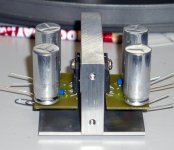

Metal part is 8.8" deep and 8.5 wide. Side panels are 0.8" thick.

To tell the truth it never even occur to me to mount the screws from the inside, I don't really like the perfectly clean look. Properly chosen screws adda bit more of a character to the overall appearance

If you check any Japanese stereo with side panels, you'll notice that screws are always mounted from the outside.

To tell the truth it never even occur to me to mount the screws from the inside, I don't really like the perfectly clean look. Properly chosen screws adda bit more of a character to the overall appearance

If you check any Japanese stereo with side panels, you'll notice that screws are always mounted from the outside.

some info for North West diyers

I went to the Boeing surplus store in Kent, WA and found an enormous amount of aluminum, titanium, steel, alloy steel and other metals in their scrapyard !!! very interestingly priced

also inside I found interesting deals such as 1U, 2U, 3U and more XU front panels in aluminum, different finish at $1.5 per pound!

I bought a few 2U and 3U plus two 12U front plates in brushed aluminum..... I thought the prices were very reasonable

I also bought ( the whole basket) electronics (Allen-Bradley) resistors but that's probably for Ebay, as I cannot see myself working through 1000 nds of them still in original packing of 100 of each value.... I paid much much less than the price of the cheapest resistors that RS has to offer!!!

they are all 0.5 Watts and 5% tolerance but, when putting some on he bench they gave pretty good results ( a 2K gave 2007 ohm)

J-P

I went to the Boeing surplus store in Kent, WA and found an enormous amount of aluminum, titanium, steel, alloy steel and other metals in their scrapyard !!! very interestingly priced

also inside I found interesting deals such as 1U, 2U, 3U and more XU front panels in aluminum, different finish at $1.5 per pound!

I bought a few 2U and 3U plus two 12U front plates in brushed aluminum..... I thought the prices were very reasonable

I also bought ( the whole basket) electronics (Allen-Bradley) resistors but that's probably for Ebay, as I cannot see myself working through 1000 nds of them still in original packing of 100 of each value.... I paid much much less than the price of the cheapest resistors that RS has to offer!!!

they are all 0.5 Watts and 5% tolerance but, when putting some on he bench they gave pretty good results ( a 2K gave 2007 ohm)

J-P

Peter Daniel said:I don't use it, as I prefer working in dry environment.

Translation: all those aluminum chips are a holy mess all over your saw when you use a lubricant. ^_^

Re: would I

Unfortunately, I can't answer this question for you

I hear slight difference in coupling caps, but never really tested it in PS. But anyway, it's not that big.

uvodee said:would I hear any difference when removing the film of the caps I use (mostly panasonic fc )

Unfortunately, I can't answer this question for you

I hear slight difference in coupling caps, but never really tested it in PS. But anyway, it's not that big.

Peter,

I never thought i'd see you working with PCB's again...

it is nice though... and i suppose if one wanted to go point to point

in this chassis, there's nothing stopping them

I can't wait to compare this amp against my brother's Krell integrated

-------

oh yeah, i knew there was a point to this post... what number are

we shooting for to make this a viable project? Last i looked at

the Wiki we were under 10 units......

I never thought i'd see you working with PCB's again...

it is nice though... and i suppose if one wanted to go point to point

in this chassis, there's nothing stopping them

I can't wait to compare this amp against my brother's Krell integrated

-------

oh yeah, i knew there was a point to this post... what number are

we shooting for to make this a viable project? Last i looked at

the Wiki we were under 10 units......

moe29 said:oh yeah, i knew there was a point to this post... what number are we shooting for to make this a viable project? Last i looked at

the Wiki we were under 10 units......

I updated the totals, and it is currently at 14 total, 10 finished and 4 unfinished.

--

Brian

I debated quite long how to populate rear panel and this is what I finally settled on. Initially I had in mind symatrical arrangement, but because the selector switch is on one side, it was logical to mount all RCAs at this end (to simplify wiring).

I also wasn't completely sure about mounting AC socket on the bottom panel. It limits the choice of power cord to be used as well in some situation when such cord is missing, prevents the usage of the amp.

So eventually I decided to mount the AC socket on the rear panel, right between binding posts. Although weired arrangement initially, it appears not too bad at all.

I also wasn't completely sure about mounting AC socket on the bottom panel. It limits the choice of power cord to be used as well in some situation when such cord is missing, prevents the usage of the amp.

So eventually I decided to mount the AC socket on the rear panel, right between binding posts. Although weired arrangement initially, it appears not too bad at all.

Attachments

The socket is mounted externally, but if panels will be CNC machined, it can be mounted from the inside as well, providing more elegant look. The only concern I have, that it's pretty close to volume control, but in reality I never encountered any problems with running AC cables side by side with interconnects and speaker cables.

Attachments

Re: some info for North West diyers

What a wonderful place ... last i was there i came away with a 12 foot lomg chunk of 8" square. 1/2" wall tubing to use for making chassis.

I might well ne intrested in some of hose before you eBay them... if i can figure what values i need. (EL84/6BM8/ECL86 amps)

dave

uvodee said:Boeing surplus store

What a wonderful place ... last i was there i came away with a 12 foot lomg chunk of 8" square. 1/2" wall tubing to use for making chassis.

(Allen-Bradley) resistors but that's probably for Ebay

I might well ne intrested in some of hose before you eBay them... if i can figure what values i need. (EL84/6BM8/ECL86 amps)

dave

Ropie said:Can you explain a little more about how you would mount the transformer?

I find these hardware from HD to be the most useful in mounting potted toroid. The bolt goes through the bottom, but since it's sort of decorative, it doesn't bother me.

Attachments

Hello Peter,

Cool amp chassis! How much is it for the finished/unfinished version? Does the finished/unfinished version have all the holes (speaker binding posts, rca jacks, iec plug, bottom feet, etc) pre drilled? If so, do you recommend the Cardas CTFA or GRFA-S female short thin nut rca and CCBPS short binding post?

Thanks

Cool amp chassis! How much is it for the finished/unfinished version? Does the finished/unfinished version have all the holes (speaker binding posts, rca jacks, iec plug, bottom feet, etc) pre drilled? If so, do you recommend the Cardas CTFA or GRFA-S female short thin nut rca and CCBPS short binding post?

Thanks

As I said, finished version shouldn't be more than $150. But untill I get a proper quote, I can't really tell. As to female RCAs I like CTFA short, but there is nothing to stop you from using GRFA ( which are actually closer to what I'm using in all my mainstreem projects).

CCBPS is a good choice for the binding post. All holes will be predrilled in a finished version of a chassis and 0.75" distance on 0.50" holes will be a standard.

CCBPS is a good choice for the binding post. All holes will be predrilled in a finished version of a chassis and 0.75" distance on 0.50" holes will be a standard.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Chassis for a group order of non-inverted GC kit?