Could you expand on what you mean by the "square" in #912?

The design is actually a 4-pivot solution, with 2 pivots stationary and the other 2 travelling, hence the square-tag. I know that the correct name should have been rombe, but when I typed I had simply forgot the geometric name.

Steen

Steen - it's just as well you used "square." I sort of understood what you meant. On the other hand, if you had written "rombe" - well let's just say "square" was better. I think your finding parallels JCarr's posts a couple of pages back that a longer pivot and shorter swing arm means better accuracy. My only concern is about building something that can handle that much cantilever. This geometry may allow that load to be shared between the two stationary pivots.

phivates - hey, it's good to know you're still checking in. If you look at the photos of the two arms I posted back a ways, you'll see three screws in the bases. Those screws allow a very small amount of bias to be dialed in that deals with the side forces. I use a blank LP side to make the adjustments and when it's set up correctly, the stylus stays still at any point.

phivates - hey, it's good to know you're still checking in. If you look at the photos of the two arms I posted back a ways, you'll see three screws in the bases. Those screws allow a very small amount of bias to be dialed in that deals with the side forces. I use a blank LP side to make the adjustments and when it's set up correctly, the stylus stays still at any point.

DD - as always, thanks for starting this thread and helping to keep it alive. A lot of what I've done wouldn't have been possible without the photos you've found and posted and the encouragement I've gotten here.

You're thanking me?! I have to thank YOU for materializing some of the concepts from this thread. I'm just an armchair quarterback but you're the one who makes real touchdowns! Your 4 pivot project is by far the simplest and most elegant DIY tangential arm I've seen here.

Regarding the 4 point pivots, I know in your design the front stationary pivot is the main base and the back stationary pivot is really acting like a guiding mechanism. Have you thought of making TWO bases for rigidity and place the vertical arm on the midpoint of the joint segment? (Or even implementing a Simon Yorke type of guided unipivot?) I'm curious if this approach can help rigidity as the cantilever arms are more solid this way for the three segments while working in unison. Maybe additional stronger bearings complicate things and yours is probably ideal already. I also would like to see a tower like hanging structure for the 4 pivots and have the vertical arm below it then you're less concerned with platter to plinth height. Think of the Schroder LT with a pivoting tower. Sorry, I'm rambling and thinking out loud here.

Hi,

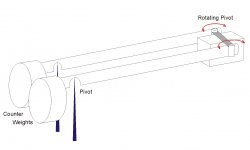

Pardon me for quick drawing, but in following concept if rotating pivots are very precisely made we can make good linear tracking tonearm. Two Counterweight are separate and tone arm rests on two fixed pivots. We can calibrate two counterweight (being separate) by test record.

Regards

Pardon me for quick drawing, but in following concept if rotating pivots are very precisely made we can make good linear tracking tonearm. Two Counterweight are separate and tone arm rests on two fixed pivots. We can calibrate two counterweight (being separate) by test record.

Regards

Attachments

......are you going with anti-skate not required or not important?

FM

If the design manage to obtain exact tangential tracking, no skate compensation would be necessary (in theory).

Some of the stuff I need to actually build this arm is now ordered, but delivery will be four weeks ore more

Steen

I've built the main pivot mechanism and will add the vertical pivot box tomorrow.

I still feel that I want to put a counterweight onto pivot 1 as all the weight is hanging off one side of that. In theory, the bearing is strong enough but it just feels like good insurance to equalise the weight. Once the arm is hanging off the other side as well, it adds up to a bit. I do appreciate that the other three bearings are also adding some support.

Does anyone think it necessary or is it a bit over the top??

It certainly helped smooth up the action on my previous (er...wrong) effort.

I still feel that I want to put a counterweight onto pivot 1 as all the weight is hanging off one side of that. In theory, the bearing is strong enough but it just feels like good insurance to equalise the weight. Once the arm is hanging off the other side as well, it adds up to a bit. I do appreciate that the other three bearings are also adding some support.

Does anyone think it necessary or is it a bit over the top??

It certainly helped smooth up the action on my previous (er...wrong) effort.

Last edited:

If the design manage to obtain exact tangential tracking, no skate compensation would be necessary (in theory). ...

Steen

Not so, not even in theory. Skating force arises when the stylus drag force vector (which is tangent to the groove) is not in line with the horizontal pivot. The drag force then acts upon a lever arm whose geometry is determined by the arm length, offset, and overhang. This sets up a twisting moment about the horizontal pivot, which manifests itself as what we know as skating. This condition occurs whenever an arm’s geometry includes an offset angle and overhang, which is the standard accepted design prescription for reducing angular tracking error in conventional pivoted arms. Stylus drag in a true linear tracking arm doesn’t resolve into any skating force because it doesn’t act on any lever arm to cause a twisting moment about a horizontal pivot.

If you analyze arms that employ ‘multiple linkage’ design methods aimed at eliminating angular tracking error, you invariably find that the stylus drag force vector does not pass through the horizontal pivot (at least not everywhere), and thus inevitably does end up creating some torque artifact that resolves into skating force, much the same way as conventional pivoted arms. Multiple linkage systems are also likely to have higher amounts of friction/sticktion which can mask the effects of skating that do exist and lead one to an erroneous conclusion that the reduction or elimination of angular tracking error alone eliminates skating force. So yes, even if the arm maintains perfect tangency across the record surface, you would still need some form of antiskate.

If the design manage to obtain exact tangential tracking, no skate compensation would be necessary (in theory).

diyrayk explains better than I can in the previous post but I just want to add Conrad Hoffman's earlier posts that give a better visual idea:

If you draw a line, or at least a vertical plane, through the stylus/cartridge and it doesn't intersect the arm pivot, you've got forces you don't want.

Still, to beat my dead horse, if the arm pivot is fixed, and if the cartridge tracks tangentially, skating forces will be generated at all but one point. Ain't no escape from that simple geometry problem via mechanical means, at least that I can think of.

Until someone can create an arm that can magically lengthen or shorten (segment "t") with only one pivot in this genre of Tangential Pivot Tonearm (TPT), skating force will always exist, just a matter of degree. It doesn't mean it's not a worthy pursuit, of course. To lessen skating force, I believe the pivot point should be as close to "P" as possible.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

To make it look like record playing, I flipped the image, taken from Wikipedia, to illustrate the point better.

An externally hosted image should be here but it was not working when we last tested it.

If the design manage to obtain exact tangential tracking, no skate compensation would be necessary (in theory).

I stand corrected.

dyyrayk and directdriver has done the explaining, and I wont argue

Steen

Instead of pivots near each other, wouldn't pivots at the Cartridge end move cartridge effortlessly with minimum load ? Just Like Garrard Zero Tonearm. Kind of like longer lever will require less effort to rotate the cartridge.

Problem being the pivot is so close to the stylus that might introduce noise. Bearing quality is paramount at that position. The Thales arms and Garrard Zero 100 are known for that genre, which is discussed extensively in many earlier posts in this thread. Go check them out. Another issue is that it has higher skating force than the Birch variants and an antiskating device is required.

...if rotating pivots are very precisely made we can make good linear tracking tonearm. Two Counterweight are separate and tone arm rests on two fixed pivots. We can calibrate two counterweight (being separate) by test record.

Your concept is similar to the Thales Simplicity tonearm (or the Van Eps arm) except yours uses two unipivot bearings. I think it's a good idea due to its simple bearing and low friction. But I would use one main arm and the other one being a skinnier secondary arm without counterweight, just acting like a guide and stabilizing azimuth. The majority of the mass falls on the main bearing. The headshell pivot would be right above the stylus tip. Thales Simplicity claims the use of two equal arms for tuning resonance and the two counterweights have embedded magnets for antiskating purpose.

Thales Simplicity tonearm

An externally hosted image should be here but it was not working when we last tested it.

Van Eps tonearm

Last edited:

Thanks DirectDriver for the insight. Have been following various tonearm designs and have learned great things from the forum itself. Mine was just an alternative or extension.

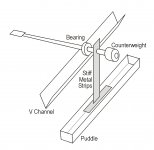

Here is another concept. Don't know how stable the arm would be. This uses 'Single' bearing and metal strips in liquid to balance the arm so azimuth doesn't change and also dampens the vibrations. Bottom strip is flat horizontal so it resist the rotational movement and Vertical strip runs parallel to the liquid so has least resistance. Again don't know how much stable it would be.

Best regards.

Here is another concept. Don't know how stable the arm would be. This uses 'Single' bearing and metal strips in liquid to balance the arm so azimuth doesn't change and also dampens the vibrations. Bottom strip is flat horizontal so it resist the rotational movement and Vertical strip runs parallel to the liquid so has least resistance. Again don't know how much stable it would be.

Best regards.

Attachments

Mr Tidy

My music room seems to be getting a bit beyond help. Ronnie suggested that cleaning 'that' room is now down to me as she can't work round stuff!!

She may be right but with so much playing going on, its hard - for me at least - to keep things tidy.

There are now six TTs visible in this shot!! The test deck has three arms, including the new tangential one which is going to have to wait for its wires for a day or so.

I have some work to do to the house, which, I am told, takes priority over yet another piece of audio equipment. I haven't reminded her that our linear tracker is on it's way from the UK. After its latest update, it will be rather difficult for me to ignore it's presence when it arrives. Better get some plastering done quick!!

My music room seems to be getting a bit beyond help. Ronnie suggested that cleaning 'that' room is now down to me as she can't work round stuff!!

She may be right but with so much playing going on, its hard - for me at least - to keep things tidy.

There are now six TTs visible in this shot!! The test deck has three arms, including the new tangential one which is going to have to wait for its wires for a day or so.

I have some work to do to the house, which, I am told, takes priority over yet another piece of audio equipment. I haven't reminded her that our linear tracker is on it's way from the UK. After its latest update, it will be rather difficult for me to ignore it's presence when it arrives. Better get some plastering done quick!!

An externally hosted image should be here but it was not working when we last tested it.

9" tonearm with no tracking error, but what to do with the friction pulling the arm joint open..??

One thing that is really bad with this thinking is that all records are off centered, and if you look at the needle it sways much more than what 1-degree tracking error from a 10" radial arm would even deliver. personally I don't see the benefit in no/low tracking error at the expense of added complexity or the non solid nature of the bearing in linear trackers.

One thing that is really bad with this thinking is that all records are off centered, and if you look at the needle it sways much more than what 1-degree tracking error from a 10" radial arm would even deliver. personally I don't see the benefit in no/low tracking error at the expense of added complexity or the non solid nature of the bearing in linear trackers.

Attachments

9" tonearm with no tracking error, but what to do with the friction pulling the arm joint open..??

One thing that is really bad with this thinking is that all records are off centered, and if you look at the needle it sways much more than what 1-degree tracking error from a 10" radial arm would even deliver. personally I don't see the benefit in no/low tracking error at the expense of added complexity or the non solid nature of the bearing in linear trackers.

Given all the technical problems may or may not be a deciding factor....... we do it:

a) because it's there

b) because it sounds better

c) because were all crazy - OK

I have one or two arms and have listened to many more. All the best sounding ones were linear trackers, followed by the longer radial arms. In spite of the fact that I like playing with toys, when it comes down to it, it is the music and the sound thereof that is the most important thing.

All this experimenting just might lead to something that sounds better still. Who knows?

Thanks DirectDriver for the insight. Have been following various tonearm designs and have learned great things from the forum itself. Mine was just an alternative or extension.

Here is another concept. Don't know how stable the arm would be. This uses 'Single' bearing and metal strips in liquid to balance the arm so azimuth doesn't change and also dampens the vibrations. Bottom strip is flat horizontal so it resist the rotational movement and Vertical strip runs parallel to the liquid so has least resistance. Again don't know how much stable it would be.

Best regards.

I have almost same idea as yours and I don’t think yours works because you don’t have a linear guide. In fact, I already got some parts for this kind of arm, but I like air bearing so much that I am building 2nd one with different construction. If you are interested, I can post my idea later on.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms