I tested a partly completed horn on the bench- without the front screwed down and laying on it's back. Made the mouth about 115 sq in.(about twice as big as the largest, closest section of the horn). Best bass seemed to be with about half of that mouth covered(so that what was left open was about the size of the inner passage near the mouth). Maybe it was more resonant, but in a way that seemed pleasing to me. Still going to need the walls nearby to bring the bass level up with the midrange and highs. Quality of bass is musical, less "pushed" or "mechanical" seeming than when coming from a big, powerful woofer. Resonant, I think, but in a different way than a big woofer in a BR cabinet. I wonder if the "waves" that come off a horn powered by a small driver are somehow different from those coming off a big woofer? I understand that a cone driver is typically about 1 percent efficient in coupling it's energy to the room air, and horns are much more efficient in that respect. Maybe we can somehow feel some of the pressure from a big woofer cone, but not hear it as sound. Or does the other, non audible energy, the 99%, just become heat?

When I play fairly uncompressed bass thru my 14" speakers, things in the room will rattle and vibrate. Hard to see that that would happen with these horns. Is there something other than frequency and amplitude at work? I understand that large bass horns can break windows-so it must have to do with the quantity of air being pushed around/vibrated.

When I play fairly uncompressed bass thru my 14" speakers, things in the room will rattle and vibrate. Hard to see that that would happen with these horns. Is there something other than frequency and amplitude at work? I understand that large bass horns can break windows-so it must have to do with the quantity of air being pushed around/vibrated.

Howard,

Great to hear that you built this! Please post some photos! Your question about quality of bass and its ability to rattle things: the simulation says that when you corner load this like you said you would, there is a +9dB boost compared to free space which is what you sort of have on a bench. SPL is SPL, and 103 dB at 1 watt at 40 Hz is a lot of sound energy for 1 watt. The comparison is how many watts does it take for your big woofer cone to get 103 dB at 40 Hz? I bet more than 1 watt. If the Fostex FE166EN excursion was not limiting, you could get even more - for example the case with the Alpair 10.3 - you could put 4 to 8 watts and I think it might shake things in the room too.

Great to hear that you built this! Please post some photos! Your question about quality of bass and its ability to rattle things: the simulation says that when you corner load this like you said you would, there is a +9dB boost compared to free space which is what you sort of have on a bench. SPL is SPL, and 103 dB at 1 watt at 40 Hz is a lot of sound energy for 1 watt. The comparison is how many watts does it take for your big woofer cone to get 103 dB at 40 Hz? I bet more than 1 watt. If the Fostex FE166EN excursion was not limiting, you could get even more - for example the case with the Alpair 10.3 - you could put 4 to 8 watts and I think it might shake things in the room too.

Howard,

Great to hear that you built this! Please post some photos! ...

I second that !

The speaker that I just built is the left channel, and will install horizontally in the wall above a set of wardrobe cabinets (that, strangely enough, will also extend into the wall cavity-to save room space) . The right channel will be in the wall vertically, like I suppose that most in the wall horns would end up being(this one going behind a bookshelf, up to 68” from the floor, like the wardrobes). A lot of design time has been consumed just getting the two driver/mouth combinations to look the same from the room, and to interact with their horns similarly enough. When I figure out how to scan in drawings, I will show all this for those who are interested.

I wonder what the truth is about making 180 degree turns near the comp chamber? Some think that it is too tight, while the Horneshop horns had a couple of tight bends there, apparently to help filter out higher frequencies from the horn.

One other thing that I wonder about is the effect of a rapidly expanding horn mouth at the end of otherwise gentle expansion? I kinda tried that here, sort of, and it didn't seem to work. Seems like if the horn expands all of a sudden that it would not load the driver much. Maybe the big expansion rates at the mouth of some small horns act like wave guides, but don't really acoustically couple/ load, the whole column of air in the horn so well.

I wonder what the truth is about making 180 degree turns near the comp chamber? Some think that it is too tight, while the Horneshop horns had a couple of tight bends there, apparently to help filter out higher frequencies from the horn.

One other thing that I wonder about is the effect of a rapidly expanding horn mouth at the end of otherwise gentle expansion? I kinda tried that here, sort of, and it didn't seem to work. Seems like if the horn expands all of a sudden that it would not load the driver much. Maybe the big expansion rates at the mouth of some small horns act like wave guides, but don't really acoustically couple/ load, the whole column of air in the horn so well.

I do need to remember how to post photos----find the cord for my camera, how to get them attached to my post. You can see that I am better at making sawdust and wood things than at "technology". A hammer is technology, but I am not sure that the current lexicon acknowledges that! I am trying to get better at electronics too, but it is a slow uphill battle for me.

I screwed the horn together and sat it upright on the bench. The sound is much tighter. Without getting out my R.Shack meter to measure spl, I played pink noise 1/3 octave(?) test bands and listened. There is audible response in the 20-30hz region. There is a hump around 40 hz and another around 100-125hz. There is annoying resonance somewhere around 100 hz that I think could be tamed somewhat by bracing.

The 30 hz or so (must be a 5-string) electric bass notes on Lyle Lovett's “Road to Ensenada”(the song, specifically, rather than the whole album) come through with a sweet, sublime ease, though I suppose it must be down a few/several db.

The 30 hz or so (must be a 5-string) electric bass notes on Lyle Lovett's “Road to Ensenada”(the song, specifically, rather than the whole album) come through with a sweet, sublime ease, though I suppose it must be down a few/several db.

In-Wall MLTL as Alternative to BLH

Using the constraint of 16 inch spacing between 2x4 studs in standard drywall interiors, I designed the following speaker that can be installed during the installation of framing, before drywall goes on. A 2x4 is really 1.75 in x 3.5 in. Thus the natural cavity in between walls in the US are 3.5 in deep x 14.25 in wide (internally). I decided to go with a TB W5-1611SAF as it has a moderate Qts that will allow deeper bass extension for a MLTL, and it has a nice smooth response with just enough sensitivity to match the bass from a MLTL port.

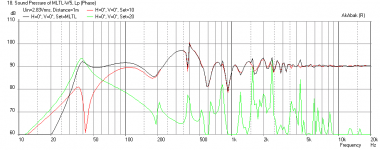

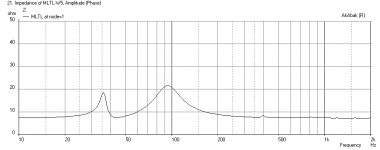

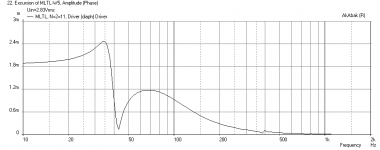

I actually used the Accidental MLTL technique to size the speaker prior to tweaking it in AkAbak. The AMLTL method assuming a length of 40 inches gave me a vent dia of 2 in x 3 in long. The driver will be mounted at 17 in from the closed end and the port will be 6 inches from the "bottom". In this case, I will flip the speaker upside down and put the port near the ceiling and the driver at about 32 in from the top of the ceiling. The following are the results of the simulation and they look pretty good: 40 Hz bass extension and 90 dB sensitivity. The impedance is pretty smooth and the cone excursion is well controlled.

So, if you are remodeling a room and have exposed joists/beams, tack some cross bars to make a cavity and seal with silicone. Silicone the drywall panels when they are installed for an airtight cavity that you prewire and stuff some polyfill or fiberglass in the top 2/3rds of the line. After drywall is done, cut out the driver hole and vent hole. Install drivers and enjoy! It will sound better than any store-bought ceiling or wall speaker.

Using the constraint of 16 inch spacing between 2x4 studs in standard drywall interiors, I designed the following speaker that can be installed during the installation of framing, before drywall goes on. A 2x4 is really 1.75 in x 3.5 in. Thus the natural cavity in between walls in the US are 3.5 in deep x 14.25 in wide (internally). I decided to go with a TB W5-1611SAF as it has a moderate Qts that will allow deeper bass extension for a MLTL, and it has a nice smooth response with just enough sensitivity to match the bass from a MLTL port.

I actually used the Accidental MLTL technique to size the speaker prior to tweaking it in AkAbak. The AMLTL method assuming a length of 40 inches gave me a vent dia of 2 in x 3 in long. The driver will be mounted at 17 in from the closed end and the port will be 6 inches from the "bottom". In this case, I will flip the speaker upside down and put the port near the ceiling and the driver at about 32 in from the top of the ceiling. The following are the results of the simulation and they look pretty good: 40 Hz bass extension and 90 dB sensitivity. The impedance is pretty smooth and the cone excursion is well controlled.

So, if you are remodeling a room and have exposed joists/beams, tack some cross bars to make a cavity and seal with silicone. Silicone the drywall panels when they are installed for an airtight cavity that you prewire and stuff some polyfill or fiberglass in the top 2/3rds of the line. After drywall is done, cut out the driver hole and vent hole. Install drivers and enjoy! It will sound better than any store-bought ceiling or wall speaker.

Attachments

Hi GM,

What's a BIB?

xrk971:

That sounds like a great idea for a great sounding solution that does not involve all of the tweaking that can be involved with a horn. Naturally it would be great if someone would build a MLTL like you have designed and test it, then others could go ahead with confidence with the easy stud-bay enclosures. I like where this is all going!

My horn, in it's present incarnation nets 5" overall depth, so it would fit in a 2x6 stud bay, in the form of a wood cabinet inside of the drywall inner surfaces. My present actual application is less standard, as both sides of the wall will be sheathed/furred out with 3/4" plywood, prior to finish surface(drywall and wood panels)application. This is the thickness of the plywood front and back of the horn.

What's a BIB?

xrk971:

That sounds like a great idea for a great sounding solution that does not involve all of the tweaking that can be involved with a horn. Naturally it would be great if someone would build a MLTL like you have designed and test it, then others could go ahead with confidence with the easy stud-bay enclosures. I like where this is all going!

My horn, in it's present incarnation nets 5" overall depth, so it would fit in a 2x6 stud bay, in the form of a wood cabinet inside of the drywall inner surfaces. My present actual application is less standard, as both sides of the wall will be sheathed/furred out with 3/4" plywood, prior to finish surface(drywall and wood panels)application. This is the thickness of the plywood front and back of the horn.

I just tried to upload the pictures of the horn project. I got this message:

Your submission could not be processed because a security token was missing.

If this occurred unexpectedly, please inform the administrator and describe the action you performed before you received this error.

Anyone know what to do about it?

Your submission could not be processed because a security token was missing.

If this occurred unexpectedly, please inform the administrator and describe the action you performed before you received this error.

Anyone know what to do about it?

photos of IN WALL BLH

Yeah!(had to upload one at a time)

The photos are blurry in the post preview. I will post it and see if they look any better. They were clear on the camera, and in my computer.

This is the one that will be installed close the ceiling and will lay horizontally like it is shown in the pictures. Notice that there are blocks in the (oversized) mouth to make it effectively smaller for testing.

Yeah!(had to upload one at a time)

The photos are blurry in the post preview. I will post it and see if they look any better. They were clear on the camera, and in my computer.

This is the one that will be installed close the ceiling and will lay horizontally like it is shown in the pictures. Notice that there are blocks in the (oversized) mouth to make it effectively smaller for testing.

thanks for the kudos!

Is .21 a proportional measure, or one using specific units? Sounds like the BIB is kind of like a Voight pipe, with different proportions.

I think that the vertically oriented cabinet design will end up being more rectilinear inside, on this one it just seemed to work out nicely to curve it this way. For those with more basic woodworking skills/tools, installing a series of smaller pieces should work just fine to form a (bumpy) curve. Not too many folks will have a need for a horizontally oriented cabinet though.

Unless you have good hand skills with a skill-saw(American slang for portable circular saw), you need a radial arm saw, or a sliding miter saw to kerf plywood like that. Shorter pieces can be managed on a table(bench) saw.

Is .21 a proportional measure, or one using specific units? Sounds like the BIB is kind of like a Voight pipe, with different proportions.

I think that the vertically oriented cabinet design will end up being more rectilinear inside, on this one it just seemed to work out nicely to curve it this way. For those with more basic woodworking skills/tools, installing a series of smaller pieces should work just fine to form a (bumpy) curve. Not too many folks will have a need for a horizontally oriented cabinet though.

Unless you have good hand skills with a skill-saw(American slang for portable circular saw), you need a radial arm saw, or a sliding miter saw to kerf plywood like that. Shorter pieces can be managed on a table(bench) saw.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- In-the-Wall Back Loaded Horns