loninappleton said:what is the suggested treatment for the CC (compression chamber)?

Clarified butter... oops that's the xmas baking. Treat the air cavity (after confusion over the term CC we are going back to Olson) as tou would a bass reflex box.

dave

From previous builds and experiments and considering the small size a treatment of the back wall to get rid of any reflections might be all that's needed.

I usually start with nothing in there to see what happens.

I remember GM mentioning the rear wall when I had the venerable 127 in a little box that I had from some desk size speakers from Nakamichi.

I think I'm going to have to play Giapetto and do some final smoothing of the wave guide. (No glue has been applied to these areas yet.)

One of those surforms would take too big a bite. I'm looking for a cheap half round file.

I usually start with nothing in there to see what happens.

I remember GM mentioning the rear wall when I had the venerable 127 in a little box that I had from some desk size speakers from Nakamichi.

I think I'm going to have to play Giapetto and do some final smoothing of the wave guide. (No glue has been applied to these areas yet.)

One of those surforms would take too big a bite. I'm looking for a cheap half round file.

'Got game

Jeez, I was down to the third page and no one talking about the Harveys-- or FrankenHarvey in my case.

I suppose every little slip seems to make the builder think that the result will look like something made by Frank Gehrey.

'Had a little glue slippage and I'm just a bit off the center line. But the glue is committed. Slippage happened during putting on long cauls and clamps to get even pressure.

I have done this much:

Glued up all sides and br chamber save for the opposite long panel.

For testing I'm going to dry fit the last side and for seal, using some 1/4 foam door seal. Then sandwich the seal with clamps and give it a whirl.

I've got game.

Over on the fonken thread they were mentioning that if the driver FE127 is surface mounted then the front baffle should have a

treatment to make it flush. I could've rabbeted a round driver but haven't got the tools to make a square recess cut.

How important is this on the Harvey?

Also made up some fine wire connecters for my Yamaha RP U100

SS amp. The fine wire (CAT5 tweak) seems to be working well on my other sample builds.

No interior treatment settled on yet.

Jeez, I was down to the third page and no one talking about the Harveys-- or FrankenHarvey in my case.

I suppose every little slip seems to make the builder think that the result will look like something made by Frank Gehrey.

'Had a little glue slippage and I'm just a bit off the center line. But the glue is committed. Slippage happened during putting on long cauls and clamps to get even pressure.

I have done this much:

Glued up all sides and br chamber save for the opposite long panel.

For testing I'm going to dry fit the last side and for seal, using some 1/4 foam door seal. Then sandwich the seal with clamps and give it a whirl.

I've got game.

Over on the fonken thread they were mentioning that if the driver FE127 is surface mounted then the front baffle should have a

treatment to make it flush. I could've rabbeted a round driver but haven't got the tools to make a square recess cut.

How important is this on the Harvey?

Also made up some fine wire connecters for my Yamaha RP U100

SS amp. The fine wire (CAT5 tweak) seems to be working well on my other sample builds.

No interior treatment settled on yet.

Harvey for Christmas

Ready for some test tones on the FrankenHarvey.

It's dry clamped with the 1/4 foam insulation I mentioned. It compressed well and removes easily-- I tested it first.

Nothing in the BR section for stuffing. I wanted to try it bare.

I sampled it with some FM broadcast on my Yamaha SS receiver. First impression is I'm wondering if the bass is overpowering everything and if there's a lot of leakage. Leakage with a setup like this is a probability but how's to check it?

The 1/4 drill trick worked fine: it released from the bottom secured joint.

Also with all this setup it was good to have wax paper under the work during glue up of the BR. The paper released fine.

My problem is handling the piece alone. From a shoulder height work surface it was a wrestling match to get it down to the floor (with all the clamps on) to a little creeper I made to position the piece.

Ready for some test tones on the FrankenHarvey.

It's dry clamped with the 1/4 foam insulation I mentioned. It compressed well and removes easily-- I tested it first.

Nothing in the BR section for stuffing. I wanted to try it bare.

I sampled it with some FM broadcast on my Yamaha SS receiver. First impression is I'm wondering if the bass is overpowering everything and if there's a lot of leakage. Leakage with a setup like this is a probability but how's to check it?

The 1/4 drill trick worked fine: it released from the bottom secured joint.

Also with all this setup it was good to have wax paper under the work during glue up of the BR. The paper released fine.

My problem is handling the piece alone. From a shoulder height work surface it was a wrestling match to get it down to the floor (with all the clamps on) to a little creeper I made to position the piece.

Where is the Little Dutch Boy?

Definitely leakage on this one from whatever source.

I can hear just about everything coming out of the throat portion of the build.

Correcting for this might be some BR interior treatment. While it's set up I'll try a bit of seat of the pants stuffing but I think the problem is elsewhere.

I'm using the BIB for FE127e as the a/b test. The difference is very audible.

For glue up, I'm going add the throat braces. Dry clamping can

flex the wood even when it might not be obvious that the throat is being warped out of shape.

Any advices on this?

(Sorry, Wisconsin, US colloquialism.)

Definitely leakage on this one from whatever source.

I can hear just about everything coming out of the throat portion of the build.

Correcting for this might be some BR interior treatment. While it's set up I'll try a bit of seat of the pants stuffing but I think the problem is elsewhere.

I'm using the BIB for FE127e as the a/b test. The difference is very audible.

For glue up, I'm going add the throat braces. Dry clamping can

flex the wood even when it might not be obvious that the throat is being warped out of shape.

Any advices on this?

(Sorry, Wisconsin, US colloquialism.)

The Twll-Tale Foam

Upon disassembly of the FrankenHarvey (Now back on the operating table) I noticed that the foam insulation used to get a seal was more compressed at some parts than others.

This makes me the goat, so okay.

Next round of tests will be on a fully glued box.

In the mean time I reinstalled my GM MLTL-- still one of the best designs (BIB included) for natural voice and instrumentation.

But every now and again I want to participate more in the group. That means building.

I would like to see some interior treatments that have worked for other builders. Most I've done inside was a light layer of pillow stuffing.

From previous posts, the goal here is to get the lower frequencies to stay in the mouth of the BVH and get rid of the frequency leakage out the throat(s).

Upon disassembly of the FrankenHarvey (Now back on the operating table) I noticed that the foam insulation used to get a seal was more compressed at some parts than others.

This makes me the goat, so okay.

Next round of tests will be on a fully glued box.

In the mean time I reinstalled my GM MLTL-- still one of the best designs (BIB included) for natural voice and instrumentation.

But every now and again I want to participate more in the group. That means building.

I would like to see some interior treatments that have worked for other builders. Most I've done inside was a light layer of pillow stuffing.

From previous posts, the goal here is to get the lower frequencies to stay in the mouth of the BVH and get rid of the frequency leakage out the throat(s).

getting ready for glue up

I decided to do another test before gluing the final side on the FrankenHarvey.

I took the advice given for the Sachiko )I think) wherein the BR portion is fully treated with damping on sides front and back.

I had no sweaters to chew up so I got some 10 lb. batting from the fabric store. They now think I am Suzy Homemaker big time since I've been shopping for fabric for grilles as well.

The batting is dence and the requested half inch thick.

I'm doing the following interim step now.

Since the only difference between BVR and BR palin vanilla is the

back vent, I'm doing a teporary test of just the BR. This is the equivalent of any small bookshelf speaker made with a piece of scrap, the shaped piece of batting stuck to it with double stick tape and gasketed and clamped.

Before doing this I had a small reversal with the building the boat in the basement dilemma but I got past that to set up in my listening area.

Initial impression of the new and improved damped version is positive. Since the enclosure is small, the sound is a bit high strung, but better that than hearing a flute sounding like it's being played by Orpheus in the Underworld.

I still don't know what the final assembly will produce.

Any advice on treating the mouth area at this time would help.

My idea is that treating the mouth would be done with the billiard felt I have to work into the tight corners.

Response from all BVR builders appreciated since I appear to be the only on this thread.

BTW a search for the thread using search did not do a whole lot. I had to page through a number of days to find it.

I decided to do another test before gluing the final side on the FrankenHarvey.

I took the advice given for the Sachiko )I think) wherein the BR portion is fully treated with damping on sides front and back.

I had no sweaters to chew up so I got some 10 lb. batting from the fabric store. They now think I am Suzy Homemaker big time since I've been shopping for fabric for grilles as well.

The batting is dence and the requested half inch thick.

I'm doing the following interim step now.

Since the only difference between BVR and BR palin vanilla is the

back vent, I'm doing a teporary test of just the BR. This is the equivalent of any small bookshelf speaker made with a piece of scrap, the shaped piece of batting stuck to it with double stick tape and gasketed and clamped.

Before doing this I had a small reversal with the building the boat in the basement dilemma but I got past that to set up in my listening area.

Initial impression of the new and improved damped version is positive. Since the enclosure is small, the sound is a bit high strung, but better that than hearing a flute sounding like it's being played by Orpheus in the Underworld.

I still don't know what the final assembly will produce.

Any advice on treating the mouth area at this time would help.

My idea is that treating the mouth would be done with the billiard felt I have to work into the tight corners.

Response from all BVR builders appreciated since I appear to be the only on this thread.

BTW a search for the thread using search did not do a whole lot. I had to page through a number of days to find it.

Scottmoose said:The felt in the mouths of the waveguides will take out any remaining HF -it won't bother the LF of course -the wavelengths are too long. I didn't bother with my prototypes, though that was a couple of years back now.

Well that's good because it would be a PITA to do at any stage of construction.

I think I'm just about set to button this one up (making one not two--

I only made 2 of the GM MLTL.)

Not quite buttoned up yet.

I spent some time testing BIB vs FrankenHarvey this afternoon:

test tones, classical, jazz, some solo instrumentation.

The BIB running FE127e seemed louder than the Harvey-- more full in overall production.

Can the BR be adjusted to put more energy out the vent? I know initially I thought there was too much. Now I'm trying to refine the effect.

All interior surfaces are covered with 10 lb. pillow/quilt batting.

With all sides covered on the inside, could I remove the stuffing from one side? Or 2 opposite sides. The front/rear has a specially cut piece with cut out for speaker in front and vent in the rear. So could I take out one or 2 of the remaining 2 panels?

Or what other actions do you suggest? I feel that I am getting closer to a good build now.

I spent some time testing BIB vs FrankenHarvey this afternoon:

test tones, classical, jazz, some solo instrumentation.

The BIB running FE127e seemed louder than the Harvey-- more full in overall production.

Can the BR be adjusted to put more energy out the vent? I know initially I thought there was too much. Now I'm trying to refine the effect.

All interior surfaces are covered with 10 lb. pillow/quilt batting.

With all sides covered on the inside, could I remove the stuffing from one side? Or 2 opposite sides. The front/rear has a specially cut piece with cut out for speaker in front and vent in the rear. So could I take out one or 2 of the remaining 2 panels?

Or what other actions do you suggest? I feel that I am getting closer to a good build now.

Reduce, or eliminate standing waves--at least that's always been my aim. Use enough batting to achieve this; which is another reason I avoid parallel walls--the need for batting is sometimes removed altogether.

I have a BIB type bass reflex cab utilizing two 18" sub-woofers. Non of the walls are parallel; as a result, there's no requirement for batting. The bass is very smooth.

I have a BIB type bass reflex cab utilizing two 18" sub-woofers. Non of the walls are parallel; as a result, there's no requirement for batting. The bass is very smooth.

I suppose I'll at least try removing the batting on one surface while I still can get at the innards, dry clamp again and see what happens.

It might be just the nature of the difference in designs. If I wanted 2 BIBs I should have made 2 BIBs. The new design is part of the adventure of the hobby.

It might be just the nature of the difference in designs. If I wanted 2 BIBs I should have made 2 BIBs. The new design is part of the adventure of the hobby.

loninappleton said:The new design is part of the adventure of the hobby.

Absolutely. If it weren't for your comments, I wouldn't have thought to alter the parallel walls in my horn adventure (Curvy Chang).

So, thanks!

glue up day

The idea for this winter project was to fiddle with it til around super bowl. No reason to watch that any more being from Wisconsin so I did the gluing today after I had my grille made up.

I use grilles. More than a home decorating element, I find that part of my field of vision needs some resting spots. Speakers exposed are totally distracting to listen to. Go figure. But it's been a personal problem for years-- and only on my right side.

Dry clamping experiments showed that My boards were uneven and I used enough glue to get a seal. Got considerable squeeze out but don't see any way to avoid it. A Stanley #97 plane (designed for

glue cleanup with the blade on top would be handy. Garrett Wade sells a look alike for $120. I'll pass.

Interior treatment is on the 2 parallel sides. Front, top, bottom and vent area are bare wood.

Cosmetics on this one (I made one only to compare with MLTL or BIB) are not the best. But I don't expect a visit from Better Homes and Gardens or Martha Stuart any time soon.

The MLTL is my reference and that design varies a bit from what GM originally gave for the design at Godzilla's site.

For the last few builds, simplest has worked best. The MLTL may not be a seat shaker but it is still the most "instrumental".

Looking to the future, I'm already eying up the Chili Chang.

And side-firing ports would, in theory, raise and change the axis of what comes out the terminus. Bill Fitzmaurice's "David" explores this as does the -- Mileva (I think.) There's a lot of designs to cope with right now.

Nothing to do but twiddle til the glue sets.

The idea for this winter project was to fiddle with it til around super bowl. No reason to watch that any more being from Wisconsin so I did the gluing today after I had my grille made up.

I use grilles. More than a home decorating element, I find that part of my field of vision needs some resting spots. Speakers exposed are totally distracting to listen to. Go figure. But it's been a personal problem for years-- and only on my right side.

Dry clamping experiments showed that My boards were uneven and I used enough glue to get a seal. Got considerable squeeze out but don't see any way to avoid it. A Stanley #97 plane (designed for

glue cleanup with the blade on top would be handy. Garrett Wade sells a look alike for $120. I'll pass.

Interior treatment is on the 2 parallel sides. Front, top, bottom and vent area are bare wood.

Cosmetics on this one (I made one only to compare with MLTL or BIB) are not the best. But I don't expect a visit from Better Homes and Gardens or Martha Stuart any time soon.

The MLTL is my reference and that design varies a bit from what GM originally gave for the design at Godzilla's site.

For the last few builds, simplest has worked best. The MLTL may not be a seat shaker but it is still the most "instrumental".

Looking to the future, I'm already eying up the Chili Chang.

And side-firing ports would, in theory, raise and change the axis of what comes out the terminus. Bill Fitzmaurice's "David" explores this as does the -- Mileva (I think.) There's a lot of designs to cope with right now.

Nothing to do but twiddle til the glue sets.

I've had the FrankenHarvey going for a couple days now. Still not settled on voicings in the CC as being clear and clean and unaffected by the BVR. I may toss in just a bit of combed out (teased) fiberfill on the remaining exposed walls to get rid of any more standing wave issues.

I need a good organ piece to test and will redo my test tones.

I need a good organ piece to test and will redo my test tones.

Harvey & siblings void fill

Do the voids in these Frugel-horn Spawn contribute anything ? Rather than fill them with foam, what happens if they are cut off (for the top and bottom) or opened up with say a 6" dia hole on each side for the internal ones above/below the compression chamber ?

Andrew

Do the voids in these Frugel-horn Spawn contribute anything ? Rather than fill them with foam, what happens if they are cut off (for the top and bottom) or opened up with say a 6" dia hole on each side for the internal ones above/below the compression chamber ?

Andrew

I decided to do another test before gluing the final side on the FrankenHarvey.

I took the advice given for the Sachiko )I think) wherein the BR portion is fully treated with damping on sides front and back.

I had no sweaters to chew up so I got some 10 lb. batting from the fabric store. They now think I am Suzy Homemaker big time since I've been shopping for fabric for grilles as well.

The batting is dence and the requested half inch thick.

I'm doing the following interim step now.

Since the only difference between BVR and BR palin vanilla is the

back vent, I'm doing a teporary test of just the BR. This is the equivalent of any small bookshelf speaker made with a piece of scrap, the shaped piece of batting stuck to it with double stick tape and gasketed and clamped.

Before doing this I had a small reversal with the building the boat in the basement dilemma but I got past that to set up in my listening area.

Initial impression of the new and improved damped version is positive. Since the enclosure is small, the sound is a bit high strung, but better that than hearing a flute sounding like it's being played by Orpheus in the Underworld.

I still don't know what the final assembly will produce.

Any advice on treating the mouth area at this time would help.

My idea is that treating the mouth would be done with the billiard felt I have to work into the tight corners.

Response from all BVR builders appreciated since I appear to be the only on this thread.

Hi loninappleton

I'm just catching up to this thread or I'd have posted sooner. In the curved Harvey, I ended up with (quite dense) felt about 1/2" thick on both side-walls - nothing else. Seems to work.

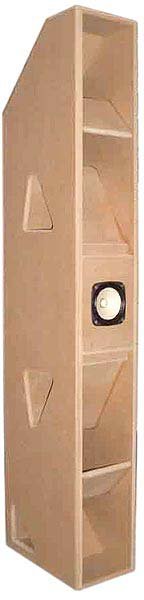

[edit]Also, I cut the side-walls away to expose the voids, thinking that this was both easier and more visually interesting than filling the voids with, say, sand and leaving the side-walls whole - see photo.[/edit]

Regards.

Aengus

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Harvey Builder's Thread