Hey Badman, can you describe the sound of the mids and above? I'm no engineer and only understand pretty limited concepts re: speakers, so these are beyond my paygrade to make sense of. Still, it seems very different from most approaches to speakers that I'm familiar with, so it's interesting to me.

Carl, I was a bit confused also till badman repeated these are surrounds. If you have been to a movie theater lately you will see maybe 10 or 12 speakers along each side wall. They are there in an attempt to replicate the enormous amount of reflected sound in real life.

In the average home that is impractical, so forcing the sound to reflect in at least two opposing directions along those side walls has become an acceptable compromise. You are correct, as badman stated, surround speaker design is almost the opposite of standard 2 ch approaches. Note my sides are not only bi-directional, but also have vertical offsets to enhance diffusion. Using the wall (and in my case the ceiling front surrounds) also allows the ambient information to be heard realistically at more locations in the room.

Mostly mid and some HF information is EQed into the 5.1 and 7.1 mix so smaller and less sophisticated drivers are sufficient - though a system with two way surrounds can benefit from having the same tweeter as the main front L/R speakers. That just provides a tonal match and as badman says, lessens the surround's potential to draw the listeners attention.

Nice work and clever idea on the roundover Mr. B Sounds like you have taken great advantage of the ability to experiment with FC.

Sounds like you have taken great advantage of the ability to experiment with FC.

In the average home that is impractical, so forcing the sound to reflect in at least two opposing directions along those side walls has become an acceptable compromise. You are correct, as badman stated, surround speaker design is almost the opposite of standard 2 ch approaches. Note my sides are not only bi-directional, but also have vertical offsets to enhance diffusion. Using the wall (and in my case the ceiling front surrounds) also allows the ambient information to be heard realistically at more locations in the room.

Mostly mid and some HF information is EQed into the 5.1 and 7.1 mix so smaller and less sophisticated drivers are sufficient - though a system with two way surrounds can benefit from having the same tweeter as the main front L/R speakers. That just provides a tonal match and as badman says, lessens the surround's potential to draw the listeners attention.

Nice work and clever idea on the roundover Mr. B

Last edited:

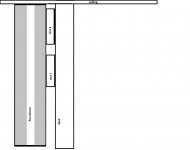

Easy constrained layers with the plastic faced foamcore:

Basic medium compression weatherstripping, with a foamcore layer fastened around the perimeter with screws/bonded washers into a wooden sub-assembly. So long as you are careful, the compression at the screws is not too bad. I'm not sure how this would work with the paper-faced- the elmer's seems to be stronger, but might be worth shellacking the surfaces to make it stiffer. With my plastic-faced stuff (it has paper under the plastic too) it makes a panel that's not only got good damping, it's also somewhat pre-tensioned, and very well damped indeed.

Basic medium compression weatherstripping, with a foamcore layer fastened around the perimeter with screws/bonded washers into a wooden sub-assembly. So long as you are careful, the compression at the screws is not too bad. I'm not sure how this would work with the paper-faced- the elmer's seems to be stronger, but might be worth shellacking the surfaces to make it stiffer. With my plastic-faced stuff (it has paper under the plastic too) it makes a panel that's not only got good damping, it's also somewhat pre-tensioned, and very well damped indeed.

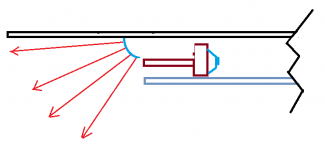

Now you've got me confused again. Where does the port/guide terminate? I was looking for something like this (top view). Roundover to radiate at multiple angles - no?

I hope these views clarify- the slot that's built into the driver

Panasonic EAB12147E 3" x 5" Full Range LCD TV Shielded Speak | 299-682

terminates into the gap between the wall and the roundover. The rectangular open end of the "Waveguide" slot is perpendicular to the ground.

Last edited:

Got it - thanks! Would still like to see a photo of the actual driver mounting - if/when you get a chance.

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures-46.html#post3877326

You can see here how the drivers are arranged- the slot "termination" is far from perfect, the devices are too wide to make an uninterrupted slot source. The mounting is actually done with hot melt glue- it grabs very aggressively to both the wood and the polyethylene waveguides.

X

I made my first FCB speakers! Small scaled down versions of the Lance. I used some small 2" BMRs I had hanging around. Took about 2 hours total. Good first attempt to learn some of the techniques for FCB. They sound pretty good! I have a pair of the Fountek FE 85s what do you recommend?

Bob

I made my first FCB speakers! Small scaled down versions of the Lance. I used some small 2" BMRs I had hanging around. Took about 2 hours total. Good first attempt to learn some of the techniques for FCB. They sound pretty good! I have a pair of the Fountek FE 85s what do you recommend?

Bob

Attachments

Bkanabe,

Those little boxes look great! How did you size the smaller TL? Just plain old scaled the drawing? That sometimes works and you get lucky. How deep is the bass would be your estimate form those 2 in BMR's? Neat computer speakers for sure. I like the black foam look and glad it worked out for you. Looks kind of like the Martellos you made in the the other thread. Are you thinking of a similar TL for the FE85's? You might want to try the mini Karlsonator for those in foam core. Easy to make and big smooth sound.

Nice work!

Those little boxes look great! How did you size the smaller TL? Just plain old scaled the drawing? That sometimes works and you get lucky. How deep is the bass would be your estimate form those 2 in BMR's? Neat computer speakers for sure. I like the black foam look and glad it worked out for you. Looks kind of like the Martellos you made in the the other thread. Are you thinking of a similar TL for the FE85's? You might want to try the mini Karlsonator for those in foam core. Easy to make and big smooth sound.

Nice work!

Just did a basic scaling and got lucky. I wasn't really expecting much given the little drivers. I have a dayton iMM-6 mic and was getting down to about 125hz before there was a big falloff. They are nice and clear. I didn't have felt, so stuffed them with pillow filling about halfway down the line. As far as technique goes, I was sealing all the inside edges with hot melt glue and also used regular wood glue to attach the pieces, but on the last side, only used glue. Do you use anything special to insure a good seal on that last piece?

I use PVA on the last piece too. Sometimes I leave a few bare spots free of PVA and add a few dabs of hot glue in addition to the PVA on the corner spots to serve as a tack clamp for the PVA to keep the lid from sliding around. I still use books to weigh it down while it dries. Cal had a technique for adding thin layers of paper strips over the PVA bead to build up the edge to evenness for final gluing.

How does that iMM6 mic work? Does it come with an app for the iPhone?

How does that iMM6 mic work? Does it come with an app for the iPhone?

I just got the mic and use it on my android phone. I bought the audiotool app as recommended by parts-express and others. It seems to work well although I can't say that I am really using it properly. It calibrated with no issues and the readings are much different than the standard mic in the phone. I'll have to play with it more to really figure it all out.

I just went out and used a signal generator on one of my phones connected via bluetooth to my amp and then to the fcb speakers to check their response and with the mic on my other phone, and found that it appears to be reasonably accurate and these little speakers are quite accurate or at least somehow consistent. I entered a tone of 100hz and measured 99 hz on the mic then went to 2500 hz and the mic showed 2.5khz then went to 15000 and the mic displayed 15.00 khz as the main tone. There were other background noises showing up, but the main tone tracked quite well.

xrk971, I know it's been a while since the experiment, but you have any recordings of the 20x30" foam core board you attached the $3.50 exciters from Parts Express to? The SPL results were impressive, so I wanted to see how it actually sounded

Here it is...

Attachments

That's insane! I'm sure they were, but I just wanted to double-check - in the recording, are we listening to just the transducers on the panels, or do you have other speakers in the system running?

That's amazing! I imagine the dispersion pattern is a little like that of an electrostatic speaker, so altering that would mean simply curving the panel it's attached to.

This is probably a silly question, but would there be any need to use them in a (unity/synergy/any kind of) horn configuration?

That's amazing! I imagine the dispersion pattern is a little like that of an electrostatic speaker, so altering that would mean simply curving the panel it's attached to.

This is probably a silly question, but would there be any need to use them in a (unity/synergy/any kind of) horn configuration?

Nothing else. Just panel and tpa3116d2 amp direct wired and fed by CD.

No unity needed - like OB panel.

Thanks X - I can see a device such as these having a high WAF when used with a poster attached to the board...or even just the low profile and the ability to not have a floor-standing unit

I see that the particular transducers you've used aren't available from PE any more, so I'll have to use an alternative. What specifications did you look at when you were choosing which to use?

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?