Last edited:

when you gona bild them,you mensioned you got a few days off.

I will be getting the wood this week to start cuttng up also my speaker is not here yet

whats up.

@ post 83 cut the pannel at 90 degrees first,then cut the angle off.

personaly idd take it to the lumberjard,the have much better machines and skilz ,it might cost a bit more but it makes live so much easyer.

my cossin has a furniture facturie with great machines,huge sawtable's af all sorts and routers ect.

if you have that you can easely diy,if not bring it to the lumberjard. imo

personaly idd take it to the lumberjard,the have much better machines and skilz ,it might cost a bit more but it makes live so much easyer.

my cossin has a furniture facturie with great machines,huge sawtable's af all sorts and routers ect.

if you have that you can easely diy,if not bring it to the lumberjard. imo

oops internal pannels are 22 1/4 internal width

how would this sound

Loud

what is the difference between stacking 2per side and 3 per side

im not good in calculating ,with compression figures ect

but a sine wave @42 hz reach x-var @ 500 watts (no compression calculated.

since music is never a sine wave you could probably put 1000wats trough it whit no problems,i think even more.

th are known to give low excursion

So 4 cab should hit 140db with no problem with the mouth cut to 2700cm2

Last edited:

epa; btw your amp has to deliver more then 1000 watts clean per box to get there[/QUOTE said:I have two 2000wattt amps at 4 ohm is that enough

I am going over the plan, just to be sure the side measurement for the cab is 48"x31" 5/16

Last edited:

correct

if you have the side pannels cut,take a ruler and draw al the inside pannels on it.

you can check if all pannels fit,and you can pre-dril the holes,put nails left and right of lines so pannels stay in positsion when you screw them tight.

use the brown expanding glue then you dont need to close the gaps afterwards.

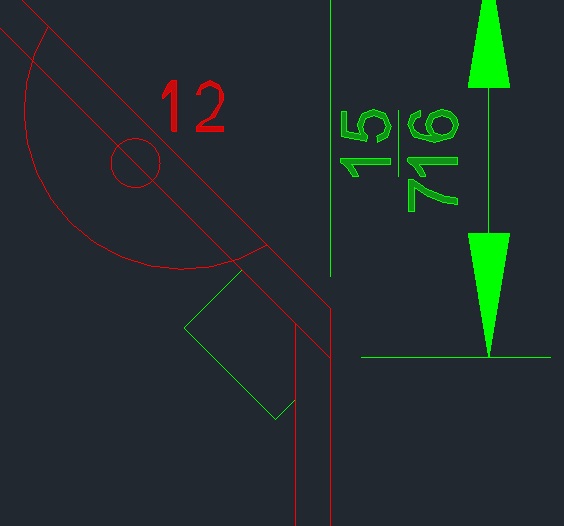

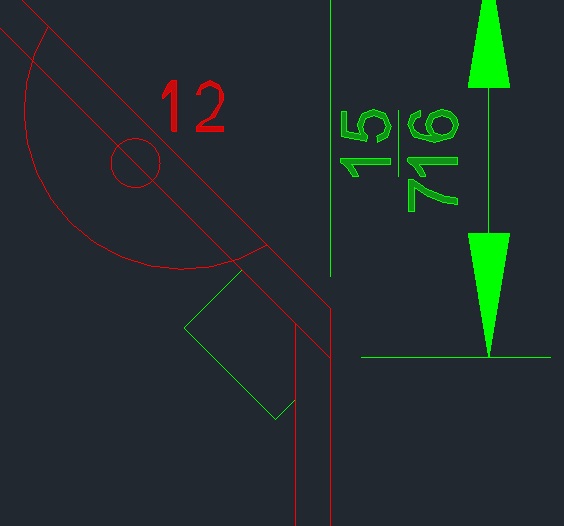

you might want to put a 1 1/2 by 2" buttan on panel 12 for security so jou dont break it out when lifting it @ the handels

if you have the side pannels cut,take a ruler and draw al the inside pannels on it.

you can check if all pannels fit,and you can pre-dril the holes,put nails left and right of lines so pannels stay in positsion when you screw them tight.

use the brown expanding glue then you dont need to close the gaps afterwards.

you might want to put a 1 1/2 by 2" buttan on panel 12 for security so jou dont break it out when lifting it @ the handels

Last edited:

correct

if you have the side pannels cut,take a ruler and draw al the inside pannels on it.

you can check if all pannels fit,and you can pre-dril the holes,put nails left and right of lines so pannels stay in positsion when you screw them tight.

use the brown expanding glue then you dont need to close the gaps afterwards.

you might want to put a 1 1/2 by 2" buttan on panel 12 for security so jou dont break it out when lifting it @ the handels

Thanks for the info.

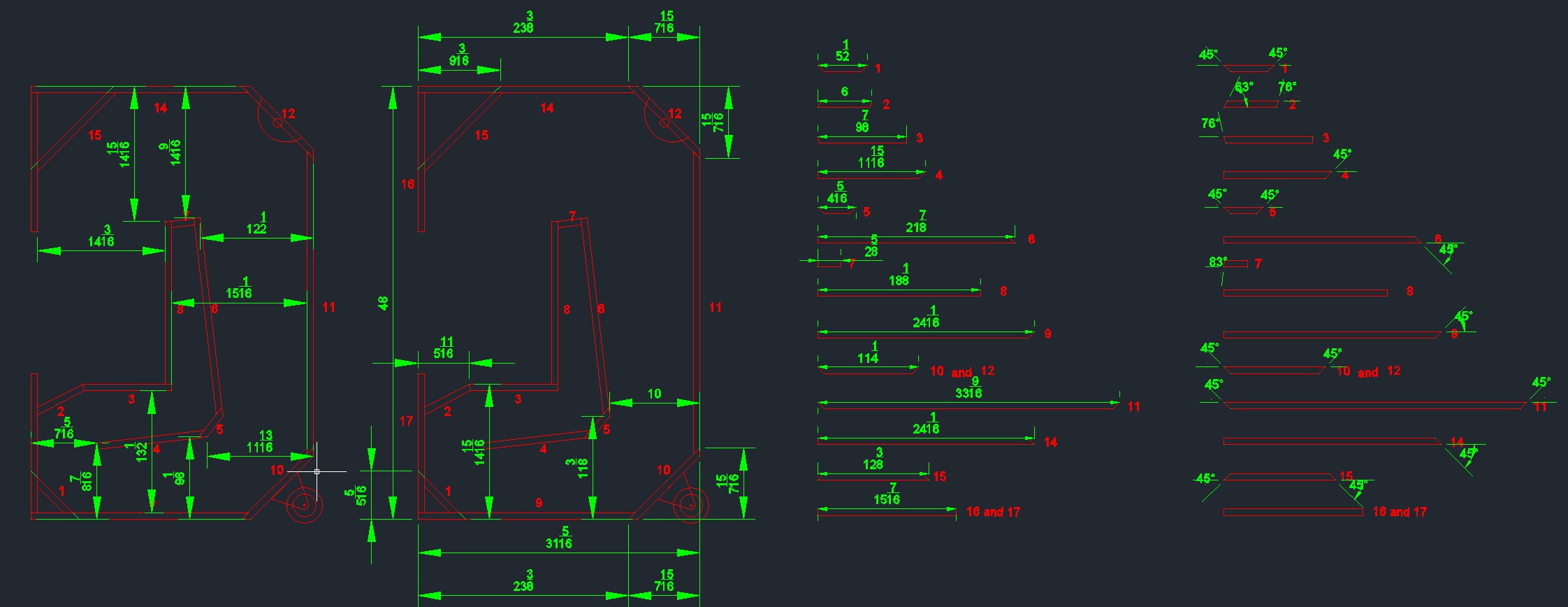

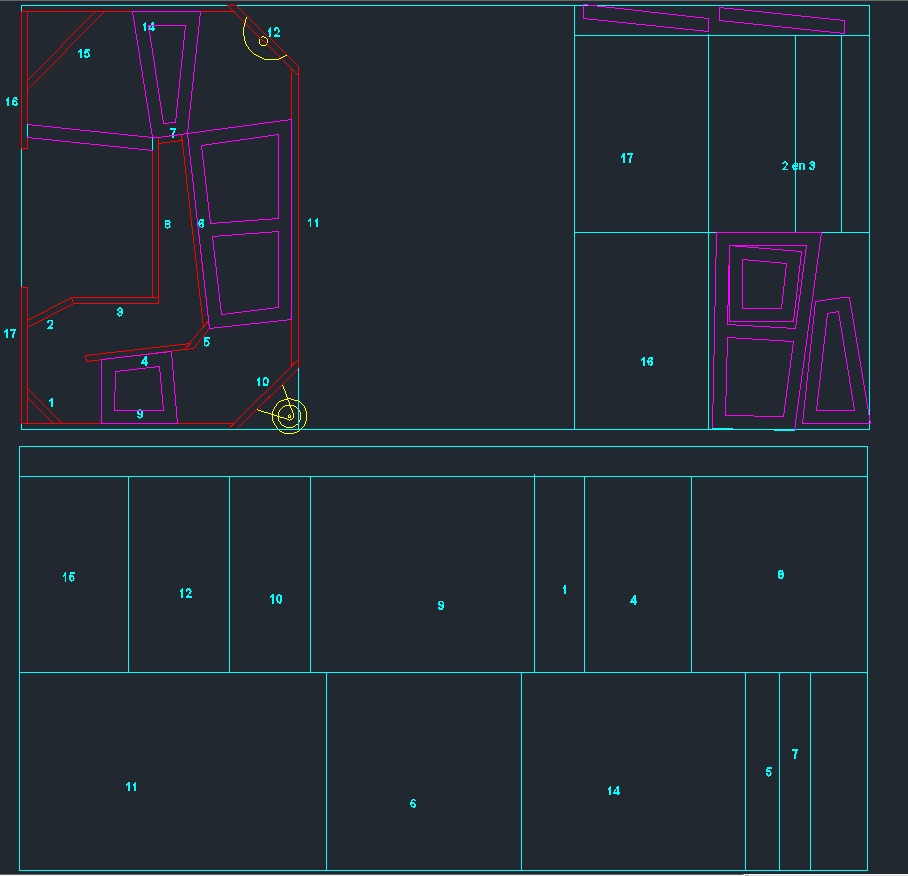

here is the saw plan

measurement wil follow

i made the 2 front pannels taller(mouthe becomes 2200 cm2),so you can cut off afterwards to the shape/area you like.

you can cut that after its bild.

i changed the top corner,its simpler and the handels wil take some volume,so you end up pretty much the same.

i updated the pic post 56 so you can see the bracings 3d

Looks like you made great use of those (2) 4x8 sheets!

Looks like you made great use of those (2) 4x8 sheets!5x5's are much cheaper on this side - I'll have to calculate if it's worth buying more of those or not.

CRESCENDO are you planing on building one.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 18TBX100 vs 2lab12