GM said:Huh! Just used the direct link to download V17 that I wasn't aware of, so thanks for the update!

GM

Hi GM,

No problems

Kind regards,

David

gedlee said:I tried to run it but it fails with "Illegal function call." Nothing that I did seemed to remove this error.

Hi everyone,

I was wondering if users other than Earl were also seeing the "Illegal function call" error message when attempting to calculate results for the Hornresp default record, while using the most recent release of the program (Model Number 1700-080106).

If you are, then I would very much appreciate an email to dmcbean@bigpond.com providing me with the details of the processor type and operating system that you are using, and any other information that you think might be relevant.

In the interests of continuous improvement, I would like to try to identify the cause of the error, and to remove it if at all possible.

Many thanks.

Kind regards,

David

I use an HP built computer with an Athalon 64(Dual) running Win XP SP2.

I suspect that the fact that I have VB 6.0 loaded is supicious since I noticed that you use VB 3. This is an outdated and obsolete version and is highly likely to cause trouble running along side VB 6.

I suspect that the fact that I have VB 6.0 loaded is supicious since I noticed that you use VB 3. This is an outdated and obsolete version and is highly likely to cause trouble running along side VB 6.

Hi Earl

10% efficiency max?

Now granted I am not talking about a home sized horn woofer but I would ask you to consider a measurement of a couple of my Tapped horns.

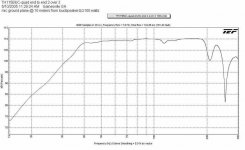

The image below is for four TH-115 woofers in a two by two stack, measured outdoors in half space at 10 meters (-20dB from 1 meter) , with the four boxes in series parallel, driven at 28Vrms for 100 Watts into the nominal impedance (+20dB over 1 Watt).

The result is a conservative 1 Watt 1 Meter equivalent.

While the frontal area of four (80in wide, 45in tall) may be enough to cause some rise on axis from directivity, it is not large enough to do that at say 40Hz where the sensitivity is still over 108dB.

Here are links to the 115 and a couple others, granted none are conventionally loaded horns but they are still horns.

TH-115

http://www.danleysoundlabs.com/pdf/Danley TH-115 Spec Sheet_r2.pdf

TH-mini (one is over 102dB 1W 1M and its tiny)

http://www.danleysoundlabs.com/pdf/Danley TH Mini Spec Sheet_r2.pdf

TH-50 goes down low but with less efficiency.

http://www.danleysoundlabs.com/pdf/Danley TH-50 Spec Sheet r1.pdf

Best,

Tom Danley

10% efficiency max?

Now granted I am not talking about a home sized horn woofer but I would ask you to consider a measurement of a couple of my Tapped horns.

The image below is for four TH-115 woofers in a two by two stack, measured outdoors in half space at 10 meters (-20dB from 1 meter) , with the four boxes in series parallel, driven at 28Vrms for 100 Watts into the nominal impedance (+20dB over 1 Watt).

The result is a conservative 1 Watt 1 Meter equivalent.

While the frontal area of four (80in wide, 45in tall) may be enough to cause some rise on axis from directivity, it is not large enough to do that at say 40Hz where the sensitivity is still over 108dB.

Here are links to the 115 and a couple others, granted none are conventionally loaded horns but they are still horns.

TH-115

http://www.danleysoundlabs.com/pdf/Danley TH-115 Spec Sheet_r2.pdf

TH-mini (one is over 102dB 1W 1M and its tiny)

http://www.danleysoundlabs.com/pdf/Danley TH Mini Spec Sheet_r2.pdf

TH-50 goes down low but with less efficiency.

http://www.danleysoundlabs.com/pdf/Danley TH-50 Spec Sheet r1.pdf

Best,

Tom Danley

Attachments

Tom

It all sounds like a numbers game to me and I don't have the time right now (or the interest) to go through the exact calculations.

The input "watts" that you quote is an approximation, and 1 Watt at 1 meter does make any sense to me since the power radiated should be independent of distance (unles that is what you mean). In which case it looks like you have "roughly" 10% efficiency - just about what I was saying. There is no way that someone is going to get to the 70% mark that was being quoted.

The lack of interest comes from my disinterest in these power numbers games as they aren't real important. What is important is the Max SPL capability because I really don't care how many "watts" it takes only that I CAN get this SPL without the system "loosing it". Admittedly this is not something easy to specify, but to me its the only thing that really counts. Voltage sensitivity is useful number, but not "watts" or efficiency.

It all sounds like a numbers game to me and I don't have the time right now (or the interest) to go through the exact calculations.

The input "watts" that you quote is an approximation, and 1 Watt at 1 meter does make any sense to me since the power radiated should be independent of distance (unles that is what you mean). In which case it looks like you have "roughly" 10% efficiency - just about what I was saying. There is no way that someone is going to get to the 70% mark that was being quoted.

The lack of interest comes from my disinterest in these power numbers games as they aren't real important. What is important is the Max SPL capability because I really don't care how many "watts" it takes only that I CAN get this SPL without the system "loosing it". Admittedly this is not something easy to specify, but to me its the only thing that really counts. Voltage sensitivity is useful number, but not "watts" or efficiency.

Hi Earl

We measure larger subwoofers at 10 meters as the size of the system distorts / occupies some of the space at one meter, doing it at 10 meters and correcting for power more closely reflects the “1W1M” figure used to estimate the SPL at a different distance and/or power.

In this case, the nominal impedance is based on the 8 Ohm drivers, in band the impedance is actually higher than an 8 Ohm load.

That series parallel load was driven at 28Vrms to produce the measurement. In this case, using a nominal 100W drive level automatically compensates the 10 meter mic distance.

If one took these four drivers (15tbx100) and put them in the right vented boxes, close coupled, the 1w 1m sensitivity would be about 6 dB greater than one driver (96dB) or about 102 dB instead of 108 to 110dB mounted in the that particular Tapped horn.

From a source that has little or no directivity, 108dB to 110dB 1W sensitivity is pretty high.

If one defines “efficiency” as the difference between I^Rdc losses to radiated power, then yes 70% is very hard and not possible over any significant bandwidth.

What SPL would you expect to measure in half space at say one Meter while radiating one acoustic Watt from an omni source?

Best,

Tom

We measure larger subwoofers at 10 meters as the size of the system distorts / occupies some of the space at one meter, doing it at 10 meters and correcting for power more closely reflects the “1W1M” figure used to estimate the SPL at a different distance and/or power.

In this case, the nominal impedance is based on the 8 Ohm drivers, in band the impedance is actually higher than an 8 Ohm load.

That series parallel load was driven at 28Vrms to produce the measurement. In this case, using a nominal 100W drive level automatically compensates the 10 meter mic distance.

If one took these four drivers (15tbx100) and put them in the right vented boxes, close coupled, the 1w 1m sensitivity would be about 6 dB greater than one driver (96dB) or about 102 dB instead of 108 to 110dB mounted in the that particular Tapped horn.

From a source that has little or no directivity, 108dB to 110dB 1W sensitivity is pretty high.

If one defines “efficiency” as the difference between I^Rdc losses to radiated power, then yes 70% is very hard and not possible over any significant bandwidth.

What SPL would you expect to measure in half space at say one Meter while radiating one acoustic Watt from an omni source?

Best,

Tom

Tom Danley said:What SPL would you expect to measure in half space at say one Meter while radiating one acoustic Watt from an omni source?

Tom

I'll say it again, I don't deal in "watts", so I don't know the answer and I am not going to calculate it.

I would look for about 96-98 dB per volt at one meter. You can "guess" the watts from V^2/ 8 ohms (would not be correct of course).

gedlee said:I use an HP built computer with an Athalon 64(Dual) running Win XP SP2.

I suspect that the fact that I have VB 6.0 loaded is supicious since I noticed that you use VB 3. This is an outdated and obsolete version and is highly likely to cause trouble running along side VB 6.

Hi Earl,

Thanks for confirming that you have an Advanced Micro Devices Athlon processor. Unfortunately, this means that you are out of luck as far as running Hornresp on your existing computer is concerned. Perhaps you could borrow a machine with an Intel processor, temporarily?

Just to put your mind at rest, Hornresp normally runs quite happily alongside VB6 - I have VB6 installed on my computer also, along with VB3. Hornresp.exe simply goes looking for the Vbrun300.dll application extension file, which it finds immediately, because it is located in the same folder as the application itself. The reason that I have not bothered to release a 32-bit VB6 version of Hornresp at this stage is because the VB6 compiled executable file is about three times larger (as I recall) and runs no faster or any better than the VB3 version. The conversion of the Hornresp source code from VB3 to VB6 is actually very easy to do.

Thanks again for confirming your processor and operating system types. Sorry that you have run into problems using Hornresp.

Kind regards,

David

Efficiency - in numbers - is not something that I deal with regularly, but your numbers seem highly suspect to me. It would be very very difficult for the acoustic impedance to be greater than the electrical impedance. Your numbers seem to be based on HornResp calculations and I'm not sure where those come from. The only definition of efficiency that I know of is the nominal, which cannot exceed 50% as I said. I don't know what "true" efficiency is.

Doing the math, following Keeles paper cited earlier, gives the nominal efficiency of 45% for my example bass horn. (Disregarding Rms losses, since Qms for the driver is 10, which is high enough for this to be permissible).

I am fully aware of that nominal efficiency cannot exceed 50%.

True efficiency, which to me seems like a better description of reality than nominal efficiency (which may be useful for comparing numbers), since it directly describe the conversion efficiency of the system, is simply defined as

(Acoustical power output)/(Electrical power input)*100%.

Doing the math, again following Keele, for the true efficiency, this comes out as 65%. That it can be higher at some frequencies, is due to ripple in the throat impedance.

When you say "It would be very very difficult for the acoustic impedance to be greater than the electrical impedance" I assume you mean "reflected acoustic impedance", since the units of the two are quite different. But in this case, the reflected acoustic resistance (asymptotical value, rho*c/St) is nearly twice the DC resistance of the driver. Since the horn used is a Salmon hyperbolic horn (T=0.65), the value is larger than 50% of its asymptotical value down to ~50Hz, allowing high efficiency in a very large part of its operating range. (True efficiency at 50Hz is about 73%, while for a conical horn with the same length and throat and mouth areas, it is 1.22%).

To calculate reflected acoustic resistance, Rae, we need to know Re and Bl, which are 5.5ohms and 25.4Tm respectively. Rae, for Sd=0.038m^2 and St=0.0095m^2 as used, gives

Rae = St*(Bl)^2/(Sd^2*rho*c) = 0.0095*(25.4)^2/(0.038^2*1.205*344) = 10.24 electrical ohms.

This is however only possible with high-Bl drivers. Going backwards, for Bl < 18.6Tm, Rae < Re.

Compression drivers usually do not achieve Bl in this range, due to the small voice coil and practical B limits. Also compression driver efficiency drops significantly above the mass rolloff corner frequency.

Since both the analysis above and also Hornresp are based on classical and well known analysis of the electro-acoustical equivalent circuit of the system, I do not feel that the numbers are suspect.

If what you say were true then compression drivers would not even get warm, but the fact is that they melt down regularly.

Compression drivers can usually not achieve efficiencies like this. Also, they are usually crossed not much more than an octave below its mass corner frequency. In most of the working range then, nominal efficiency, which is based on the resistive impedances of the system, gives an inaccurate picture, and true efficiency would give a better idea. For pop and rock music (cymbals, distorted guitars etc) the power content in this range is quite high. Amplifier clipping also plays a part in feeding the driver with high frequency power.

Best regards,

B

If one defines “efficiency” as the difference between I^Rdc losses to radiated power, then yes 70% is very hard and not possible over any significant bandwidth.

Excuse my confusion, but do you here define efficiency as

(Ploss / Pradiated)*100%? I must be missing something.

Things gets confusing when we don't have a common definition. In a hope of clearing up things, I have calculated the values for the system for both nominal and true (conversion) efficiency above.

The Beyma 102Nd driver used in the example has very high efficiency-bandwidth product, with fs=53Hz and Qes=0.09. Things are of course different with less efficient drivers, my point was to show that it was possible to achieve the stated conversion efficiency.

Regarding my first reference to 70% conversion efficiency, this comes from "Loud Speakers and Michrophones" by E.C. Wente and A.L. Thuras, Bell System Technical Journal, April 1934. The efficiency was first calculated from the parameters of the driver and the horn, later measured. Note that in this article, efficiency is conversion efficiency, not nominal efficiency.

I think conversion efficiency is what is normally used in other energy conversion systems. Please correct me if I'm wrong.

At least, this discussion shows the need for stating what efficiency is used.

Best regards,

B

David McBean said:Thanks for confirming that you have an Advanced Micro Devices Athlon processor. Unfortunately, this means that you are out of luck as far as running Hornresp on your existing computer is concerned. Perhaps you could borrow a machine with an Intel processor, temporarily?

I have five computers and two laptops - not one of them uses Intel. This explaination does not make sense to me either since SPEAK is written in VB (version 3 through 6) and it never had a problem that was CPU dependent. And its not like AMD is some abscure hardware - all HP computers use AMD. I now only use HP computers because of the performance and reliability that I have seen over the years.

Kolbrek said:True efficiency at 50Hz is about 73%, while for a conical horn with the same length and throat and mouth areas, it is 1.22%.

As I have stated, this detailed discussion of power and efficiency is not of much interest to me, at least not enough to sort out the details. But the above statement is once again quite suspect. This huge difference between the horns is not at all consistant with my experience and seems to be based on a ficticious theoretical loading achieved for an infinite "Webster" horn and not on realistic systems and data.

Tom's numbers seemed far more reasonable to me and those appear to be actual measured data.

Hi kolbrek,Kolbrek said:Doing the math, again following Keele, for the true efficiency, this comes out as 65%.

the simulations on the horn I originally asked about bring to me to a max SPL at 1m of 133 dB which is what I am roughly interested in - seeing whether the speaker can keep up with the rest of the system, ghost talk like 65% does not mean anything to me in the real situation - PA.

Cheers Dan

Kolbrek said:The Beyma 102Nd driver used in the example has very high efficiency-bandwidth product, with fs=53Hz and Qes=0.09. Things are of course different with less efficient drivers, my point was to show that it was possible to achieve the stated conversion efficiency.

this Beyma felt very sensitive, nonetheless the high sensitivity is only valid in the band of 600-2k so your predicted picture from hornresp seems pretty suspicious, it is just a 10 inch and I doubt its capability to move large volumes of air necessary to reproduce low frequencies.

This huge difference between the horns is not at all consistant with my experience and seems to be based on a ficticious theoretical loading achieved for an infinite "Webster" horn and not on realistic systems and data.

The difference is huge at some frequencies, not at others. At 75Hz, the conversion efficiency is 49% for the conical horn and 55% for the hyperbolic horn. This corresponds to a peak in the throat impedance for the conical horn. At 50Hz there is a dip, giving the low efficiency at that frequency.

This is not the performance for inifinite horns. The simulation in Hornresp is admittedly 1P, but we are talking long wavelengths here, and the difference from actual performance should not be too different from reality. Many users can confirm that the Hornresp model is quite accurate when modelling bass horns, myself included.

The difference between different horn contours depends on many things. Short horns with large Sm/St (mouth area to throat area) ratio or long horns with small Sm/St ratio will show less differences than, say, a long horn with large Sm/St ratio, as is the case here. The horn is 3.8m long, Sm = 4.26m^2 and St = 0.0095cm^2. Reducing Sm to 0.5m^2 also reduces the differences.

The differences very much on the driver. As an example, by reducing Bl to 5, differences above 70Hz are quite small.

Regards,

B

Attachments

ghost talk like 65% does not mean anything to me in the real situation - PA.

65% conversion efficiency simply means that when you put 1W in you get 0.65 acoustic watts out. (This is not 2.83Vrms, you must use the voltage that produces 1W in the speaker at that particular frequency). The rest is left for heating the voice coil and other losses in the driver.

My calculations were not aimed at your particular project, but rather to show that high efficiency is possible with the right driver.

Regards,

B

Kolbrek said:Many users can confirm that the Hornresp model is quite accurate when modelling bass horns, myself included.

Once again, a reality check says "something wrong!". Never have I seen a real horn system with as good a response as you have shown - unles EQ'd with a complex filter set (as in Tom Danley's plots).

Unfortunately, I can't confirm HornResp calculations and apparantly never will be able to.

this Beyma felt very sensitive, nonetheless the high sensitivity is only valid in the band of 600-2k so your predicted picture from hornresp seems pretty suspicious

There is a quite big difference between horns and direct radiators. For a 10" driver in an infinite baffle (reference conditions) the resistive air load is rising to significant values at around 600Hz. Thus the efficiency rises here, and is high up to the point where the diaphragm mass reduces it again.

For a horn, the load is high from a bit over the flare frequency and upwards. One of the reasons for the high efficiency of horn systems is the ability to present the driver with a high value of resistive load impedance. This load can be as high (Compression ratio 1:1) or higher than the load present to a direct radiator in the mid frequency range.

it is just a 10 inch and I doubt its capability to move large volumes of air necessary to reproduce low frequencies.

That was not my concern when giving this example. It can't play extremely loud, but it can reproduce low frequencies. Xmax is only 2mm. Horn systems also need volume displacement.

Regards,

B

Once again, a reality check says "something wrong!"

Hornresp aside, calculating a reference value for nominal efficiency and conversion efficiency is easy from the given driver parameters and compression ratio. I have just used an efficient driver and accepted techniques for efficiency calculations. The nominal efficiency comes out at 45%, less than the 50% max.

Remember that efficiency rises with Bl squared, and this is a very high Bl driver.

Never have I seen a real horn system with as good a response as you have shown - unles EQ'd with a complex filter set (as in Tom Danley's plots).

And I don't think you have seen a straight horn system with a highly efficient 10" driver and a 4.3m^2 mouth either

The simulated response is the power response. It does not include boundary effects, diffraction, directivity, problems arising from bends etc. As far as I know the method of calculating the response is quite similar to your own compression driver simulations, apart from directivity.

Conclusion: I have presented efficiency figures that refuses to fall below the expected 10%, using both simulation software and direct efficiency calculations from driver parameters. Please show any error in my math, and I will stand corrected.

Regards,

B

Originally posted by gedlee:

"Once again, a reality check says "something wrong!". Never have I seen a real horn system with as good a response as you have shown "

Hello,

Give a look to:

http://www.azurahorn.com/6681_on_160.pdf

Best regards from Paris,

Jean-Michel Le Cléac'h

"Once again, a reality check says "something wrong!". Never have I seen a real horn system with as good a response as you have shown "

Hello,

Give a look to:

http://www.azurahorn.com/6681_on_160.pdf

Best regards from Paris,

Jean-Michel Le Cléac'h

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Horn Design - Sanity Check