Member

Joined 2009

Paid Member

can they play vinyl?Not to forget the Kiwi Fisher & Paykel popularising Direct Drive top loaders....

Probably could be done [emoji23] you're tempting me nowcan they play vinyl?

Do Top-Loaders still exist ??

Had to reset my mind. A TopLoader is a 4-speed gearbox popular in drag racing.

Ah, dirty clothes! Yes, the default washer in a US appliance store, you throw your rags in the top. Standard size Top-load starts $400-$700. Front-load starts at $600 and up and up.

HomeDespot's Top Sellers (apologies if the site redirects UK viewers.)

A Laundromat machine (frontload) is $1500 w/coinbox. You can spend $1800 for 5.8cf black frontload w/steam and WiFi.

In Canada, 10 years ago yes. Not the case anymore. Top loaders are pushed to the back of the store. The front loaders use so much less water and less electricity that they are hard to argue with considering the price drop as of late.Yes, the default washer in a US appliance store, you throw your rags in the top.

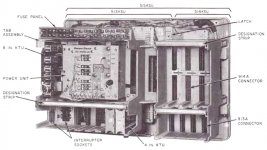

Open House H628 Termination Hub

Open House H619 RJ45 Telephone Interface Hub

Open House H312Kit 12-Inch Enclosure

I need to lose the bodge-job where five lines come off the inside box, and be able to disconnect lines to isolate problems....

Since that note the phone went out AGAIN. Not my fault-- lighting hit the box at the end of the street.

I also learned that the "test phone" I was using to verify at the pole is bad. Trashed with prejudice.

And the new patchbay is installed!! (For now.)

Bottom board splits the one line from the company box to a lot of mod-jacks. Top board takes lines coming down from the house to individual mod-jacks. Short jumpers let me make/break/test each one.

Yes, 8-wire mod-jacks are overkill for a one-line (2-conductor) household, but they are cheap enough from the network market.

The box, while low-price, is too big and hardly worth the money. I have already ordered a simple bracket to hold the two cards.

Attachments

The top load washer was half the cost of the front load washer.

Water cost in my part of the USA is pretty low. I only pay around $35/mo for water and garbage pickup combined.

I don't do but three loads a week, and most loads are low or medium water level. Water savings with front load would be minimal.

Water cost in my part of the USA is pretty low. I only pay around $35/mo for water and garbage pickup combined.

I don't do but three loads a week, and most loads are low or medium water level. Water savings with front load would be minimal.

In the UK we dont directly pay for refuse collection.

I'd guess water here in a Victorian terrace is maybe £50 to £75 a quarter.

But in modern properties where water is metered, then a 1 bed apartment is probably a similar cost.

I personally think Top loaders are ergonomically far better designed (for your back), just bulky for the typical UK home. I'm not even sure you can buy one in the UK any longer.

I'd guess water here in a Victorian terrace is maybe £50 to £75 a quarter.

But in modern properties where water is metered, then a 1 bed apartment is probably a similar cost.

I personally think Top loaders are ergonomically far better designed (for your back), just bulky for the typical UK home. I'm not even sure you can buy one in the UK any longer.

As I rent my apt, water (hot&cold) is free, so is heating, garbage etc.

But electrickery is expensive. We pay per kWh, but if one kWh is just a few lires, centimes or pennies, to this comes tax, and a special tax for using ”dirty electricity”. On top of the taxes that are on the level of the cost per kWh I pay VAT (tax-on-tax).

Next I have to pay a distribution fee to the company that transported the (probably pre-owned)electrons in their wires to my place + tax + VAT, making the distribution fee more expensive than my consumption of electricity.

But electrickery is expensive. We pay per kWh, but if one kWh is just a few lires, centimes or pennies, to this comes tax, and a special tax for using ”dirty electricity”. On top of the taxes that are on the level of the cost per kWh I pay VAT (tax-on-tax).

Next I have to pay a distribution fee to the company that transported the (probably pre-owned)electrons in their wires to my place + tax + VAT, making the distribution fee more expensive than my consumption of electricity.

Hi PRR,

Gee, I use a BIX-10A to hold the BIX-1A blocks and the BIX-5A I use for Bell line distribution. The lines are cross-connected to a Partner ACS-6 phone system in a 5 slot carrier. I might put the voice mail card back in if I get another number for my service work.

So there is the telecom / network area. It's funny how the more complicated these things look, the simpler they are to work with.

-Chris

Gee, I use a BIX-10A to hold the BIX-1A blocks and the BIX-5A I use for Bell line distribution. The lines are cross-connected to a Partner ACS-6 phone system in a 5 slot carrier. I might put the voice mail card back in if I get another number for my service work.

So there is the telecom / network area. It's funny how the more complicated these things look, the simpler they are to work with.

-Chris

Attachments

> I use a BIX-10A to hold the BIX-1A blocks

Huh. I may have seen a BIX once; not where I could touch it. (The PBX I knew best was a W.E. A1(?) with whirring motor and clacking relays.)

For a larger rig, that BIX stuff would be nice. I just have one line to 5 jacks, but *need* easy disconnect to diagnose the former owner's crapwire when trouble develops.

Huh. I may have seen a BIX once; not where I could touch it. (The PBX I knew best was a W.E. A1(?) with whirring motor and clacking relays.)

For a larger rig, that BIX stuff would be nice. I just have one line to 5 jacks, but *need* easy disconnect to diagnose the former owner's crapwire when trouble develops.

Hi PRR,

The BIX is more of a Canadian thing, so I'm not surprised you haven't seen many. Better wire retention than the older "66" block. I hate them actually. The device you have uses "110" blocks, which is most commonly used in CAT-5/6 jack panels. Another really good connector system with good wire retention from being pulled out accidentally. The biggest difference between the 110 / BIX and your connectors would be the inclusion of the "mod plugs". Easier for you to troubleshoot. We would normally pull cross-connect wire off, then re-punch it if that line was okay, or leave it disconnected until the problem was located and corrected. Mod plugs take up too much room and are a potential source of failure or noise. That and the desire of some folks to play "operator".

Did you know that BIX labels have a meaning per colour used? So does the cross-connect wire. I worked for a company that was once part of ITT, so we followed their conventions and standards. You could walk up to any of my installations and tell what was going on with a quick look, same for any company, like Bell Canada up here for example. These days I see technicians using the wrong colours or any colour for their connections. I desperately hope that they have to come back in a few years and trace a fault.

At any rate, yours is a clean job. Mine is a mess since I'm often changing something, but that is the messiest it gets. Imagine a wall filled with BIX-10A carriers fully loaded. We have some sites like that and it is a matter of survival to follow a strict wiring plan. BIX-10A carriers have a set layout plan in quads separated by "D" rings to guide wiring. It can look pretty awesome if you stand back and look at the entire thing.

Sorry, I bet you didn't want or care to know that much about phone wiring.

-Chris

The BIX is more of a Canadian thing, so I'm not surprised you haven't seen many. Better wire retention than the older "66" block. I hate them actually. The device you have uses "110" blocks, which is most commonly used in CAT-5/6 jack panels. Another really good connector system with good wire retention from being pulled out accidentally. The biggest difference between the 110 / BIX and your connectors would be the inclusion of the "mod plugs". Easier for you to troubleshoot. We would normally pull cross-connect wire off, then re-punch it if that line was okay, or leave it disconnected until the problem was located and corrected. Mod plugs take up too much room and are a potential source of failure or noise. That and the desire of some folks to play "operator".

Did you know that BIX labels have a meaning per colour used? So does the cross-connect wire. I worked for a company that was once part of ITT, so we followed their conventions and standards. You could walk up to any of my installations and tell what was going on with a quick look, same for any company, like Bell Canada up here for example. These days I see technicians using the wrong colours or any colour for their connections. I desperately hope that they have to come back in a few years and trace a fault.

At any rate, yours is a clean job. Mine is a mess since I'm often changing something, but that is the messiest it gets. Imagine a wall filled with BIX-10A carriers fully loaded. We have some sites like that and it is a matter of survival to follow a strict wiring plan. BIX-10A carriers have a set layout plan in quads separated by "D" rings to guide wiring. It can look pretty awesome if you stand back and look at the entire thing.

Sorry, I bet you didn't want or care to know that much about phone wiring.

-Chris

...The device you have uses "110" blocks, which is most commonly used in CAT-5/6 jack panels.

Hence common, familiar (to me), and cheap. (Usually good quality, unlike dollar-store phone jacks/wire.)

biggest difference between the 110 / BIX and your connectors would be the inclusion of the "mod plugs". Easier for you to troubleshoot. We would normally pull cross-connect wire off, then re-punch it if that line was okay

Pulling wires out/in 110 is easier than the former screw-block or these darn Scotchloks the last tech used, but not as swift as mod-jacks. Also a phone can plug-in at any point for troubleshooting. (I have not got a buttset with telco probes, yet.)

yours is a clean job.

Sorry, I bet you didn't want or care to know that much about phone wiring.

I described the job to a friend and he wrote the opposite: "You sound like someone very much into phone lines, LOL! I understand what you described for the most part, but that was some esoteric stuff! I do understand one thing completely - that a screwed-up phone line is a BUMMER." He was having router problems...getting hot, restarting, etc. Turned out to be a bad splice in the phone wire, in fieldstone foundation and crawlspace. The whole wire insulation was falling apart. A testimony to plastics of the 1950s. He unrolled a new one.

Yes, it was a W.E. 1A1 PBX where I worked. You knew when ringers were pulsing by the whirCLAKwhirCLAK.

Attachments

Last edited:

Hi PRR,

I wish I had a picture of a rotary contactor switch we found in the basement of a water treatment plant! You would have appreciated that. It was probably 6' high with "floors" of switches.

You got the noise they make right on! I bet it was a loud room when the phones were busy!

Rotting phone lines were a massive pain. My area covered some ancient wire installations. When we located a bad line and reported it, they would just move the bad pair to another line. It got so I could follow the bad pair around. They wouldn't replace the lines due to the capital expenditure. They did lay off that customer once I told them what was going on and that I had been following the moving bad pair for months. They had 23 lines and the bad luck to be on the one BIX (25 pairs) connector, so the smarty-pants techs didn't realize that they were doing was something so obvious.

Most of the street wiring was on old "66" blocks that only held the wire by the conductor. So you would be punching one pair down and you might see a wire float away from the wall. Damn! Entire walls of corroded copper wire. It really didn't help that the wire had 35VDC ~ 50 VDC across the pair at rest. Corrosion was very quick if water began leaking down the wall. A real nightmare, and working by flashlight just to make life less enjoyable.

-Chris

I wish I had a picture of a rotary contactor switch we found in the basement of a water treatment plant! You would have appreciated that. It was probably 6' high with "floors" of switches.

You got the noise they make right on! I bet it was a loud room when the phones were busy!

Rotting phone lines were a massive pain. My area covered some ancient wire installations. When we located a bad line and reported it, they would just move the bad pair to another line. It got so I could follow the bad pair around. They wouldn't replace the lines due to the capital expenditure. They did lay off that customer once I told them what was going on and that I had been following the moving bad pair for months. They had 23 lines and the bad luck to be on the one BIX (25 pairs) connector, so the smarty-pants techs didn't realize that they were doing was something so obvious.

Most of the street wiring was on old "66" blocks that only held the wire by the conductor. So you would be punching one pair down and you might see a wire float away from the wall. Damn! Entire walls of corroded copper wire. It really didn't help that the wire had 35VDC ~ 50 VDC across the pair at rest. Corrosion was very quick if water began leaking down the wall. A real nightmare, and working by flashlight just to make life less enjoyable.

-Chris

Midimuso CV-12 ORAC (MIDI-to-CV converter)

Read too late in the docs that this thing is only pitch-accurate to within a few cents, hmm. Hopefully it won't drive me crazy until I can get my old Aries (analog) keyboard working again.

Read too late in the docs that this thing is only pitch-accurate to within a few cents, hmm. Hopefully it won't drive me crazy until I can get my old Aries (analog) keyboard working again.

...a rotary contactor switch we found...

The 1967 Mercury Cougar had the sequential 1-2-3 turn-signals.

A rubber mat in the mud-pocket behind the rear wheel had a phenolic board with a gear-motor, cams, and microswitches.

The phenolic warped after 20 damp years and didn't sequence.

On top of all the other old-Ford wiring faults. I have a picture of me with the whole tail harness draped on my shoulders while I peer into a microfilm reader (Helm didn't have paper manuals for that car anymore).

By 1970 Cougar had a transistor sequencer, but the connectors had changed. Bending the cam-fingers to match the warp did not take long.

......getting a blown wheel bearing fixed......Especially for a $10 bearing.

Wheel bearings for a non driven wheel used to be $5 and you could change them yourself on the side of the road with common tools.....I did that once in the 70's.

The front wheel bearing on a modern FWD car (4WD in this case) is a $50 to $150 part depending on where you buy it, and it must be pressed into the hub with a hydraulic press. The hub mist be removed from the car to do this which requires some serious disassembly, usually involving removing a half shaft and possibly the front strut. When I was younger and did such stuff myself I could do everything except the bearing press. I had to take the parts to a shop.

I hope the rest of your time is spent the way you planned.

Yes, we got back late last night. Much fun was had despite tropical storm Barry. I was playing in 4 to 6 foot waves with 40 MPH winds on Florida's gulf coast, something that "never happens." Ever see surfers and kite boarders in the gulf waters?

I was out in the water beyond the breakers when a Lee County Sheriff's deputy approached my wife and her friends asking them if the idiot in the water (me) belonged to them. When she said yes, he told them that a person had drowned while saving his family (true) less than a mile from where I was, then he left. After thinking about it, I realized this man's tact. He could have screamed at me through his bull horn creating a possible hostile situation. Instead he instilled fear in the females present and let nature take it's course. I got out of the water.

Note....I spent 40+ years of my life playing in the Atlantic ocean where this surf (and it's perils) was the norm....but I was much younger.

... HA-4700, four output headphone amplifier.......Many of B-ringer's products are stolen wholesale from others.

Their clones of vintage music synthesizers seem to prove this point. The "Model D" is not a direct copy of the original Minimoog Model D. It borrows some of it's circuitry and SMD tech from some later synths notably the Taurus, and adds MIDI and several other improvements. I have a B-ringer Model D and have been carefully examining it's circuitry, since I can't afford to rip apart an original. I'm looking at using it's circuits to drive some of my own Eurorack designs.

Note that I'm avoiding the use the company's name on purpose....

Last edited:

- Home

- Member Areas

- The Lounge

- And what did we buy today?