Hi,

This is stuff that's been talked about before here and should be one of the first things you should understand about tubes before you touch them, not after.

And no, like most other things in life, nothing's ever truly black or white....

Cheers,

Which is why I took up the issue. It's something we should all know, the level of knowledge we posses, yet it keeps coming up. So I wanted a definite thread, or actually a statement, to let all know we don't need standby switches...at least not for the tube's sake. (Many other reasons, they've been mentioned earlier in the thread).

The 6CJ3 works good in a 6DW4 socket. A 6DW4 is OK so long as the 250mA dc rating (instead of 350mA) is enough for your application.

Having said that, the boxes my GE 6CJ3 came in say "6CJ3/6DW4", so maybe a later data sheet made them equivalents.

In a hybrid bridge, each diode only sees half of the current, so you could just check that the rated 1300mA current peaks are not exceeded, using your value of capacitance. Use Duncan Amplification PSU designer software to check peak current.

Having said that, the boxes my GE 6CJ3 came in say "6CJ3/6DW4", so maybe a later data sheet made them equivalents.

In a hybrid bridge, each diode only sees half of the current, so you could just check that the rated 1300mA current peaks are not exceeded, using your value of capacitance. Use Duncan Amplification PSU designer software to check peak current.

The datasheets I have are 6CJ3 GE and 6DW4 RCA. The tubes I received are 6DW4 RCA, so I made a second order, this times for GE tubes with 6CJ3 printed on the box. 250mA constant current of 6DW4 may be enough and it may not be enough, since I haven't built the amp yet. 350mA of 6CJ3 gives me enough headroom.

No, I think you need to reread the whole shebang. This is not a thread about IBM, Microsoft, or cathode ray tubes.

It's about B+ on cold cathodes in indirectly heated tubes.

Oh, and wether someone knows or believes a cathode should be hot, or is ok cold, has nothing to do about how he designs and builds tube circuits. It's only of interest in regards of the tube's life.

I know all there is to know about tubes, have been for ten years, still I learn something new all the time. Next year I'm sure I'll wonder over all the things I know that I didn't just a year prior...just like you[/QUOTE]

Hopefully, within ten years, you'll teach me something then.

From now on, you're on your own, kiddo.

Cheers,

I have read a lot of pages of this thread (not all of them). I was thinking to do the following:

(1) Include a soft start circuit to protect the rectifiers and the reservoir, not the tubes. (still, I read that this could do harm)

(2) Include a delay circuit for the speakers, to protect them from pops - this should also work just before B+ is off.

(3) Soft-start the filaments.

(4) Include a standby mode, not to protect any tubes, but to save energy while not using the amp - I could be referring to Morgan Jones implementation of a RIAA preamp, where he keeps filaments down to 4V. Of course, this means that the mains soft start should be quite quick, in order not to wait too long before the amp is usable again.

Which of these seem harmful or weird? I am a bit confused having read things on the topic.

(1) Include a soft start circuit to protect the rectifiers and the reservoir, not the tubes. (still, I read that this could do harm)

(2) Include a delay circuit for the speakers, to protect them from pops - this should also work just before B+ is off.

(3) Soft-start the filaments.

(4) Include a standby mode, not to protect any tubes, but to save energy while not using the amp - I could be referring to Morgan Jones implementation of a RIAA preamp, where he keeps filaments down to 4V. Of course, this means that the mains soft start should be quite quick, in order not to wait too long before the amp is usable again.

Which of these seem harmful or weird? I am a bit confused having read things on the topic.

Last edited:

Wow. More questons than answers, it seems.

I finally came into the coin to dive into my own tube amp. Tube life is, obviously, a huge concern. I'm quite able to solder up whatever I may, but the question is what may that be. Seems nobody knows nutt'n, but there are a lot of people with ideas and some good, and maybe not so good, justifications for holding them. So, I too know nutt'n, and have ideas...

I have a sense this might get a bit long, I apologize...

So, why do tubes fail? They obviously do, and the given answers are...

- Filament failure. Happens, rumored to be quite rare.

- Arc over. From the sound of it - not so rare.

- Gas. Happens, I guess.

- Emissions decay. Seems to be the "ripe 'ol way out".

- Unspecified "Rattling dead one's". Heard 'em myself.

- Dropped on Floor. Pop - done.

The problem is pretty clear. We are dealing with a multi-variant problem. A problem with multiple variables, unknowns, multiple interrelationships, and mostly dealing with probabilities. A nice social game of perpetual "whack a mole" if I've ever seen one. Analysis oftentimes does work, and yes scientific studies would be nice, but unlikely.

So what does/might a standby switch accomplish?

It turns the heaters on before the B+ ...

Ok, so what does that do for us?

The main argument seems to be "it prevents cathode stripping and/or poisoning". Ok, but... It also preheats the assembly, if mainly the heater and grid structures. It starts preheating the rest of the assembly, and getter too. It starts heating internal gases, envelope, and pins as well. The heater is generally the most gentle heat source in the tube, btw.

Oh, and yes, it can provide instant gratification.

And, what might any of that stuff accomplish (for the tubes)?

- Cathode stripping is bad. Given. But that happens, I've seen suggested, by high energy positive ions smashing into the cathode and tearing it apart. In a cold tube, without B+, what's creating these ions, exactly? No B+, so no high energy electrons to smash into gases, so no positive ions. If you apply B+ first, you have minimal emission, what with a cold cathode and all, so while perhaps not "none", you surely don't have many ions at this point either. "Energy" matters too, a boulder dropped from a roof (10V) and that same bolder dropped from the ork cloud (1000V) will surely do different amounts of damage. How hot is hot?

- Cathode poisoning is bad. Also given. Now, I do believe, the oxide coating does contain gettering elements. Heating it while it is unable to build a protective charge cloud could be "bad". It could start out-gettering the cold getter.

- Preheating the assembly wouldn't seem to do much - unless you ramp the heater voltage over a fair bit of time. Slow heating would reduce thermal stresses as the heat shock dissipates through the assembly at a lower delta peak temperature. Thermal expansion is more closely matched between the components, fewer welds are likely to break, and grids are less likely to be longitudinally compressed between supports that haven't yet expanded in length. Ramp heating the remaining components is probably a good idea too, except, perhaps, for the getter. The getter really just needs be hot 24x7.

How might we mitigate any of that bad stuff, just saying, in case it really is happening? I mean, really, turn heater on and they getter, don't and they strip. Really, what's one to do with that fancy new $500 tube?

Well, I'd think as far as positive ion terrors, you could pre-charge the grid to the tubes cutoff voltage. That would put a nice fuzzy force field around your ever so delicate cathode - hot or not. Then apply B+. Nice thing about a cutoff grid is when B+ does hit you'll reduce, or eliminate, the peak pulse. You'll also allow the charge cloud to build as the heater gets hot, without initially precious electrons being pointlessly pulled to the anode. Then, you can ramp the grid to your operating bias setting, slowly, allowing the plate to absorb a slowly increasing idle current and more gently heat soak the plate assembly.

I finally came into the coin to dive into my own tube amp. Tube life is, obviously, a huge concern. I'm quite able to solder up whatever I may, but the question is what may that be. Seems nobody knows nutt'n, but there are a lot of people with ideas and some good, and maybe not so good, justifications for holding them. So, I too know nutt'n, and have ideas...

I have a sense this might get a bit long, I apologize...

So, why do tubes fail? They obviously do, and the given answers are...

- Filament failure. Happens, rumored to be quite rare.

- Arc over. From the sound of it - not so rare.

- Gas. Happens, I guess.

- Emissions decay. Seems to be the "ripe 'ol way out".

- Unspecified "Rattling dead one's". Heard 'em myself.

- Dropped on Floor. Pop - done.

The problem is pretty clear. We are dealing with a multi-variant problem. A problem with multiple variables, unknowns, multiple interrelationships, and mostly dealing with probabilities. A nice social game of perpetual "whack a mole" if I've ever seen one. Analysis oftentimes does work, and yes scientific studies would be nice, but unlikely.

So what does/might a standby switch accomplish?

It turns the heaters on before the B+ ...

Ok, so what does that do for us?

The main argument seems to be "it prevents cathode stripping and/or poisoning". Ok, but... It also preheats the assembly, if mainly the heater and grid structures. It starts preheating the rest of the assembly, and getter too. It starts heating internal gases, envelope, and pins as well. The heater is generally the most gentle heat source in the tube, btw.

Oh, and yes, it can provide instant gratification.

And, what might any of that stuff accomplish (for the tubes)?

- Cathode stripping is bad. Given. But that happens, I've seen suggested, by high energy positive ions smashing into the cathode and tearing it apart. In a cold tube, without B+, what's creating these ions, exactly? No B+, so no high energy electrons to smash into gases, so no positive ions. If you apply B+ first, you have minimal emission, what with a cold cathode and all, so while perhaps not "none", you surely don't have many ions at this point either. "Energy" matters too, a boulder dropped from a roof (10V) and that same bolder dropped from the ork cloud (1000V) will surely do different amounts of damage. How hot is hot?

- Cathode poisoning is bad. Also given. Now, I do believe, the oxide coating does contain gettering elements. Heating it while it is unable to build a protective charge cloud could be "bad". It could start out-gettering the cold getter.

- Preheating the assembly wouldn't seem to do much - unless you ramp the heater voltage over a fair bit of time. Slow heating would reduce thermal stresses as the heat shock dissipates through the assembly at a lower delta peak temperature. Thermal expansion is more closely matched between the components, fewer welds are likely to break, and grids are less likely to be longitudinally compressed between supports that haven't yet expanded in length. Ramp heating the remaining components is probably a good idea too, except, perhaps, for the getter. The getter really just needs be hot 24x7.

How might we mitigate any of that bad stuff, just saying, in case it really is happening? I mean, really, turn heater on and they getter, don't and they strip. Really, what's one to do with that fancy new $500 tube?

Well, I'd think as far as positive ion terrors, you could pre-charge the grid to the tubes cutoff voltage. That would put a nice fuzzy force field around your ever so delicate cathode - hot or not. Then apply B+. Nice thing about a cutoff grid is when B+ does hit you'll reduce, or eliminate, the peak pulse. You'll also allow the charge cloud to build as the heater gets hot, without initially precious electrons being pointlessly pulled to the anode. Then, you can ramp the grid to your operating bias setting, slowly, allowing the plate to absorb a slowly increasing idle current and more gently heat soak the plate assembly.

I am from the camp of letting the tubes warm up, not that long maybe a few seconds.... because I never experienced issues when doing so...close to 40 years....

The reason is because I have seen first hand many tubes get wrecked, when voltage was immediately applied.... these were customers of mine who did not want to warm up their tubes and thought it was nonsense, until they messed up vintage Telefunkens, Vintage Gold Lions, Mullards....ect....in front of their own eyes...

Some power tubes can handle high PLATE voltages when cold as indicated in many data sheets....I agree, but there is no mention of SCREEN VOLTAGE when cold... I have no problem applying high B+ immediately to only the PLATES on a cold power tube, but then I soft-start the screens, since it is way easier.....

All the papers I have read so far on this issue have not been impressive in terms of in depth analysis. I would prefer statistical analysis over a wide spread and multiple lots... instead of someone writing an article of opinion saying to believe them because they have a credible name...

There have been other types of tube failures during start up scenarios depending on the circuit topology....

For example, stacked topologies with heater to cathode flash-over....

In circuits without Voltage Regulation, the B+ may be exceedingly high prior to tube current flow, in this brief time I have seen flash-overs...

The reason is because I have seen first hand many tubes get wrecked, when voltage was immediately applied.... these were customers of mine who did not want to warm up their tubes and thought it was nonsense, until they messed up vintage Telefunkens, Vintage Gold Lions, Mullards....ect....in front of their own eyes...

Some power tubes can handle high PLATE voltages when cold as indicated in many data sheets....I agree, but there is no mention of SCREEN VOLTAGE when cold... I have no problem applying high B+ immediately to only the PLATES on a cold power tube, but then I soft-start the screens, since it is way easier.....

All the papers I have read so far on this issue have not been impressive in terms of in depth analysis. I would prefer statistical analysis over a wide spread and multiple lots... instead of someone writing an article of opinion saying to believe them because they have a credible name...

There have been other types of tube failures during start up scenarios depending on the circuit topology....

For example, stacked topologies with heater to cathode flash-over....

In circuits without Voltage Regulation, the B+ may be exceedingly high prior to tube current flow, in this brief time I have seen flash-overs...

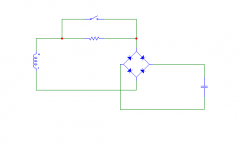

I've seen this somewhere too, in a nice commercial amp. The switch is a relay pole in that case. Guitar amps have used the same trick, but with a manual standby switch.

Not sure what happens at a low B+ though.

Sorry about the +/- indicators on the coil, that's micro-cap, not me

Not sure what happens at a low B+ though.

Sorry about the +/- indicators on the coil, that's micro-cap, not me

Attachments

Several Billion Radios and TV sets and industrial electronics using valves round the world built from 20's to 70's Cant be wrong Ive NEVER seen a Valve TV set or Radio with a B+/Standby switch for B+ Have you?--yest they Still WORK even now some over 70 years old with Original tubes....

Some TV sets even have a thermistor in heater-supply which actually Increases the warm-up time of the heaters,--it is there to reduce heater current surges and inrush current...

B+ at turn on every time.

IF a valve is in such a state that its gonna fail at turn-on under B+ conditions--It'll fail anyway, whether there's B+ present or not during cathode warm-up. Would have thought the severe JOLT it gets from a heated cathode without the B+, Then applying B+ would be Much more Abusive to any valve, having to draw tons of current to charge all the de-coupling-caps etc, instead of a slow charge by current-limited cool cathodes...

Best let it blow and get it outta the way-If its gonna blow, It'll blow no matter What you do!

I suggest those that have seen a valve fail Maybe some 'golden-lion', a Telefunken or a million Mullards at turn-on and THINK it was due to B+ present at the time are mistaking another issue--such as a Gassy tube--(most Likely, Micro-Cracks round the base-pins from too much 'Tube Rolling' probably!), or one that has some other internal issue that succumbed to its leak/problem finally--usually spectacularly.

Getters are Not Always White when a tube is gassy!!

--Just because its some mega-bux W.E. or what-have-you, they can ALL still fail and do. There's NOTHING that can be done about a valve that just fails.

NOTHING lasts Forever--Especially Electronic devices.

Unless its a Transmitter valve running above a 1kV, where the phenomenon of 'Stripping' IS a possibility then having a delayed B+ is a Waste Of Time--Literally, --Utterly Pointless, unless you are liking the Placebo it gives you.

No stripping at lower voltages has been found under Lab conditions.

Some TV sets even have a thermistor in heater-supply which actually Increases the warm-up time of the heaters,--it is there to reduce heater current surges and inrush current...

B+ at turn on every time.

IF a valve is in such a state that its gonna fail at turn-on under B+ conditions--It'll fail anyway, whether there's B+ present or not during cathode warm-up. Would have thought the severe JOLT it gets from a heated cathode without the B+, Then applying B+ would be Much more Abusive to any valve, having to draw tons of current to charge all the de-coupling-caps etc, instead of a slow charge by current-limited cool cathodes...

Best let it blow and get it outta the way-If its gonna blow, It'll blow no matter What you do!

I suggest those that have seen a valve fail Maybe some 'golden-lion', a Telefunken or a million Mullards at turn-on and THINK it was due to B+ present at the time are mistaking another issue--such as a Gassy tube--(most Likely, Micro-Cracks round the base-pins from too much 'Tube Rolling' probably!), or one that has some other internal issue that succumbed to its leak/problem finally--usually spectacularly.

Getters are Not Always White when a tube is gassy!!

--Just because its some mega-bux W.E. or what-have-you, they can ALL still fail and do. There's NOTHING that can be done about a valve that just fails.

NOTHING lasts Forever--Especially Electronic devices.

Unless its a Transmitter valve running above a 1kV, where the phenomenon of 'Stripping' IS a possibility then having a delayed B+ is a Waste Of Time--Literally, --Utterly Pointless, unless you are liking the Placebo it gives you.

No stripping at lower voltages has been found under Lab conditions.

Last edited:

flash overs?

from where to where?

Flash-Over was heater to cathode..... In topologies such as followers and or stacked tubes..

I will add that even the slightest delay in B+ rise is quite sufficient in an amp with "fixed" bias O/P tubes. The SS rectified bias supply rises immediately and the negative potential applied to the control grids shields the cathodes electrostatically against the possibility of cathode stripping.

I've seen it said that the famous Philips flash is related to providing protection, when directly heated rectifiers, like the 5U4, are employed. Whether that tale is true or not, I don't know.

I've seen it said that the famous Philips flash is related to providing protection, when directly heated rectifiers, like the 5U4, are employed. Whether that tale is true or not, I don't know.

NOS Tubes--No matter What Make...

Lets look at this a Different way!

We would ALL Love to think that our precious NOS Tubes have spent the last 50 years in some store-room.....

Lets look at the much more likely Life those valves have had. We'll take a quad of 50's KT66 as an example....

It was mid 1955 when this quad were dispatched from Osram to a Co called Kershaws in Leeds.

This Co makes and installs/maintains Cinema projectors and Amplifiers all round the Country and in later years supplies the Odeon chain.

Our set of four KT's at Kershaws were issued to a Field Engineer and became part of his Emergency-spares-kit.

Now, Normally Under-Contract work every 6 months or so, Cinemas had a engineer call and one of the jobs was to replace all 4 KT66 in the then current 'Duosonic' range of amplifiers.

As part of a normal consumable service-call, our engineer draws a set of KT's from Stores and goes to the job,--so he doesnt need to touch his emergency-four-pack,--some 100 miles away, Actually he has several calls on that run--but you get the idea.

He doesnt 'Rotate' the stock of valves, so the emergency four are still in his emergency-kit.

--Thats where they stay for 23 years, in his emergency-spares kit. They got dropped once, one broke, so he replaced it with one drawn from Stores, the broken one sent back as 'faulty'

So, They stay there,--Till the guy retires....

They have done close to 850,000 miles on their travels, over bumpy roads,Up and down Snowdon a hundred times, round and round Rhondda, all over the UK in a 50's and 60's Commercial-vehicle, exposed to moisture, heat, cold vibration etc etc....

Eventually, these same four valves end up overseas having passed from Kershaws when they closed in the late 70's to various electronic spares vendors again chucked around in out of boxes, tested, etc then end up at a Tube-Vendor in USA, Nice set, markings maybe a little worn, but test perfect, in good boxes, having been put in new repro-boxes in the mid 2K's.

Hmm--They are sold, and they last just under a year--Then fail--And YOU WONDER WHY!!

What I'm saying--WE JUST DON'T KNOW WHATS HAPPENED TO THESE ALLEGEDLY NOS TUBES--and Neither does the Vendor Selling Em!!....

They are upwards of 30 years old, Gawd-Knows where/whats happened to 'em!

Lets look at this a Different way!

We would ALL Love to think that our precious NOS Tubes have spent the last 50 years in some store-room.....

Lets look at the much more likely Life those valves have had. We'll take a quad of 50's KT66 as an example....

It was mid 1955 when this quad were dispatched from Osram to a Co called Kershaws in Leeds.

This Co makes and installs/maintains Cinema projectors and Amplifiers all round the Country and in later years supplies the Odeon chain.

Our set of four KT's at Kershaws were issued to a Field Engineer and became part of his Emergency-spares-kit.

Now, Normally Under-Contract work every 6 months or so, Cinemas had a engineer call and one of the jobs was to replace all 4 KT66 in the then current 'Duosonic' range of amplifiers.

As part of a normal consumable service-call, our engineer draws a set of KT's from Stores and goes to the job,--so he doesnt need to touch his emergency-four-pack,--some 100 miles away, Actually he has several calls on that run--but you get the idea.

He doesnt 'Rotate' the stock of valves, so the emergency four are still in his emergency-kit.

--Thats where they stay for 23 years, in his emergency-spares kit. They got dropped once, one broke, so he replaced it with one drawn from Stores, the broken one sent back as 'faulty'

So, They stay there,--Till the guy retires....

They have done close to 850,000 miles on their travels, over bumpy roads,Up and down Snowdon a hundred times, round and round Rhondda, all over the UK in a 50's and 60's Commercial-vehicle, exposed to moisture, heat, cold vibration etc etc....

Eventually, these same four valves end up overseas having passed from Kershaws when they closed in the late 70's to various electronic spares vendors again chucked around in out of boxes, tested, etc then end up at a Tube-Vendor in USA, Nice set, markings maybe a little worn, but test perfect, in good boxes, having been put in new repro-boxes in the mid 2K's.

Hmm--They are sold, and they last just under a year--Then fail--And YOU WONDER WHY!!

What I'm saying--WE JUST DON'T KNOW WHATS HAPPENED TO THESE ALLEGEDLY NOS TUBES--and Neither does the Vendor Selling Em!!....

They are upwards of 30 years old, Gawd-Knows where/whats happened to 'em!

When not using standby (always on) on my guitar amp at turn on, I hear pops from the speaker till the tubes are fully warm.

What is the cause?

Also, what is the cause of clicks and pops from the glass/tube when it cools off after turn off?

Alastair E,

So you say that slow and growing electron flow (around 10s) towards the plate is much safer and will prolong the tubes life, than a huge electron flow at once as when using a standby switch?

We are talking about soft starting current, what about voltage? These two elements can kill a tube in different ways.

I'd say that a current inrush at turn on is much more damaging to the tube than a sudden voltage swing at rated voltage.

Voltage swing is what a tube supposed to do, it's what it was designed for.

What is the cause?

Also, what is the cause of clicks and pops from the glass/tube when it cools off after turn off?

Alastair E,

So you say that slow and growing electron flow (around 10s) towards the plate is much safer and will prolong the tubes life, than a huge electron flow at once as when using a standby switch?

We are talking about soft starting current, what about voltage? These two elements can kill a tube in different ways.

I'd say that a current inrush at turn on is much more damaging to the tube than a sudden voltage swing at rated voltage.

Voltage swing is what a tube supposed to do, it's what it was designed for.

Last edited:

Cooling! This causes thermal contraction. Different parts shrink at different rates, so they move relative to each other. You may get some temporary sticking and sudden releasing (a bit like an earthquake in miniature).James Freeman said:Also, what is the cause of clicks and pops from the glass/tube when it cools off after turn off?

Stand-by switches can cause sudden inrush currents, so that is one reason why they should be avoided. If you are building a high power valve PA or radio transmitter then some power sequencing may be needed. For everything else the most that is needed (for SS rectifiers) is some inrush limiting - and not even that for low power stuff.

Arcing

Maybe the answer is, "just get over it, there's nothing you can do". But its quite clear that failure modes do happen (like, say, arcs), and it seems there are some things that can mitigate them (like, maybe, pre-heating the cathode for a few seconds).

I played with lots of TVs as a kid, tubes of course. I've watched a few brand new tubes arc upon installation. Seems its much more probable these days with NOS being decades, rather than perhaps only years old. I guess, Gas was probably the culprit in these cases.

So, keeping with that game... What list of faults can cause arcing? Gas, yes. Structure alignment, yes. Over voltage, startup spike from any supply, or perhaps a very low impedance one, possibly. Peak point (a sharp little mountain on the cathode surface) emission from a cold cathode, possible as well. Any others?

Then, how might each of these modes come to pass, and what can be done to retard any, or all, of them?

A short pre-heat would probably reduce peak point emission probabilities.The entire structure's emission impedance is lowered and a charge cloud forms along the length of the cathode, likely retarding small point discharge locations.

It might also act by bringing the cathode to gettering temperature and clearing the local space, not great but it would get the tube on the longer side of its lifecycle. But, it might speed emission decay as well.

The heat might also start aligning the grid/cathode structure into a more appropriate position.

On about voltage surges... Per the article in Audio Express (google is you friend), making sure you have grid suppressors and staging B+ from input to output may well reduce over volt surges. That author claims to have eliminated arcs and extended output tubes lives from hundreds to thousands of hours. Alas, hardly scientific, but does seem to have been a considered study. Seems little downside, except for a grid resistor muddling some people's noise.

As for gas, baking tubes would seem to be a good idea, too. Getter down the gases before the tube even sees voltage.

Leaving tubes "on" (in some optimal way) all the time would probably help by keeping the getter going.

Keeping the envelope as cool as possible might help, or maybe not. I do believe many glasses are more permeable when hot, an/or unevenly warm.

Lots of moles to whack, it seems.

So, a standby switch would seem to be a dead simple way to get your few seconds of pre-heat and that would seem to have a some positive impact on tube life.

As for keeping things on standby all/much of the time, I'm still unclear.

carrem, I'm pretty sure we're never going to see that statistical analysis. Sad tho, because you're right it really would help. Dedcution can only get you so far, but its not always the best way to a proof. I, for one, would love to KNOW how to MAXIMIZE my tubes. The Tube Factory(tm), is probably pretty much fine with us blowing 'em up by whatever means we choose.I am from the camp of letting the tubes warm up, not that long maybe a few seconds.... because I never experienced issues when doing so...close to 40 years....

The reason is because I have seen first hand many tubes get wrecked, when voltage was immediately applied.... these were customers of mine who did not want to warm up their tubes and thought it was nonsense, until they messed up vintage Telefunkens, Vintage Gold Lions, Mullards....ect....in front of their own eyes...

Maybe the answer is, "just get over it, there's nothing you can do". But its quite clear that failure modes do happen (like, say, arcs), and it seems there are some things that can mitigate them (like, maybe, pre-heating the cathode for a few seconds).

I played with lots of TVs as a kid, tubes of course. I've watched a few brand new tubes arc upon installation. Seems its much more probable these days with NOS being decades, rather than perhaps only years old. I guess, Gas was probably the culprit in these cases.

So, keeping with that game... What list of faults can cause arcing? Gas, yes. Structure alignment, yes. Over voltage, startup spike from any supply, or perhaps a very low impedance one, possibly. Peak point (a sharp little mountain on the cathode surface) emission from a cold cathode, possible as well. Any others?

Then, how might each of these modes come to pass, and what can be done to retard any, or all, of them?

A short pre-heat would probably reduce peak point emission probabilities.The entire structure's emission impedance is lowered and a charge cloud forms along the length of the cathode, likely retarding small point discharge locations.

It might also act by bringing the cathode to gettering temperature and clearing the local space, not great but it would get the tube on the longer side of its lifecycle. But, it might speed emission decay as well.

The heat might also start aligning the grid/cathode structure into a more appropriate position.

On about voltage surges... Per the article in Audio Express (google is you friend), making sure you have grid suppressors and staging B+ from input to output may well reduce over volt surges. That author claims to have eliminated arcs and extended output tubes lives from hundreds to thousands of hours. Alas, hardly scientific, but does seem to have been a considered study. Seems little downside, except for a grid resistor muddling some people's noise.

As for gas, baking tubes would seem to be a good idea, too. Getter down the gases before the tube even sees voltage.

Leaving tubes "on" (in some optimal way) all the time would probably help by keeping the getter going.

Keeping the envelope as cool as possible might help, or maybe not. I do believe many glasses are more permeable when hot, an/or unevenly warm.

Lots of moles to whack, it seems.

So, a standby switch would seem to be a dead simple way to get your few seconds of pre-heat and that would seem to have a some positive impact on tube life.

As for keeping things on standby all/much of the time, I'm still unclear.

Several Billion Radios and TV sets and industrial electronics using valves round the world built from 20's to 70's Cant be wrong Ive NEVER seen a Valve TV set or Radio with a B+/Standby switch for B+ Have you?

Not sure your point, exactly.

I spent plenty of time with my father in Radio Shack testing, and yes, replacing, tubes. TV, "Hi-Fi", etc. Probably a couple, or three, times a year. If it wasn't for the car, or something tubular, dad simply did not go "shopping", ever. And somehow I was always volunteered to go with him.

Millions of people smoke cigarettes, most don't get cancer. So, you're saying, cigarettes don't cause cancer. Ok, 'cus why?

wkirkpa.... Thanks for your input....

What I can say is that all the equipment I built over the years with soft start has not one failed or noisy tube....many have the same tubes...

What I have noticed is that PLATE voltage has never been an issue when applied to cold tubes... It seemed that the SCREEN voltage was the culprit... My guess is that many Audio power Amps run the tubes at max voltages....with screen supply feed from the plate supply through a choke....ect..

At cold start-up the power supply may be at a very High Voltage due to no current draw.... these voltages may be insanely high and when fed to the SCREEN, thus a SCREEN to GRID or SCREEN to CATHODE arc....exceeding the MAX SCREEN voltage excessively...

When the tube is warmed up a bit, it can flow currents instantly upon hitting the STANDBY SWITCH, this avoiding exceddingly high screen voltages even briefly...

I believe most tube equipment such as TV's ..ect that have no stand-by switches have tubes operating in much more safer conservative ranges, thus can easily live through a cold start-up....

What I can say is that all the equipment I built over the years with soft start has not one failed or noisy tube....many have the same tubes...

What I have noticed is that PLATE voltage has never been an issue when applied to cold tubes... It seemed that the SCREEN voltage was the culprit... My guess is that many Audio power Amps run the tubes at max voltages....with screen supply feed from the plate supply through a choke....ect..

At cold start-up the power supply may be at a very High Voltage due to no current draw.... these voltages may be insanely high and when fed to the SCREEN, thus a SCREEN to GRID or SCREEN to CATHODE arc....exceeding the MAX SCREEN voltage excessively...

When the tube is warmed up a bit, it can flow currents instantly upon hitting the STANDBY SWITCH, this avoiding exceddingly high screen voltages even briefly...

I believe most tube equipment such as TV's ..ect that have no stand-by switches have tubes operating in much more safer conservative ranges, thus can easily live through a cold start-up....

They can cause inrush, I agree. But why? Simply declaring the concept "DOA" isn't much help. Please let us know why other inrush limiting options don't/can't ever work. Why might some of these other options, in combination, perhaps, with a standby switch have no potential value?Stand-by switches can cause sudden inrush currents, so that is one reason why they should be avoided.

For those that may be lost at the moment, a standby switch can cause a B+ surge when B+ is finally applied. The HV supply has time to fully charge, while the standby switch is heating the filaments. When the switch is flipped, the HV supply is all primed up ready to dump a massive amount of energy all at once. It may also present a slightly higher set of initial voltages than expected, since it hasn't been seeing any draw from the circuit during this time.

All of that would, I expect, cause arcs and/or massive thermal stresses on the assembly.

But, one can provide a soft start on the HV. One could also flip from "Standby" to "Operate" through the mains (HV primary) rather than the secondary side of the HV transformer, possibly with a mains soft start thermistor as well. One could also, possibly, initialize the tubes at cutoff.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Lets settle the b+ on cold tubes issue!