Nice pictures of the circuit boards. The user interface looks the same as an SPA250, but the transistors and board layouts are different. I looked for the SA240 schematic(s) and came up empty. No schematic definitely hurts the cause. If you are knowledgeable, you can try to measure some of the DC Voltages. First thing to do is a detailed visual inspection. Then its time to decide between passive, unpowered troubleshooting and active, signal injection troubleshooting. The latter requires a load, audio source, and O'scope. You can use a DVM to check for continuity and E-B-C junctions with no power applied. You are limited without a schematic. Do you have any test equipment?

An update on my SPA250:

I had the courage to open it up and I probably have found the high pitched sound, it is coming from one component (I think).

I used a phone with a connected Dayton Audio iMM-6 mic, and it seems at around the 16khz-20khz range as I expected (very annoying sound).

I went through each part of the amp to localize the high pitched sound, and it seems this component was the culprit (see pics with red arrow).

I tried touching it with a plastic rod, but there is no mechanical vibration (well not felt anyway). I also tried tapping it or leaving (pressing) the plastic rod on it to try and see if the high pitch whine lessens or goes away, without any success. It also doesn't heat up (I measured it with a laser thermometer), so heat wasn't the issue. It whines even if the unit is turned off (but plugged into the wall outlet).

What component might this be? The PCB board that it is located from isn't present in the SPA240 that the previous poster sent (you may compare pics), so it may be a new addition (to a new revision).

I had the courage to open it up and I probably have found the high pitched sound, it is coming from one component (I think).

I used a phone with a connected Dayton Audio iMM-6 mic, and it seems at around the 16khz-20khz range as I expected (very annoying sound).

I went through each part of the amp to localize the high pitched sound, and it seems this component was the culprit (see pics with red arrow).

I tried touching it with a plastic rod, but there is no mechanical vibration (well not felt anyway). I also tried tapping it or leaving (pressing) the plastic rod on it to try and see if the high pitch whine lessens or goes away, without any success. It also doesn't heat up (I measured it with a laser thermometer), so heat wasn't the issue. It whines even if the unit is turned off (but plugged into the wall outlet).

What component might this be? The PCB board that it is located from isn't present in the SPA240 that the previous poster sent (you may compare pics), so it may be a new addition (to a new revision).

Attachments

You Asked, "What component might this be? The PCB board that it is located from isn't present in the SPA240 that the previous poster sent (you may compare pics), so it may be a new addition (to a new revision)."

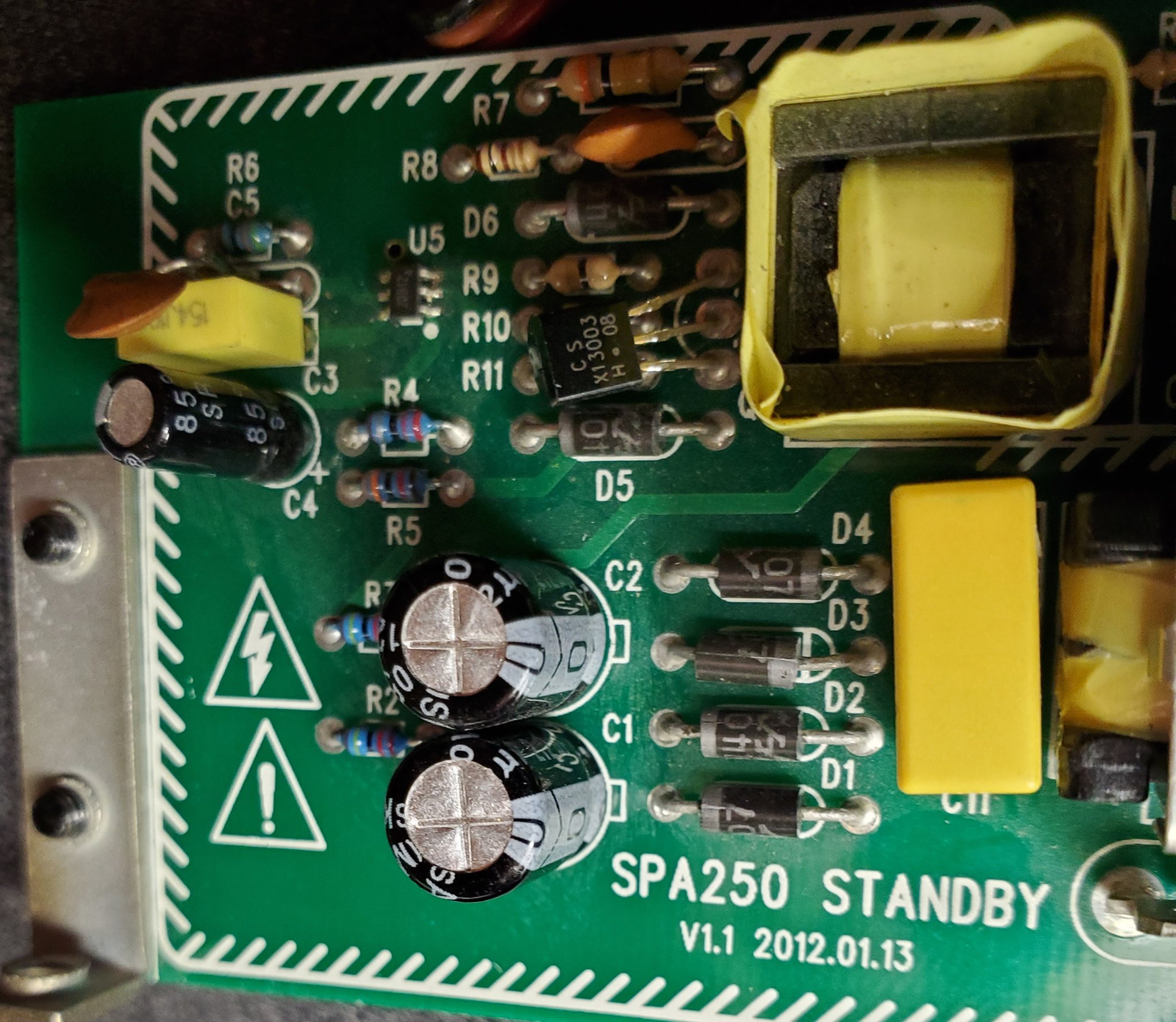

Congratulations, I think you found it! Your photo, 1.JPG shows the new circuit card in the SPA250. This board was labeled STBY in my amp. It has the ON-AUTO-OFF circuitry and power relay. It also has a small DC power supply that is always on, even in the off mode. The component identified by your arrow in 2.JPG is a low current transformer for this P/S. It is very possible this transformer is resonating at a high frequency (Directly below it is a yellow inductor). There are a few options available.

1) Transformers are usually dipped in electronics varnish. This varnish helps keep the windings intact while eliminating moisture and vibration. It might be possible to remove the transformer and dip it in varnish. After a 2-day cure, the transformer can be re-installed and tested.

2) A transformer shop can rebuild the transformer.

3) You might be able to buy a replacement transformer from the Manufacturer of the SPA250 or from the Internet. The Transformer has markings on it- usually a date code and part number.

4) The scariest possibility – some circuitry external to the transformer is causing it to resonate or apply DC voltages to the windings. . . This is also the lowest percentage failure. Although rare, I have seen both things happen.

My best guess (stress the word ‘guess’) is the transformer was manufactured incorrectly and needs further investigation. You can also perform a sanity check by using passive resistance checks on the components around the transformer. If you can read the transformer marking, please post it. You are getting really close, well done! EVMan.

Congratulations, I think you found it! Your photo, 1.JPG shows the new circuit card in the SPA250. This board was labeled STBY in my amp. It has the ON-AUTO-OFF circuitry and power relay. It also has a small DC power supply that is always on, even in the off mode. The component identified by your arrow in 2.JPG is a low current transformer for this P/S. It is very possible this transformer is resonating at a high frequency (Directly below it is a yellow inductor). There are a few options available.

1) Transformers are usually dipped in electronics varnish. This varnish helps keep the windings intact while eliminating moisture and vibration. It might be possible to remove the transformer and dip it in varnish. After a 2-day cure, the transformer can be re-installed and tested.

2) A transformer shop can rebuild the transformer.

3) You might be able to buy a replacement transformer from the Manufacturer of the SPA250 or from the Internet. The Transformer has markings on it- usually a date code and part number.

4) The scariest possibility – some circuitry external to the transformer is causing it to resonate or apply DC voltages to the windings. . . This is also the lowest percentage failure. Although rare, I have seen both things happen.

My best guess (stress the word ‘guess’) is the transformer was manufactured incorrectly and needs further investigation. You can also perform a sanity check by using passive resistance checks on the components around the transformer. If you can read the transformer marking, please post it. You are getting really close, well done! EVMan.

Thanks so much for your comprehensive reply EVMan.

Your explanation about the small DC power supply with the low current transformer resonating makes good sense.

The transformer is labelled:

EPC13

DGC 2128

Unfortunately, I do not have any experience with regards to varnishing a transformer (especially this small), as I just might ruin it even more.

Is it possible to just cover that transformer with glue gun or maybe silicone sealant to "hold" it down or absorb/cover the resonance?

Your explanation about the small DC power supply with the low current transformer resonating makes good sense.

The transformer is labelled:

EPC13

DGC 2128

Unfortunately, I do not have any experience with regards to varnishing a transformer (especially this small), as I just might ruin it even more.

Is it possible to just cover that transformer with glue gun or maybe silicone sealant to "hold" it down or absorb/cover the resonance?

3) You might be able to buy a replacement transformer from the Manufacturer of the SPA250 or from the Internet. The Transformer has markings on it- usually a date code and part number.

This would probably be the easiest route, as I would just have to replace the defective transformer with a new one and solder it

Not sure how competent with a DMM you are, but if you are comfortable, you can take measurements (in AC) on both sides and then measure in mm the spacing for all the pins and likely find a cheap replacement on AliExpress that is "potted/sealed" - I bought one a few weeks back for <$5 and worked great.

The other thing to check, I have had a buzzing, whining stand-by xfrmr that the plastic around the windings deteriorated and shorted and took out one of the smoothing caps. replaced the transformer and capacitor and all is quiet again.

Just a couple suggestions, not advocating you do this if you are not comfortable with the shock hazard or the risk associated.

EDIT: most likely a 12V (check for a voltage regulator 5V or 12V and will give you a hint to the voltage) transformer. You need to determine if the primary and/or secondary are single (2 pins) or dual 4 pins) windings, on each side of the transformer going through the PCB.

The other thing to check, I have had a buzzing, whining stand-by xfrmr that the plastic around the windings deteriorated and shorted and took out one of the smoothing caps. replaced the transformer and capacitor and all is quiet again.

Just a couple suggestions, not advocating you do this if you are not comfortable with the shock hazard or the risk associated.

EDIT: most likely a 12V (check for a voltage regulator 5V or 12V and will give you a hint to the voltage) transformer. You need to determine if the primary and/or secondary are single (2 pins) or dual 4 pins) windings, on each side of the transformer going through the PCB.

Last edited:

RE Transformers: Best practice for manufacturers is to apply Transformer Varnish prior to final test. The varnish does several things: (1) It protects against moisture, (2) aids in heat dissipation, (3) reduces vibration. The simplest method is involves dipping the entire transformer. The most advanced (and costly) method uses vacuum depositing. I would guess that this transformer missed the varnishing step altogether. Transformer varnish is a specialized formulation. It goes on as a liquid and dries to a hard plastic while also being heat conductive. Being a liquid allows the varnish to penetrate the windings before solidifying. If you re-dip the transformer, remove moisture by heating it up in direct sunlight for a few hours. A transformer shop will have the ovens, varnish, etc. They could even re-wind it if necessary. DO NOT use epoxy or any other substitute! Substitutes will not conduct heat away from the windings. . .

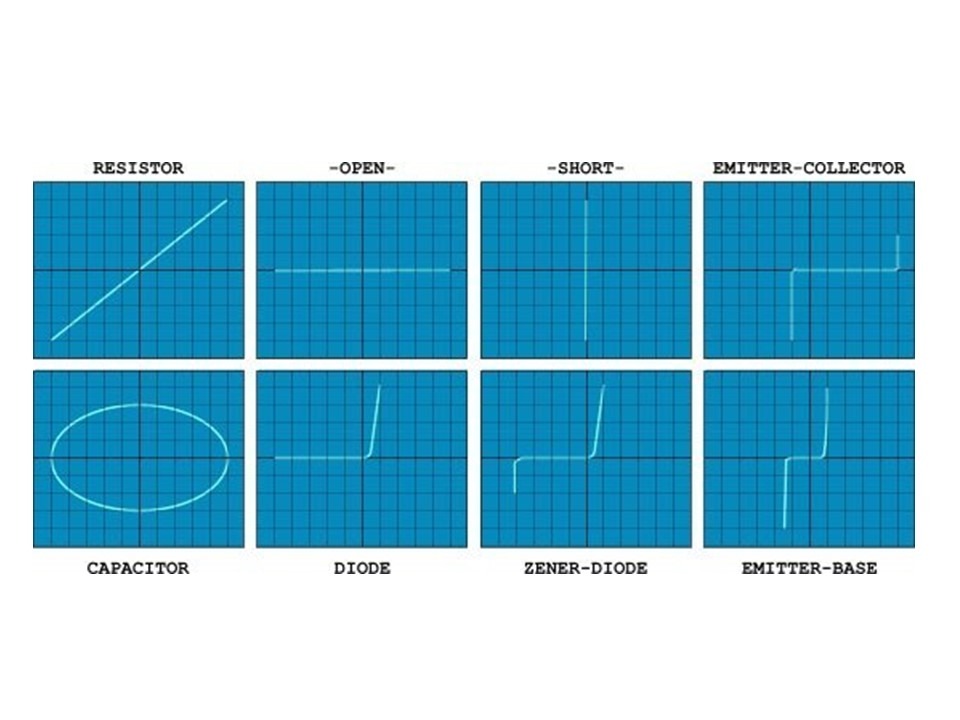

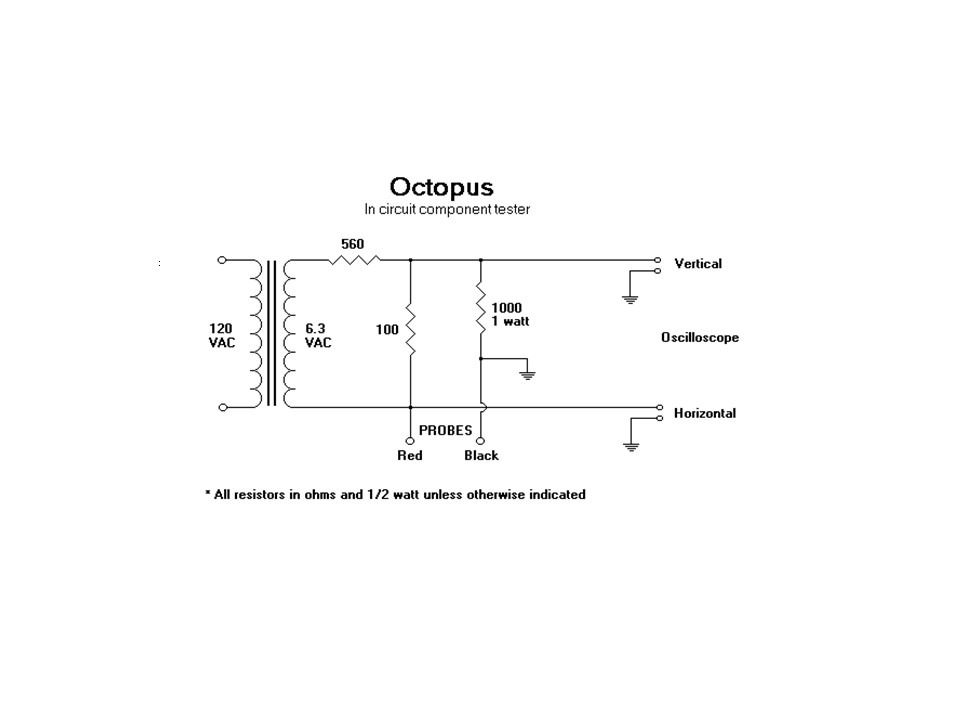

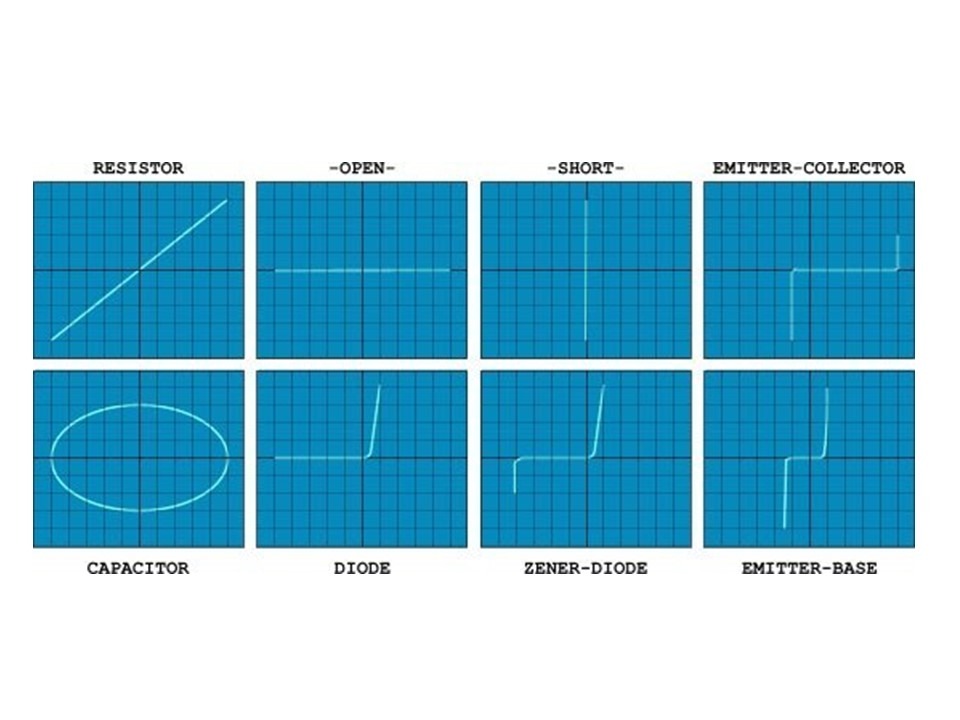

I believe you stated that you had another SPA250 in working order. You can use the good one as the ‘Standard’ and compare Ohm readings with the bad unit. An Ohm check may or may not reveal the problem. If you have access to an O’Scope with X-Y capabilities and an Octopus tester, you can compare Lissajous figures. Because the test signal is AC, you never have to reverse the test leads. A couple of JPG’s are attached. EPC13 might be part of a standardized line of transformers. Chinese manufacturers in the New Territories outside Hong Kong are where a lot of this stuff is made (including the SPA250). You can check Alibaba for transformer manufacturers I looked up the manufacturer awhile back. IIRC they were in Shenzhen.

You should definitely check the transformer secondary output to return. This should be close to the value of the bleeder resistor, around 1K Ohm. A shorted filter cap can cause transformer vibration/hum/resonance. . .

I believe you stated that you had another SPA250 in working order. You can use the good one as the ‘Standard’ and compare Ohm readings with the bad unit. An Ohm check may or may not reveal the problem. If you have access to an O’Scope with X-Y capabilities and an Octopus tester, you can compare Lissajous figures. Because the test signal is AC, you never have to reverse the test leads. A couple of JPG’s are attached. EPC13 might be part of a standardized line of transformers. Chinese manufacturers in the New Territories outside Hong Kong are where a lot of this stuff is made (including the SPA250). You can check Alibaba for transformer manufacturers I looked up the manufacturer awhile back. IIRC they were in Shenzhen.

You should definitely check the transformer secondary output to return. This should be close to the value of the bleeder resistor, around 1K Ohm. A shorted filter cap can cause transformer vibration/hum/resonance. . .

Last edited:

Just want to give a shout out to Wacgen and EVMan for guidance concerning the C8 cap and in my particular case, also the C18 cap as well. Both caps were successfully replaced within an hour and this was my first time doing it. Hooked up the amp to the denon via LFE and rewired some speakers for a test (I dismantlement my theater room while renovating it, which is when the amp conked out. Cop cars and electronics should never be shut off) and VIOLA! the glorious SVS 20-39CS sprung back to life  Thank you again.

Thank you again.

RXV- thanks for your updates. One favor if possible: There is a small Integrated Circuit (IC Chip) with 6 leads labeled "U5" on the upper left portion of the board. Is there any chance that you can use a magnifying glass to read the part number and post it here? thanks a million. EVMan

RE Transformers: Best practice for manufacturers is to apply Transformer Varnish prior to final test. The varnish does several things: (1) It protects against moisture, (2) aids in heat dissipation, (3) reduces vibration. The simplest method is involves dipping the entire transformer. The most advanced (and costly) method uses vacuum depositing. I would guess that this transformer missed the varnishing step altogether. Transformer varnish is a specialized formulation. It goes on as a liquid and dries to a hard plastic while also being heat conductive. Being a liquid allows the varnish to penetrate the windings before solidifying. If you re-dip the transformer, remove moisture by heating it up in direct sunlight for a few hours. A transformer shop will have the ovens, varnish, etc. They could even re-wind it if necessary. DO NOT use epoxy or any other substitute! Substitutes will not conduct heat away from the windings. . .

I believe you stated that you had another SPA250 in working order. You can use the good one as the ‘Standard’ and compare Ohm readings with the bad unit. An Ohm check may or may not reveal the problem. If you have access to an O’Scope with X-Y capabilities and an Octopus tester, you can compare Lissajous figures. Because the test signal is AC, you never have to reverse the test leads. A couple of JPG’s are attached. EPC13 might be part of a standardized line of transformers. Chinese manufacturers in the New Territories outside Hong Kong are where a lot of this stuff is made (including the SPA250). You can check Alibaba for transformer manufacturers I looked up the manufacturer awhile back. IIRC they were in Shenzhen.

You should definitely check the transformer secondary output to return. This should be close to the value of the bleeder resistor, around 1K Ohm. A shorted filter cap can cause transformer vibration/hum/resonance. . .

View attachment 1161597

View attachment 1161596

View attachment 1161597

Thanks for all your help EVMan! Unfortunately, I am not adept in varnishing transformers, as well as check the circuitry as mentioned above (I am a newbie at best). But I will do check my 2nd SPA250 and try to compare them. Thanks!

RXV- thanks for your updates. One favor if possible: There is a small Integrated Circuit (IC Chip) with 6 leads labeled "U5" on the upper left portion of the board. Is there any chance that you can use a magnifying glass to read the part number and post it here? thanks a million. EVMan

I finally found the U5 chip, but the letters/labeling are so small that it is almost invisible to the naked eye. I'll try to see if I could borrow a magnifying glass or maybe a zoom-in camera

RXV- Thanks for trying to look at U5. I looked at my pictures, but cannot make out the part number. Definitely need a magnifying glass and good eye sight to read anything. Oh and BTW, EPC13 refers to a transformer bobbin (core + former). This standardizes the footprint, but not the winding configuration. The EPC series of bobbins were almost all based on high frequency cores. This is why I asked about U5; it could be part of a switching power supply. This could also explain the high pitched noise that you hear. . .

Last edited:

This is a small SMPS which feeds the audio input section of the plate amp. When the audio section detects a signal, it activates the mains relay at the SMPS which switches on the main transformer. So this small SMPS is "always on".

If possible return the plate amp to the seller for exchange or refund.

SMPS repair is no fun and can have serious consequences, as you handle deadly voltage.

Many experienced audio people refuse to repair SMPS because of unavailable schematics and spares. So no sense in messing with it.

If it was an older amp, after checking frequency around it with an osciloscope, I would remove as much tape as possible from the windings of the high frequency transformer (the large yellow one) and fill it up with epoxy. Be aware: This might not be the cause for the noise, as it should resonate at a much higher, inaudible frequency. So the real cause could be another defective or wrong part which may play up even worse in the future.

Do not forget, this is an always on circuit. So it may start a fire while you sleep or work. I don't know if it was wise to take such a risk for a part that should be fixed by the seller anyway. Any repair you do makes you responsible for anything that might happen later! The seller/ manufacturer is off the hook.

If possible return the plate amp to the seller for exchange or refund.

SMPS repair is no fun and can have serious consequences, as you handle deadly voltage.

Many experienced audio people refuse to repair SMPS because of unavailable schematics and spares. So no sense in messing with it.

If it was an older amp, after checking frequency around it with an osciloscope, I would remove as much tape as possible from the windings of the high frequency transformer (the large yellow one) and fill it up with epoxy. Be aware: This might not be the cause for the noise, as it should resonate at a much higher, inaudible frequency. So the real cause could be another defective or wrong part which may play up even worse in the future.

Do not forget, this is an always on circuit. So it may start a fire while you sleep or work. I don't know if it was wise to take such a risk for a part that should be fixed by the seller anyway. Any repair you do makes you responsible for anything that might happen later! The seller/ manufacturer is off the hook.

Building one or least buying one that isn't Ch!nese made is a good option. Mid and even "high end" (subjective) level commercial sub plates aren't immune from break downs. Including Rel. Witch is why mine is powered by outboard amplification. But I have a list of companies whos plate failed over the course or 10 or so years. If people got at least 5 years use from one, that seems OK, not great. But often some of them failed within a year. Good for warranty bad for the typical subwoofer fan.

Good ones are many times the price in some cases. But if you think of it as likely being trouble free for years to come and you will likely not have to replace it. Second for the possible net of some SQ as added bonus.

I know it isn't exactly OT and the OP chose to fix theirs.

Good ones are many times the price in some cases. But if you think of it as likely being trouble free for years to come and you will likely not have to replace it. Second for the possible net of some SQ as added bonus.

I know it isn't exactly OT and the OP chose to fix theirs.

A quick update. The STANDBY board is essentially a PWM switching power supply. C8 is the output filter. This should be a SMPS rated capacitor. i. e. High Ripple current and low ESR, not a regular electrolytic. Good switching caps are made by Panasonic and Nicichon to name two. I was not able to verify the switching diodes in the flyback circuit- they should be fast switching types with soft recovery. . .

Current work involves generating a parts list and schematic. For those interested, the power supply circuit looks like a lift of Silicone General’s SG6848 PWM IC's reference design. I bought some old SPA250 parts for documentation efforts. When the SPA parts come in, I will finish the drawings. Famous last words.

Current work involves generating a parts list and schematic. For those interested, the power supply circuit looks like a lift of Silicone General’s SG6848 PWM IC's reference design. I bought some old SPA250 parts for documentation efforts. When the SPA parts come in, I will finish the drawings. Famous last words.

The SPA250 arrived in pieces as expected. The STANDBY board has two transistors, Q1 and Q2. Q2 is labeled C1815 and this correlates to a low Hfe NPN transistor. Q1 is more troublesome to identify. it is labeled "CSX13003H08" per the attached photo. Running various permutations of this number led to two viable possible alternatives: (1) a 600V MOSFET or (2) a 450V NPN bipolar. This is the main switching element for the flyback transformer, so I would expect it to be an 'N' Channel MOSFET. If anyone can shed some light on Q1 . . .

Same deal with U5, a 6-Pin SOIC. Markings include A67 and 20812 per the attached photo. I believe this is a SG6848 clone, a PWM Controller. However, I cannot find a data sheet. I believe that both Q1 and U5 are of Chinese origin. Any help in identifying either part would be deeply appreciated. Thanks- EVMan

Same deal with U5, a 6-Pin SOIC. Markings include A67 and 20812 per the attached photo. I believe this is a SG6848 clone, a PWM Controller. However, I cannot find a data sheet. I believe that both Q1 and U5 are of Chinese origin. Any help in identifying either part would be deeply appreciated. Thanks- EVMan

Attachments

Rehosted & Edited PM’s

EVMan: RXV- Thank you so much for the information. You enabled the parts list and schematic effort. The theory of operation is now understood (no doubt why C8 goes bad all the time) and that should lead to solving your amp’s problem of, “The whining transformer.” If things go well, we could probably exchange your bad STANDBY board for the good one. If you are agreeable, I will send you a good board in exchange for your bad unit. There is only one 3-Pin Molex Connector and three FAST-ON™ slip connectors plus the four retaining screws. What do you think?

RXV: Hi, Good to hear that you now understand the schematics and why there are possible faults in the design (well, I myself can't understand those LOL). Unfortunately, I have no clue on how we will be able to swap boards, as I am situated in the Philippines and have no idea on any shipping solutions

The STANDBY board that I have now is actually working normally and without fault (working as it should and producing clean bass). It's just that "whining" sound that bothers me, well at least for now (its brand new anyway). I am actually tempted to try and "varnish" that SMSP transformer. Is it possible to use clear nail polish as a varnish (I saw in some forums using those), if it's possible and safe of course?

EVMan: Shipping to/from the Philippines for small items is best handled by the post office should that be necessary. There are companies that specialize in 'Balikbyan' shipments but they are for larger boxes.

Nail polish may or may not quiet the transformer sound level. It definitely is not thermally conductive. If you are in Manila, there is the electronics district. If you ask around, you should be able to find a "rewind" shop. They rebuild/rewind transformers, fan motors, etc. Simply bring in your SPA250 and ask them to apply the transformer varnish. Should not cost more than a Red Horse beer.

RXV: Yes, I have been in Quiapo (Manila) before. But it is very far from us here, and it is difficult nowadays to travel there (let alone find a reputable transformer repair shop there), as there are a lot of scammers and swindlers there.

With regards to transformer varnish, I am just thinking about it (but will not necessary do it) since I am not experienced in that regard (I might just mess it up more). I'll probably read up on it more to see if it is feasible

EVMan: My bad. I assumed that you were in Manila. Where are you, Visayas? No matter. DHL and FedEx are expensive overseas, which is why I suggested the post office. They were the most reliable, hassle free method in Thailand and Pakistan. Sorry to hear that the post office is unreliable there. Sounds like a board swap would be difficult.

If the Amp is working (with the whine), it makes sense to coat it. I would use nail polish as an absolute last resort. There should be a rewind shop in a town of any size. Transformer varnish and heat conductive epoxy are hard to find and expensive. So, it is really up to you. Short of swapping out the boards, there is not much else that I can do except answer questions . . . I will keep you informed via the main SPA250 thread. Good luck!! EVMan

RXV: Hi EVMan,

I believe I made a boo-boo this time. This is going to be a long read (apologies for bothering your precious time). As discussed before, I initially planned to add some insulating varnish to the small "whining" transformer found in the Standby board.

I first removed the attached yellow Kapton tape surrounding the outer edge of the transformer, and found out that it was there to hold 2 pieces of small ferrite cores. I believe these 2pcs are the ones vibrating (hence causing the high-pitched vibration), since they're only being held by the yellow Kapton tape. I removed the 2 separate ferrite cores from the main transformer base (the one soldered to the board)

I also tried peeking into the center transformer part (where the copper windings are supposed to be for varnishing (as planned), but after peeling the yellow tape, I don't know of the dark yellow part (shown in picture below) are the wires already (just insulated), or just another kind of tape (I didn't bother to remove them anymore as I might just damage it more). So the varnishing plan is initially scrapped. Here is where my carelessness comes in:

I then re-attached everything back into place EXCEPT for the 2 ferrite cores from the small transformer. I wanted to test if those 2 ferrite cores were indeed the ones doing the vibration, hence I did not put them back.

I then plugged in the plate amp, and then turned it on. After a few seconds, I heard a loud "pop", as if a component exploded, so I turned off the amp immediately. The next day (to ensure that there was no stored energy for electrocution), I observed the Standby board to see on what chip/component might have exploded. I took me a while to find any physical damage, and unfortunately, of all the components to get destroyed, it seems it was the

U5 chip that got busted (there are very small burn marks in the board, more of black dust burns during the explosion)

So, there you go, another one bites the dust. I actually don't know what to do anymore, I should have left it alone huhuhu

(Note: Some excellent photos would not copy)

EVMan: Ouch! By omitting the ferrite cores, you radically lowered the transformer impedance. Low impedance = high current. Transistor Q1 is probably bad as well as IC Chip U5. Could have smoked the transformer windings as well. Can you possibly bend Q1 a little bit to get the part number and photo? This is why quality companies use transformer varnish . . . EVMan

RXV: Huhuhuhu it seems I really did a very bad decision in trying to "fix" it, which only got worse.

Based on your assessment, it seems that the Standby board itself is pretty dead and unusable by this point

Q1 is labelled: 13003 Fe 118

U2? I don't seem to find any U2 here, maybe you meant Q2?

Just in case, here's what's labelled into the

Q2: K130 C3198 GR

NOTE: Upon plugging (turning on) the amp, it only took around 2-3 seconds before the pop (explosion), in which I pulled the plugged immediately Other than the small burn marks on the U5, I haven't seen (or smelled) any other burn marks as well as any physical damage to the other components

EVMan: Hi RXV, how are you? Yes, your STANDBY board is bad now. Thank you for the part number info on Q1 & Q2. I have not been able to find good part numbers for U5 or Q1 (sorry about that- I meant Q2, not U2 in previous post). Parts Express does not carry any replacement parts for the SPA250. I have a working (I think) STANDBY board. That is one option. Another option is to contact the manufacturer directly and see if they will sell the STANDBY Board. I had all of their info and was going to contact them, but then I found C8 was bad and dropped it. Chinese manufacturers vary greatly. Some will DHL the board for free, others will not even acknowledge your message. Give me 24 hours to come up with a good idea. . EVMan

. EVMan

RXV: All is NOT well: cry: That's one good reason why I shouldn't tinker on things I don't know about huhuhu.

Oh, really? You were able to track the manufacturer?

By chance, do they also sell the complete SPA250? (Just curious on how much they sell them VS Part Express price)

EVMan: Hey, don't feel bad, you are in learning mode. I did track the manufacturer before I found the bad C8 Capacitor. I am trying to "re-discover" that information. I do remember that they were in the New Territories outside of Hong Kong. I don't know the wholesale cost but my guess is around 50% of the PE sales price. If you remember, I asked if you ever traveled to Hong Kong. That was the reason why. I have been searching for three hours and identified 3 or 4 possible manufacturers. They are ranked most likely to least likely. I do believe it's the 1st company listed, but cannot prove it. Their offerings look similar and they have been in business the longest. It is also probable that the SPA250 is proprietary (no support- no schematics, no parts). Still working on it. You can check your amp for any company names . . . Good luck!

Vistron(Dong Guan) Audio Equipment Co.

Shenzhen Tianzhongtian Trading

Shenzhen Maoxing Weiye Technology Co., Ltd.

Foshan Yinchi Electronics Co.,

Rakoit Technology (sz) Co., Ltd.

Ningbo Mellisong Electronic Technology

Guangzhou Suiyu Technology Co., Ltd.

RXV: Hi, Wow! You're really on the hunt for the manufacturer, that takes real time and dedication

Yes, I'm sure Parts Express does have proprietary rights to that amp (to avoid customers just ordering direct from China instead)

May I ask out of curiosity, why did you choose to buy the used SPA250 parts from the seller here in DIYA? Did you need some of the components (for your actual SPA250)? Or you got it to just experiment on things?

Ok, I will also try to find for any labels or prints if there are any company names printed in the board

EVMan: How are you? I spent most of the day researching companies and comparing pictures of amps. Retirement means extra time for hobbies and it beats watching TV or solving crosswords. I am pretty sure that the first company listed is the right one (the other Parts Express DSP Plate amps are made by another company). I sent them an E-Mail asking if they sold any repair parts. Have not heard anything back from them yet. I also sent an E-Mail to Parts Express and this is what they said:

"Hello Miles, Thank you for this information. I am passing it on to the Dayton product team for their review. We cannot supply the name of our suppliers for any product. Repair parts are not available for any model. Dayton does handle any warranty issues on an exchange basis only. I am not aware of any changes or decision on this item by Dayton. As mentioned previously there have been changes over the years on the item and some of these may have addressed your concerns. Unfortunately, I do not have a list available of these changes."

I bought the old SPA for two reasons: (1) I was curious about the STANDDBY Board and (2) I thought you might need this part. This bad SPA is in terrible shape- it would cost more to fix than to buy a new one. However, the STANDBY Board still looks brand new. It is yours if you want it. I still need to finish the schematic. I think we should move most of this conversation back to the main post area. More people will see it and potentially more people will learn and contribute. EVMan

EVMan: RXV- Thank you so much for the information. You enabled the parts list and schematic effort. The theory of operation is now understood (no doubt why C8 goes bad all the time) and that should lead to solving your amp’s problem of, “The whining transformer.” If things go well, we could probably exchange your bad STANDBY board for the good one. If you are agreeable, I will send you a good board in exchange for your bad unit. There is only one 3-Pin Molex Connector and three FAST-ON™ slip connectors plus the four retaining screws. What do you think?

RXV: Hi, Good to hear that you now understand the schematics and why there are possible faults in the design (well, I myself can't understand those LOL). Unfortunately, I have no clue on how we will be able to swap boards, as I am situated in the Philippines and have no idea on any shipping solutions

The STANDBY board that I have now is actually working normally and without fault (working as it should and producing clean bass). It's just that "whining" sound that bothers me, well at least for now (its brand new anyway). I am actually tempted to try and "varnish" that SMSP transformer. Is it possible to use clear nail polish as a varnish (I saw in some forums using those), if it's possible and safe of course?

EVMan: Shipping to/from the Philippines for small items is best handled by the post office should that be necessary. There are companies that specialize in 'Balikbyan' shipments but they are for larger boxes.

Nail polish may or may not quiet the transformer sound level. It definitely is not thermally conductive. If you are in Manila, there is the electronics district. If you ask around, you should be able to find a "rewind" shop. They rebuild/rewind transformers, fan motors, etc. Simply bring in your SPA250 and ask them to apply the transformer varnish. Should not cost more than a Red Horse beer.

RXV: Yes, I have been in Quiapo (Manila) before. But it is very far from us here, and it is difficult nowadays to travel there (let alone find a reputable transformer repair shop there), as there are a lot of scammers and swindlers there.

With regards to transformer varnish, I am just thinking about it (but will not necessary do it) since I am not experienced in that regard (I might just mess it up more). I'll probably read up on it more to see if it is feasible

EVMan: My bad. I assumed that you were in Manila. Where are you, Visayas? No matter. DHL and FedEx are expensive overseas, which is why I suggested the post office. They were the most reliable, hassle free method in Thailand and Pakistan. Sorry to hear that the post office is unreliable there. Sounds like a board swap would be difficult.

If the Amp is working (with the whine), it makes sense to coat it. I would use nail polish as an absolute last resort. There should be a rewind shop in a town of any size. Transformer varnish and heat conductive epoxy are hard to find and expensive. So, it is really up to you. Short of swapping out the boards, there is not much else that I can do except answer questions . . . I will keep you informed via the main SPA250 thread. Good luck!! EVMan

RXV: Hi EVMan,

I believe I made a boo-boo this time. This is going to be a long read (apologies for bothering your precious time). As discussed before, I initially planned to add some insulating varnish to the small "whining" transformer found in the Standby board.

I first removed the attached yellow Kapton tape surrounding the outer edge of the transformer, and found out that it was there to hold 2 pieces of small ferrite cores. I believe these 2pcs are the ones vibrating (hence causing the high-pitched vibration), since they're only being held by the yellow Kapton tape. I removed the 2 separate ferrite cores from the main transformer base (the one soldered to the board)

I also tried peeking into the center transformer part (where the copper windings are supposed to be for varnishing (as planned), but after peeling the yellow tape, I don't know of the dark yellow part (shown in picture below) are the wires already (just insulated), or just another kind of tape (I didn't bother to remove them anymore as I might just damage it more). So the varnishing plan is initially scrapped. Here is where my carelessness comes in:

I then re-attached everything back into place EXCEPT for the 2 ferrite cores from the small transformer. I wanted to test if those 2 ferrite cores were indeed the ones doing the vibration, hence I did not put them back.

I then plugged in the plate amp, and then turned it on. After a few seconds, I heard a loud "pop", as if a component exploded, so I turned off the amp immediately. The next day (to ensure that there was no stored energy for electrocution), I observed the Standby board to see on what chip/component might have exploded. I took me a while to find any physical damage, and unfortunately, of all the components to get destroyed, it seems it was the

U5 chip that got busted (there are very small burn marks in the board, more of black dust burns during the explosion)

So, there you go, another one bites the dust. I actually don't know what to do anymore, I should have left it alone huhuhu

(Note: Some excellent photos would not copy)

EVMan: Ouch! By omitting the ferrite cores, you radically lowered the transformer impedance. Low impedance = high current. Transistor Q1 is probably bad as well as IC Chip U5. Could have smoked the transformer windings as well. Can you possibly bend Q1 a little bit to get the part number and photo? This is why quality companies use transformer varnish . . . EVMan

RXV: Huhuhuhu it seems I really did a very bad decision in trying to "fix" it, which only got worse.

Based on your assessment, it seems that the Standby board itself is pretty dead and unusable by this point

Q1 is labelled: 13003 Fe 118

U2? I don't seem to find any U2 here, maybe you meant Q2?

Just in case, here's what's labelled into the

Q2: K130 C3198 GR

NOTE: Upon plugging (turning on) the amp, it only took around 2-3 seconds before the pop (explosion), in which I pulled the plugged immediately Other than the small burn marks on the U5, I haven't seen (or smelled) any other burn marks as well as any physical damage to the other components

EVMan: Hi RXV, how are you? Yes, your STANDBY board is bad now. Thank you for the part number info on Q1 & Q2. I have not been able to find good part numbers for U5 or Q1 (sorry about that- I meant Q2, not U2 in previous post). Parts Express does not carry any replacement parts for the SPA250. I have a working (I think) STANDBY board. That is one option. Another option is to contact the manufacturer directly and see if they will sell the STANDBY Board. I had all of their info and was going to contact them, but then I found C8 was bad and dropped it. Chinese manufacturers vary greatly. Some will DHL the board for free, others will not even acknowledge your message. Give me 24 hours to come up with a good idea.

RXV: All is NOT well: cry: That's one good reason why I shouldn't tinker on things I don't know about huhuhu.

Oh, really? You were able to track the manufacturer?

By chance, do they also sell the complete SPA250? (Just curious on how much they sell them VS Part Express price)

EVMan: Hey, don't feel bad, you are in learning mode. I did track the manufacturer before I found the bad C8 Capacitor. I am trying to "re-discover" that information. I do remember that they were in the New Territories outside of Hong Kong. I don't know the wholesale cost but my guess is around 50% of the PE sales price. If you remember, I asked if you ever traveled to Hong Kong. That was the reason why. I have been searching for three hours and identified 3 or 4 possible manufacturers. They are ranked most likely to least likely. I do believe it's the 1st company listed, but cannot prove it. Their offerings look similar and they have been in business the longest. It is also probable that the SPA250 is proprietary (no support- no schematics, no parts). Still working on it. You can check your amp for any company names . . . Good luck!

Vistron(Dong Guan) Audio Equipment Co.

Shenzhen Tianzhongtian Trading

Shenzhen Maoxing Weiye Technology Co., Ltd.

Foshan Yinchi Electronics Co.,

Rakoit Technology (sz) Co., Ltd.

Ningbo Mellisong Electronic Technology

Guangzhou Suiyu Technology Co., Ltd.

RXV: Hi, Wow! You're really on the hunt for the manufacturer, that takes real time and dedication

Yes, I'm sure Parts Express does have proprietary rights to that amp (to avoid customers just ordering direct from China instead)

May I ask out of curiosity, why did you choose to buy the used SPA250 parts from the seller here in DIYA? Did you need some of the components (for your actual SPA250)? Or you got it to just experiment on things?

Ok, I will also try to find for any labels or prints if there are any company names printed in the board

EVMan: How are you? I spent most of the day researching companies and comparing pictures of amps. Retirement means extra time for hobbies and it beats watching TV or solving crosswords. I am pretty sure that the first company listed is the right one (the other Parts Express DSP Plate amps are made by another company). I sent them an E-Mail asking if they sold any repair parts. Have not heard anything back from them yet. I also sent an E-Mail to Parts Express and this is what they said:

"Hello Miles, Thank you for this information. I am passing it on to the Dayton product team for their review. We cannot supply the name of our suppliers for any product. Repair parts are not available for any model. Dayton does handle any warranty issues on an exchange basis only. I am not aware of any changes or decision on this item by Dayton. As mentioned previously there have been changes over the years on the item and some of these may have addressed your concerns. Unfortunately, I do not have a list available of these changes."

I bought the old SPA for two reasons: (1) I was curious about the STANDDBY Board and (2) I thought you might need this part. This bad SPA is in terrible shape- it would cost more to fix than to buy a new one. However, the STANDBY Board still looks brand new. It is yours if you want it. I still need to finish the schematic. I think we should move most of this conversation back to the main post area. More people will see it and potentially more people will learn and contribute. EVMan

- Home

- Loudspeakers

- Subwoofers

- Dayton SPA250 Plate Amplifier repair help