/voicecoil, which of course most are. So the woofer may be toast too. At least I know that sub+PR is a good way to go!

The Dynavox Uniquorn was a flat enclosure speaker for near wall placement.

dynavox uniqorn - Google-Suche

It was more a horn-reflex (short horn and big compression chamber).

dynavox uniqorn - Google-Suche

It was more a horn-reflex (short horn and big compression chamber).

Hi el`Ol,

Those are interesting looking speakers. The link was in languages that my English-only skills couldn't translate, so I will have to do some more looking to really get how they work.

I have built rear horns with the driver mounted on the wider side so that they can be pretty close to a wall. They work well. They are 6" deep overall. The mouths are to the side, and theyare a mirror pair, so that they can be pointed in together or out, possibly into adjacent corners. I mentioned these earlier in this thread as the ones that did well in the 2008 PNWAS speaker contest. I want to do some photos of them, and put them up so others can see them.

They are a horn/MLTL hybrid; have a restricted(mass loaded) terminus (which helps them be only 32" tall). I heard them next to a very nicely built pair of Frugal Horns with Fostex Sigma drivers that were about the same size as the FE 126e in my speakers, and my smaller(and uglier) mass loaded "horns" had much more, and different, bass.

Those are interesting looking speakers. The link was in languages that my English-only skills couldn't translate, so I will have to do some more looking to really get how they work.

I have built rear horns with the driver mounted on the wider side so that they can be pretty close to a wall. They work well. They are 6" deep overall. The mouths are to the side, and theyare a mirror pair, so that they can be pointed in together or out, possibly into adjacent corners. I mentioned these earlier in this thread as the ones that did well in the 2008 PNWAS speaker contest. I want to do some photos of them, and put them up so others can see them.

They are a horn/MLTL hybrid; have a restricted(mass loaded) terminus (which helps them be only 32" tall). I heard them next to a very nicely built pair of Frugal Horns with Fostex Sigma drivers that were about the same size as the FE 126e in my speakers, and my smaller(and uglier) mass loaded "horns" had much more, and different, bass.

I was thinking about venting the front firing subwoofer that I mentioned a few posts ago(that I still have no pics of) into the horn, instead of directly in to the room with a PR or port. Not sure what would happen with that.

Update on the sub: The foam PR spider is toasted, but the woofer spider is impregnated cloth and is ok.

Update on the sub: The foam PR spider is toasted, but the woofer spider is impregnated cloth and is ok.

In-wall MLTL Sub with 6.5 in Silver Flute

Howard,

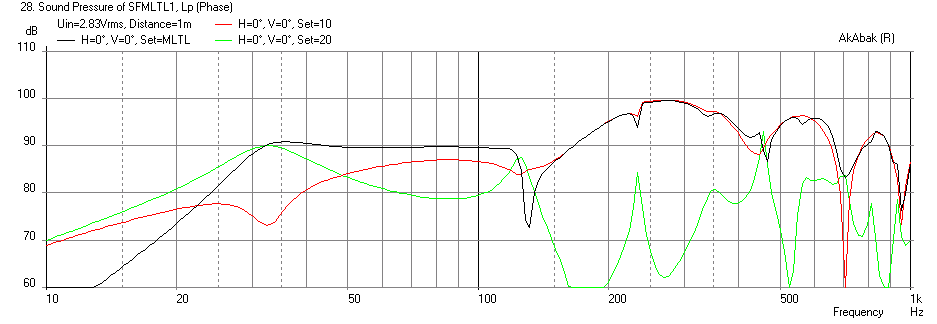

Per your request to have a sub that fits in a 21 in wide x 29 in tall x 3.5 in deep wall cavity that reaches 30 Hz. I decided to use the Silver Flute W17RC38-08 driver and a MLTL alignment. The Silver Flute has 3 in depth which is perfect for this wall mount application. The design is a single-fold so put a divider down the middle with the channel being 10.5 in wide on each side. Put the driver at 1/3rd distance from closed end. On the distal end make a slot vent that is 0.75 in high x 10.5 in wide x 9 in long with a parallel-to-the-wall shelf vent. Damping in the first 2/3rds of the line.

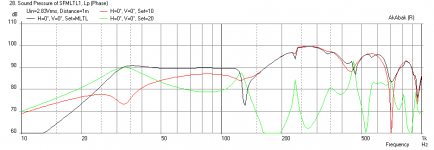

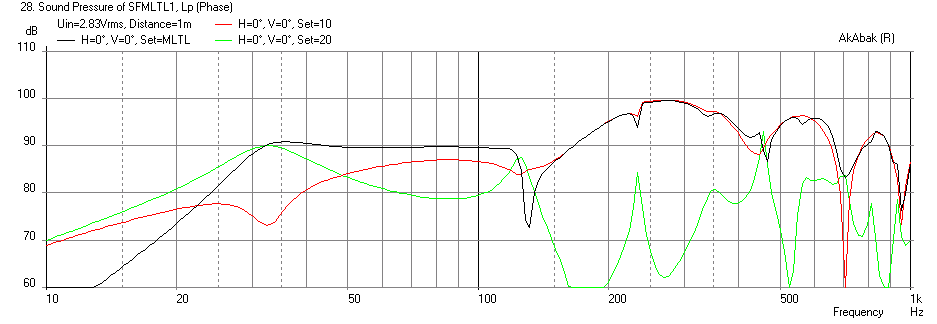

Here is the SPL vs Freq for 1 watt at 1 meter

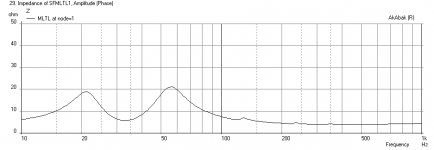

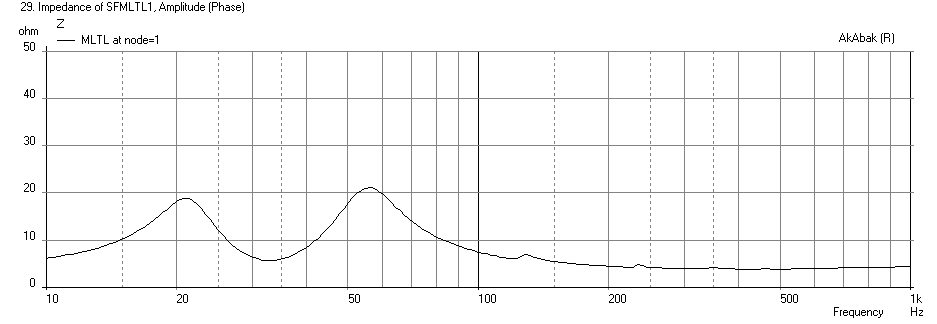

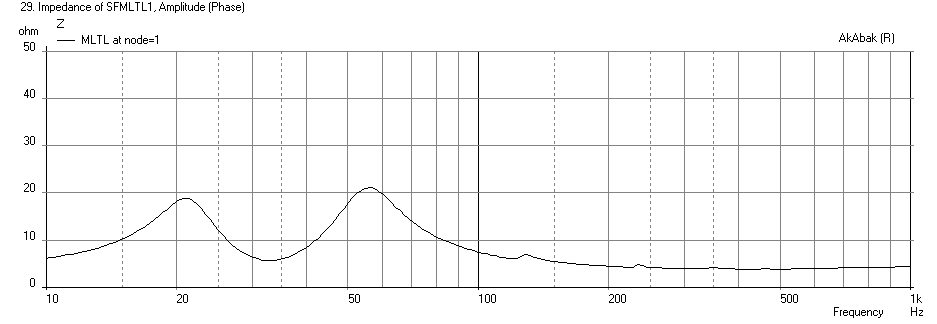

Here is the Impedance

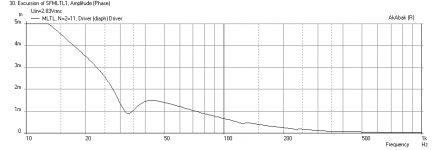

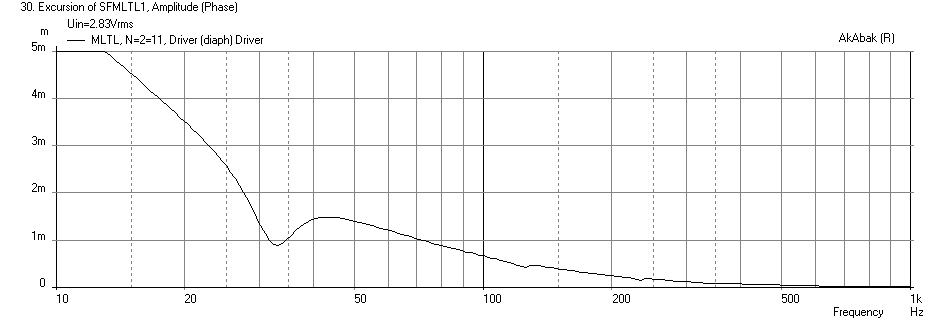

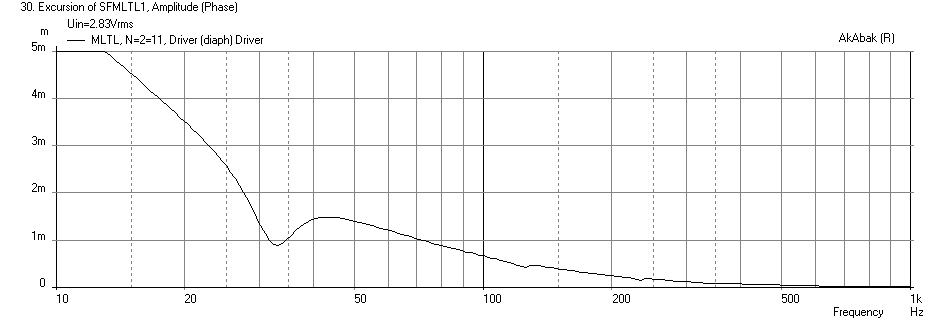

Here is the cone excursion

Let me know what you think. You plan to use a subwoofer plate amp with built in cross-over so that can take care of preventing too much excursion on the low end and stop the HF from leaking out. Probably want to XO at no higher than 120 Hz before the notch.

Howard,

Per your request to have a sub that fits in a 21 in wide x 29 in tall x 3.5 in deep wall cavity that reaches 30 Hz. I decided to use the Silver Flute W17RC38-08 driver and a MLTL alignment. The Silver Flute has 3 in depth which is perfect for this wall mount application. The design is a single-fold so put a divider down the middle with the channel being 10.5 in wide on each side. Put the driver at 1/3rd distance from closed end. On the distal end make a slot vent that is 0.75 in high x 10.5 in wide x 9 in long with a parallel-to-the-wall shelf vent. Damping in the first 2/3rds of the line.

Here is the SPL vs Freq for 1 watt at 1 meter

Here is the Impedance

Here is the cone excursion

Let me know what you think. You plan to use a subwoofer plate amp with built in cross-over so that can take care of preventing too much excursion on the low end and stop the HF from leaking out. Probably want to XO at no higher than 120 Hz before the notch.

Attachments

AS A SUB WOOFER ADDITION TO ANOTHER SYSTEM I ALREADY HAVE IN THE WORKS

I could also see this plate-amp-sub in a box of 11"x12"x30.5", over-all dimensions. That way two of them could be stands for a 2 way pair that I am now working on. I have two Fostex/Planet10 ff85wkeN full ranges (that I presently have running in) that I want to x-over above 300hz from a silver flute 6.5” or 8”.

Maybe even make the sub design using the 8” Silver Flute(some tweaking required of course) and use the 6.5”Silver Flute with the Fostex ff85wkeN full range, 2-way, in some vintage 15 Liter cabs I already have. That would make for some serious bass capabilities in a moderate sized room.

I could also see this plate-amp-sub in a box of 11"x12"x30.5", over-all dimensions. That way two of them could be stands for a 2 way pair that I am now working on. I have two Fostex/Planet10 ff85wkeN full ranges (that I presently have running in) that I want to x-over above 300hz from a silver flute 6.5” or 8”.

Maybe even make the sub design using the 8” Silver Flute(some tweaking required of course) and use the 6.5”Silver Flute with the Fostex ff85wkeN full range, 2-way, in some vintage 15 Liter cabs I already have. That would make for some serious bass capabilities in a moderate sized room.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- In-the-Wall Back Loaded Horns